Self-healing antiskid unvulcanizedrubber material and preparation method thereof

A non-vulcanized rubber, self-healing technology, applied in the field of self-healing anti-slip non-vulcanized rubber materials and preparations, can solve the problems of dynamic disulfide bond hysteresis, serious pollution, unfavorable rubber repair, etc. Effects of abrasion resistance, good wet skid resistance and grip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

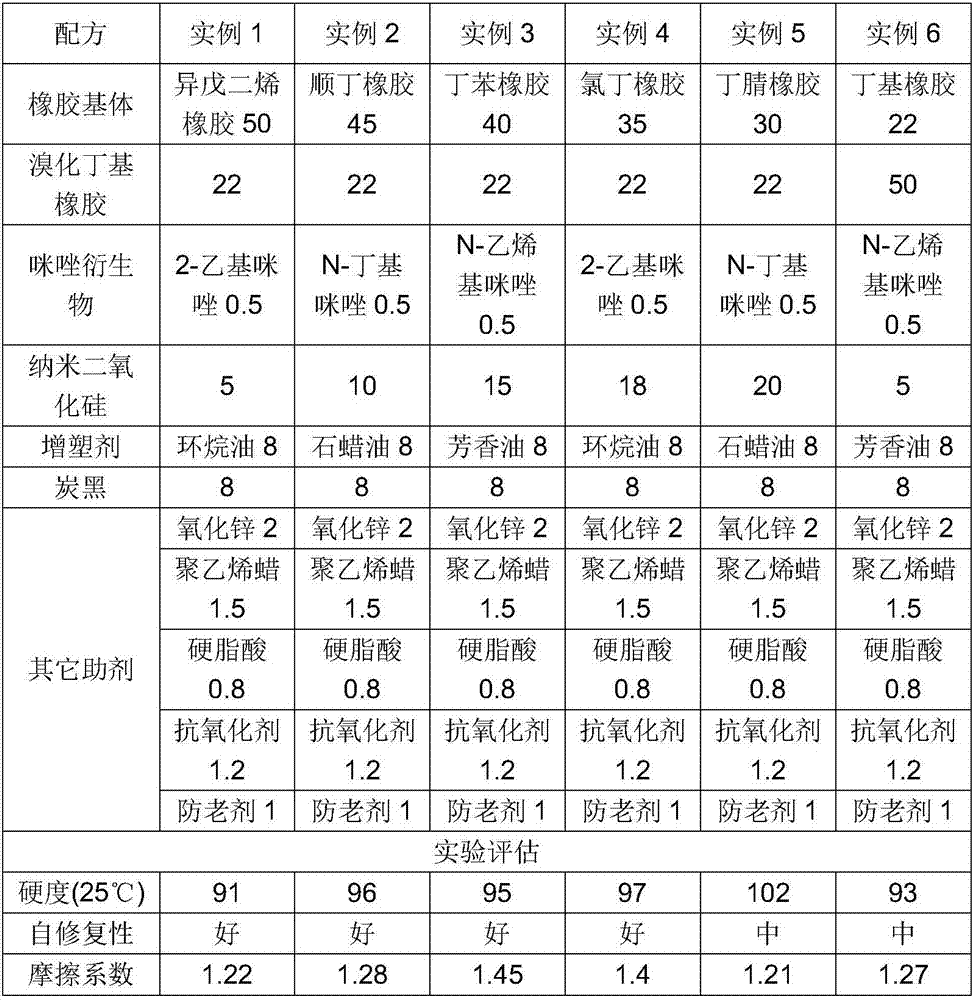

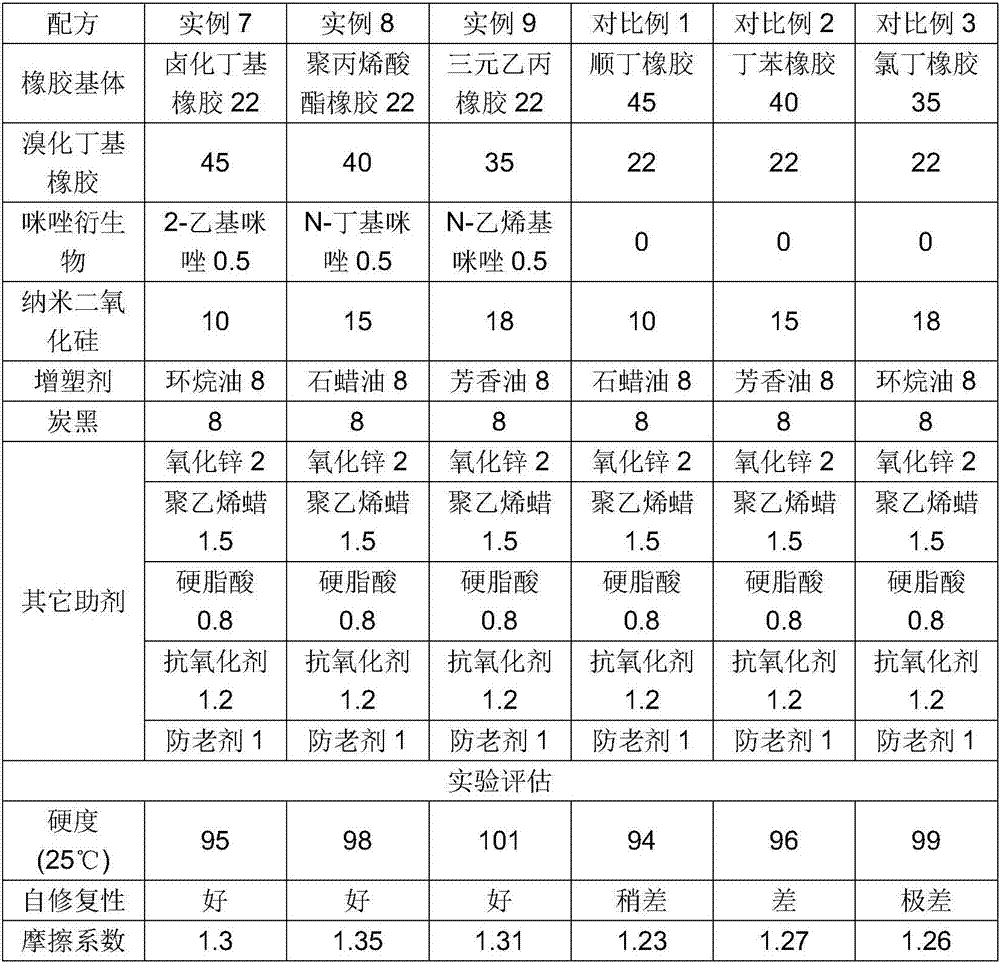

Embodiment 1

[0032] 50wt% isoprene rubber, 22wt% bromobutyl rubber, 0.5wt% 2-ethylimidazole, 5wt% nano-silica, 8wt% naphthenic oil, 8wt% carbon black, 2wt% zinc oxide, 1wt% % antioxidant, 1.2wt% antioxidant and 1.5wt% polyethylene wax and 0.8wt% stearic acid;

[0033] Firstly, 22wt% bromobutyl rubber and 50wt% isoprene rubber were kneaded separately on the open mill; then the kneaded brominated butyl rubber and 0.5wt% 2-ethyl Imidazole, after mixing for 3 minutes, add other rubber after kneading, and then knead for 3 minutes; add 2wt% zinc oxide, 1wt% anti-aging agent, 1.2wt% antioxidant and other additives, mix for 5 minutes; finally add 5wt% nanometer Silicon oxide, mixed for 5 minutes; then add 8wt% carbon black and 8wt% naphthenic oil as a plasticizer, mix it for 10 minutes and then transfer it to an open mill to take out the sheet and pack it for subsequent use;

[0034] After the prepared rubber sheet was parked at room temperature for 8 hours, according to the "hardness test method...

Embodiment 2

[0036] 45wt% butadiene rubber, 22wt% bromobutyl rubber, 0.5wt% N-butyl imidazole, 10wt% nano-silica, 8wt% paraffin oil, 8wt% carbon black, 2wt% zinc oxide, 1wt% antioxidant , 1.2wt% antioxidant and 1.5wt% polyethylene wax and 0.8wt% stearic acid;

