Repeatable shaping breathable fabric structure and products thereof

A breathable fabric and moldable technology, applied in textiles and papermaking, synthetic resin layered products, knitting, etc., can solve the problems of limited plasticity, poor air permeability and blockage of moldable fabrics, and achieve the effect of improving air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

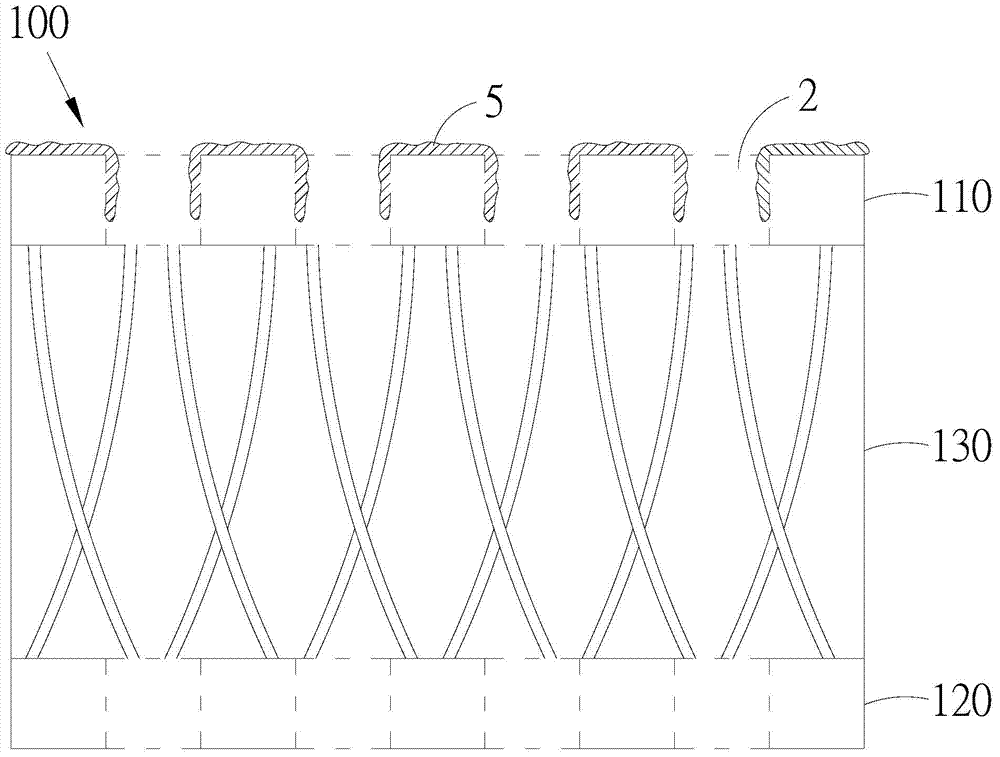

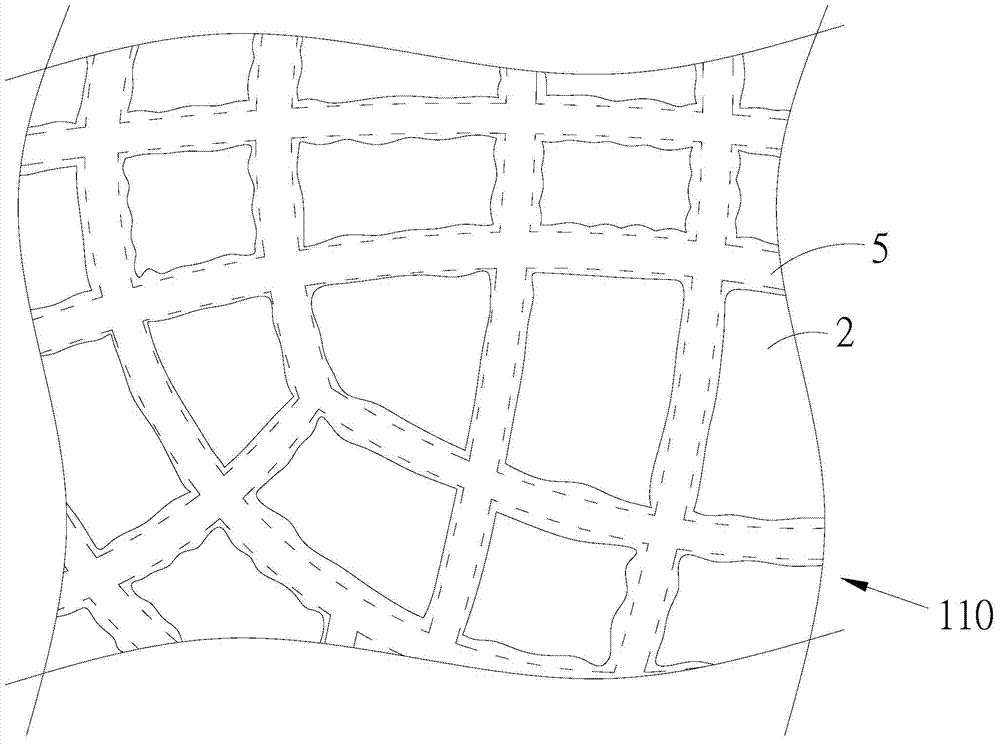

[0028] Such as figure 1 As shown, it is a schematic diagram of the first embodiment of the remouldable breathable fabric structure of the present invention. In the first embodiment, the remodelable breathable fabric structure includes a three-dimensional breathable sheet 100 and a thermoplastic material 5 . The three-dimensional breathable sheet 100 is a flexible three-dimensional breathable sheet. The three-dimensional breathable sheet 100 also includes two breathable outer layers 110 , 120 and a middle fabric layer 130 . The middle fabric layer 130 is positioned between the two breathable outer layers 110,120. The two air-permeable outer layers 110 , 120 have a plurality of holes 2 .

[0029] Furthermore, the coating method of the thermoplastic material 5 in the present invention can be a dip coating method, and the thickness of the dip coating infiltrated into the fabric varies according to the type of fabric selected, so when the thermoplastic material 5 When dip-coate...

Embodiment 2

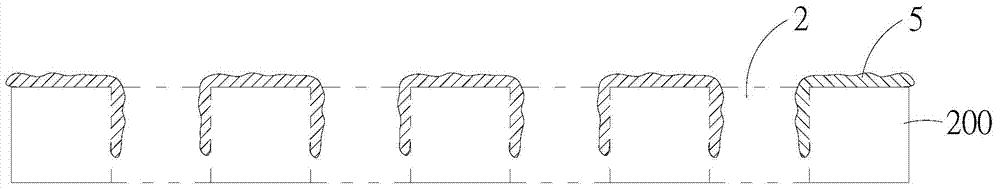

