Preparation method for anticorrosion resin emulsion paint

An anti-corrosion resin and coating technology, applied in the field of coatings, can solve the problems of poor corrosion resistance and adhesion stability, easy foaming, fading and falling off, etc., achieve stable quality, good use effect, increase anti-corrosion performance and adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

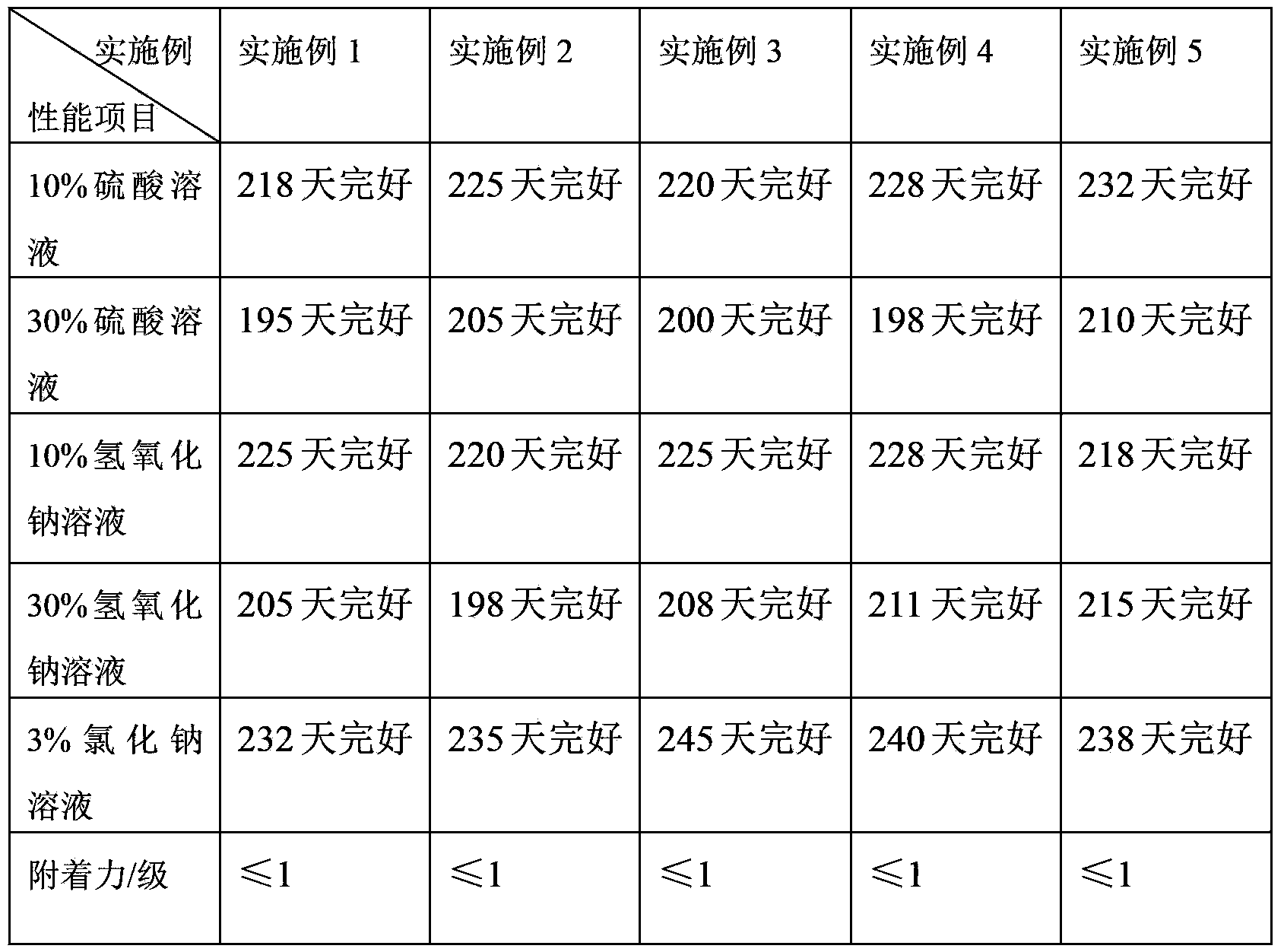

Examples

Embodiment 1

[0019] A kind of anticorrosion resin coating, its component is made up of following composition by weight percentage: the A component of 60% and the B component of 40%;

[0020] The A component includes the following components in parts by weight: 50 parts of polyester resin, 14 parts of epoxy resin, 8 parts of titanium dioxide, 5 parts of barium metaborate, 5 parts of talcum powder, 0.5 parts of additives, 5 parts of mixed Solvent; the mixed solvent is composed of xylene and butyl acetate, and the volume ratio of xylene and butyl acetate in the mixed solvent is 4:1; the auxiliary agent is composed of defoamer, anti-settling agent and thixotropic agent ; The additives include defoamers, anti-settling agents and thixotropic agents in a weight ratio of 1:1:2

[0021] The B component includes the following components in parts by weight: 1 part of dibutyl phthalate, 3 parts of tricarboxymethylpropane, 15 parts of toluene diisocyanate, 1 part of cyclohexanone, and 0.5 part of polyu...

Embodiment 2

[0027] A kind of anticorrosion resin coating, its component is made up of following composition by weight percentage: the A component of 80% and the B component of 20%;

[0028] The A component includes the following components in parts by weight: 40 parts of polyester resin, 19 parts of epoxy resin, 12 parts of carbon black, 10 parts of aluminum tripolyphosphate, 7 parts of precipitated barium sulfate and mica powder, 2 parts of auxiliary agent, 15 parts of mixed solvent; the volume ratio of xylene and butyl acetate in the mixed solvent is 4:1; the auxiliary agent includes defoamer, anti-settling agent and thixotropic agent in weight ratio of 1:1:2 ;

[0029] The B component includes the following components in parts by weight: 0.5 parts of dioctyl phthalate, 8 parts of tricarboxymethylpropane, 25 parts of toluene diisocyanate, 3 parts of cyclohexanone, and 2 parts of polyurethane dehydrating agent.

[0030] The preparation method of above-mentioned anticorrosion resin coati...

Embodiment 3

[0035] A kind of anticorrosion resin coating, its component is made up of following composition by weight percentage: 70% A component and 30% B component;

[0036] The A component includes the following components in parts by weight: 45 parts of polyester resin, 16 parts of epoxy resin, 10 parts of phthalocyanine blue, 8 parts of zinc molybdate, 6 parts of natural barite powder, 1 part of auxiliary agent, 10 parts of mixed solvent; the volume ratio of xylene and butyl acetate in the mixed solvent is 4:1; the auxiliary agent includes defoamer, anti-settling agent and thixotropic agent in weight ratio of 1:1:2;

[0037] The B component includes the following components in parts by weight: 0.8 parts of dioctyl phthalate and dibutyl phthalate, 6 parts of tricarboxymethylpropane, 20 parts of toluene diisocyanate, 2 parts of cyclohexane Ketone, 1 part polyurethane dehydrating agent.

[0038] The preparation method of above-mentioned anticorrosion resin coating, comprises the steps:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com