Bio-based straw composite plastic and preparation method thereof

A composite plastic and bio-based technology, applied in the field of polymer materials, can solve problems such as the gap in mechanical properties, the limited effect of straw modification, and the inability to meet daily use, etc., to achieve small additions, improve processability, and maximize utilization value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

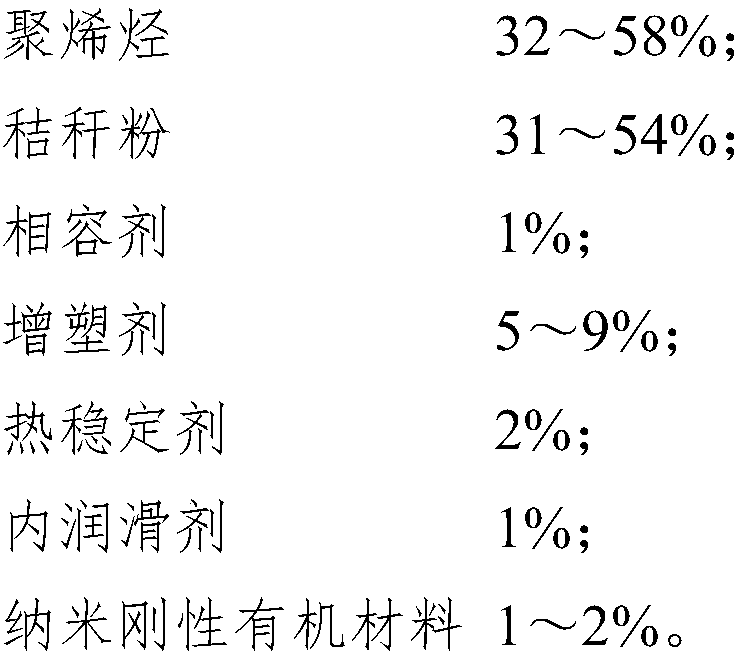

Method used

Image

Examples

Embodiment

[0030] (1) Mix the compatibilizer into an ethanol solution, spray it evenly on the mixture containing CNCs or CNFs and straw powder, leave it at room temperature for 6 hours, then dry at 105°C for 2 hours, and dry the mixed material for use; add polyolefin and plasticize Agent, heat stabilizer, internal lubricant, stir and mix well at 60~150℃;

[0031] (2) Reaction in a twin-screw extruder: the material obtained in step (1) is added to the twin-screw extruder, mixed at 130-220°C, and pelletized to obtain bio-based straw composite plastic;

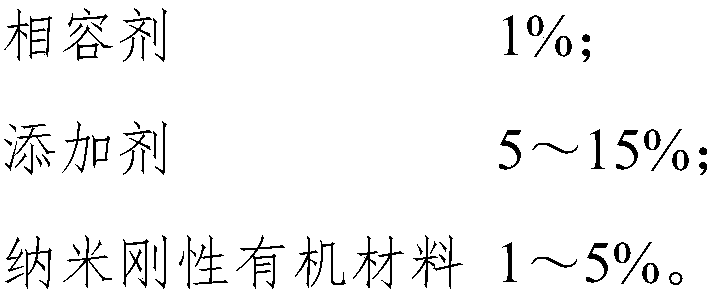

[0032] The raw material components are shown in the following table:

[0033]

[0034] The properties of the bio-based straw composite plastic of the embodiment are as follows:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com