Preparation method of metal feeling low-luster automotive interior material

A technology of automotive interior and metal texture, which is applied in the field of automotive interior materials, can solve problems such as low gloss, and achieve high material utilization, excellent scratch resistance, and high-grade effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

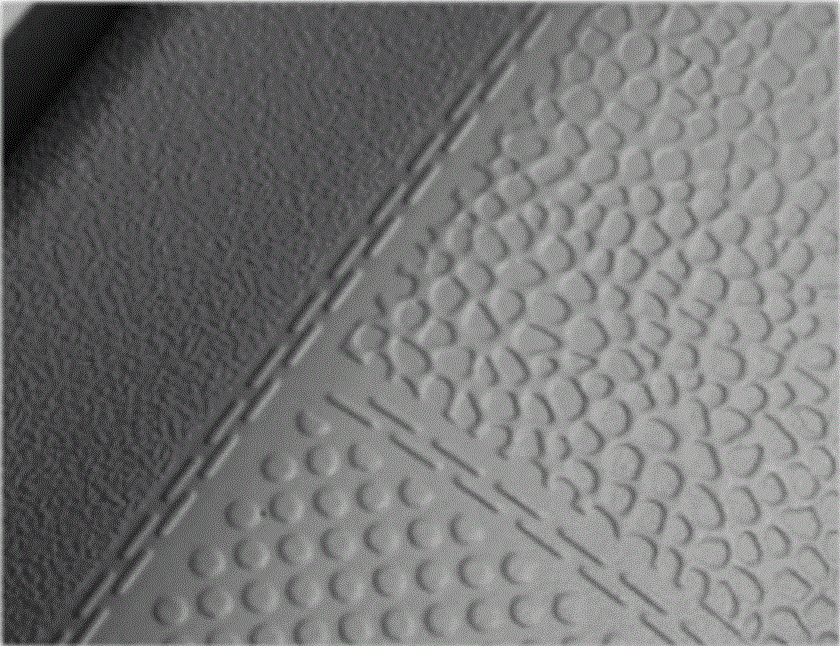

Image

Examples

Embodiment 1

[0034] In Example 1, the film material formula was screened, and the film material formula included: 60 parts of polypropylene, 15 parts of rubber, 0.5 part of solubilizer, and 20 parts of inorganic filler.

[0035] Among them, the rubber includes ethylene octene rubber, ethylene butene rubber, and ethylene propylene rubber.

[0036] The solubilizer includes: maleic acid grafted polypropylene, maleic anhydride grafted polypropylene, maleic acid grafted polyethylene, maleic anhydride grafted polyethylene.

[0037] The inorganic filler includes: talcum powder, glass fiber, mica, calcium carbonate and barium sulfate.

[0038] The particle size of talcum powder, mica, calcium carbonate and barium sulfate is 300 mesh, and the length of glass fiber is 50 μm.

[0039] Waterborne polyurethane coating material formula: 60 parts of waterborne polyurethane dispersion, 0.5 part of polyurethane thickener, 0.1 part of isocyanate curing agent, 30 parts of water, 0.5 part of silicon dioxide,...

Embodiment 2

[0041] The film material formula in Example 2: 70 parts of polypropylene, 27 parts of rubber, 1.5 parts of solubilizer, and 33 parts of inorganic filler.

[0042] Among them, the rubber includes ethylene octene rubber, ethylene butene rubber, and ethylene propylene rubber.

[0043] The solubilizer includes: maleic acid grafted polypropylene, maleic anhydride grafted polypropylene, maleic acid grafted polyethylene, maleic anhydride grafted polyethylene.

[0044] The inorganic filler includes: talcum powder, glass fiber, mica, calcium carbonate and barium sulfate.

[0045] The particle size of talcum powder, mica, calcium carbonate and barium sulfate is 500 mesh, and the length of glass fiber is 50 μm.

[0046] Water-based polyurethane coating material formula: 72 parts of water-based polyurethane dispersion, 1 part of polyurethane thickener, 0.25 parts of isocyanate curing agent, 45 parts of water, 1.75 parts of silicon dioxide, and 28 parts of metal powder.

Embodiment 3

[0048] The film material formula includes: 80 parts of polypropylene, 30 parts of rubber, 2 parts of solubilizer, and 45 parts of inorganic filler.

[0049] Among them, the rubber includes ethylene octene rubber, ethylene butene rubber, and ethylene propylene rubber.

[0050] The solubilizer includes: maleic acid grafted polypropylene, maleic anhydride grafted polypropylene, maleic acid grafted polyethylene, maleic anhydride grafted polyethylene.

[0051] The inorganic filler includes: talcum powder, glass fiber, mica, calcium carbonate and barium sulfate.

[0052] The particle size of talcum powder, mica, calcium carbonate and barium sulfate is 900 mesh, and the length of glass fiber is 50 μm.

[0053] Water-based polyurethane coating material formula: 75 parts of water-based polyurethane dispersion, 1.5 parts of polyurethane thickener, 0.5 parts of isocyanate curing agent, 60 parts of water, 2 parts of silica, 35 parts of metal powder.

[0054] Step 1, preparing each compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com