High-power foaming production of thermoplastic elastomer composite material

A composite material and plasticity technology, applied in the field of foam material manufacturing, can solve problems such as difficult molding, difficult recycling of waste materials, environmental pollution, etc., and achieve the effects of high elasticity and anti-slip properties, simple formula, and easy secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

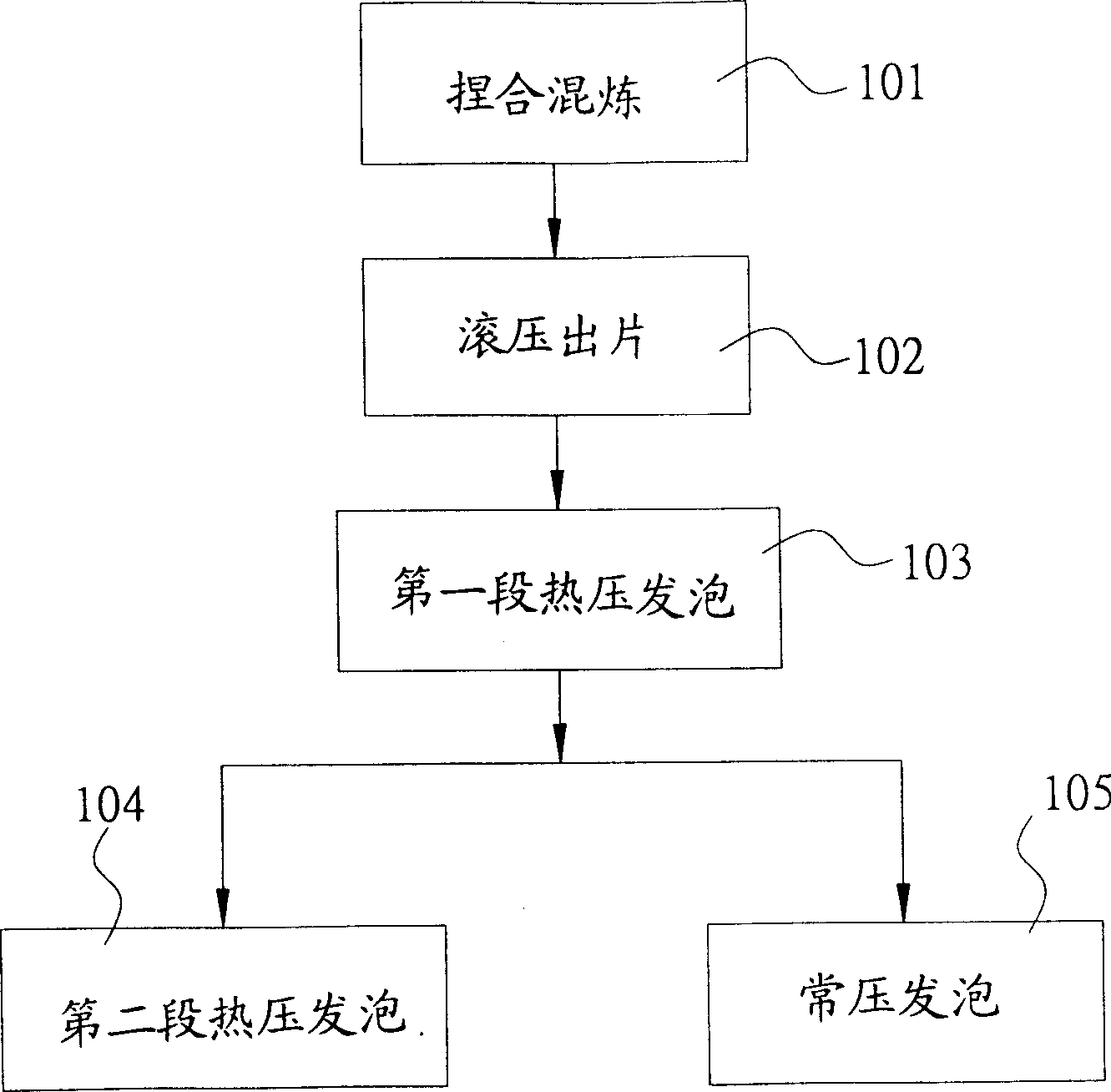

[0022] The invention relates to a high-expansion foaming manufacturing method of a thermoplastic elastomer composite material, which includes using a thermoplastic elastomer as a base material composite material, adding foaming agents and bridging agents with different functions, etc. The device performs kneading and sheet-out processing to form tablets of appropriate size, and then accumulates a certain number of tablets according to actual needs, and sends them into the first-stage hot-pressing mold for the first compression mold foaming , and then the obtained pre-foamed blank is sent to the second section of the hot-pressing mold or long oven while it is hot for the second compression mold foaming or normal pressure foaming treatment to make the foaming ratio 15 times more foam material.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com