Degradable rodent-proof bio-based garbage bag and preparation method thereof

A bio-based, garbage bag technology, applied in the direction of garbage cans, biological packaging, garbage collection, etc., can solve the problems of garbage bag edible biological damage, secondary pollution, white pollution of garbage bags, etc., to improve processability, high efficiency half-life , surface smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

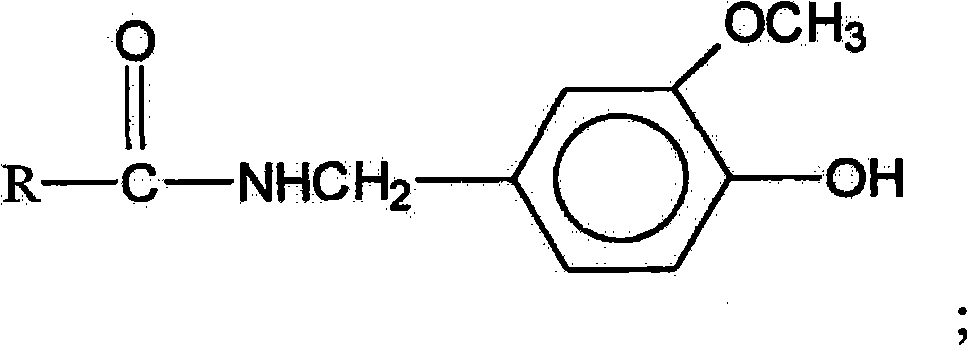

Method used

Image

Examples

Embodiment 1

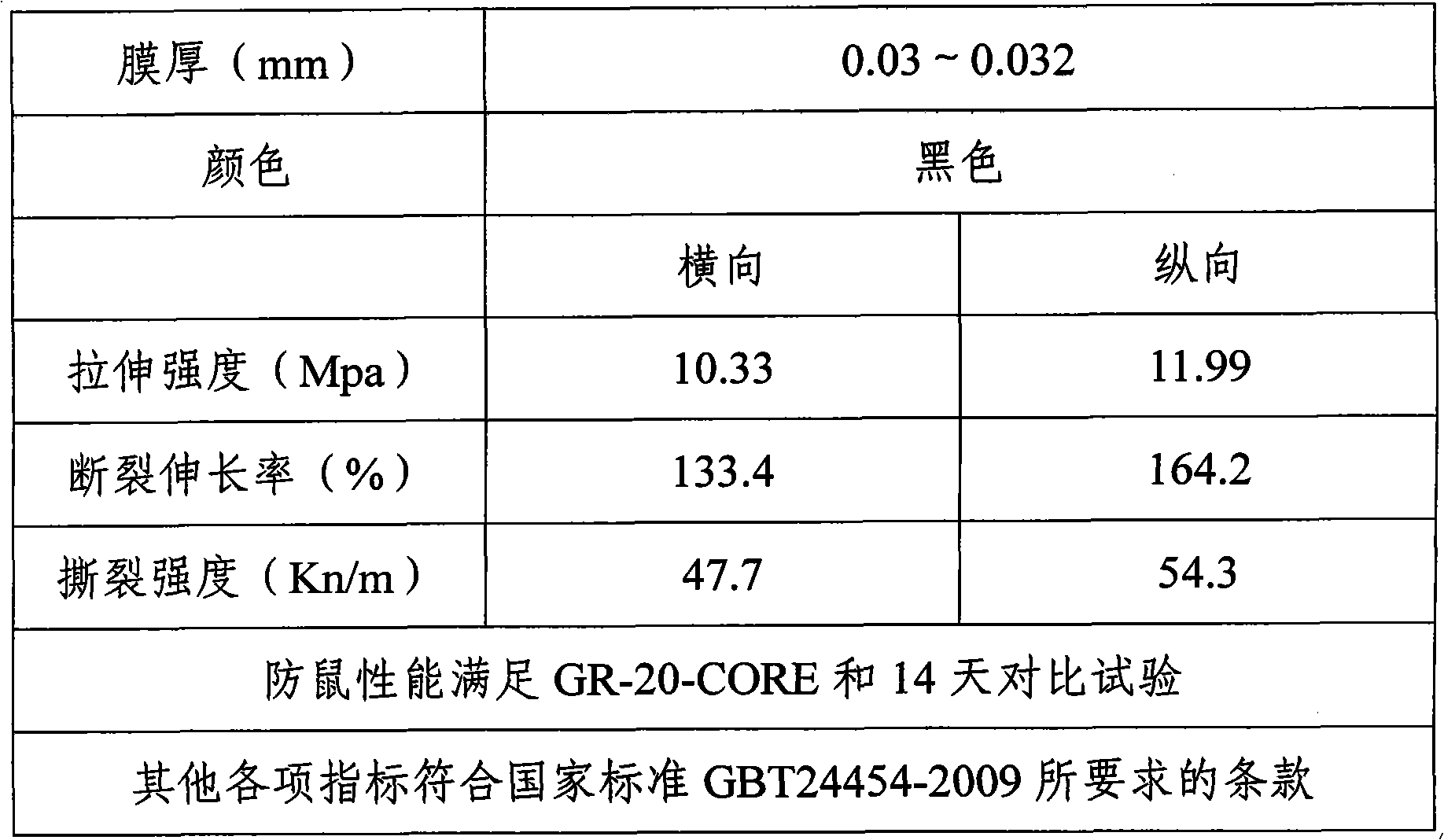

[0039] 20 parts by mass of low-density polyethylene, 60 parts by mass of cornstarch, 10 parts by mass of glycerol and 10 parts by mass of nonanoyl vanillic acid were mixed uniformly in a high-speed mixer; then the mixture was mixed in a twin-screw extruder, wherein , the temperature of each section of the twin-screw extruder is set to T 1 =150°C, T 2 =160°C, T 3 =180°C, T 4 =200°C, T 5 =205°C, T 6 =210°C, twin-screw extruder speed r=300r·min -1 ; After extrusion, cooling, and granulation, the bio-based material used for the degradable rodent-proof bio-based garbage bag can be obtained; and the degradable rodent-proof bio-based garbage bag can be obtained after secondary processing with the color masterbatch. as follows:

