Fully-degradable mulching film capable of applying fertilizer, and preparation method for fully-degradable mulching film

A fully degradable and mulching technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve problems such as inability to absorb and utilize crops, secondary environmental pollution, and decline in cultivated land quality, so as to maintain full biodegradability and improve processability , The effect of increasing the interface binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

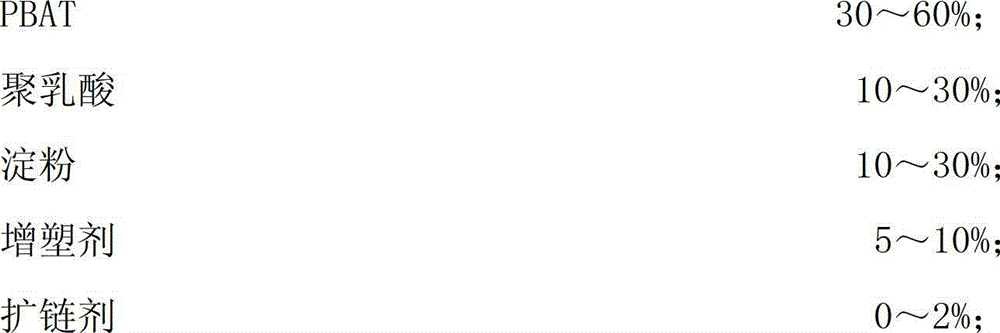

Method used

Image

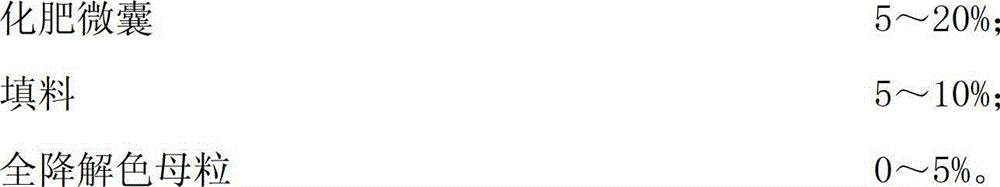

Examples

Embodiment 1

[0031] First dissolve the polyvinyl alcohol in hot glycerol under stirring conditions, then disperse the pulverized ammonium sulfate powder into the polyvinyl alcohol glycerol solution, and then spray the mixture into an inert hot air flow to make droplets Shrink it into a spherical shape and then dry to obtain ammonium sulfate microcapsules.

[0032] 30 parts by mass of PBAT, 10 parts by mass of polylactic acid, 30 parts by mass of corn starch, 10 parts by mass of glycerol, 2 parts by mass of BASF chain extender JONCRYL ADR-4368, 8 parts by mass of ammonium sulfate microcapsules and 10 parts by mass of light The calcium carbonate is mixed uniformly in a high-speed mixer, and then the mixture is mixed in a twin-screw extruder, and the temperature of each section of the twin-screw extruder is set to T 1 =150℃, T 2 =160℃, T 3 =160℃, T 4 =165℃, T 5 =165℃, T 6 =170℃, the speed of twin-screw extruder is R=300r·min -1 ; After that, extrusion, cooling and granulation are used t...

Embodiment 2

[0037] First dissolve the polyvinyl alcohol in hot glycerol under stirring conditions, then disperse the crushed potassium chloride powder into the polyvinyl alcohol glycerol solution, and then spray the mixture into an inert hot air flow to make the solution The drop is shrunk into a spherical shape and then dried to obtain potassium chloride microcapsules.

[0038] 60 parts by mass of PBAT, 10 parts by mass of polylactic acid, 10 parts by mass of tapioca starch, 5 parts by mass of ethylene glycol, 10 parts by mass of potassium chloride microcapsules and 5 parts by mass of talc were mixed uniformly in a high-speed mixer, and then the mixture was mixed. Mixing in a twin-screw extruder, the temperature of each section of the twin-screw extruder is set to T 1 =155℃, T 2 =165℃, T 3 =165℃, T 4 =165℃, T 5 =170℃, T 6 =175℃, the speed of twin-screw extruder is R=300r·min -1 ; After that, extrusion, cooling and granulation are used to obtain the material for fully degradable top...

Embodiment 3

[0043] First dissolve the polyvinyl alcohol in hot glycerol under stirring conditions, then disperse the crushed calcium superphosphate into the polyvinyl alcohol glycerol solution, and then spray the mixture into an inert hot air flow to make droplets Shrink it into a spherical shape and then dry to obtain superphosphate microcapsules.

[0044] 30 parts by mass of poly PBAT, 30 parts by mass of polylactic acid, 10 parts by mass of corn starch, 5 parts by mass of propylene glycol, 20 parts by mass of superphosphate microcapsules and 5 parts by mass of light calcium carbonate were mixed uniformly in a high-speed mixer, and then The mixture is mixed in a twin-screw extruder, and the temperature of each section of the twin-screw extruder is set to T 1 =145°C, T 2 =155℃, T 3 =165℃, T 4 =165℃, T 5 =170℃, T 6 =175℃, the speed of twin-screw extruder is R=300r·min -1 ; After that, extrusion, cooling and granulation are used to obtain the material for the fully degradable top-dre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com