Acrylate rubber-nylon thermoplastic vulcanzate and preparation method thereof

A thermoplastic vulcanizate and acrylate technology, applied in thermoplastic vulcanizate and its preparation, acrylate rubber/nylon thermoplastic vulcanizate and its preparation field, can solve the problem of high cost, complicated preparation process, unfavorable for vulcanizing agent and accelerator and Other processing aids are fully dispersed to achieve the effect of reducing pollution and excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

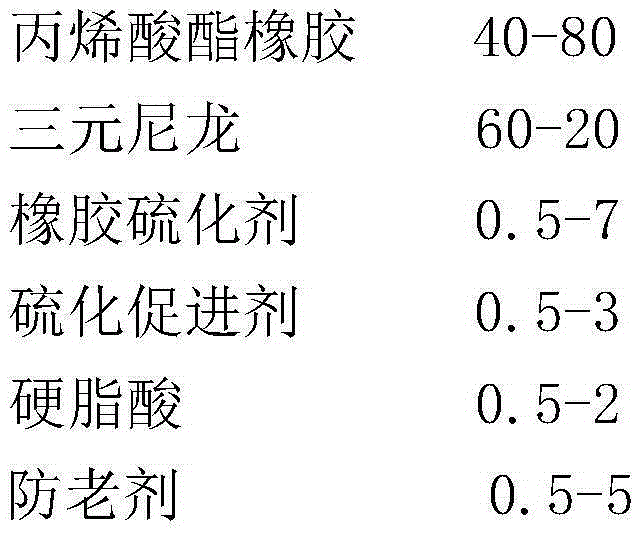

Method used

Image

Examples

Embodiment 1

[0024] An acrylic rubber / nylon thermoplastic vulcanizate with a mass ratio of 70 / 30 was prepared.

[0025] The operation steps are as follows:

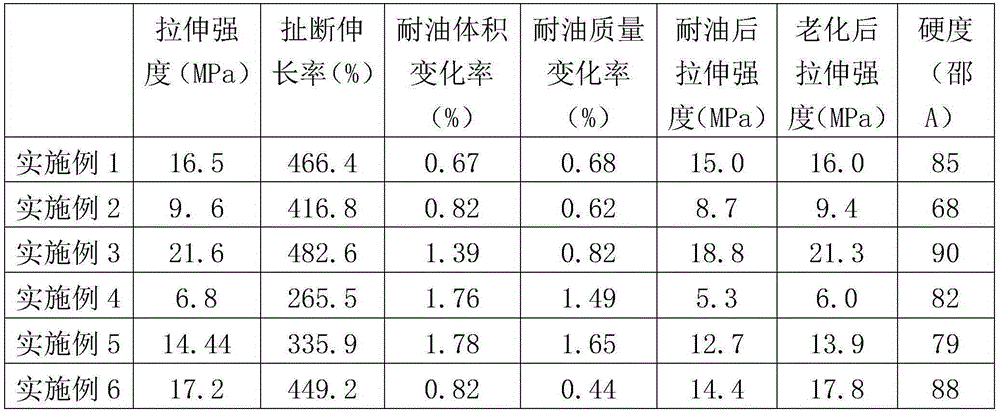

[0026] Mix and extrude 189g ternary nylon, 4.41g stearic acid, 2.21g sulfur, 26.46g sodium stearate and 2.65g potassium stearate on a twin-screw extruder at 175°C to obtain master batches. Weigh 75g of the obtained masterbatch and 147g of acrylate rubber for dynamic vulcanization in an internal mixer, the dynamic vulcanization temperature is 170°C, and the rotor speed is 60r / min to obtain acrylate / nylon thermoplastic vulcanizate, which is molded at 170°C for performance testing. The properties of thermoplastic vulcanizates are shown in Table 1.

Embodiment 2

[0028] Acrylate rubber / nylon thermoplastic vulcanizate with a mass ratio of 80 / 20 was prepared. The difference from Example 1 is that the material quality is different.

[0029] The operation steps are as follows:

[0030] 126g of ternary nylon, 5.04g of stearic acid, 2.52g of sulfur, 30.18g of sodium stearate, and 3.02g of potassium stearate were mixed and extruded on a twin-screw extruder at 175°C to obtain master batches. Weigh 55.59g of the obtained masterbatch, 168g of acrylate rubber is dynamically vulcanized in the internal mixer, the dynamic vulcanization temperature is 170°C, and the rotor speed is 60r / min to obtain acrylate / nylon thermoplastic vulcanizate, and the performance test is carried out after molding at 170°C , The properties of thermoplastic vulcanizate are shown in Table 1.

Embodiment 3

[0032] An acrylic rubber / nylon thermoplastic vulcanizate with a mass ratio of 60 / 40 was prepared. The difference from Example 1 is that the material quality is different.

[0033] The operation steps are as follows:

[0034] 252g of ternary nylon, 3.78g of stearic acid, 1.89g of sulfur, 22.68g of sodium stearate, and 2.27g of potassium stearate were mixed and extruded on a twin-screw extruder at 175°C to obtain master batches. Weigh 94.21g of the obtained masterbatch, 126g of acrylate rubber is dynamically vulcanized in an internal mixer, the dynamic vulcanization temperature is 170°C, and the rotor speed is 60r / min to obtain acrylate / nylon thermoplastic vulcanizate, and the performance test is carried out after molding at 170°C , The properties of thermoplastic vulcanizate are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com