Patents

Literature

112results about How to "Thermoplastic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

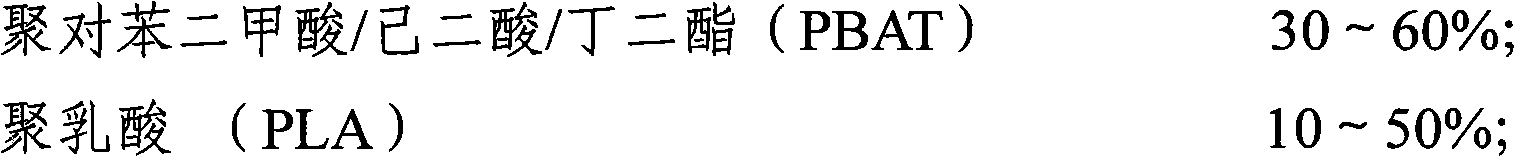

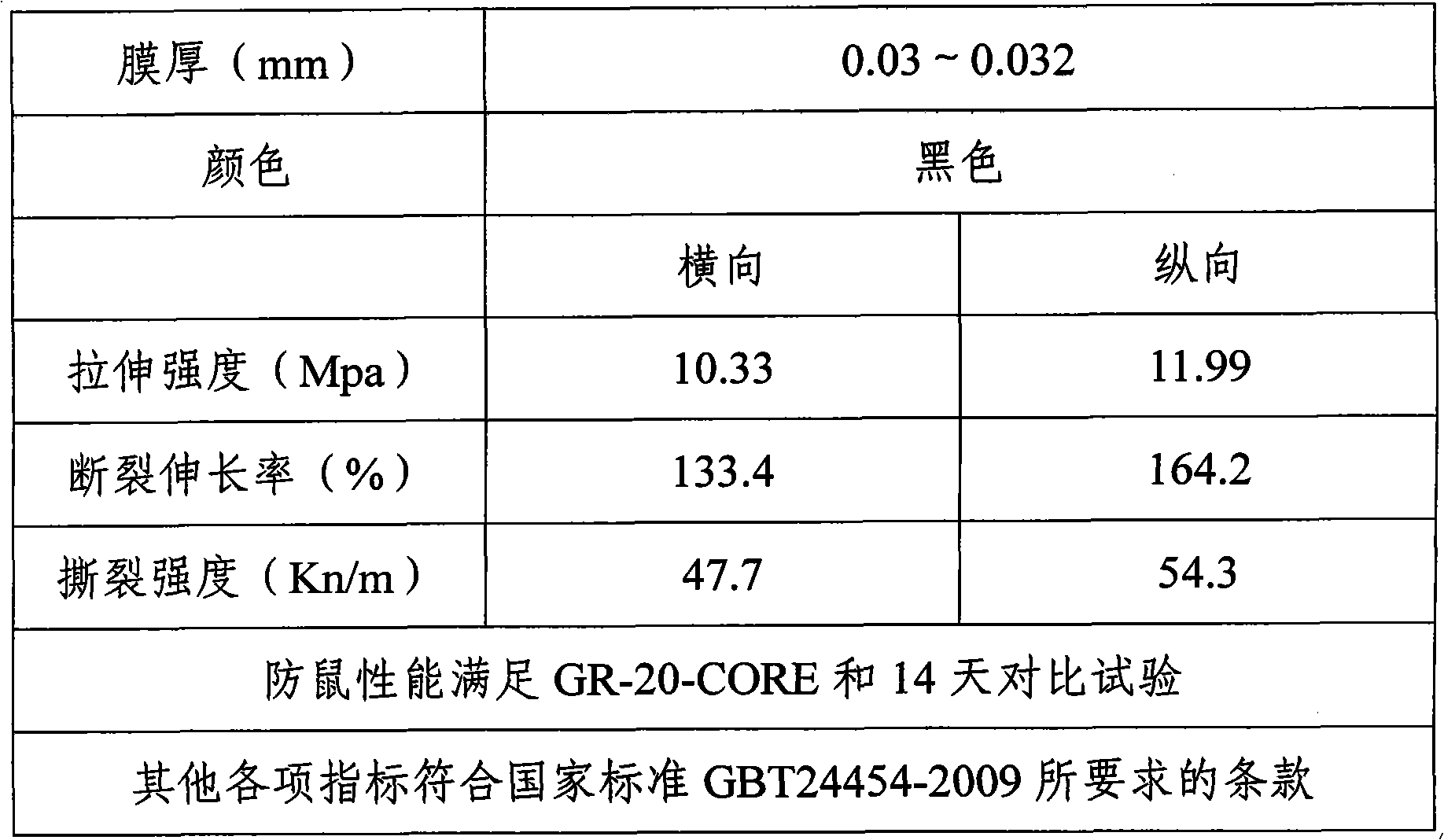

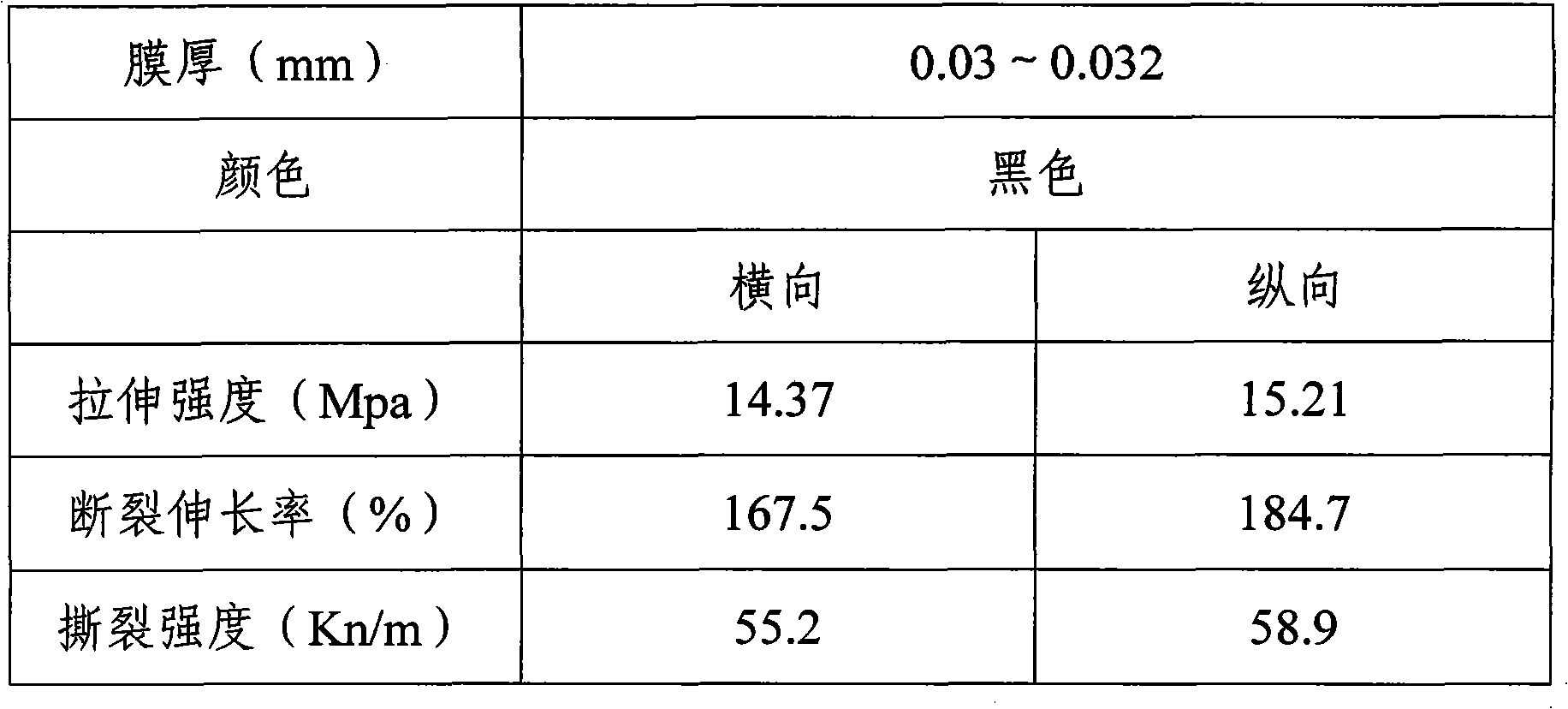

Fully-degradable ratproof garbage bag and preparation method thereof

The invention relates to a fully-degradable ratproof garbage bag and a preparation method thereof. The fully-degradable ratproof garbage bag comprises the following components by weight percent: 30-60% of poly(butylene adipate / terephthalate), 10-30% of polylactic acid, 10-30% of starch, 5-10% of plasticizer, 0-2% of chain extender, 5-20% of filler, 5-10% of ratproof repellent and 0.5-2% of color masterbatch. The preparation method comprises the following steps: firstly, preparing poly(butylene adipate / terephthalate), starch, polylactic acid, the plasticizer, the chain extender, the ratproof repellent and the filler into a biological material for the fully-degradable ratproof garbage bag according to a specific production process; and then carrying out secondary processing on the biological material matched with the color masterbatch so as to obtain the fully-degradable ratproof garbage bag. According to the invention, thermoplastic starch is adopted to fill poly(butylene adipate / terephthalate) and polylactic acid, so that the thermoplastic starch is evenly dispersed into a substrate of a resin mixture, thus the fully-biodegradable property of the material is maintained while the cost of the material lowered.

Owner:WUHAN HUALI ENVIRONMENTAL PROTECTION IND CO LTD

Anticorrosion conductive coating for metal grounding network and application method thereof

InactiveCN102229778AThermoplasticImprove applicabilityPretreated surfacesAnti-corrosive paintsEpoxyCross-link

The invention discloses an anticorrosion conductive coating for a metal grounding network and an application method thereof. The conductive coating is characterized by comprising the following components in mass fraction: 40-50 of epoxy resin, 20-30 of flaky conductive graphite, 8-15 of plasticizers and 3-5 of additive, wherein the plasticizers are at least one of polrvinyl chloride, polypropylene, polyethylene and polyvinyl butyral, the epoxy resin is at least one of E8, E10, E12, E14 and E 20, the additive comprises sebacic dihydrazide and dicyandiamide in the mass ratio of 1:4; the coating can be prepared into a powdery coating and a solvent type coating, and the thickness of a coating layer is 50-250 mum; the coating does not have cross-linking reaction at room temperature and can have cross-linking reaction to form a film only after being heated; the solvent type coating can be of a single-component type and can be stored for a long time; and the coating has thermoplasticity and can be coated and heated many times till a required thickness is reached.

