High-thermal-conductivity reconfigurable liquid crystal elastomer composite material, and preparation method and application thereof

A technology of liquid crystal elastomers and composite materials, which is applied in the direction of liquid crystal materials, heat exchange materials, chemical instruments and methods, etc., can solve the problems of self-repair function and micro cracks in thermal conductive composite materials, and achieve good thermal conductivity and thermal conductivity. The effect of improving the coefficient and saving the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

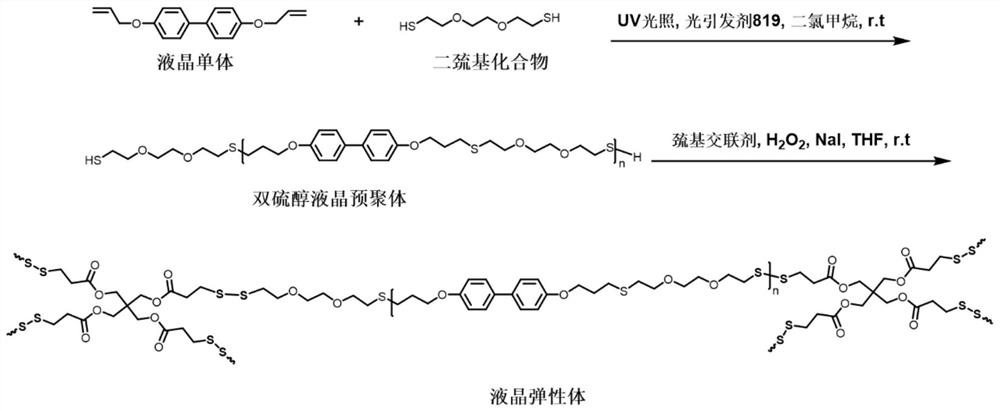

[0052] A method for preparing a high thermal conductivity remodelable liquid crystal elastomer composite material, comprising the following steps:

[0053] (1) First prepare a mercapto-terminated liquid crystal prepolymer: 5.33 parts by mass of 4,4'-divinyloxybiphenyl and 5.47 parts by mass of 3,6-dioxa-1,8-octanedithiol are dissolved in In dichloromethane, then add 0.2 parts by mass of photoinitiator 819, at a light intensity of 60mW / cm 2 , the maximum emission wavelength is 365nm UV light reaction for 2 hours, then the reaction mixture was added dropwise in a large amount of methanol to obtain a viscous precipitate, the methanol was removed by pouring, and then the dichloromethane was used to dissolve the product again, and the Precipitation with methanol was repeated 3 times, and the viscous product finally obtained was baked at 60° C. for 12 hours for use.

[0054] (2) 10 parts by mass of the prepolymer obtained in step (1) and 0.67 parts by mass of mercapto crosslinking ...

Embodiment 2

[0058] A method for preparing a high thermal conductivity remodelable liquid crystal elastomer composite material, comprising the following steps:

[0059] (1) First prepare a mercapto-terminated liquid crystal prepolymer: 6.45 parts by mass of 4,4'-bis(allyloxy)-3,3',5,5'-tetramethyl-1,1'-biphenyl Dissolve 3.67 parts by mass of 1,4-butanedithiol in dichloromethane, then add 0.2 parts by mass of photoinitiator 819, at a light intensity of 60mW / cm 2 , the maximum emission wavelength is 365nm UV light reaction for 2 hours, then the reaction mixture was added dropwise in a large amount of methanol to obtain a viscous precipitate, the methanol was removed by pouring, and then the dichloromethane was used to dissolve the product again, and the Precipitation with methanol was repeated 3 times, and the viscous product finally obtained was baked at 60° C. for 12 hours for use.

[0060] (2) 10 parts by mass of the prepolymer obtained in step (1) and 0.59 parts by mass of mercapto cros...

Embodiment 3

[0064] A method for preparing a high thermal conductivity remodelable liquid crystal elastomer composite material, comprising the following steps:

[0065] (1) First prepare a mercapto-terminated liquid crystal prepolymer: 9.77 parts by mass of 2,5-bis[4-(allyloxy)benzoyloxy]benzoate and 4.51 parts by mass of 1,6 hexanedisulfide Dissolve alcohol in dichloromethane, then add 0.2 parts by mass of photoinitiator 184, at a light intensity of 60mW / cm 2 , the maximum emission wavelength is 365nm UV light reaction for 2 hours, then the reaction mixture was added dropwise in a large amount of methanol to obtain a viscous precipitate, the methanol was removed by pouring, and then the dichloromethane was used to dissolve the product again, and the Precipitation with methanol was repeated 3 times, and the viscous product finally obtained was baked at 60° C. for 12 hours for use.

[0066] (2) 10 parts by mass of the prepolymer obtained in step (1) and 0.75 parts by mass of mercapto cross...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com