Reversible cross-linking thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and cross-linking technology, applied in the field of thermoplastic polyurethane materials, can solve the problems of insufficient material elasticity, difficulty in meeting the requirements of thermoplastic polyurethane processing and molding, linear chain structure growth, etc., to achieve increased cross-linking effect and excellent self-healing effect of ability

Active Publication Date: 2019-11-15

ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

View PDF11 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, patent CN201310006811.8 provides a reversible covalently cross-linked thermoplastic polyurethane, which uses a small molecule diol chain extender containing maleimide side groups (dienophiles) to react with isocyanates and long-chain polyols Obtain a prepolymer, then add a cross-linking agent containing at least two furan groups (dienes) to obtain a reversibly cross-linked TPU, however, the reversible chain extender in this patent scheme needs to be prepared in the presence of a large amount of organic solvents , the solvent is difficult to recover later, it is only suitable for a small amount of research in the laboratory, and it is difficult for large-scale industrial production; patent CN201710046449.5 discloses a polyurethane that can be used for 3D printing. Polymerization of diisocyanate and dendritic polymer of imide, but the direct addition of crosslinking agent maleimide-terminated diisocyanate composition in the process of polyurethane synthesis in this patent will cause the molecular weight growth of the reaction system to be limited, and eventually It affects the comprehensive performance and application of materials; similarly, patents CN201710032884.2 and CN201710032790.5 use maleimide-containing polyols, diisocyanates, triisocyanate compositions containing furan groups at the end groups or The 3D printing polyurethane material prepared by trimaleimide-terminated triisocyanate composition and dendritic polymer, due to the existence of maleimide-terminated triisocyanate composition in the polymerization process, is also easy to cause the linearity of the material. The growth of the chain structure is limited, resulting in insufficient elasticity of the material, and at the same time, the structure of the triisocyanate composition leads to an excessively high density of intermolecular cross-linking points, making the material brittle

[0004] Existing research on the reversible crosslinking of polyurethane and thermoplastic polyurethane materials mainly focuses on the modification of macromolecular polyols, chain extenders or isocyanates with dienophiles or dienes and then one-step polymerization reaction. The above-mentioned one-step preparation of reversibly cross-linked TPU will limit the growth of the chain molecular structure of TPU. In addition, it will affect the linear chain structure of TPU, and cause the final material to be significantly less elastic or even brittle. It is difficult to achieve the repeated processing and molding of thermoplastic polyurethane. Requirements, while the temperature resistance of the material is insufficient and ultimately affects its processing and application

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0073] The TPU (b2) of Example 1 is a polyether product of Zhejiang Huafeng Thermoplastic Polyurethane Co., Ltd. brand HF-4375A;

Embodiment 2

[0074] The TPU (b2) of Example 2 is a polyether product of Zhejiang Huafeng Thermoplastic Polyurethane Co., Ltd. brand HF-4385A;

Embodiment 3

[0075] The TPU (b2) of Example 3 is a polyether product of Zhejiang Huafeng Thermoplastic Polyurethane Co., Ltd. brand HF-4388A;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