Owner:STATE GRID CORP OF CHINA +2

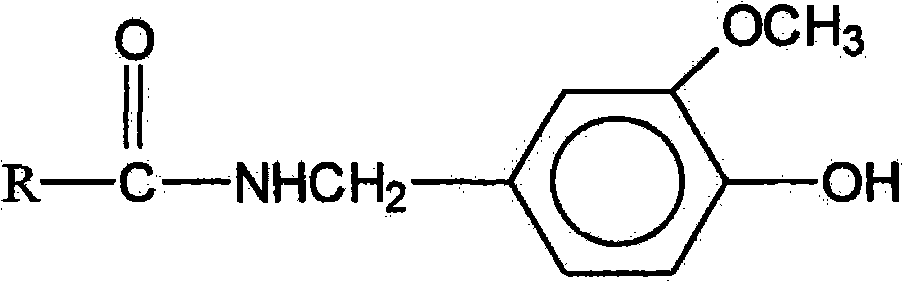

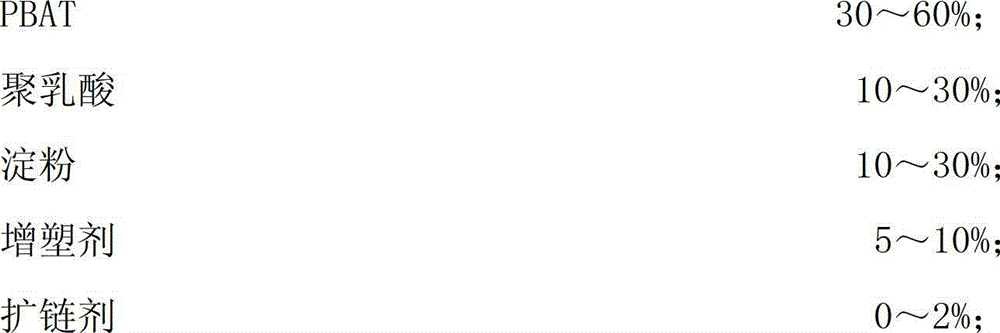

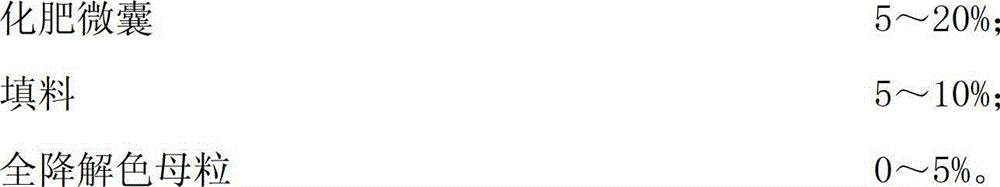

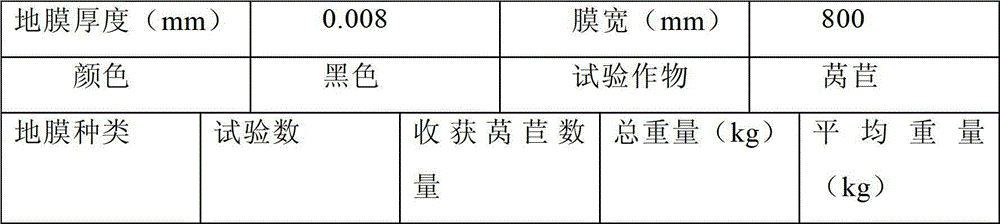

Fully-degradable mulching film capable of applying fertilizer, and preparation method for fully-degradable mulching film

InactiveCN102875231APlay the role of topdressingSoil enhancementFertilizer mixturesPolyvinyl alcoholPlasticizer

The invention discloses a fully-degradable mulching film capable of applying fertilizer. The fully-degradable mulching film capable of applying the fertilizer is characterized by comprising the following components in percentage by mass: 30 to 60 percent of poly(butylene adipate-co-terephthalate) (PBAT), 10 to 30 percent of polylactic acid, 10 to 30 percent of starch, 5 to 10 percent of plasticizer, 0 to 2 percent of chain extender, 5 to 20 percent of chemical fertilizer microcapsule, 5 to 10 percent of filler and 0 to 5 percent of fully-degradable color master batch. The space region is covered by the fully-degradable mulching film to ensure that the temperature and the humidity meet the requirement, polyvinyl alcohol on the surfaces of the fertilizer microcapsules is dissolved to ensure that the surfaces of the fertilizer microcapsules have porous sustained-release structures, and the fertilizer is slowly separated out under the humid conditions for drop irrigation of crops, so that the function of applying the fertilizer to the crops is exerted. After the crops are harvested completely, the fully-degradable mulching film is not needed to be recovered.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

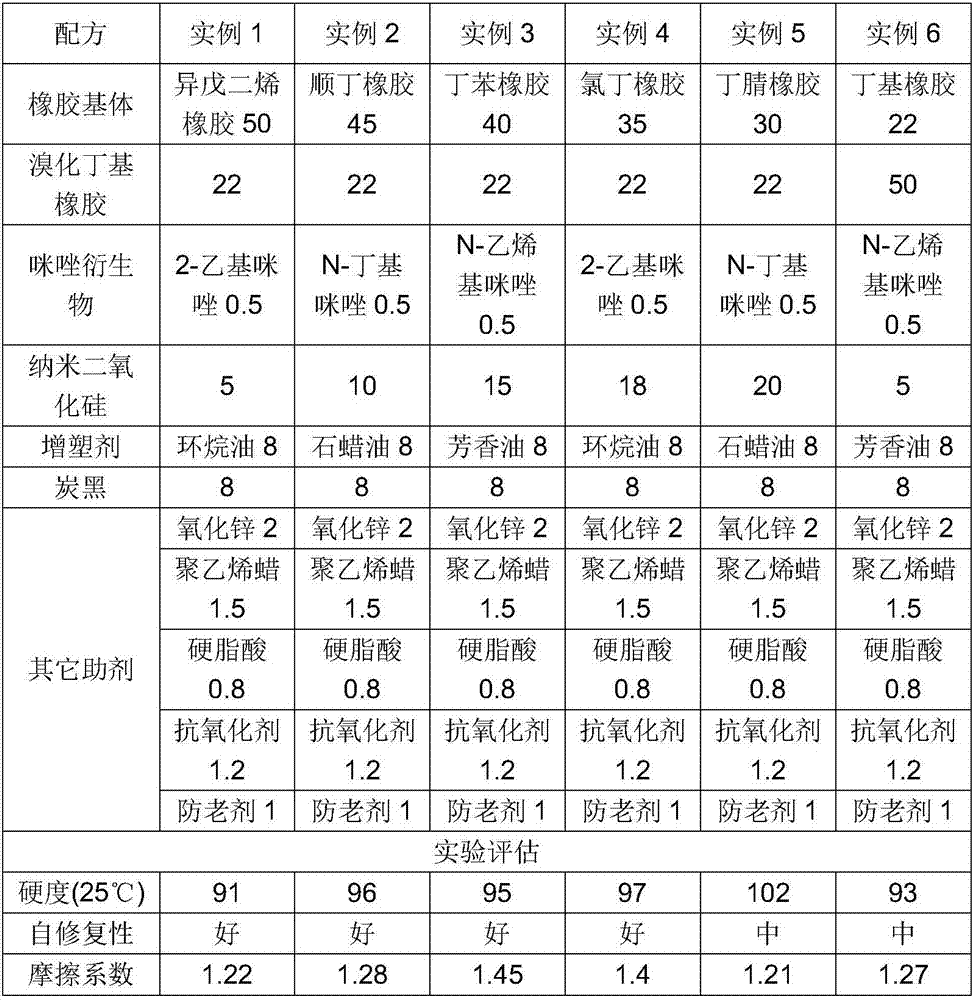

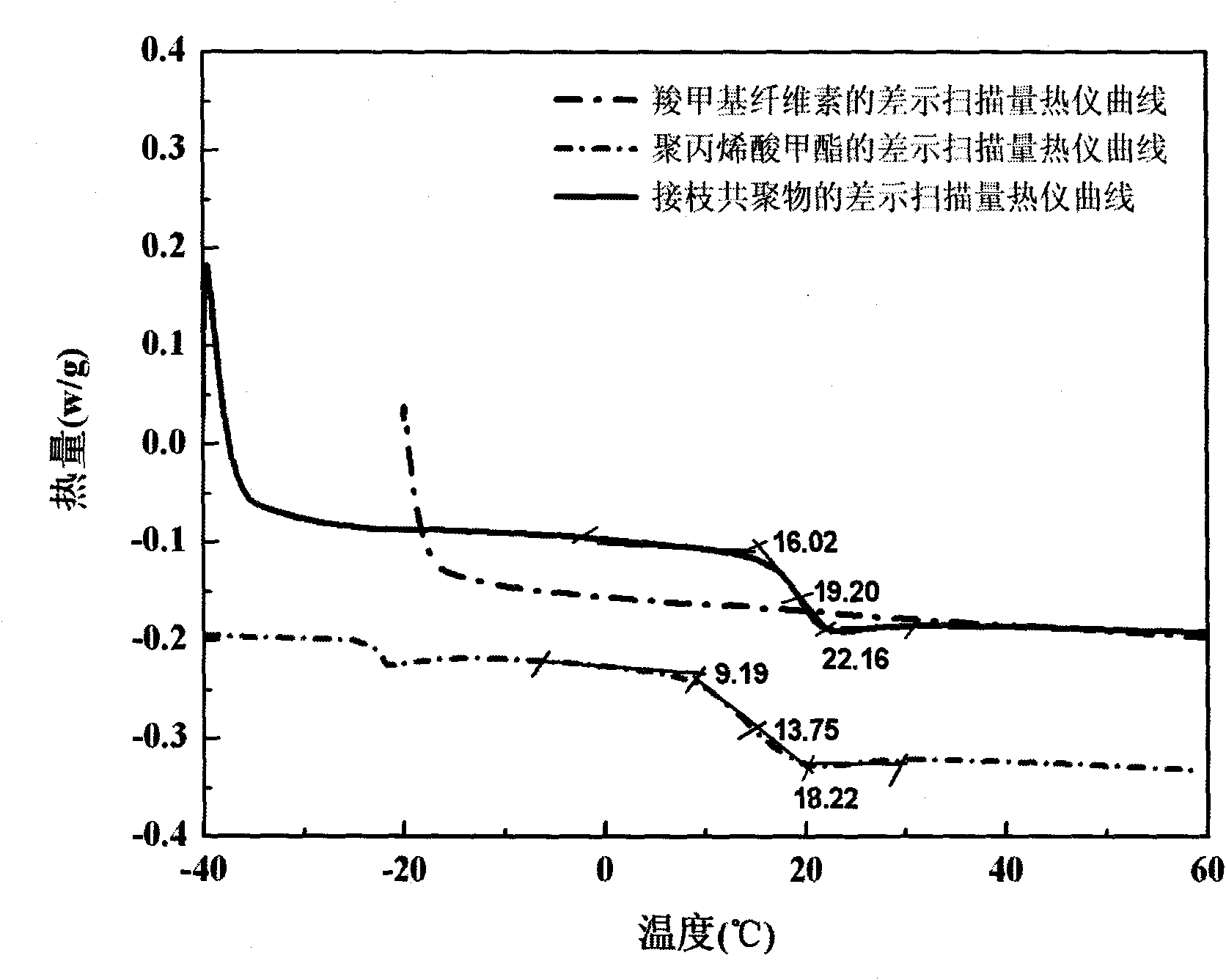

Self-healing antiskid unvulcanizedrubber material and preparation method thereof

The invention discloses a self-healing antiskid unvulcanized rubber material comprising the following components in percentage by weight: 20-50wt% of a rubber matrix, 1-50wt% of brominated butyl rubber, 0.1-0.5wt% of an imidazole derivative, 5-25wt% of nano silicon dioxide, 5-20wt% of a plasticizer, 5-10wt% of carbon black, and 1-5wt% of an auxiliary agent. The invention also discloses a preparation method. The self-healing antiskid unvulcanized rubber material disclosed by the invention has excellent weathering resistance, water tightness and air tightness, has good resistance to chemicals, oils, solvents and the like, can be used for manufacturing a sole material, automobile tires, and antiskid wear-resistant materials in various aspects of processing and manufacturing, and can also be used as a sealing ring and a waterproof material.

