Borate-based self-repairing polyurethane based on internal coordination and preparation method thereof

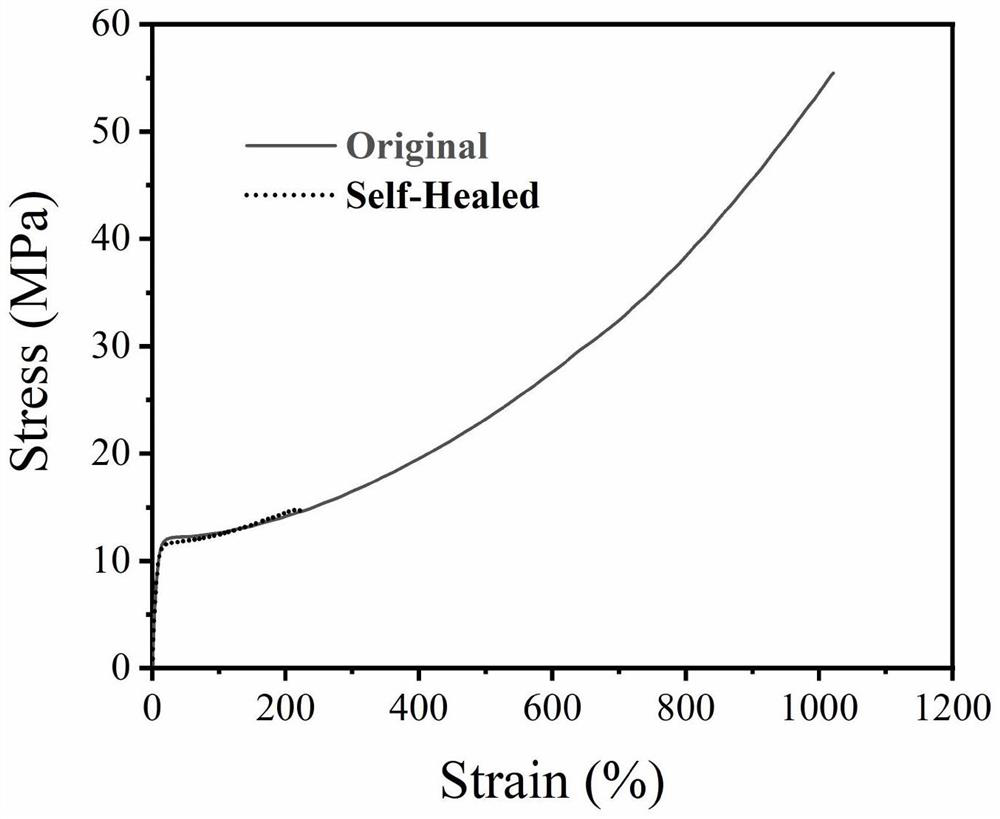

A technology of boric acid ester and polyurethane, which is applied in the field of polyurethane polymers, can solve problems such as poor hydrolysis stability, and achieve the effects of low cost, simple operation method, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

