Polydimethylsiloxane self-repairing elastomer based on hydrazide bond and preparation method thereof

A polydimethylsiloxane and self-repairing technology, which is applied in the field of polymer materials, can solve the problems of poor stability and less research, and achieve the effects of fast repair speed, simple preparation method and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Example 1. Preparation of self-healing elastomer based on tetrahydrazide functionalized polydimethylsiloxane and terephthalaldehyde

[0052] 1) 50.0g of diamino-terminated polydimethylsiloxane (2500g / mol, 0.02mol) (purchased from Sigma-Aldrich company, the name provided by the company is poly(dimethylsiloxane), bis(3 -Aminopropyl) capping) was added to 120g methanol, and nitrogen gas was passed for 30min. Then, 7.2 g of methyl acrylate (0.08 mol) was added to the system, protected by nitrogen, and reacted at room temperature for 24 h. Rotary evaporation, methanol and excess methyl acrylate were removed to obtain 54.0 g of ester functionalized polydimethylsiloxane with a yield of 95%;

[0053] 2) Weigh 52.0g of the above product (0.07mol ester group) and add it to 45g of hydrazine hydrate, N 2 Protection, reaction at 115°C for 24h. After the reaction, add an appropriate amount of chloroform for dilution, wash with a 1:1 mixture of water and saturated saline, and satur...

Embodiment 2

[0060] Example 2, Preparation of self-healing elastomer based on tetrahydrazide functionalized polydimethylsiloxane and terephthalaldehyde

[0061] 1) 0.5g terephthalaldehyde and 5.3g tetrahydrazide functionalized polydimethylsiloxane prepared according to Example 1 were mixed and dissolved in toluene, the total mass fraction was 15%, and the hydrazide group and The molar ratio of the aldehyde group is 1:1, stirred at room temperature for 24 hours, transferred to a polytetrafluoroethylene mold, volatilized at room temperature to remove most of the solvent, and vacuum-dried at 80°C until the quality no longer changes, that is, a self-healing Functional polydimethylsiloxane elastomer;