Owner:成都微熵科技有限公司

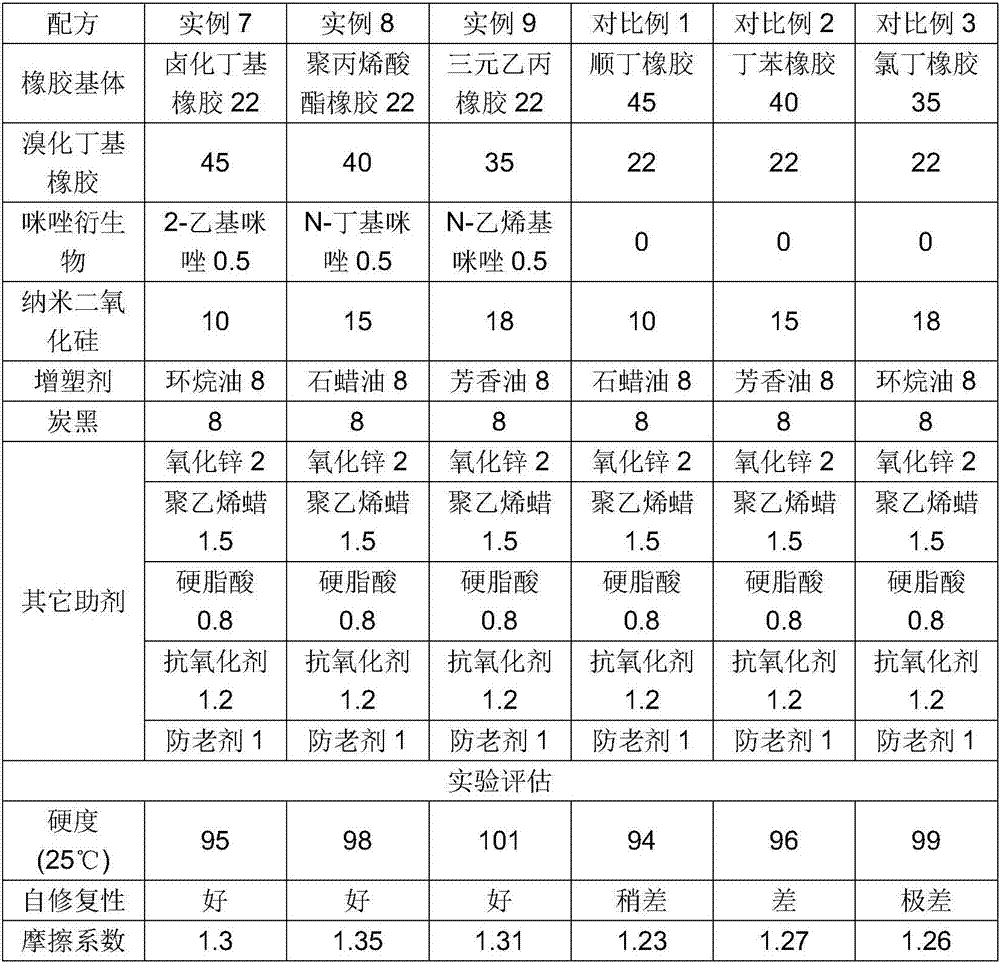

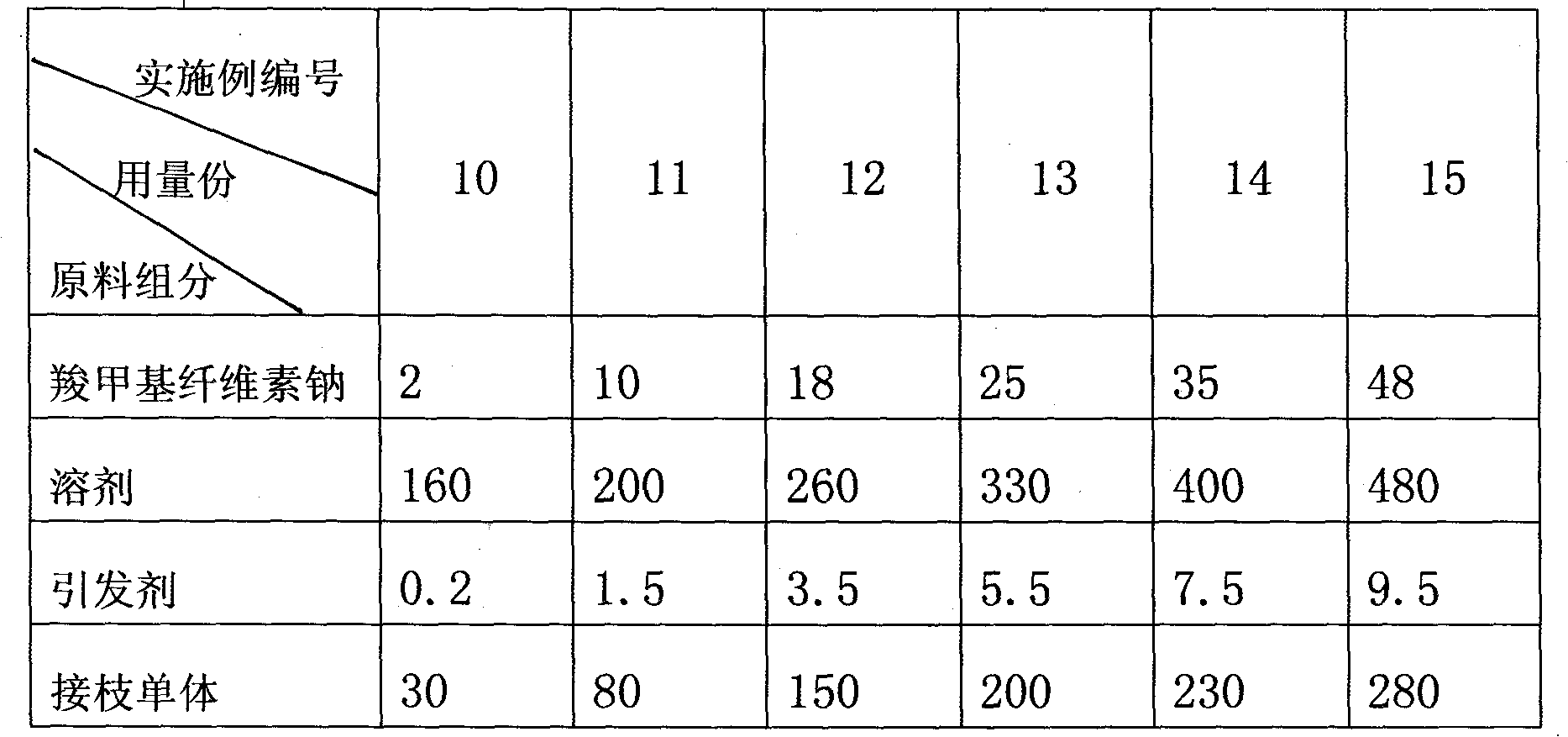

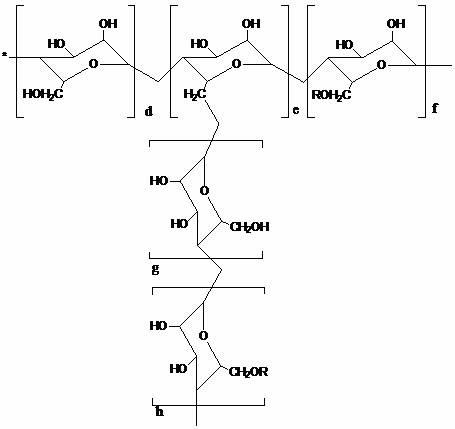

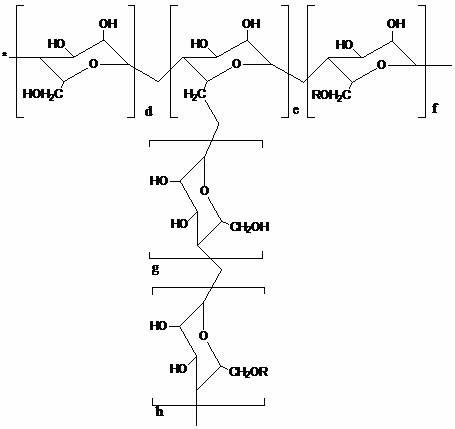

Method for preparing environment-friendly modified carboxymethyl cellulose thermoplastic material

The invention discloses a method for preparing an environment-friendly modified carboxymethylcellulose thermoplastic material. The method is characterized by comprising the following steps of: adding 1-50 parts by weight of carboxymethyl cellulose into 150-500 parts by weight of solvent water, swelling for 1-4 h at 30-60 DEG C, then adding 0.1-10 parts by weight of initiator, controlling the temperature at 40-85 DEG C, carrying out initiation reaction for 0.1-2 h, then adding 20-300 parts by weight of grafting monomer, reacting for 0.5-8 h at 40-85 DEG C; cooling the reacted materials, adding 150-300 parts by weight of acetone, stirring, standing for 5-10 h, filtering, washing a solid with water and drying the solid to obtain the modified carboxymethylcellulose thermoplastic material. The product can be processed and molded by using traditional extrusion molding, injection molding and blow molding methods. The thermoplastic material product is widely applied to the fields of petroleum drilling, mining engineering, textile industry, textile industry, coating material industry, daily chemical products, and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

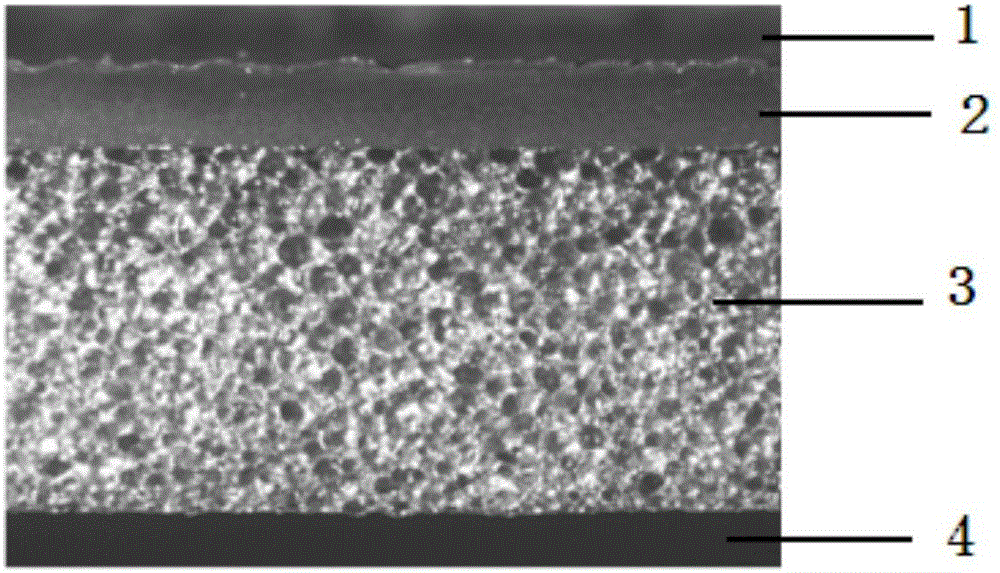

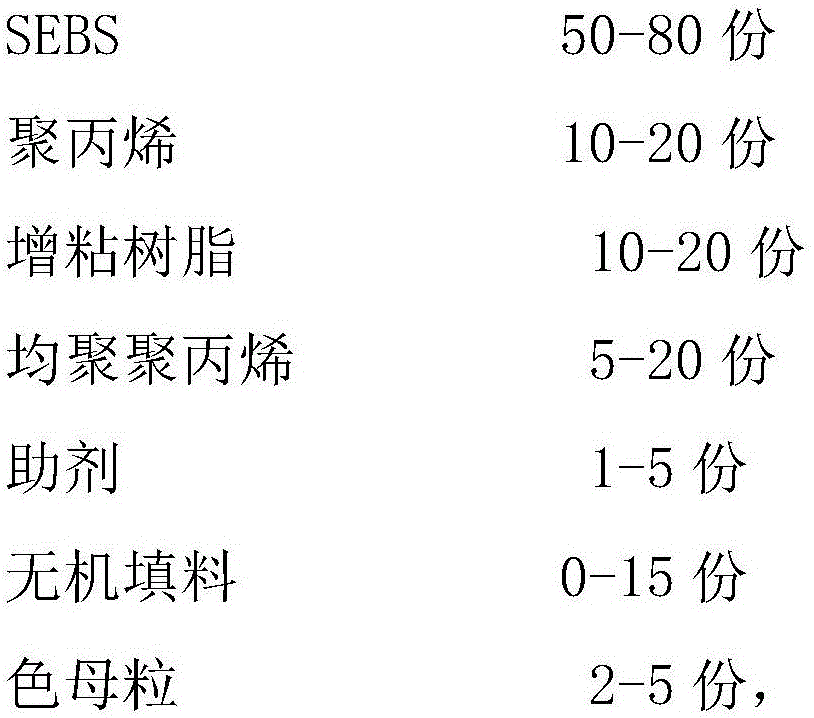

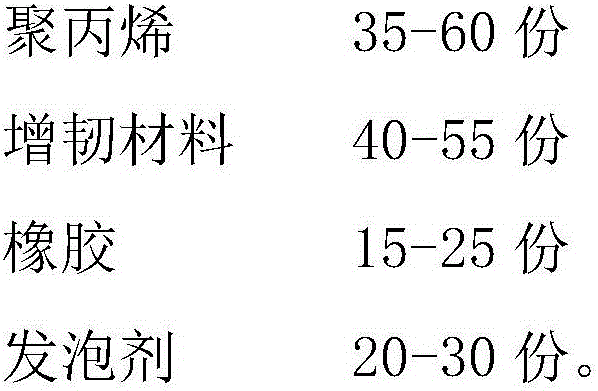

SEBS-based eco-friendly TPO automobile internal decorating material and preparation method thereof

