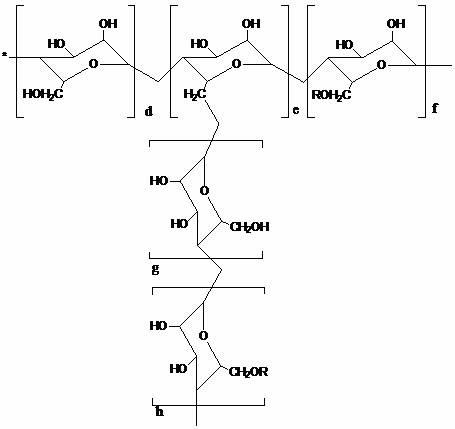

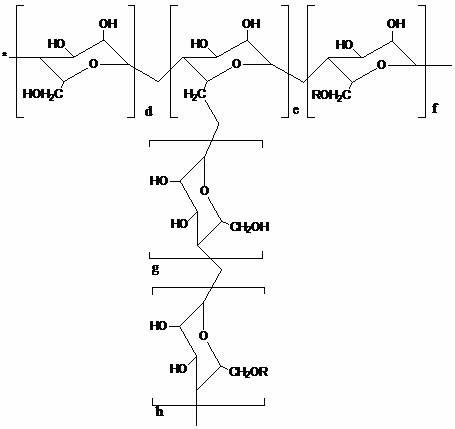

Biodegradation composition, and preparation method and application thereof

A biodegradable and biodegradable resin technology, applied in the field of biodegradable compositions and their preparation, can solve the problems of poor processing performance, low mechanical properties, difficult practical application requirements, etc., achieve good physical properties and processing properties, and enhance water resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Weigh each component according to the following weight percentages:

[0067] cornstarch 30

[0068] potato starch 30

[0069] Tapioca starch 30

[0070] Hydrochloric acid solution 10

[0071] The pH value of the hydrochloric acid solution is 4.5

[0072] According to the above ratio, pre-dry the weighed various starches in an oven at 80°C for 5 hours, then stir with hydrochloric acid solution in a high-speed mixer for 10 minutes at a low speed, and then leave after 4 minutes of high-speed stirring, and send them into the same phase twin-screw extrusion In the machine, extrude and granulate at a temperature of 100° C. to obtain the product dextrin, and the molecular weight of the obtained dextrin is 27961 g / mol.

Embodiment 2

[0074] Weigh each component according to the following weight percentages:

[0075] cornstarch 84

[0076] Sulfuric acid solution 16

[0077] The pH value of the sulfuric acid solution is 5.0

[0078] According to the above ratio, pre-dry the weighed various starches in an oven at 80°C for 5 hours, then stir with hydrochloric acid solution in a high-speed mixer for 10 minutes at a low speed, and then leave after 4 minutes of high-speed stirring, and send them into the same phase twin-screw extrusion In the machine, extrude and granulate at a temperature of 100° C. to obtain the product dextrin, and the molecular weight of the obtained dextrin is 33678 g / mol.

Embodiment 3

[0080] Weigh each component according to the following weight percentages:

[0081] Potato Starch 95

[0082] Phosphoric acid solution 5

[0083] The pH value of the sulfuric acid solution is 5.5

[0084] According to the above ratio, pre-dry the weighed various starches in an oven at 80°C for 5 hours, then stir with hydrochloric acid solution in a high-speed mixer for 10 minutes at a low speed, and then leave after 4 minutes of high-speed stirring, and send them into the same phase twin-screw extrusion In the machine, extrude and granulate at a temperature of 100° C. to obtain the product dextrin, the molecular weight of the obtained dextrin is 39782 g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com