Anti-track uvioresistant ADSS optical cable jack material

A technology of anti-ultraviolet and sheathing materials, applied in the field of optical cable sheathing materials, can solve problems such as friction resistance, crimp resistance, and poor weather resistance, and achieve excellent heat resistance, improved toughness, and high flash point.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

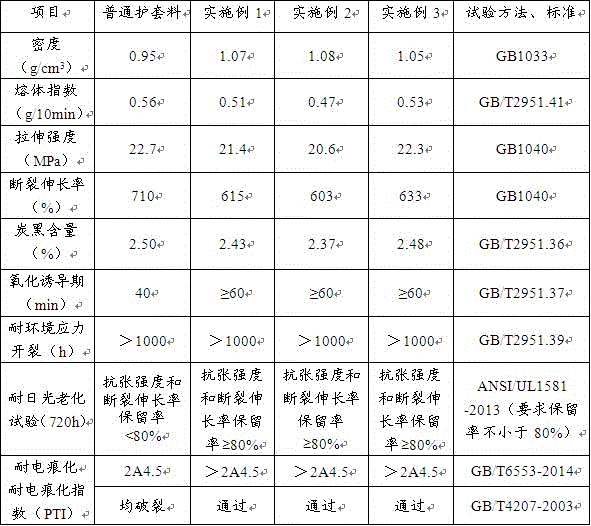

Embodiment 1

[0020] An anti-tracking and anti-ultraviolet ADSS optical cable sheath material in this embodiment, the sheath material contains the following raw materials in parts by weight: 68 parts of high-density polyethylene (HDPE) resin, 17 parts of ethylene acrylic acid copolymer (EAA) , 9.5 parts of polyethylene (PE) grafting material, 5.5 parts of polydimethylsiloxane, 18 parts of magnesium hydroxide, 5.2 parts of carbon black masterbatch, 0.8 part of ultraviolet absorber, 0.8 part of antioxidant, the above raw materials Put it in a high-speed mixer and mix evenly. After being extruded by a twin-screw extruder twice in a row, the sheath material prepared by the present invention is obtained through cooling, pelletizing, and drying. The temperature of the twin-screw extruder is 160-230°C.

[0021] The high-density polyethylene (HDPE) resin described in this example is 6098F grade.

[0022] The magnesium hydroxide described in this example has a purity of 99.5% and a particle size of...

Embodiment 2

[0030] An anti-tracking and anti-ultraviolet ADSS optical cable sheath material in this embodiment, the sheath material contains the following raw materials in parts by weight: 65 parts of high-density polyethylene (HDPE) resin, 20 parts of ethylene acrylic acid copolymer (EAA) , 9 parts of polyethylene (PE) grafting material, 6 parts of polydimethylsiloxane, 20 parts of magnesium hydroxide, 5.0 parts of carbon black masterbatch, 1.0 part of ultraviolet absorber, 0.5 part of antioxidant, the above raw materials Put it in a high-speed mixer and mix evenly. After being extruded by a twin-screw extruder twice in a row, the sheath material prepared by the present invention is obtained through cooling, pelletizing, and drying. The temperature of the twin-screw extruder is 160-230°C.

[0031] The high-density polyethylene (HDPE) resin described in this example is 6098F grade.

[0032] The magnesium hydroxide described in this example has a purity of 98% and a particle size of ≤5 μm...

Embodiment 3

[0036] An anti-tracking and anti-ultraviolet ADSS optical cable sheath material in this embodiment, the sheath material contains the following raw materials in parts by weight: 70 parts of high-density polyethylene (HDPE) resin, 15 parts of ethylene acrylic acid copolymer (EAA) , 10 parts of polyethylene (PE) grafting material, 5 parts of polydimethylsiloxane, 15 parts of magnesium hydroxide, 5.5 parts of carbon black masterbatch, 0.5 part of ultraviolet absorber, 1.0 part of antioxidant, the above raw materials Put it in a high-speed mixer and mix evenly. After being extruded by a twin-screw extruder twice in a row, the sheath material prepared by the present invention is obtained through cooling, pelletizing, and drying. The temperature of the twin-screw extruder is 160-230°C.

[0037] The high-density polyethylene (HDPE) resin described in this example is 6098F grade.

[0038] The magnesium hydroxide described in this example has a purity of 99.2% and a particle size of ≤5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com