[0037] First, 22wt% brominated butyl rubber and 45wt% butadiene rubber are milled separately on the open mill; then in the kneader at 100°C, add brominated butyl rubber and 0.5wt% N-butylimidazole after milling, After mixing for 3 minutes, add other rubber after kneading, and knead for 3 minutes; add 2wt% zinc oxide, 1wt% anti-aging agent, 1.2wt% antioxidant and other additives, mix for 5 minutes; finally add 10wt% nano silicon dioxide , mixed for 5 minutes; then add 8wt% carbon black and 8wt% paraffin oil as a plasticizer, after mixing for 10 minutes, transfer to an open mill to go out and pack for subsequent use;

[0038] After the prepared rubber sheet was parked at room temperature for 8 hours, according to the "hardness test met...

Embodiment 3

[0040] 40wt% styrene-butadiene rubber, 22wt% bromobutyl rubber, 0.5wt% N-vinylimidazole, 15wt% nano-silica, 8wt% aromatic oil, 8wt% carbon black, 2wt% zinc oxide, 1wt% antioxidant , 1.2wt% antioxidant and 1.5wt% polyethylene wax and 0.8wt% stearic acid;

[0041] First, 22wt% brominated butyl rubber and 40wt% styrene-butadiene rubber were milled separately on an open mill; then brominated butyl rubber and 0.5wt% N-vinylimidazole were added to the kneader at 100 ° C, After mixing for 3 minutes, add other rubber after kneading, and then knead for 3 minutes; add 2wt% zinc oxide, 1wt% anti-aging agent, 1.2wt% antioxidant and other additives, mix for 5 minutes; finally add 15wt% nano silicon dioxide , mixed for 5 minutes; then add 8wt% carbon black and 8wt% aromatic oil as a plasticizer, mix it for 10 minutes and then transfer it to an open mill to go out and pack for subsequent use;

[0042] After the prepared rubber sheet was parked at room temperature for 8 hours, according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com