[0040]

Embodiment 2

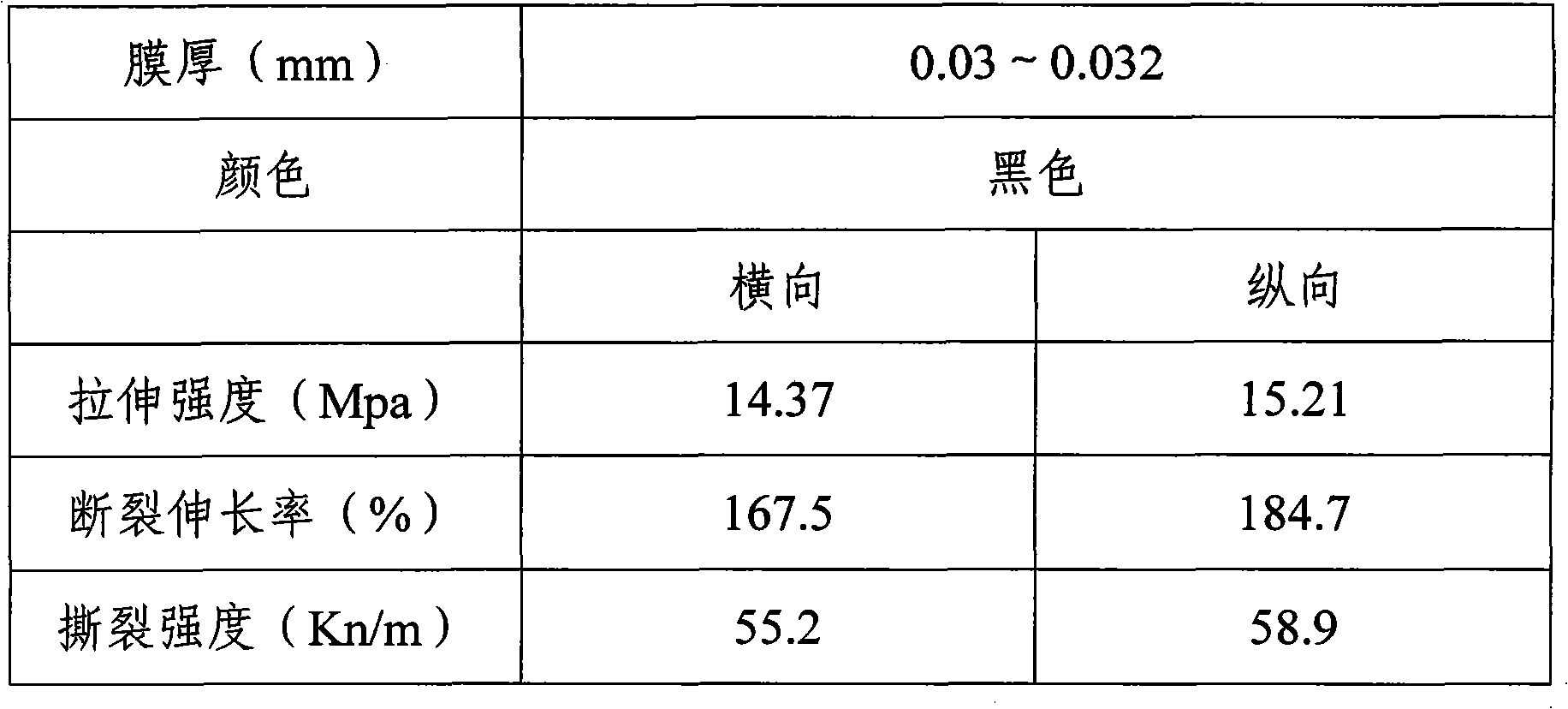

[0042] 70 parts by mass of low-density polyethylene, 15 parts by mass of cornstarch, 5 parts by mass of formamide and 10 parts by mass of capryl vanillic acid were mixed uniformly in a high-speed mixer; then the mixture was mixed in a twin-screw extruder, double The temperature of each section of the screw extruder is set to T 1 =155°C, T 2 =165°C, T 3 =185°C, T 4 =205°C, T 5 =215°C, T 6 =220°C, twin-screw extruder speed is r=320r·min -1 ; After extrusion, cooling, and granulation, the bio-based material used for the degradable rodent-proof bio-based garbage bag can be obtained; and the degradable rodent-proof bio-based garbage bag can be obtained after secondary processing with the color masterbatch. as follows:

[0043]

[0044]

Embodiment 3

[0046] The mixture of 40 mass parts of low density polyethylene and linear low density polyethylene, 45 mass parts of tapioca starch, 10 mass parts of ethylene glycol and 5 mass parts of octanoyl vanillic amide are mixed uniformly in a high-speed mixer; Mixing in the extruder, the temperature of each section of the twin-screw extruder is set to T 1 =145°C, T 2 =155°C, T 3 =165°C, T 4 =180°C, T 5 =195°C, T 6 =205°C, twin-screw extruder speed r=300r·min -1; After extrusion, cooling, and granulation, the bio-based material used for the degradable rodent-proof bio-based garbage bag can be obtained; and the degradable rodent-proof bio-based garbage bag can be obtained after secondary processing with the color masterbatch. as follows:

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com