ActiveCN106380772AImprove soft feelGood flexibilitySynthetic resin layered productsPolyurea/polyurethane coatingsFoaming agentSurface layer

The invention discloses a SEBS-based eco-friendly TPO automobile internal decorating material. A TPO surface layer comprises 50-80 parts of SEBS, 10-20 parts of polypropylene, 10-20 parts of tackifying resin, 5-20 parts of homo-polypropylene, 1-5 parts of an auxiliary agent, 0-15 parts an inorganic filling material and 2-5 parts of color master batches. A sponge layer comprises 35-60 parts of polypropylene, 40-55 parts of a toughening material, 15-25 parts of rubber and 20-30 parts of a foaming agent. SEBS is a linear three-block copolymer composed of polystyrene as a tail end segment and an ethene-butylene copolymer prepared through polybutadiene hydrogenation as a middle elastic block, has thermoplasticity, can be re-processed, is environmentally friendly, does not contain nonsaturated double bonds, has excellent aging resistance, contains polybutadiene, has a good handle and appropriate hardness, does not contain rubber and has a small smell and low VOC content.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

Polymer repairing mortar and preparation method thereof

The invention discloses a polymer repairing mortar. The polymer repairing mortar comprises 400-500 parts of cement, 500-600 parts of quartz sand, 1-5 parts of a high-molecular polymer, 5-15 parts of a polymer, 1-5 parts of silicon micropowder and 0.1-0.3 parts of wood fiber, wherein the high-molecular polymer is cellulose ether, and the polymer is re-dispersible latex powder. The purpose of the invention is to provide the polymer repairing mortar with the characteristic of long service life and no cracking, and a preparation method thereof.

Owner:浙江泰正建材有限公司

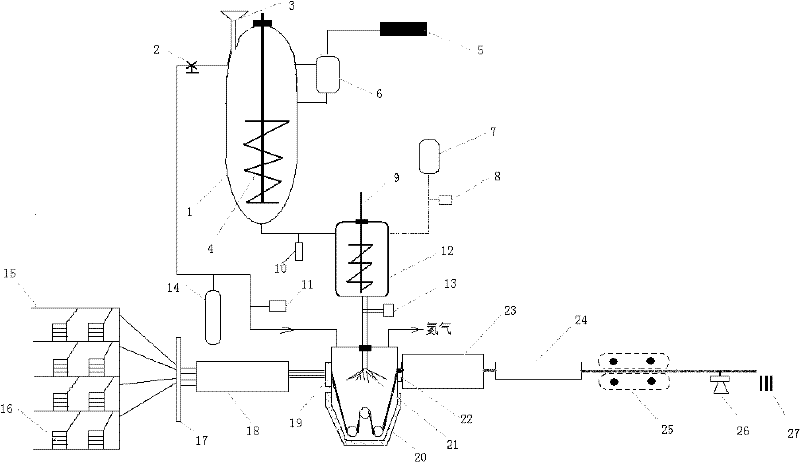

Pultrusion production process for nylon-based fiber reinforced thermo plastics

The invention belongs to the technical field of composite materials and discloses a pultrusion production process for nylon-based fiber reinforced thermo plastics. The production process comprises the following steps of: dissolving a tackifier in a lactam monomer at the temperature of between 110 and 210DEG C in a dehydration kettle to obtain tackified slurry; adding a catalyst and a lubricating agent into the tackified slurry, performing vacuum dehydration at the temperature of between 110 and 190DEG C for 5 to 60 minutes, reducing temperature to 70-100DEG C, discharging the material into an activating tank, keeping the temperature of the activating tank between 70 and 100DEG C, and maintaining a stirring state; adding an activator into the activating tank through a metering pump to obtain activated slurry; arranging fibers by using a yarn guide screen board, impregnating the fibers by using the obtained activated slurry, making the impregnated fibers form bundles by using a pre-land plate, dragging into a curing and shaping mold for curing, feeding into a postcuring oven, and dragging and cutting to obtain a fiber reinforced thermo plastic product. The production process has the advantage of low cost.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

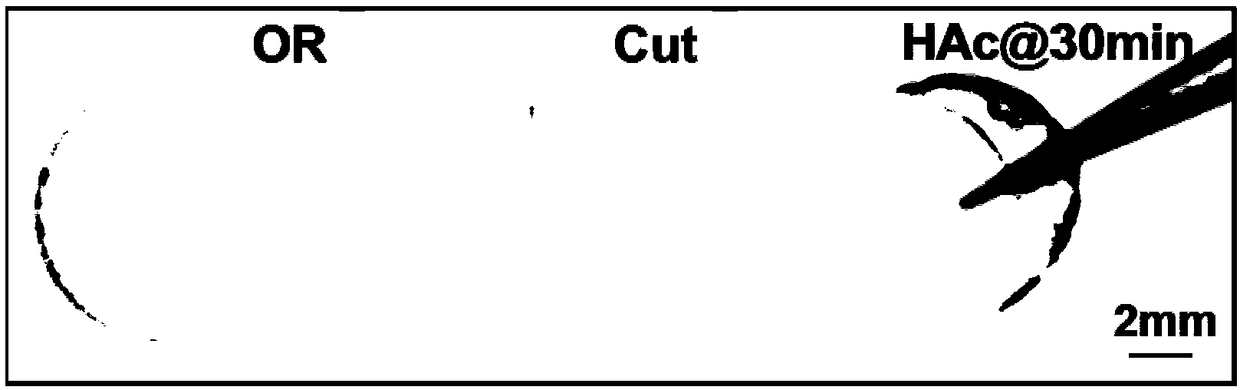

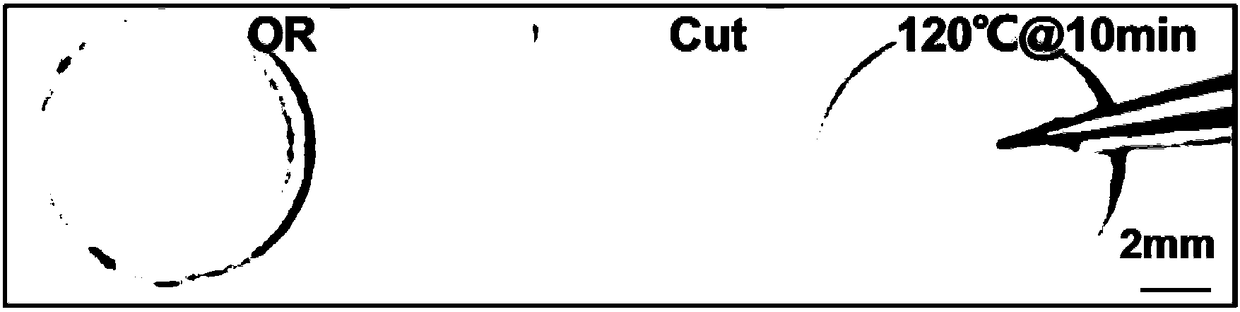

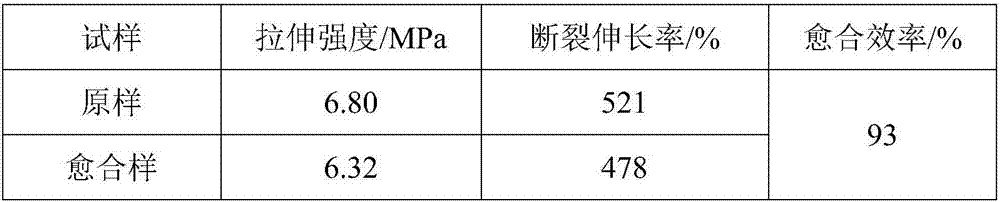

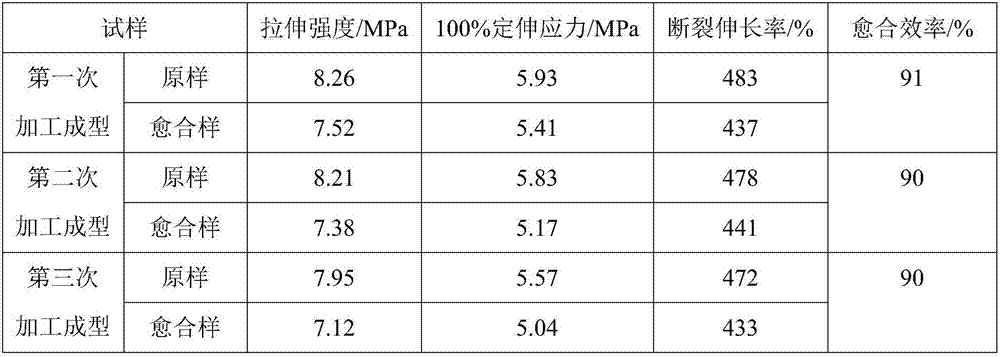

Polydimethylsiloxane self-repairing elastomer based on hydrazide bond and preparation method thereof

The invention discloses a polydimethylsiloxane self-repairing elastomer based on a hydrazide bond and a preparation method thereof. The self-repairing elastomer is prepared from tetrahydrazide-functionalized polydimethylsiloxane and polyaldehyde through solution volatilization for film formation. The preparation method is simple; the elastomer can realize self-repairing under the catalysis of a small amount of external acid at room temperature or under simple heating conditions, and is fast in repairing speed and good in repair performance. In addition, through the introduction of the dynamichydrazide bond, the elastomer has thermoplastic performance and can be repeatedly formed by hot pressing, so the elastomer has good application prospects.

Owner:INST OF CHEM CHINESE ACAD OF SCI

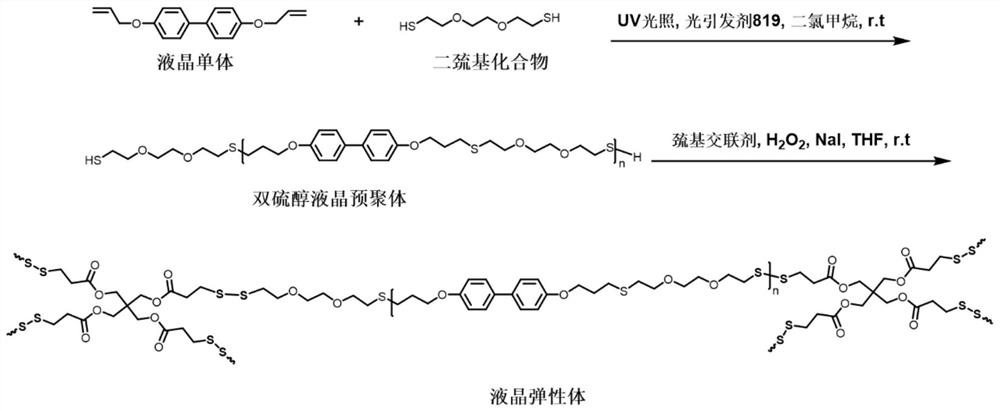

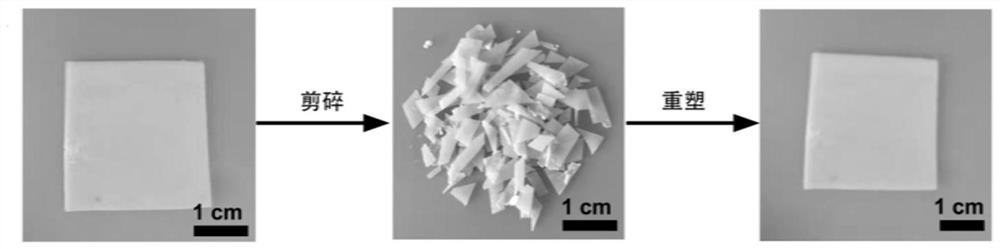

High-thermal-conductivity reconfigurable liquid crystal elastomer composite material, and preparation method and application thereof

PendingCN111607086AImprove thermal conductivityExcellent self-healing performanceLiquid crystal compositionsHeat-exchange elementsPolymer scienceIn situ polymerization

The invention belongs to the technical field of polymer composite materials, and discloses a high-thermal-conductivity remoldable liquid crystal elastomer composite material, and a preparation methodand application thereof. The high-thermal-conductivity reconfigurable liquid crystal elastomer composite material is obtained by mixing a sulfydryl-terminated liquid crystal prepolymer with a filler and then carrying out a cross-linking reaction A under the action of a sulfydryl cross-linking agent. The invention also provides a preparation method of the composite material. The preparation methodcomprises the following steps: firstly, preparing a sulfydryl-terminated liquid crystal prepolymer through photoinduced sulfydryl alkene click chemistry; then, the self-repairing liquid crystal elastomer containing the disulfide bond is obtained through an oxidation reaction between the prepolymer and the sulfydryl cross-linking agent; meanwhile, the heat-conducting filler and the like are introduced into the elastomer system in an in-situ polymerization mode, so that the composite material with good heat-conducting property and a recyclable remodeling function is obtained, and the composite material can be applied to the fields of aerospace, microelectronics and the like.

