Method of preparing thermoplastic hard foam

A manufacturing method and foam technology, applied in the field of finished products without joints, can solve the problems of complex formula, difficult recycling of waste materials, large dust or chemical pollution, etc., and achieve the effect of simple formula and easy secondary processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a clearer understanding and understanding of the purpose of the present invention, the concept of the invention and the technical principle, the specific embodiments are now listed in conjunction with the accompanying drawings, and the detailed description is as follows:

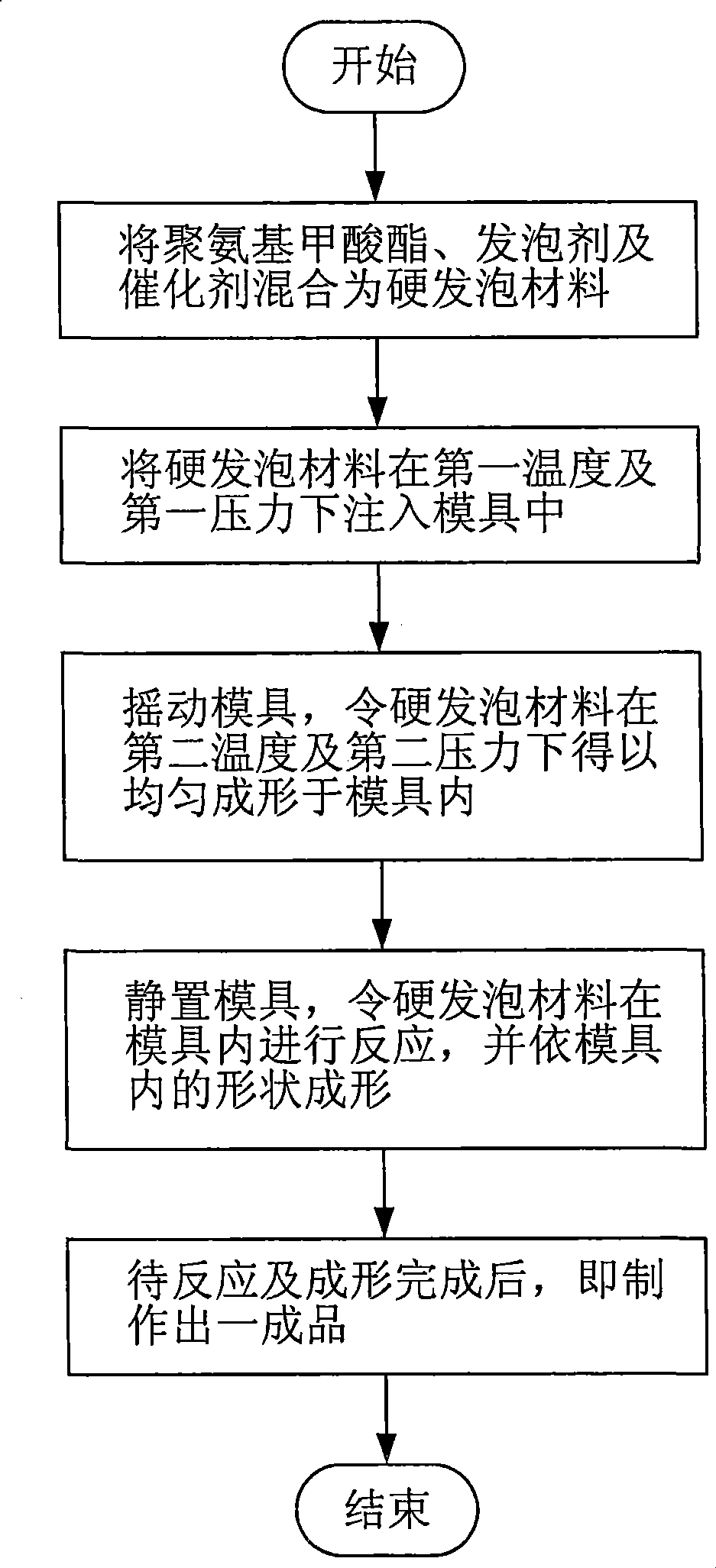

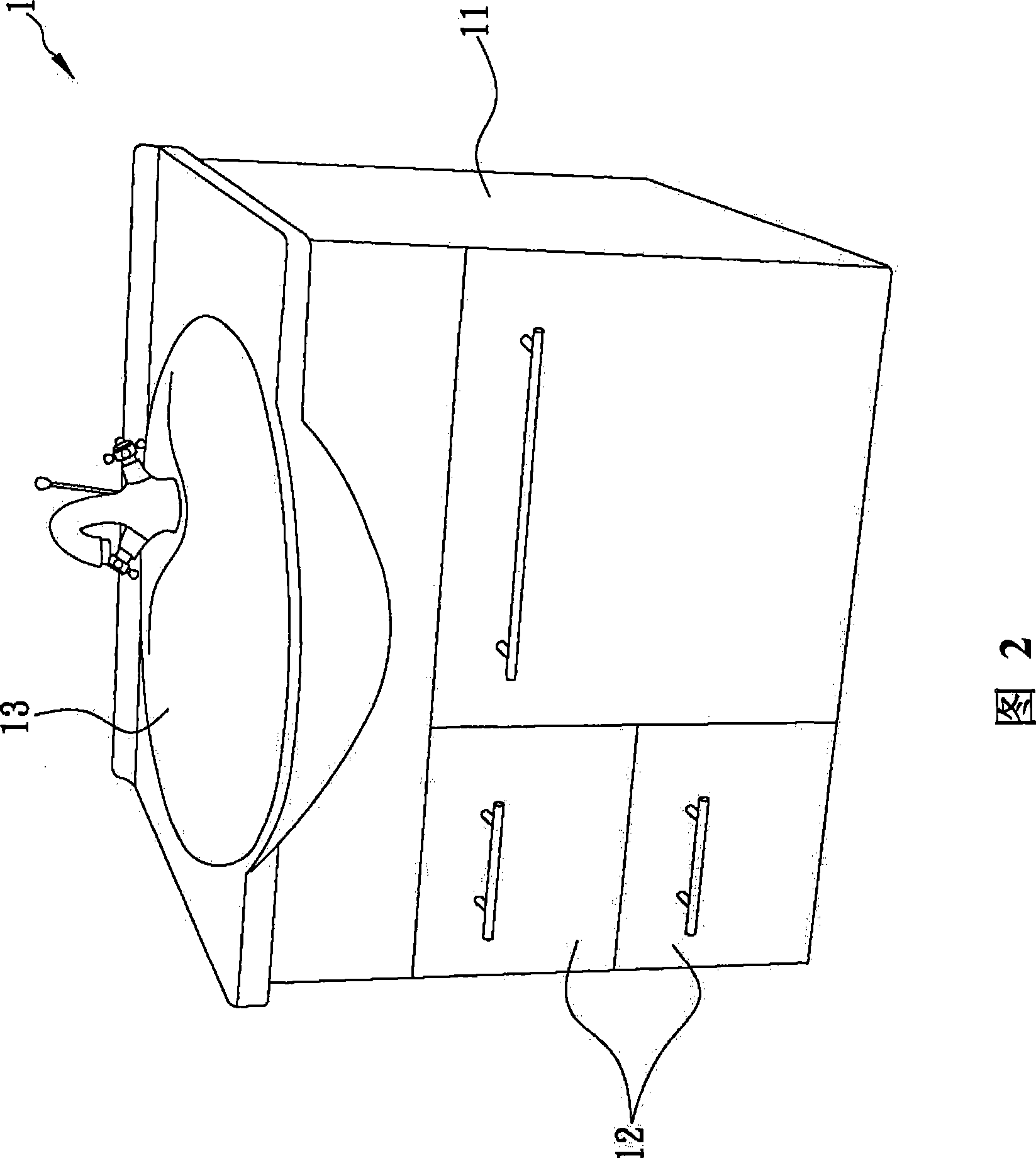

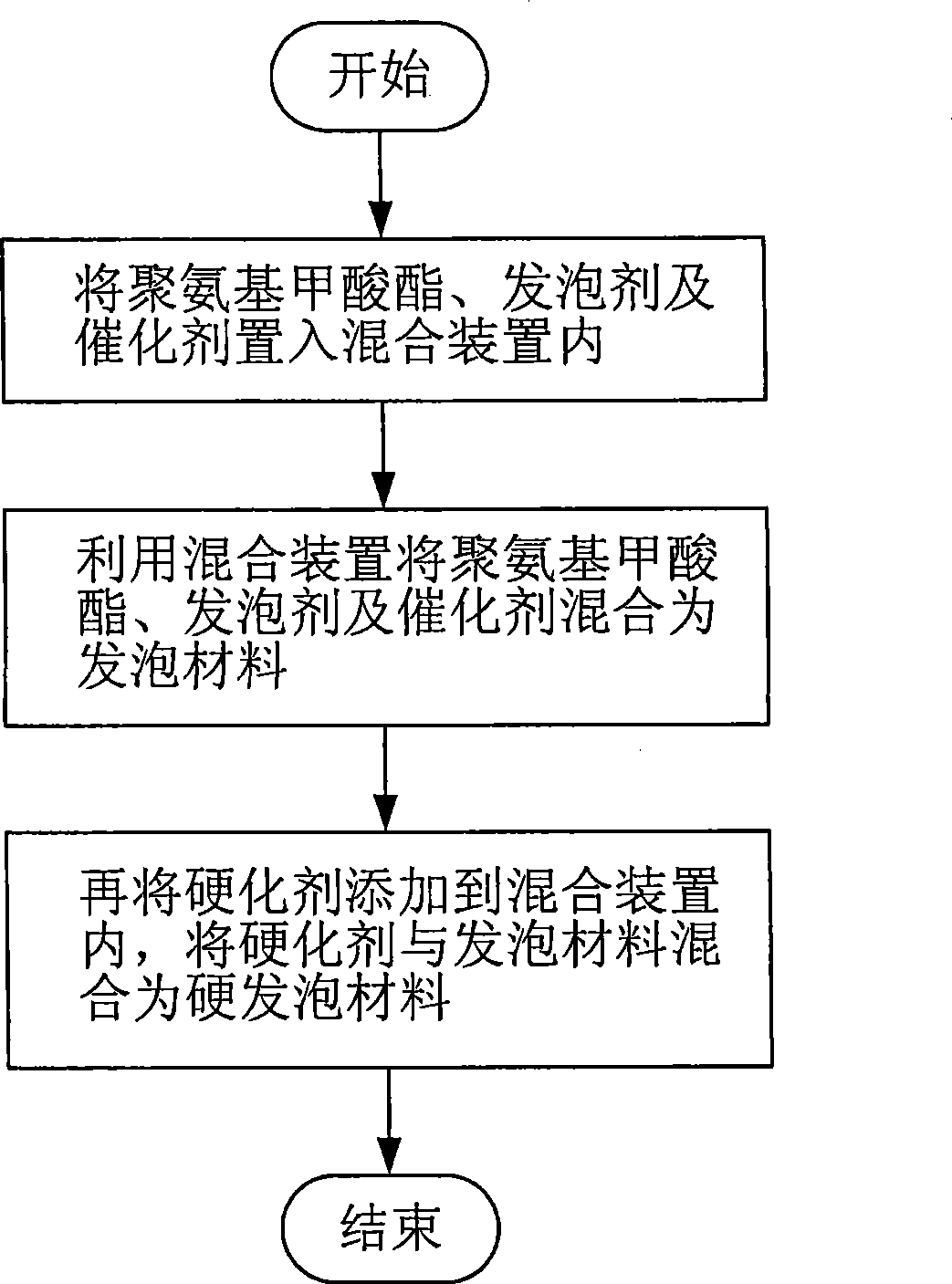

[0019] The present invention provides a kind of manufacturing method of thermoplastic rigid foam, please refer to figure 1 As shown, the method is to first add materials such as polyurethane (Polyurethane, PU for short), foaming agent and catalyst (such as: water) into a mixing device, and mix them into a hard foaming material; The hard foaming material is injected into a mold at a first temperature and a first pressure; then the mold is shaken so that the hard foaming material can be uniformly formed in the mold at a second temperature and a second pressure; The mold reacts the hard foaming material in the mold and forms it according to the shape in the mold. After the reaction and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com