Method for preparing environment-friendly modified carboxymethyl cellulose thermoplastic material

A technology of carboxymethyl cellulose and thermoplastic materials, applied in the field of preparation of ecological environment materials, can solve the problems such as the thermoplastic modification method of carboxymethyl cellulose and the lack of reports in the literature of thermoplastic materials, and achieve good processing performance , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

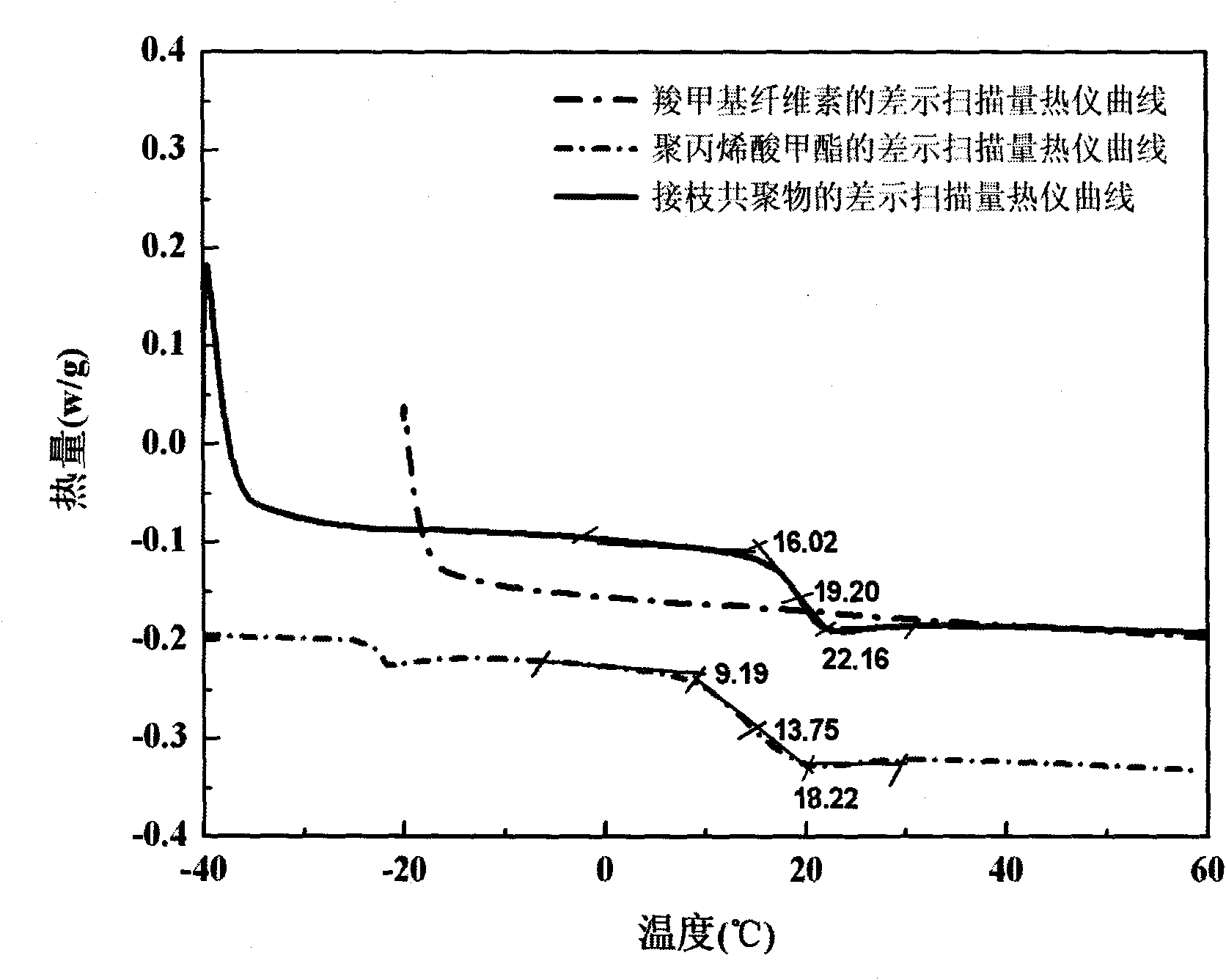

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of an environmentally friendly modified carboxymethyl cellulose thermoplastic material, comprising the following steps:

