Wood-plastic tile

A wood-plastic and wood powder technology, applied in the field of wood-plastic tiles, can solve the problems of high load-bearing requirements, small application range, and high damage rate, and achieve the effects of strong processing plasticity, convenient transportation, and convenient secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

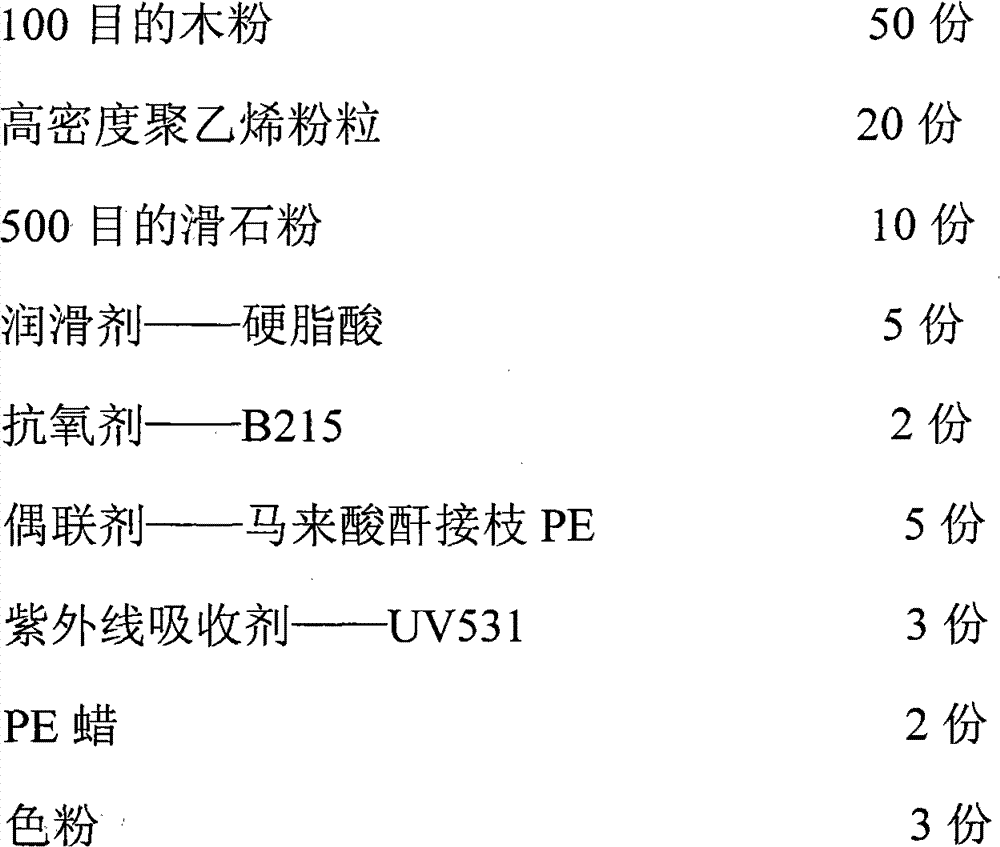

[0013] A kind of wood-plastic tile, by weight, adopts the following materials:

[0014]

[0015] Among them, the water content of wood powder is not higher than 2%, and the above materials are used to manufacture wood-plastic tiles according to the following steps:

[0016] Step 1: by weight, with 50 parts of 100 mesh wood flour, 20 parts of high density polyethylene powder, 10 parts of 500 mesh talcum powder, 5 parts of stearic acid, 2 parts of B215, 5 parts of Maleic anhydride grafted PE, 3 parts of UV531, 2 parts of PE wax and 3 parts of toner are placed in a high-low two-speed mixer and mixed at high speed for 15-20 minutes, mixed evenly, and then the temperature rises to 115 Mix at low speed for 10-15 minutes at -120°C to form a mix.

[0017] Step 2: Add the mixture to the conical reverse twin-screw granulation extruder, wrap the electric heating sheet from the front end to the discharge port of the granulation extruder, and make the material of the granulation extrud...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com