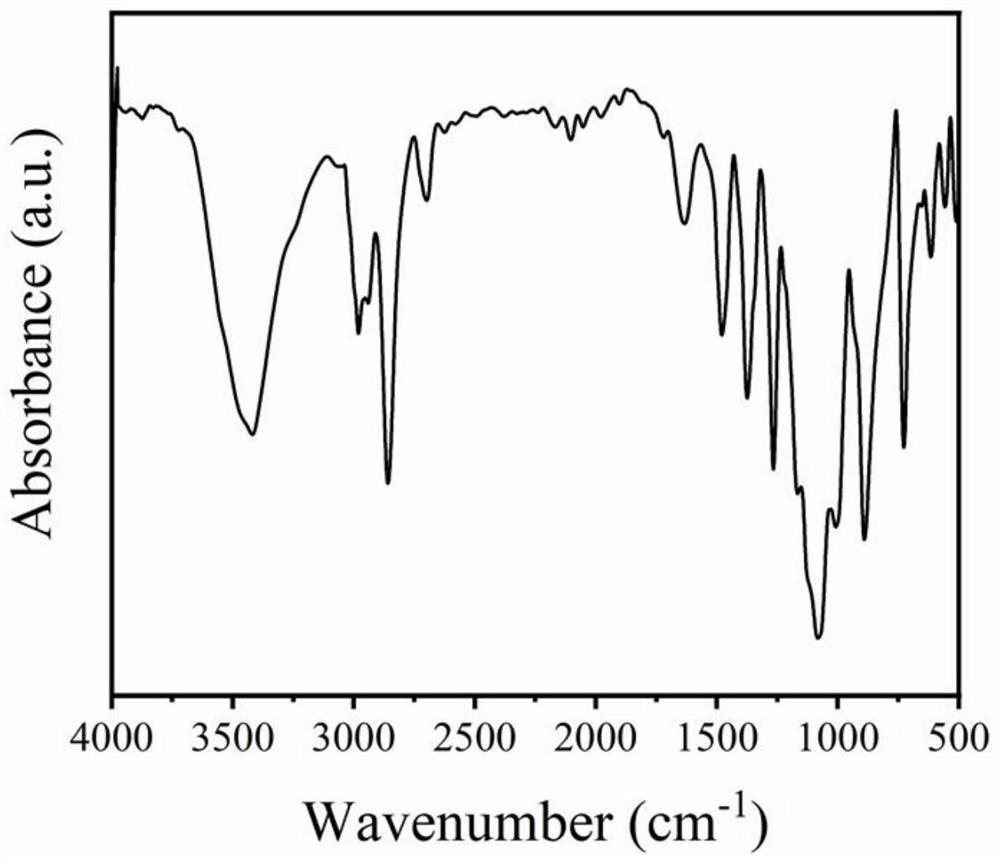

[0036] The present invention proposes a kind of preparation method based on the self-healing polyurethane of borate bond, it comprises:

[0037] 1) Mixing functional group-containing phenylboronic acid A, functional group-containing collar diol monomer B with an organic solvent, and generating a borate-based small-molecule chain extender C based on nitrogen-boron coordination through condensation reaction;

[0038] The dosage ratio of A, B and the organic solvent is 1 mol: 1 mol: 4-10L; the synthesis condition of the small molecule chain extender is: at a temperature of 25-60°C, the condensation reaction is 0.5-2h, preferably, the reaction time is 1h;

[0039] 2) adding polydiol D and diisocyanate E to the organic solvent and mixing respectively, and reacting to generate polyurethane prepolymer;

[0040] The amount ratio of polydiol D, diisocyanate E and organic solvent is 1mol: 1mol: 2.2-3.3L; the synthesis conditions of the prepolymer are: at a temperature of 60-80°C, react ...

