Wood and calcium plastic mixed and co-extruded material

A wood-plastic and mixing technology, applied in the field of decorative materials, can solve the problems of fragility and deformation of calcium-plastic products, and achieve the effect of good body shape, enhanced use range, and not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

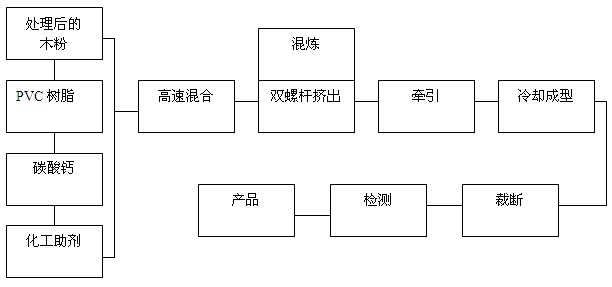

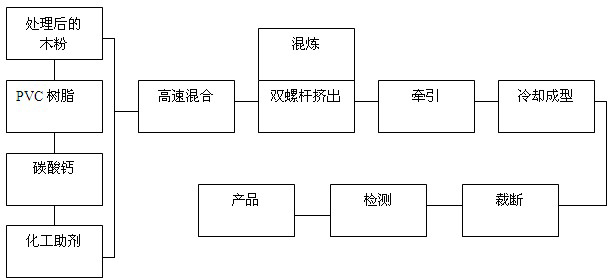

Image

Examples

Embodiment 1

[0012] Embodiment 1: A kind of wood-plastic, calcium-plastic mixing and co-extrusion material, which is obtained by mixing and co-extruding the raw materials of the following weight ratio: PVC resin 25kg, wood powder 50-80 mesh 50kg, calcium powder 800 mesh or more 35kg , maleic anhydride grafted 2.5kg, PA-021.8kg, ultraviolet light absorber salicylate phenyl ester 0.1kg, antioxidant tert-butyl hydroquinone 0.1kg, thermal composite lead salt stabilizer 3kg, ACR4013kg, dibutyl Fat 2kg, paraffin 0.8kg, PE vinegar 0.5kg, stearic acid (1801) 0.3kg.

[0013] The process is as follows:

[0014] The above raw materials are mixed at high speed, then kneaded, extruded by twin-screw extrusion equipment, drawn, cooled and formed, cut, tested and other finished products.

Embodiment 2

[0016] PVC resin 25kg, bran powder 50-80 mesh 45kg, calcium powder 800 mesh or more 40kg, maleic anhydride grafting 2.5kg, PA-021.8kg, ultraviolet light absorber salicylate phenyl ester 0.1kg, antioxidant tert-butyl p- Hydroquinone 0.1kg, thermal composite lead salt stabilizer 3.5kg, ACR401 2kg, dibutyl fat 2kg, paraffin 0.8kg, PE vinegar 0.5kg, stearic acid (1801) 0.3kg.

[0017] The above raw materials are mixed at high speed, then kneaded, extruded by twin-screw extrusion equipment, drawn, cooled and formed, cut, tested and other finished products.

Embodiment 3

[0019] PVC resin 25kg, bran powder 50-80 mesh 48kg, calcium powder 800 mesh or more 38kg, maleic anhydride grafted 2.5kg, PA-021.8kg, ultraviolet light absorber salicylate phenyl ester 0.1kg, antioxidant tert-butyl p- Hydroquinone 0.1kg, thermal composite lead salt stabilizer 3.3kg, ACR401 2.5kg, dibutyl fat 2kg, paraffin 0.8kg, PE vinegar 0.5kg, stearic acid (1801) 0.3kg.

[0020] The above raw materials are mixed at high speed, then kneaded, extruded by twin-screw extrusion equipment, drawn, cooled and formed, cut, tested and other finished products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com