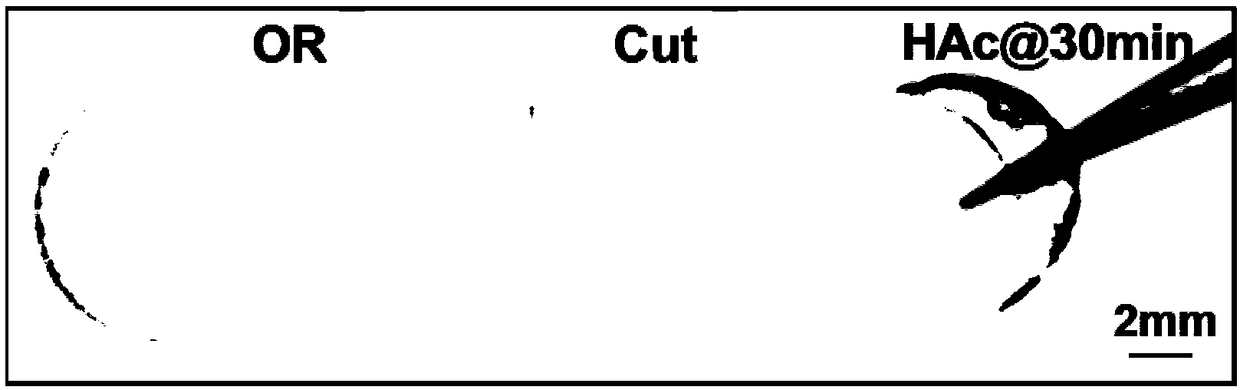

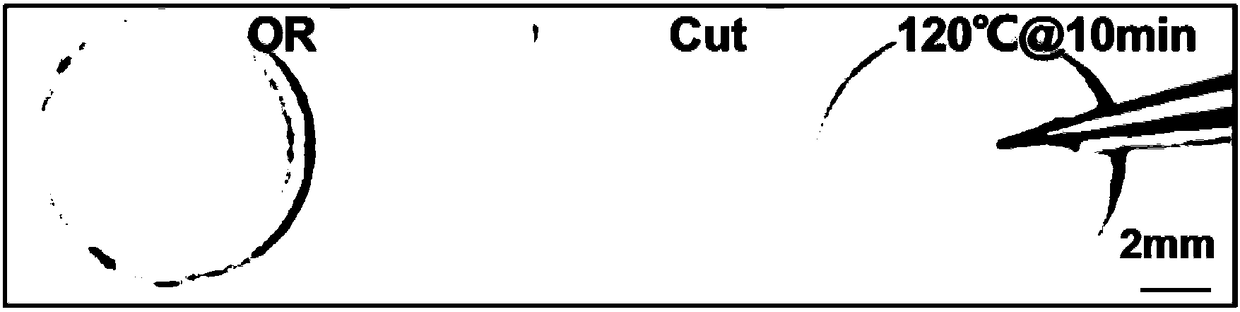

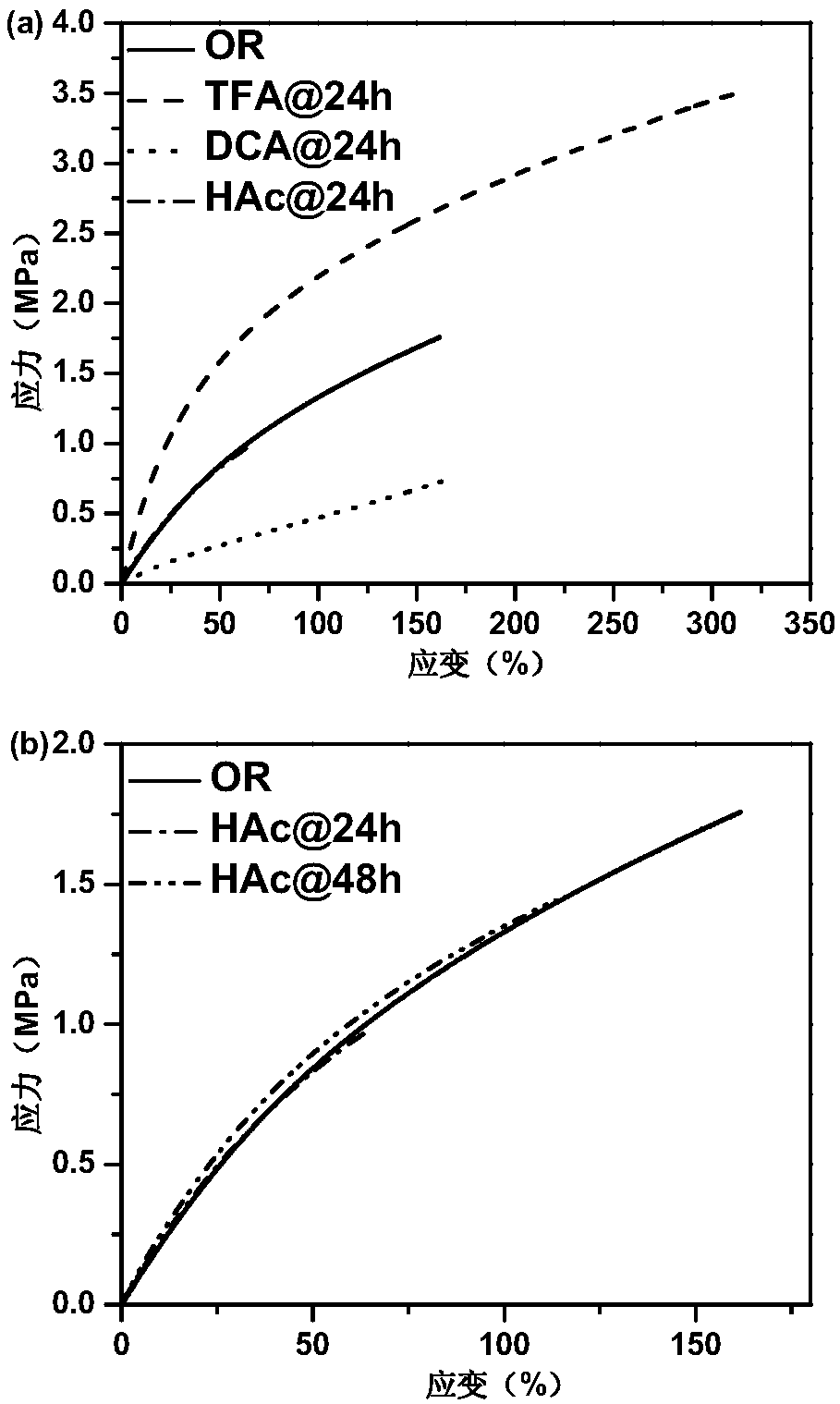

[0062] 2) Acid healing test: the prepared polydimethylsiloxane elastomer was cut into discs with a diameter of 8 mm and a thickness of 0.7 mm, and the sample was cut along the diameter direction with a blade. At room temperature, apply 2 drops of glacial acetic acid or trifluoroacetic acid or di...

Embodiment 3

[0067] Example 3, Preparation of self-healing elastomer based on tetrahydrazide functionalized polydimethylsiloxane and terephthalaldehyde

[0068] 1) 0.25g of terephthalaldehyde and 5.3g of tetrahydrazide functionalized polydimethylsiloxane prepared according to Example 1 were mixed and dissolved in chloroform, the total mass fraction was 10%, and the hydrazide group The molar ratio to the aldehyde group is 1:0.5, stirred at room temperature for 24 hours, transferred to a polytetrafluoroethylene mold, volatilized at room temperature to remove most of the solvent, and vacuum-dried at 80°C until the quality no longer changes, that is, to obtain Healing polydimethylsiloxane elastomer;

[0069] 2) Acid healing test: the prepared polydimethylsiloxane elastomer was cut into discs with a diameter of 8 mm and a thickness of 0.7 mm, and the sample was cut along the diameter direction with a blade. At room temperature, apply 2 drops of glacial acetic acid or trifluoroacetic acid or di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com