Owner:国科广化精细化工孵化器(南雄)有限公司 +3

Bio-based non-woven fabrics and preparation method thereof

InactiveCN103147227AImprove environmental friendlinessImprove machinabilityFilament forming substance formingMelt spinning methodsPolypropyleneWoven fabric

The invention discloses bio-based non-woven fabrics and a preparation method thereof. The non-woven fabrics is prepared from the following components in ratio by mass part: 30-60 parts of polypropylene, 25-55 parts of starch, 5-10 parts of plasticizer, 0.5-2 parts of polypropylene flow promoter, and 0.5-5 parts of filler. The preparation method is as follows: firstly, the polypropylene, the starch, the plasticizer, the polypropylene flow promoter and the filler are prepared into a required bio-based material as per specific production process, and then the bio-based material is processed for the second time by virtue of the spunbonding technology so as to form the bio-based non-woven fabrics. According to the method, the thermoplastic starch and polypropylene resin blending system are adopted, so that the thermoplastic starch can be dispersed in the polypropylene matrix uniformly; the plasticizer is used, so that the starch has the thermoplasticity, and the processibility of the starch and the compatibility of the starch with the polypropylene resin are improved; and moreover, the polypropylene flow promoter is used, so that the melt flow rate of the polypropylene / thermoplastic starch is improved and thus the spinnability of the material is improved.

Owner:WUHAN HUALI BIOLOGY CO LTD

Blended yarn of terylene, rabbit hair and silkworm pupa protein fiber

The invention provides blended yarn of terylene, rabbit hair and silkworm pupa protein fiber. The blended yarn comprises the following components: 65-75 weight parts of terylene, 25-35 weight parts of rabbit hair and 10-20 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of terylene, rabbit hair and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

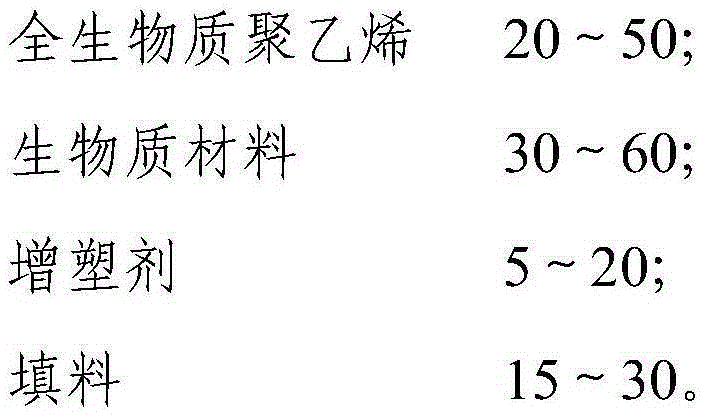

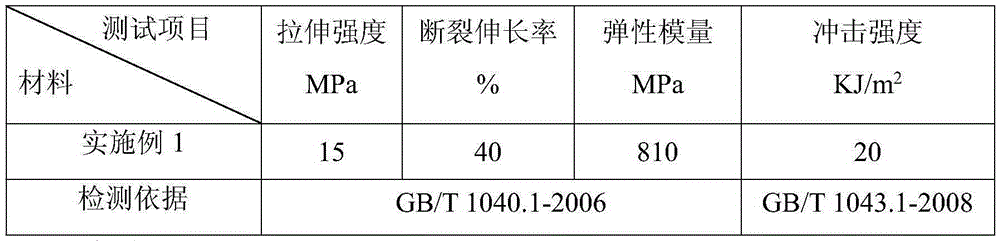

Total biomass composite injection moulding material and preparation method thereof

The invention discloses a total biomass composite injection moulding material and a preparation method thereof. The raw materials of the total biomass composite injection moulding material contain the following components in part by weight: 20-50 parts of total biomass polyethylene; 30-60 parts of a biomass material; 5-20 parts of a plasticizer; 15-30 parts of a filling material. The preparation method comprises the following steps: raw materials are uniformly mixed and added into a double screw extruder, a mixing is carried out at 150-220 DEG C, a granulation is carried out, and the product is obtained. Raw materials of the products are totally selected from natural renewable substances, thermoplastic renewable substances are blended with the total biomass polyethylene for granulation, along with biodegradation of renewable substances, the whole material is disintegrated into fragments, so that the material has a certain degradation performance.

Owner:WUHAN HUALI BIOLOGY CO LTD

Butyl rubber hot-melt pressure-sensitive adhesive with enhanced cohesion strength and preparation method of butyl rubber hot-melt pressure-sensitive adhesive

ActiveCN107057607AImprove sticking powerHigh peel strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPlasticizerAntioxidant

The invention discloses a butyl rubber hot-melt pressure-sensitive adhesive with enhanced cohesion strength. The butyl rubber hot-melt pressure-sensitive adhesive comprises components in percentage by weight as follows: 10%-35% of butyl rubber, 3%-20% of brominated butyl rubber, 3%-18% of other matrix resin, 0.05%-1% of imidazole derivatives, 10%-35% of tackifying resin, 5%-35% of a plasticizer, 18%-55% of reinforcing filler and 0.1%-0.6% of an antioxidant. The invention further discloses a preparation method. The butyl rubber hot-melt pressure-sensitive adhesive has reversible hot workability and has the capacity of coating and bonding one more time in the heating state.

Owner:成都微熵科技有限公司

Flexible printed wiring board and semiconductor device

InactiveCN101212863AThermoplasticWon't hurtSemiconductor/solid-state device detailsPrinted circuit aspectsInsulation layerHeat resistance

The flexible printed board of the present invention is characterized in that on a surface of a basal layer that is an insulation layer composed of resin which molecule is provided with imine structure and amide structure, etching an electrolytic copper foil of a laminating body forming by means of directly laminating a electrolytic copper foil containing a S surface and a M surface with various surface roughness, to form a wiring diagram, the surface roughness (Rzjis) on one side of the S surface is less than 1.0 [Mu]m and the glazing degree [Gs(60 DEG)] of the M surface is equal to or more than 400. By means of using the resin with imine structure and amide structure in the insulation molecule, the present invention provides a printed board with excellent mechanical property, thermal endurance and alkali tolerance etc., in particular a COF basal plate.

Owner:MITSUI MINING & SMELTING CO LTD

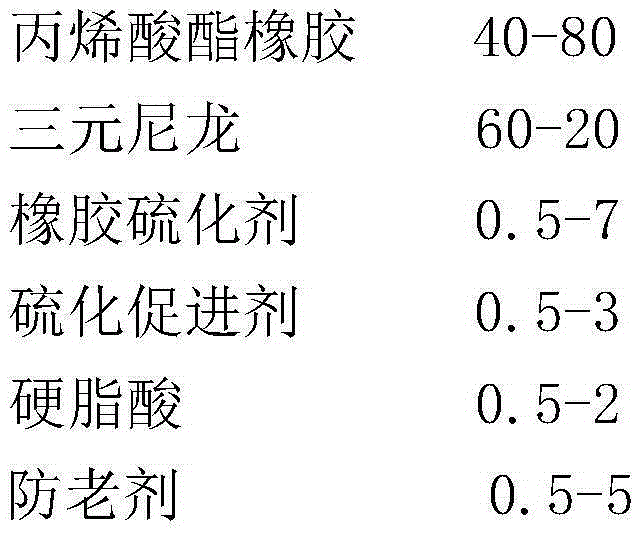

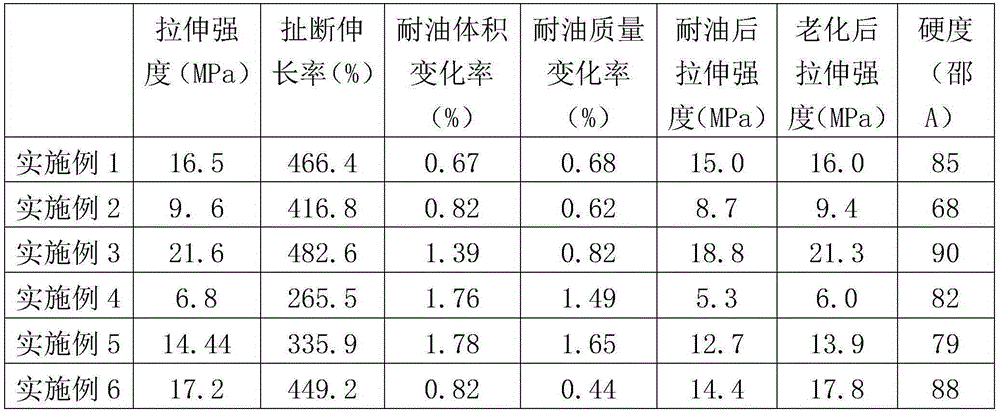

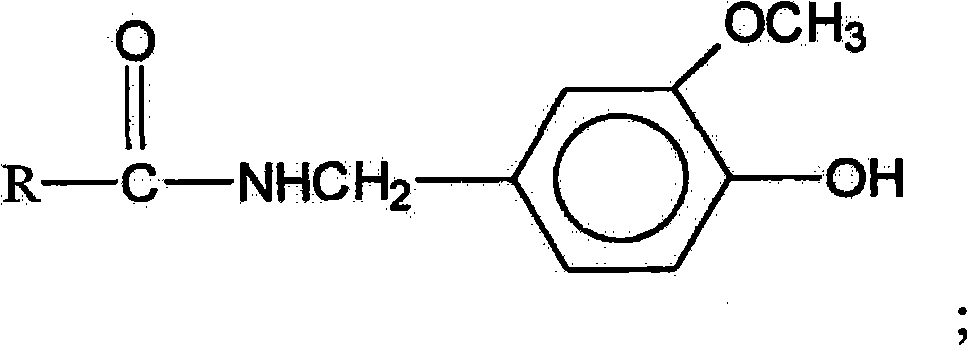

Acrylate rubber-nylon thermoplastic vulcanzate and preparation method thereof

The invention discloses acrylate rubber-nylon thermoplastic vulcanizate and a preparation method thereof. The thermoplastic vulcanizate is prepared from, by weight, 40-80 parts of acrylate rubber, 20-60 parts of ternary nylon, 0.5-7 parts of rubber vulcanizers, 0.5-3 parts of vulcanization accelerators, 0.5-2 parts of stearic acid and 0.5-5 parts of anti-aging agents. The thermoplastic vulcanizate has the advantages that the excellent oil resistance and high temperature resistance are achieved, the thermoplasticity is achieved while the high elasticity of the rubber is kept, rubber products can be produced through a plastic producing technology, pollution is reduced, energy conservation and environment protection are achieved, and the thermoplastic vulcanizate can be widely applied to products such as seal parts, rubber pipes and cables.