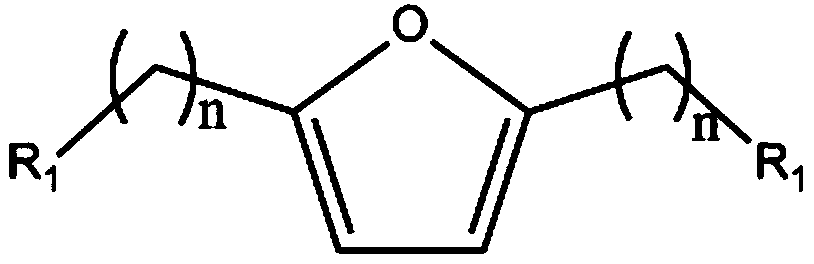

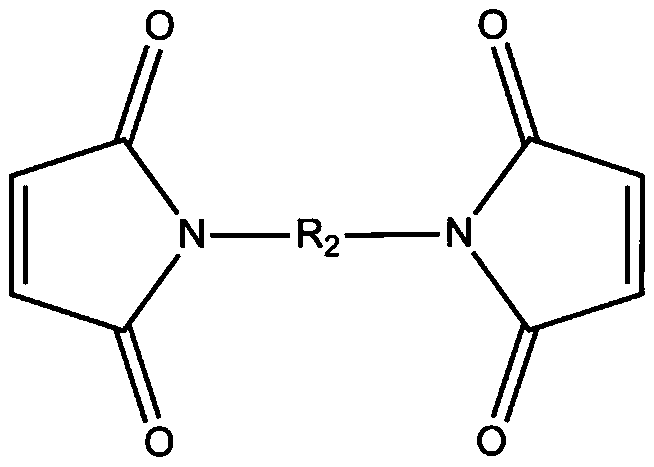

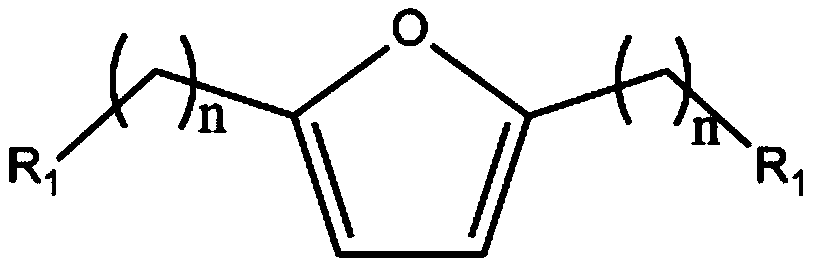

The invention discloses a reversible cross-linking thermoplastic polyurethane elastomer and a preparation method thereof. The reversible cross-linking thermoplastic polyurethane elastomer comprises afuran-containing thermoplastic polyurethane (TPU) component (A) and a bismaleimide component (B); the furan-containing TPU component (A) is prepared from the following raw materials by weight: 25-46 parts by weight of an isocyanate (a1), 32-67 parts by weight of a polymer polyol (a2), 3.5-13 parts by weight of a small molecular dihydric alcohol (a3) and 0.3-4.5 parts by weight of furan (a4) containing two reactive groups for isocyanate radicals; and the bismaleimide component (B) is a mixture of a bismaleimide-containing compound (b1) and TPU (b2). According to the invention, through a reversible Diels-Alder reaction of functional components, the cross-linking effect among molecular chains is increased, the thermoplastic property of TPU is ensured, and the TPU is endowed with an excellentself-repairing ability.

Description

technical field [0001] The invention relates to a thermoplastic polyurethane elastomer and a preparation method thereof, and relates to a thermoplastic polyurethane material with a reversible crosslinking structure. Background technique [0002] The main difference between thermoplastic resin materials and thermosetting resin materials is that most linear polymers of thermoplastic resin materials can flow and deform after heating, and can maintain a certain shape after cooling; thermosetting resin materials have a network cross-linked structure. It cannot be plasticized again, but due to the chemical crosslinking of thermosetting resins, it also has the characteristics of high temperature resistance, high rigidity, and good dimensional stability of products, which are not available in conventional thermoplastic resin materials. In addition, thermoplastic polyurethane elastomer (TPU), as a kind of block linear polymer, has hydrogen bond crosslinking between linear molecules o...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G18/66C08G18/32C08G18/42C08G18/48C08K5/3415C08L75/06C08L75/08

CPCC08G18/3206C08G18/3218C08G18/3246C08G18/4202C08G18/4238C08G18/4854C08G18/6651C08G18/6685C08K5/3415C08L75/06C08L75/08

Inventor 李俊江陈斌陈敏陈天培林龙范莉颜坚坚袁仁能施龙敏陈光静范东风马肥夏东黄伟杰

Owner ZHEJIANG HUAFENG THERMOPLASTIC POLYURETHANE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com