[0035] Such as image 3 As shown, it is a schematic diagram of the second embodiment of the remouldable breathable fabric structure of the present invention. In the second embodiment, the remouldable breathable fabric structure includes a single-layer breathable mesh 200 and a thermoplastic material 5 . The single-layer breathable mesh sheet 200 has a plurality of holes 2 . The single-layer air-permeable mesh sheet 200 can be any air-permeable flat-woven, knitted or non-woven fabric. And wherein the thermoplastic material 5 can be attached to the surrounding walls of the multiple holes 5 of the single-layer breathable mesh 200 . Thermoplastic material 5 may comprise polyester fiber (PET), polyurethane (TPU), polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), ethylene-vinyl acetate (EVA) or nylon (NYLON )Wait. The above are only examples, but should not be used to limit the protection scope of the present invention.

[0036] Among the above, the thermoplastic...

Embodiment 3

[0041] It is worth mentioning that in the first embodiment of the present invention, the directly woven reshapeable breathable fabric structure can also be laminated and combined to form a moldable fabric structure that is soft on the outside and hard on the inside, and applied On fabrics such as women's bras. Such as Figure 4 As shown, it is a schematic diagram of the third embodiment of the finished product of the remouldable breathable fabric structure of the present invention. In the third embodiment, a finished product 1000 of a remodelable breathable fabric structure includes a first remouldable breathable fabric structure 1001 and a second remouldable breathable fabric structure 1002 . The first remodelable breathable fabric structure 1001 includes a first three-dimensional breathable sheet 300 and a first thermoplastic material 6 . The first three-dimensional breathable sheet 300 also includes two first breathable outer layers 310 , 320 and a first middle fabric lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com