Method for manufacturing paper water pipe

A manufacturing method and technology for water pipes, which are applied in the directions of cardboard wound articles, paper, papermaking, etc., can solve the problems of easy aging, environmental protection and high price of PVC plastic pipes, and achieve the effects of light weight, low price and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

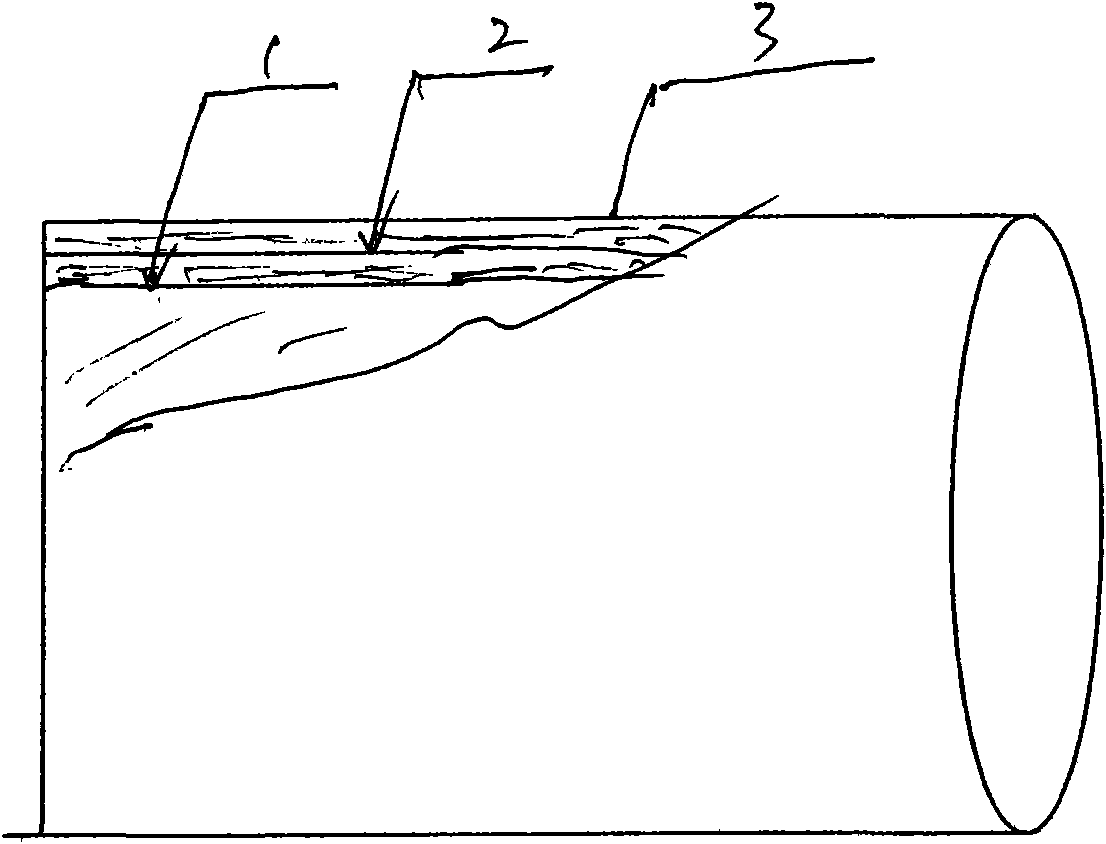

[0011] Raw material formula: get 88.54% wood pulp paper, 9% glue for each paper tube, get 1% aluminized film (VMPEP), 0.06% film (OPE), 0.4% film (PE), and its manufacturing steps are: 1. Cut paper strips for backup: Cut wood pulp paper in tubes into long strips through a paper separator; 2. Arrange the strips in order: put the spare long strips of wood pulp paper, aluminized film, aluminum platinum paper, and paper-plastic composite The membranes are arranged in a certain order on the paper frame: the innermost layer is aluminum-plastic composite membrane, the middle layer is multi-layer wood pulp paper, and the outermost layer is paper-plastic composite membrane, which is the most basic paper water pipe structure; 3 1. Gluing: Gluing can be done on one side or double sided. According to the different layers of the glue, glue should be selected and added to the glue hopper of the gluing machine; 4. Heat sealing device: installed on the coiling machine Heat-sealing device, and...

Embodiment 2

[0013] Raw material formula: take 87.83% wood pulp paper, 10% paper tube glue for each grade, 1.1% aluminized film (VMPEP), 0.07% film (OPE), and 1% film (PE). In order to strengthen the strength of the paper water pipe, in the second step of the manufacturing process: arrange the spare strips of wood pulp paper, aluminized film, aluminum platinum paper, and paper-plastic composite film in a certain order on the paper stand: The innermost layer is aluminum-plastic composite film, the middle layer is multi-layer wood pulp paper, and the outermost layer is the basic structure of paper-plastic composite film. A layer of multi-layer wood pulp paper is added to the sub-outer layer of the outer layer, and a layer of paper-plastic composite film is added to the outermost layer to form a paper water pipe with six layers in total. Other processing steps of embodiment 2 are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com