Owner:QINGDAO UNIV OF SCI & TECH

Terylene, bamboo fiber and milk protein fiber blended yarn

The invention provides a terylene, bamboo fiber and milk protein fiber blended yarn which comprises the following components in parts by weight: 55-65 parts of terylene, 20-30 parts of bamboo fiber, and 10-20 parts of milk protein fiber. According to the blended yarn provided by the invention, the characteristics of the terylene, the bamboo fiber and the milk protein fiber are integrated, so as to play the advantages of the the terylene, the bamboo fiber and the milk protein fiber.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Blended yarn of terylene and glass fiber

The invention provides blended yarn of terylene and glass fiber. The blended yarn comprises the following components: 80-90 weight parts of terylene and 10-20 weight parts of glass fiber. The blended yarn enables the characteristics of terylene and glass fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Degradable rodent-proof bio-based garbage bag and preparation method thereof

The invention relates to a rat-proof biobased garbage bag and a preparation method thereof. The rat-proof biobased garbage bag comprises the following components in parts by mass: 20-70 percent of polyethylene, 15-60 percent of starch, 5-10 percent of plasticizer, 5-10 percent of rat-proof repellent and 0.5-2 percent of color master batch. The preparation method of the degradable rat-proof biobased garbage bag comprises the following steps of: preparing a required biobased material from the polyethylene, the starch, the the plasticizer and the rat-proof repellent according to a specific production process; and matching the biobased material with the color master batch and carrying out secondary processing to obtain the degradable rat-proof biobased garbage bag. In the invention, the polyethylene is filled with the thermoplastic starch, so that the thermoplastic starch is uniformly dispersed in a polyethylene matrix; then a polyethylene modified material is disintegrated into fragments along with the biodegradation of the starch, so that the polyethylene modified material has a certain biodegradability; and due to the utilization of the plasticizer, the starch has thermoplasticity, so that the machinability of the starch and the compatibility of polyethylene matrix resin are improved.

Owner:WUHAN HUALI ENVIRONMENTAL PROTECTION IND CO LTD

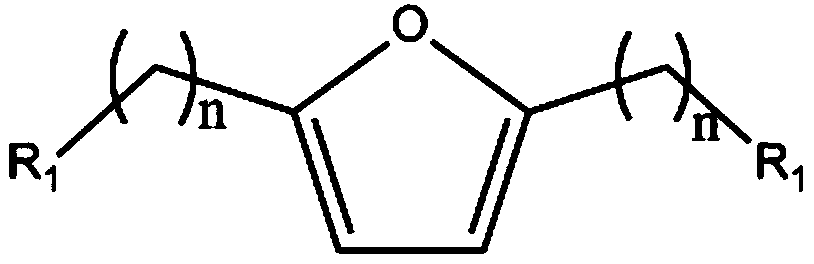

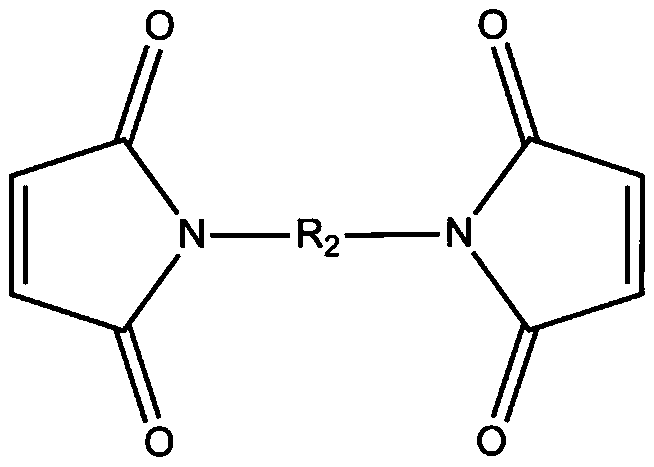

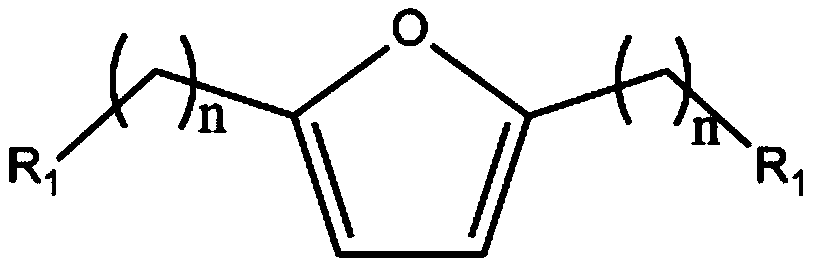

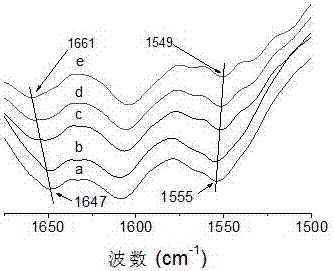

Reversible cross-linking thermoplastic polyurethane elastomer and preparation method thereof

The invention discloses a reversible cross-linking thermoplastic polyurethane elastomer and a preparation method thereof. The reversible cross-linking thermoplastic polyurethane elastomer comprises afuran-containing thermoplastic polyurethane (TPU) component (A) and a bismaleimide component (B); the furan-containing TPU component (A) is prepared from the following raw materials by weight: 25-46 parts by weight of an isocyanate (a1), 32-67 parts by weight of a polymer polyol (a2), 3.5-13 parts by weight of a small molecular dihydric alcohol (a3) and 0.3-4.5 parts by weight of furan (a4) containing two reactive groups for isocyanate radicals; and the bismaleimide component (B) is a mixture of a bismaleimide-containing compound (b1) and TPU (b2). According to the invention, through a reversible Diels-Alder reaction of functional components, the cross-linking effect among molecular chains is increased, the thermoplastic property of TPU is ensured, and the TPU is endowed with an excellentself-repairing ability.

Owner:ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

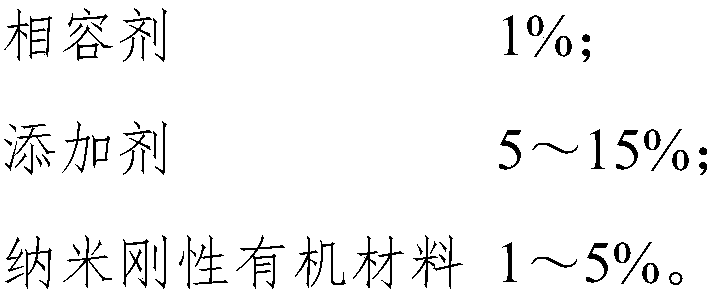

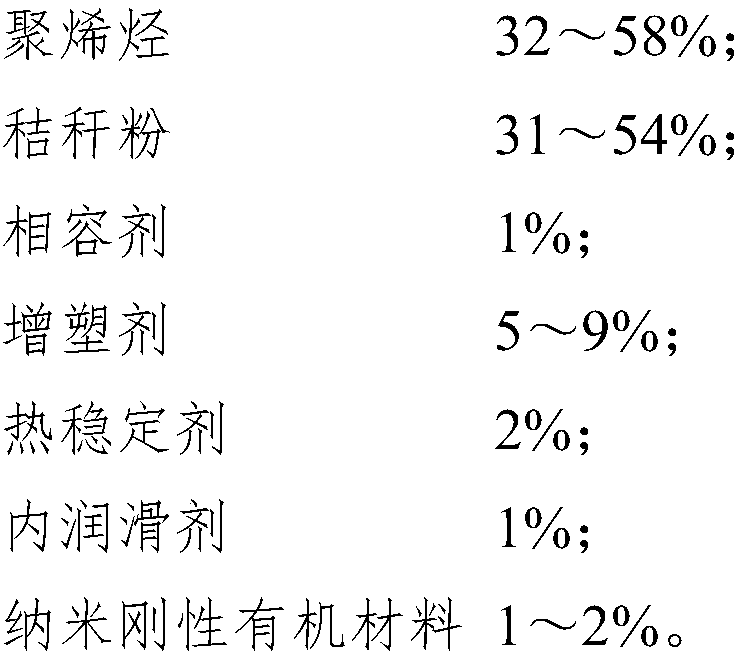

Bio-based straw composite plastic and preparation method thereof

The invention discloses a bio-based straw composite plastic and a preparation method thereof. The plastic comprises the following raw materials: 30-60% of a polyolefin, 30-55% of straw powder, 1% of acompatibilizer, 5-15% of an additive, and 1-5% of a nano rigid organic material, wherein the compatibilizer is one or more of polyethylene glycol, a silane coupling agent, aluminum titanate and titanate; the additive is one or more of a plasticizer, a heat stabilizer and an inner lubricant; and the nano rigid organic material is a cellulose nanocrystal or a cellulose nanofibril. The preparation method comprises the following steps: preparing an ethanol solution from the compatibilizer, uniformly spraying the obtained solution into a mixture of the straw powder and the nano rigid organic material, performing placement at room temperature, performing drying, adding the remaining raw materials, performing uniform mixing under stirring, adding the mixed material into a twin-screw extruder, performing mixing and performing granulation. The plastic provided by the invention has better mechanical properties than a traditional straw composite plastic, and a part of raw materials are from natural renewable substances and have certain degradation properties.

Owner:WUHAN HUALI ENVIRONMENT PROTECTION SCI & TECH

A self-healing elastomer material and a preparing method thereof

ActiveCN107099137AImprove mechanical propertiesLower glass transition temperaturePrepolymerDouble bond

A self-healing elastomer material and a preparing method thereof are disclosed. The method includes (1) reacting a first component containing a double bond and an ester group or carboxyl and a second component containing two or more amino groups at a temperature ranging from -15 DEG C to 50 DEG C for 1-72 h to obtain a prepolymer, removing an organic solvent, and then reacting the mixture at 25-200 DEG C for 1-12 h to obtain hyperbranched polyamidoamine (HPAMAM) having an amino molecular chain tail end; and (2) reacting the HPAMAM, polybasic acid and an alkaline metal compound which are metered at 100-200 DEG C for 1-24 h to obtain the self-healing elastomer material. The functional material synthesized based on the hyperbranched polyamidoamine is a hyperbranched material formed by self-assembling of hydrogen bonds and ionic bonds. The material has elasticity at room temperature. As reversible hydrogen bonds and ionic bonds exist, the material has a property that the material is self-healing at room temperature, is thermoplastic and can be repeatedly processed.