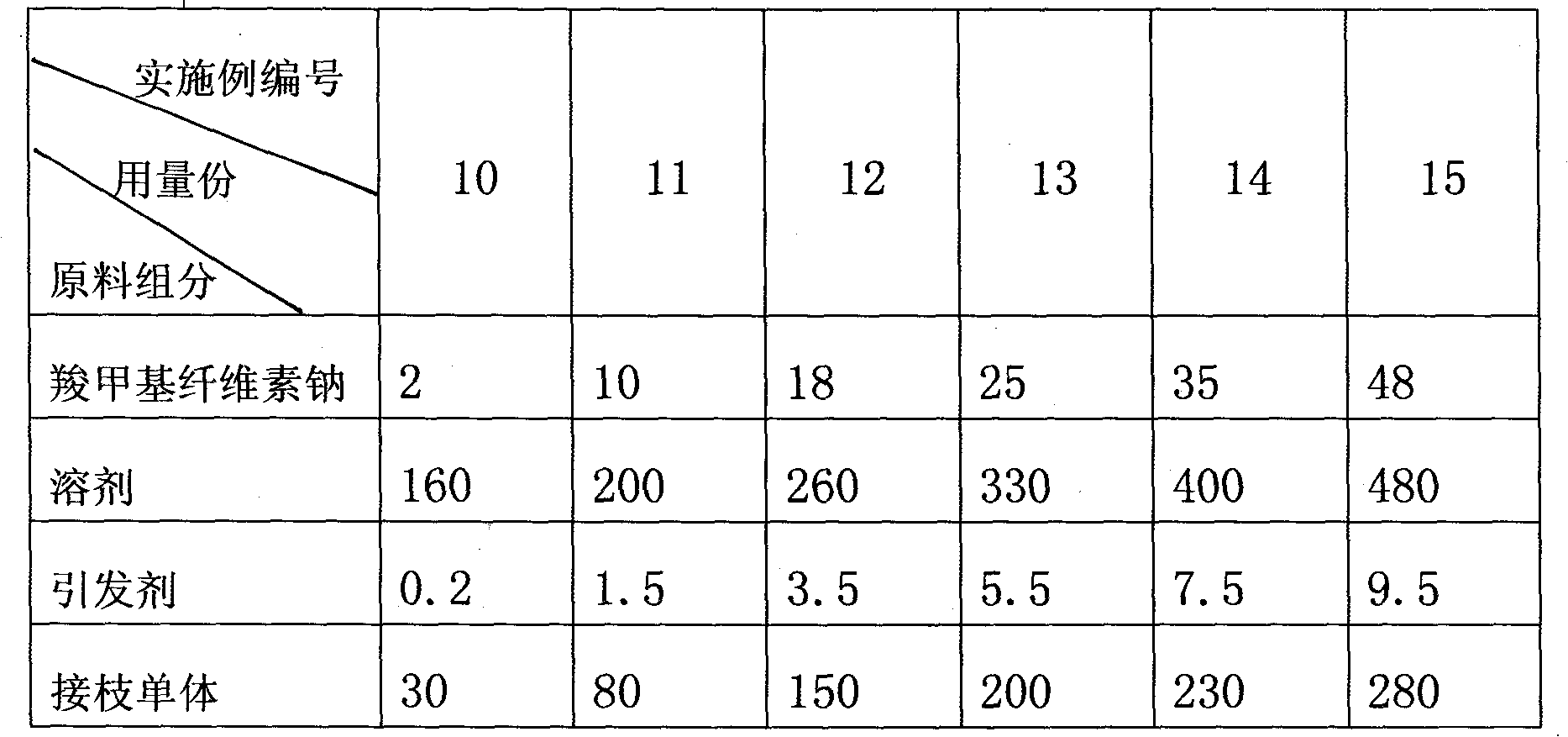

[0031] Add 5 parts of sodium carboxymethylcellulose to 150 parts of solvent, control the temperature at 30°C, and swell for 1 hour; add 0.1 part of initiator to the swollen sodium carboxymethylcellulose, control the temperature at 40°C, and initiate the reaction The time is 0.1 hour; after initiating the reaction, add 50 parts of methyl acrylate, control the reaction temperature at 50°C, and the reaction time is 3 hours; cool the liquid after the reaction, add 150 parts of acetone, stir for 2 hours, and then let it stand for 5 hours before filtering. Wash the solid with water (preferably distilled water), and dry at 50° C. for 6 hours to obtain milky yellow thermoplastic carboxymethyl cellulose material (ie: modified carboxymethyl cellulose thermoplastic material).

Embodiment 2

[0033] A preparation method of an environmentally friendly modified carboxymethyl cellulose thermoplastic material, comprising the following steps:

[0034] Add 10 parts of sodium carboxymethylcellulose to 200 parts of solvent, control the temperature at 40°C, and swell for 2 hours; add 1 part of initiator to the swollen sodium carboxymethylcellulose, control the temperature at 50°C, and initiate the reaction The time is 0.2 hours; after initiating the reaction, add 100 parts of methyl acrylate, control the reaction temperature at 60°C, and the reaction time is 4 hours; cool the liquid after the reaction, add 150 parts of acetone, stir for 3 hours, and then let it stand for 6 hours before filtering. Wash the solid with water (preferably distilled water), and dry at 60° C. for 8 hours to obtain milky yellow thermoplastic carboxymethyl cellulose material (ie: modified carboxymethyl cellulose thermoplastic material).

Embodiment 3

[0036] A preparation method of an environmentally friendly modified carboxymethyl cellulose thermoplastic material, comprising the following steps:

[0037] Add 15 parts of sodium carboxymethyl cellulose to 300 parts of solvent, control the temperature at 45°C, and swell for 2.5 hours; add 2 parts of initiator to the swollen sodium carboxymethyl cellulose, control the temperature at 60°C, and initiate the reaction The time is 0.5 hours; add 150 parts of methyl acrylate after initiating the reaction, control the reaction temperature at 65°C, and the reaction time is 5 hours; cool the liquid after the reaction, add 200 parts of acetone, stir for 4 hours, and then let it stand for 6 hours before filtering. Wash the solid with water (preferably distilled water), and dry at 65° C. for 12 hours to obtain milky yellow thermoplastic carboxymethyl cellulose material (ie: modified carboxymethyl cellulose thermoplastic material).

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com