A self-healing elastomer material and a preparing method thereof

An elastomer material and self-healing technology, applied in the field of materials, to achieve the effects of low preparation cost, high healing efficiency, and high strength healing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Place the metered amount of methyl methacrylate, ethylenediamine and diethylenetriamine in a reactor filled with methanol, and the molar ratio of methyl methacrylate to ethylenediamine and diethylenetriamine is 1:0.1:0.1 , the mass ratio of methyl methacrylate to methanol is 1:1, react at 50°C for 1 hour to obtain a prepolymer. The prepolymer was placed in a rotary evaporator to remove the organic solvent methanol, and then reacted at 50° C. for 10 h to obtain a hyperbranched polyamidoamine (HPAMAM) with amino groups at the end of the molecular chain. The amine value of HPAMAM was determined to be 8.21 mmol / g by acid-base titration. Then add HPAMAM, sebacic acid and magnesium hydroxide into the reactor, and measure it with the molar ratio of the corresponding amino group, carboxyl group and basic metal compound as 1:0.2:0.1, and react at 100°C for 24h under nitrogen atmosphere to obtain Self-healing elastomeric materials based on hyperbranched polyamidoamines.

[0028...

Embodiment 2

[0032]The measured lauryl methacrylate and triaminobenzene are placed in a reactor equipped with ethanol, the mol ratio of lauryl methacrylate and triaminobenzene is 1:1, and the mass ratio of lauryl methacrylate to ethanol is 1:10, react at -10°C for 72h to obtain a prepolymer. The prepolymer was placed in a rotary evaporator to remove the organic solvent ethanol, and then reacted at 80°C for 8 hours to obtain a hyperbranched polyamidoamine (HPAMAM) with amino groups at the end of the molecular chain. The amine value of HPAMAM was determined to be 7.05 mmol / g by acid-base titration. Then add HPAMAM, suberic acid and calcium oxide into the reactor, measure with the molar ratio of the corresponding amino group, carboxyl group and basic metal compound as 1:1:0.5, and react at 120°C for 20h under nitrogen atmosphere to obtain Hyperbranched polyamidoamine self-healing elastomeric materials.

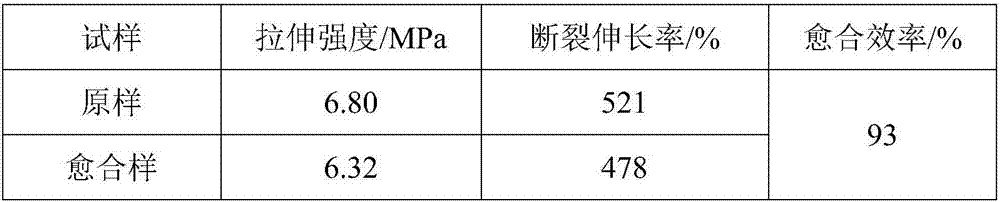

[0033] The elastic material was hot-pressed for 10 minutes to prepare a standard dumbbe...

Embodiment 3

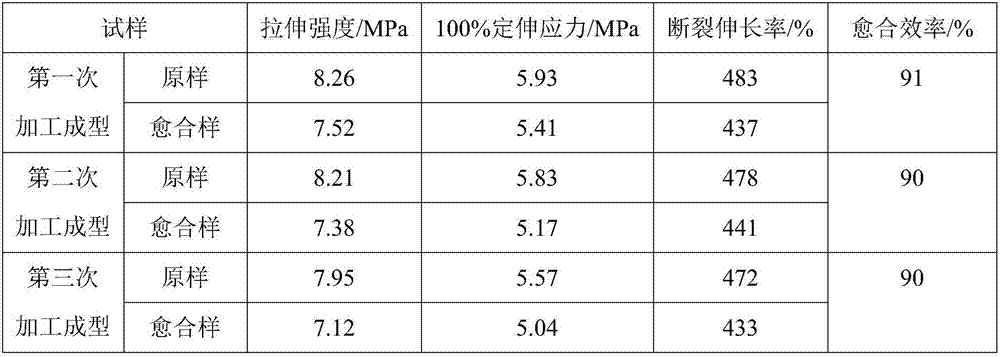

[0035] Place the metered acrylic acid / methyl acrylate mixture and triethylenetetramine in a reactor filled with ethanol, the molar ratio of acrylic acid, methyl acrylate and triethylenetetramine is 0.5:0.5:10, the acrylic acid / methyl acrylate mixture The mass ratio with ethanol is 1:20, react at 10°C for 36h to obtain a prepolymer. The prepolymer was placed in a rotary evaporator to remove the organic solvent ethanol, and then reacted at 100° C. for 6 hours to obtain a light yellow sticky substance, which was hyperbranched polyamidoamine (HPAMAM) with amino groups at the end of the molecular chain. The amine value of HPAMAM was determined to be 8.76 mmol / g by acid-base titration. Then add HPAMAM, pimelic acid and aluminum hydroxide into the reactor, and measure it with the molar ratio of the corresponding amino group, carboxyl group and basic metal compound as 1:10:1, and react at 200°C for 1h under nitrogen atmosphere to obtain Self-healing elastomeric materials based on hyp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Amine value | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com