Owner:SOUTH CHINA UNIV OF TECH

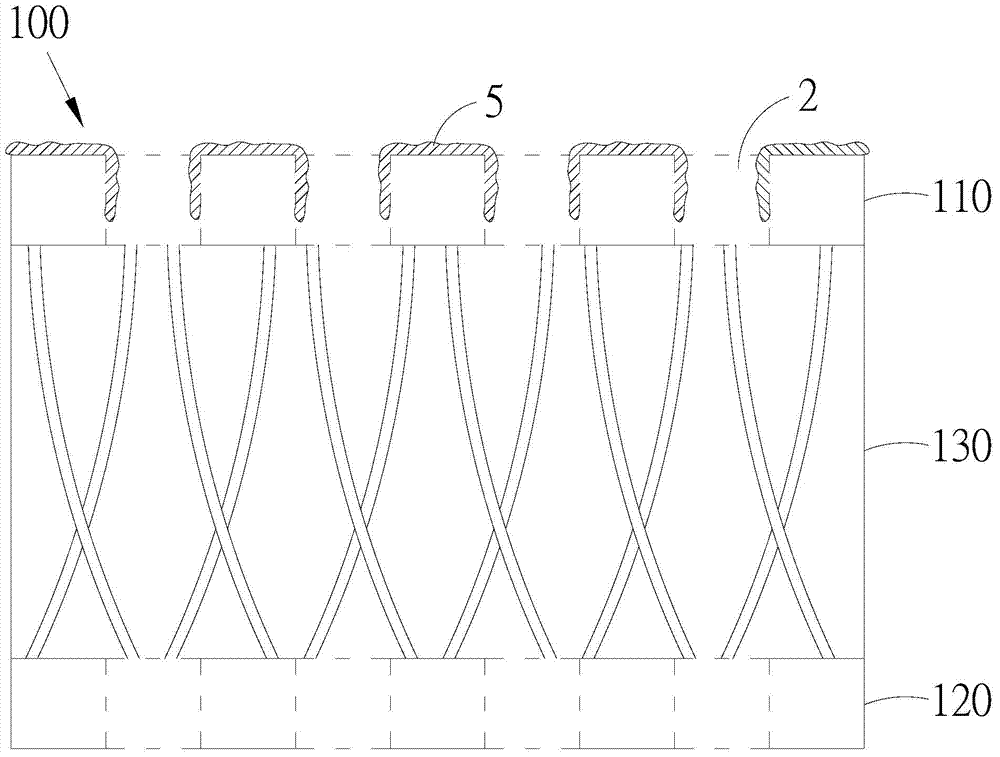

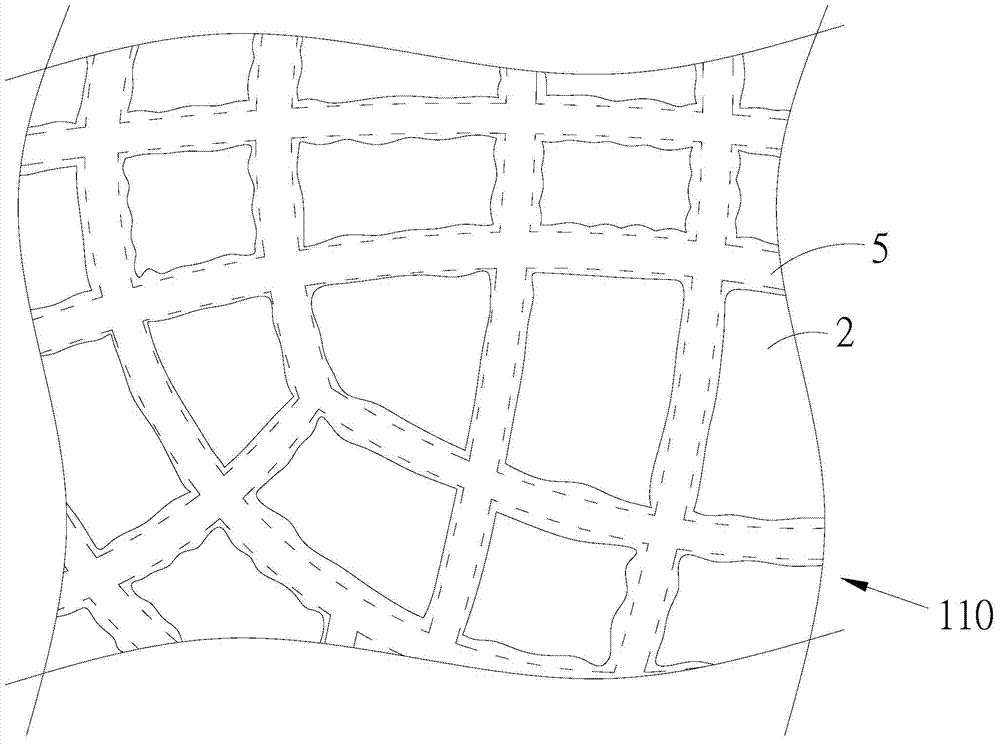

Repeatable shaping breathable fabric structure and products thereof

InactiveCN103707563AImprove breathabilityThermoplasticFibre treatmentWarp knittingBiomedical engineeringFabric structure

The invention discloses a repeatable shaping breathable fabric structure and products thereof. The repeatable shaping breathable fabric structure comprises a three-dimensional breathable sheet and a thermoplastic material, wherein the three-dimensional breathable sheet comprises two breathable outer layers with a plurality of holes, and the thermoplastic material is attached to the peripheral wall of the holes of one breathable outer layer of the three-dimensional breathable sheet.

Owner:JADE LONG JOHN ENTERPRISE

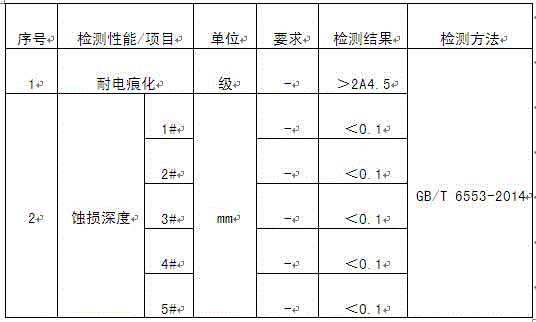

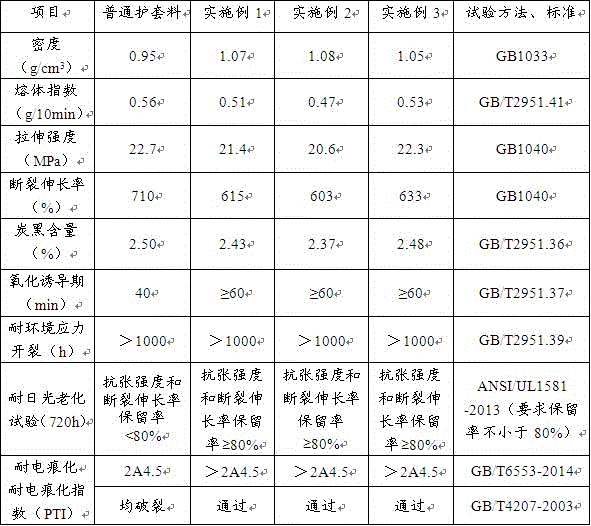

Anti-track uvioresistant ADSS optical cable jack material

The invention discloses an anti-track uvioresistant ADSS optical cable jack material which comprises the following raw materials by weight part: 65-70 parts of high density polyethylene resins, 15-20 parts of ethylene acrylic copolymers, 9-10 parts of polyethylene grafting materials, 5-6 parts of polydimethylsiloxane, 15-20 parts of magnesium hydrate, 5.0-5.5 parts of carbon black master batches, 0.5-1.0 part of ultraviolet light absorber and 0.5-1.0 part of antioxidant. In a preparation process, the raw materials are put into a high-speed mixing machine and are uniformly mixed, and then are continuously extruded by a double-screw extruder for two times, and are cooled, cut into grains and dried, so that the jack material provided by the invention is acquired; the temperature of the double-screw extruder is at 160-230 DEG C. The anti-track uvioresistant ADSS optical cable jack material can serve as the jack material special for 220KV and above ADSS optical cable, can realize high-altitude suspending remote conveying, can resist corona and electric track, can resist ultraviolet irradiation, can bear the cold environment test under wind, rain, snow and frost environments and has excellent physical and mechanical properties.

Owner:HUANGMEI KEPUDA INDAL

Terylene and carbon fiber blended yarn

The invention provides a terylene and carbon fiber blended yarn which comprises the following components in parts by weight: 85-90 parts of terylene, and 10-15 parts of carbon fiber. According to the blended yarn provided by the invention, the characteristics of the terylene and the carbon fiber are integrated, so as to play the advantages of the terylene and the carbon fiber.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

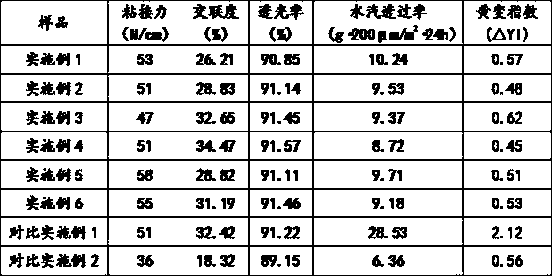

EMMA optical film for full fitting of electronic screen and preparation method thereof

InactiveCN108165181AImprove processing phenomenonSolve process defects such as difficulty in laminationNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveControl layerWater vapor

The invention discloses an EMMA optical film for full fitting of an electronic screen and a preparation method thereof. The EMMA optical film for full fitting of the electronic screen is prepared by pre-mixing 100 parts by weight of an ethylene-methyl methacrylate copolymer (EMMA), 0.5-2.0 parts by weight of a photoinitiator, 0.3-1.5 parts by weight of a crosslinking agent, 0.3-1.2 parts by weightof a tackifier, 0.1-0.6 part by weight of an optical stabilizer, 0.1-1.1 parts by weight of a plasticizer and 0.2-1.0 part by weight of an antioxidant by a stirrer, putting the mixture into a single-screw tape-casting machine and tape-casting into the optical film according to set process parameters. The prepared EMMA optical film has the advantages of excellent bonding properties, high light transmittance, low water vapor transmittance and high weather resistance, also is in thermal plasticity before curing, easily fills segment gaps, adapts to the complex interface fitting, and can adapt torequirements of fitting of electronic screen protection layers, touch control layers and display layers with different sizes.