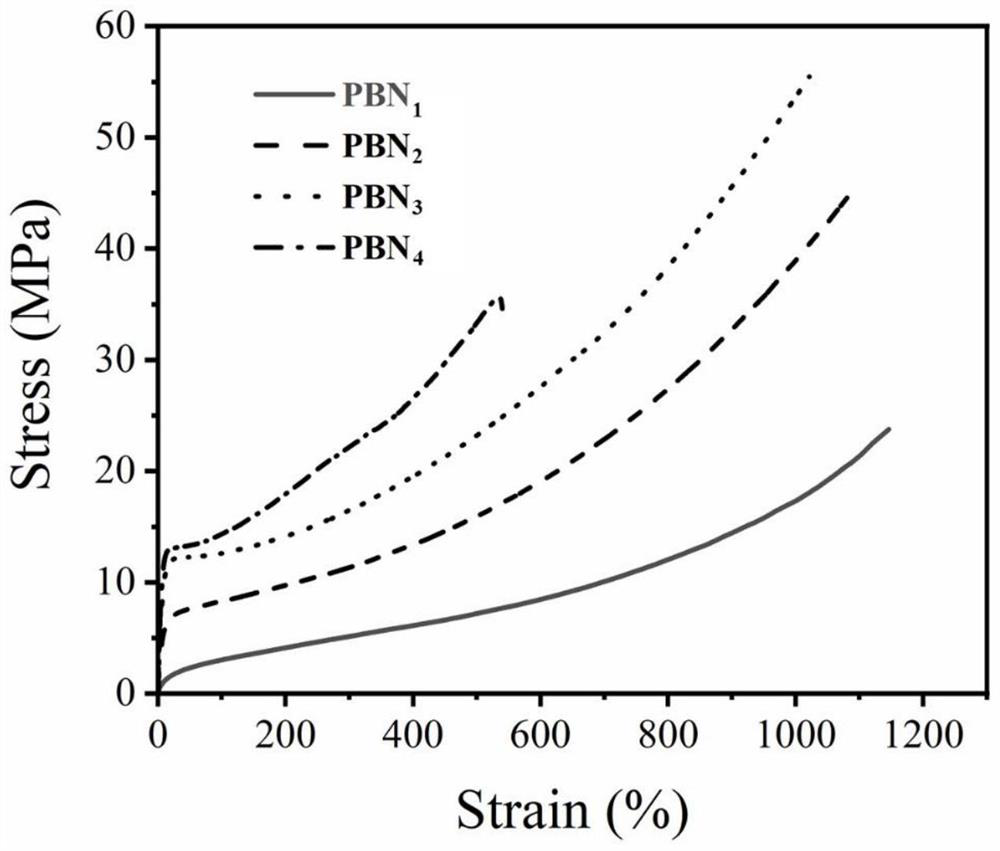

Embodiment 1

[0069] The preparation method of the self-healing polyurethane based on the borate ester bond provided in this embodiment comprises:

[0070] 1) Dissolve 4-hydroxyphenylboron (1.24g, molecular weight 137.93, 0.009mol) and triethanolamine (1.34g, molecular weight 149.188, 0.009mol) in 50ml of DMF solution, react at 60°C for 1h, remove the solvent to obtain Small molecule chain extender C;

[0071] 2) Dissolve isophorone diisocyanate (8.4g, molecular weight 222.32, 0.038mol) and polyethylene glycol (9g, 0.038mol) in 100ml of DMF solution, and react at 75°C for 4h to generate polyurethane prepolymer solution;

[0072] 3) Add all the small molecule chain extender C dropwise to all the polyurethane prepolymer solutions, and continue to react for 1 hour after the dropwise addition to obtain the polyurethane primary polymer F;

[0073] 4) Add the crosslinking agent 2,4,6-triaminopyrimidine (0.99g, molecular weight 125.13, 0.008mol) in batches to the entire polyurethane primary poly...

Embodiment 2

[0075] The preparation method of the self-healing polyurethane based on the borate ester bond provided in this embodiment comprises:

[0076] 1) Dissolve 4-hydroxyphenylboron (0.74g, 0.0053mol) and triethanolamine (0.8g, 0.0053mol) in 50ml of DMF solution, react at 60°C for 1h, remove the solvent, and obtain small molecule chain extender C ;

[0077] 2) Dissolve isophorone diisocyanate (6.72g, 0.030mol) and polyethylene glycol (9g, 0.030mol) in 100ml of DMF solution, and react at 75°C for 4h to generate a polyurethane prepolymer solution;

[0078] 3) Add all the small molecule chain extender C dropwise to all the polyurethane prepolymer solutions, and continue to react for 1 hour after the dropwise addition to obtain the polyurethane primary polymer F;

[0079] 4) Add the crosslinking agent 2,4,6-triaminopyrimidine (0.59g, 0.0047mol) in batches to the entire polyurethane primary polymer F, react at 45°C for 2h, and then pour the obtained solution into the mold Dry to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com