Automatic flatness detection device and test method

A flatness detection and equipment technology, applied in mechanical roughness/irregularity measurement, electrical/magnetic roughness/irregularity measurement, measurement devices, etc. The effect of secondary processing, high degree of automation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

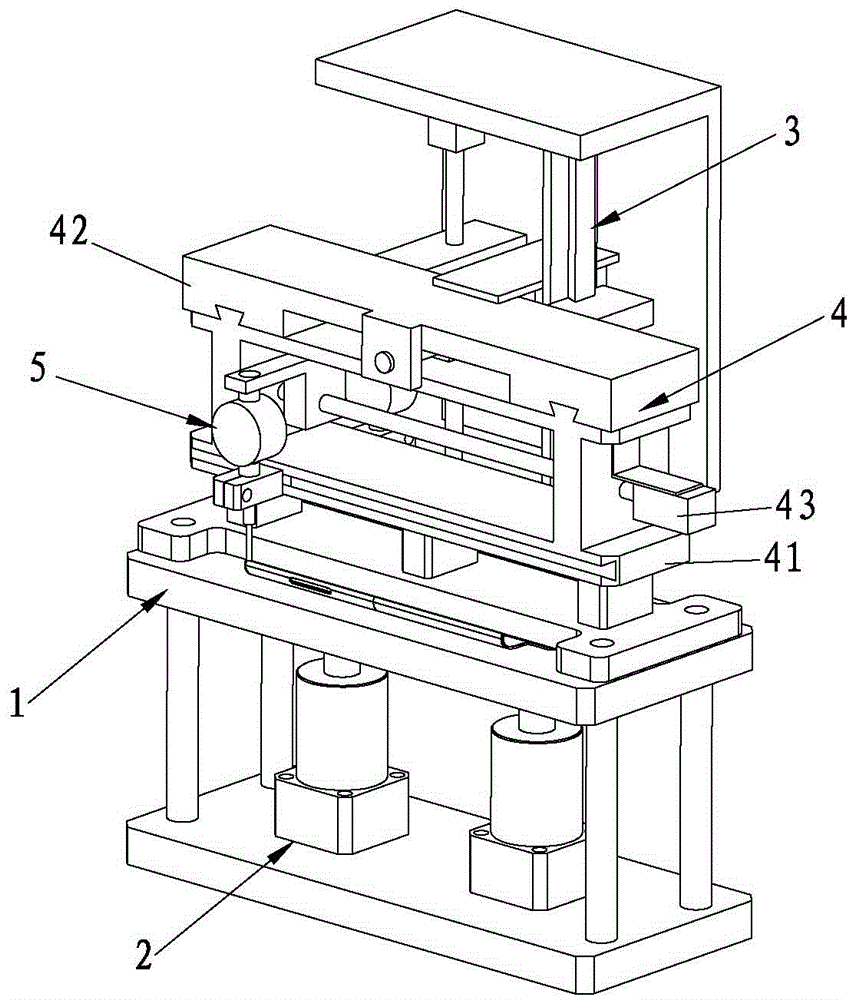

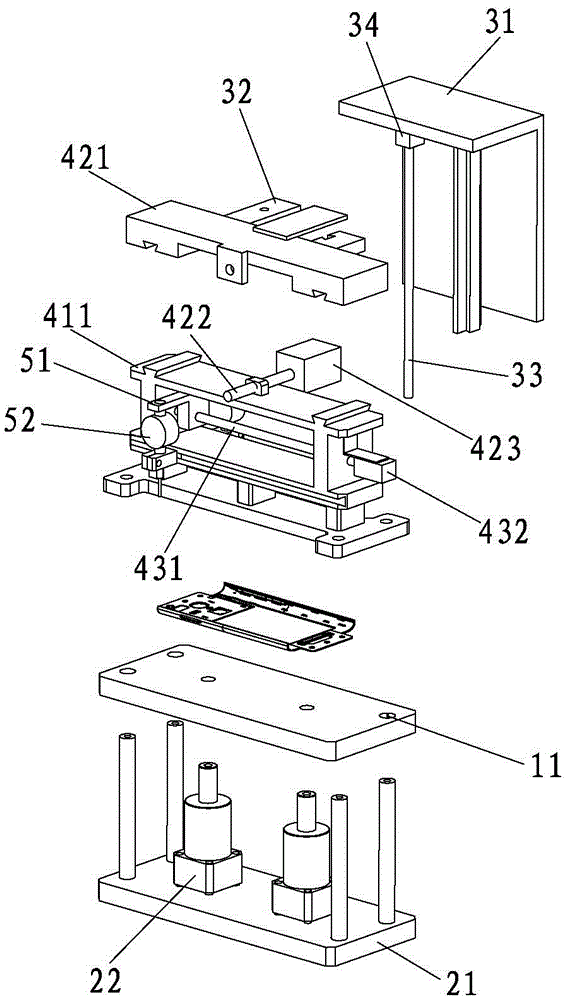

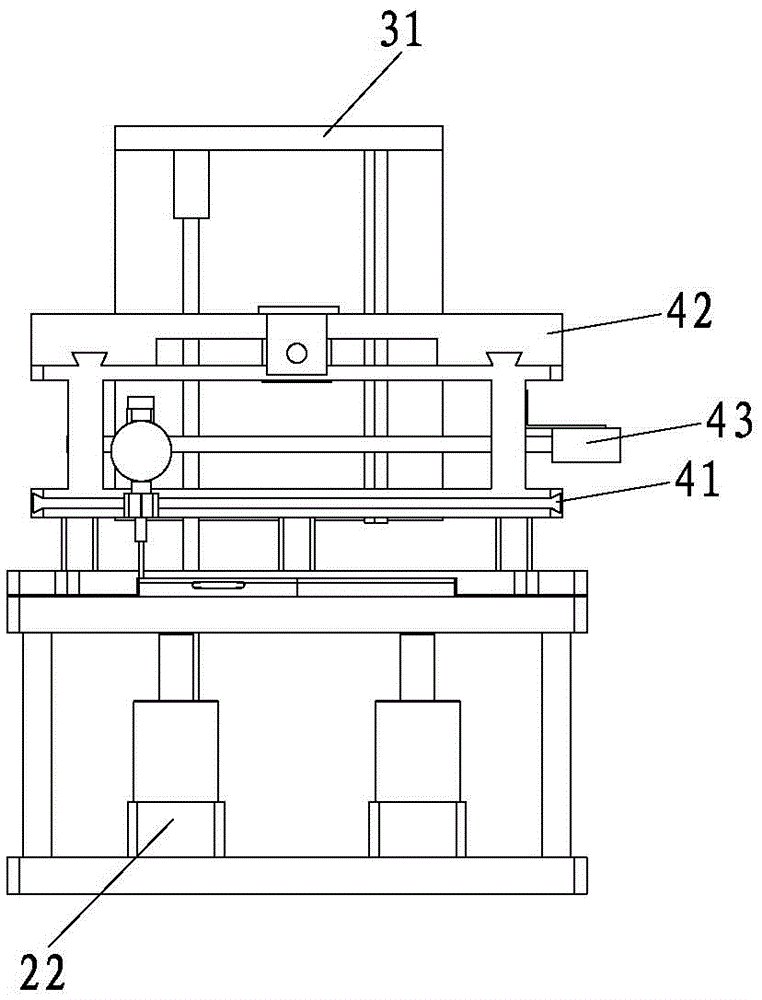

[0029] see Figure 1~Figure 3 , an automatic flatness testing device, comprising a fixed table 1 for installing a test piece and a lifting mechanism 2 for driving the fixed table 1 to move up and down, the top of the fixed table 1 is connected with a vertical fine-tuning device 3 and a The horizontal displacement device 4 that device 3 is connected, and described horizontal displacement device 4 is connected with at least one plane detection device 5; Electrically connected with the control device. When the testing equipment is working, the test piece is installed on the fixed platform 1, and then the lifting mechanism 2 raises the fixed platform 1, and the vertical fine-tuning device 3 moves the plane detection device 5 downward and makes the plane detection device 5 and the test piece The surface forms a detection conflict; further, under the action of the horizo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com