Owner:GUANGDONG POLYTECHNIC OF ENVIRONMENTAL PROTECTION ENG

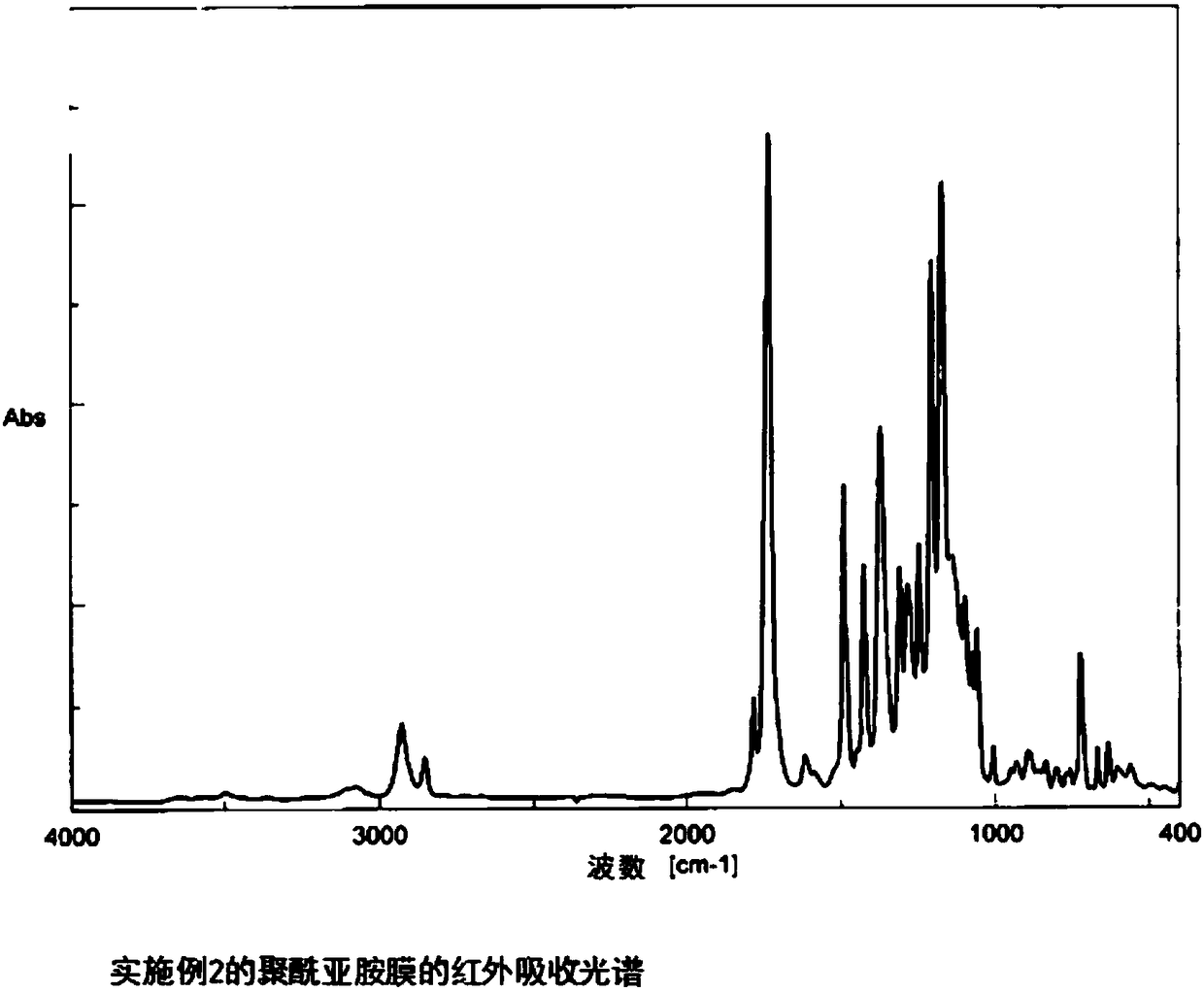

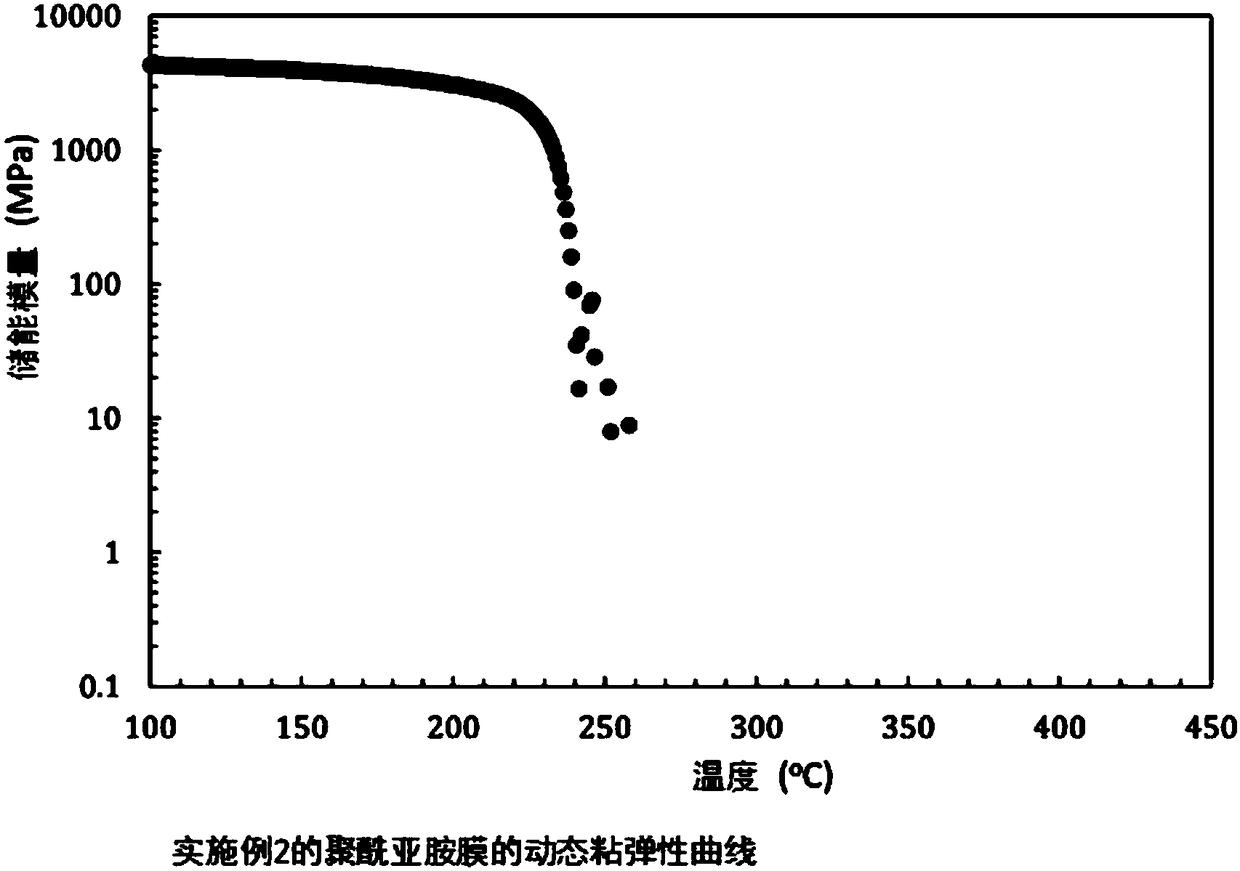

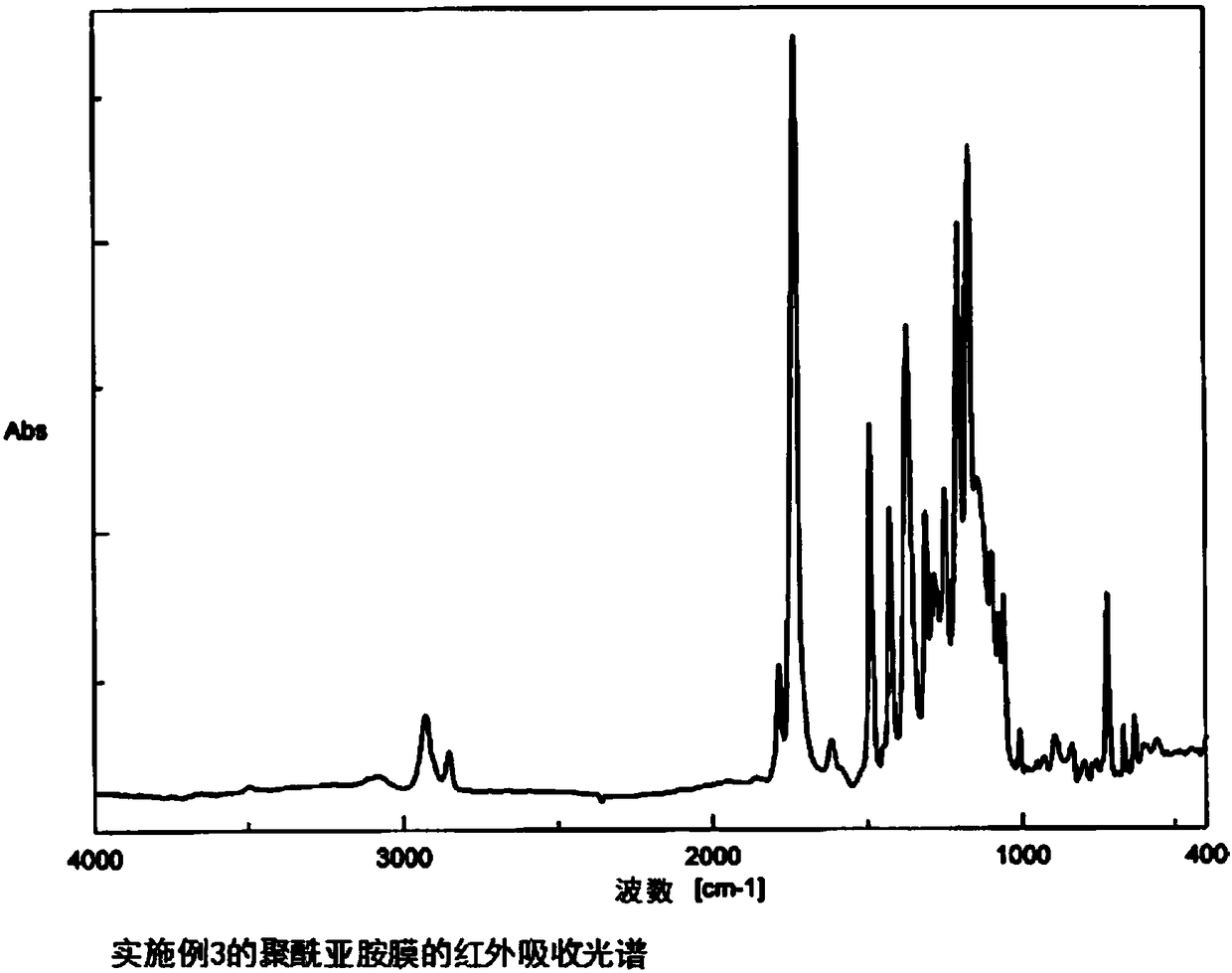

Novel tetracarboxylic dianhydride, polyimide derived from said tetracarboxylic dianhydride, and molded article produced from said polyimide

The present invention addresses the problem of providing: a polyimide which is derived from a novel tetracarboxylic dianhydride, has both excellent solubility in various types of organic solvents andthermoplasticity and therefore has excellent processability, and also has both a low linear thermal expansion coefficient and high light permeability (transparency); and a molded article produced fromthe polyimide. The problem can be solved by a polyimide derived from a tetracarboxylic dianhydride represented by formula (1).

Owner:HONSHU CHEM INDAL +1

Preparation method of metal feeling low-luster automotive interior material

PendingCN106380616AThermoplasticSolve the disadvantages of plastic feelingPolyurea/polyurethane coatingsPaints with free metalsQuality levelPolyurethane coating

The invention discloses a preparation method of a metal feeling low-luster automotive interior material. The preparation method comprises 1, film material preparation: S101, uniformly mixing polypropylene, rubber, a solubiliser, an inorganic filler and color master batches, putting the uniform mixture into a double-roller open mill, carrying out open milling and preparing a film material with the thickness of 1-10mm and S102, carrying out corona treatment on the film material obtained by the step S101 so that surface polarity of the film subjected to corona treatment is improved, 2, preparing an aqueous polyurethane coating material and 3, coating the surface of the film material with a uniform polyurethane coating and carrying out drying to obtain the metal feeling low-luster automotive interior material. The preparation method solves the problem of plastic feeling of the existing injection molding plastic, is free of a later paint spraying process and satisfies requirements of low VOC, scratch resistance, low luster and high quality level provided by the automobile manufacturer on automotive interiors.

Owner:BENECKE CHANGSHUN AUTO TRIMZHANGJIAGANG

Biodegradation composition, and preparation method and application thereof

ActiveCN102070795AThermoplasticMolecular weight controllableConjugated synthetic polymer artificial filamentsBlow moldingPolymer science

The invention discloses a biodegradation composition, and a preparation method and application thereof. The biodegradation composition consists of a biodegradation resin, dextrin and a plasticizer, wherein the mass ratio of the biodegradation resin to the dextrin is 1:9 to 9:1; the content of the plasticizer is 1 to 30 percent based on the total weight of the biodegradation composition; and the dextrin is prepared from the mixture of dried natural starch and acid solution in melting and mixing equipment. The biodegradation composition is prepared from the mixture of the components in the smelting and mixing equipment. The biodegradation composition provided by the invention has relatively higher physical properties and processability, relatively higher water resistance and medium biodegradation speed, well satisfies the needs of practical application, and can be prepared into various products by universal processing methods such as blowing molding, extrusion molding, injection molding, spinning molding and the like.

Owner:KINGFA SCI & TECH CO LTD +2

Polyethylene base film specially used for compounding with polyvinyl alcohol film and preparation method thereof

The present invention discloses a polyethylene base film specially used for compounding with a polyvinyl alcohol film and a preparation method thereof, the polyethylene base film comprises 70-90.5 wt% of polyethylene (PE), 5-15 wt% of an ethylene-acrylic acid copolymer (EAA); 3-10 wt% of polyethylene oxide (PEO); 1-3 wt% of polyethylene glycol (PEG) and 0.5-2.0 wt% of precipitated white carbon black, and the polyethylene base film is prepared as follows: granulating at 120-180 DEG C with a twin-screw extruder, blowing for molding or flow-casting to form the film at 160-180 DEG C with a single screw extruder. The modified polyethylene (PE) film is compounded with the polyvinyl alcohol (PVA) film, erosion damage in moisture or high humidity environment can be significantly improved, and after a composite film is processed at 23 DEG C in environment with the relative humidity RH of 90% for 48 hours, the peel strength is greater than or equal to 2.0N / 15min.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com