Method and device for supporting side-roll torsion bar system of railway vehicle

A technology of a rail vehicle and a supporting method, which is applied in the direction of the device for lateral relative movement between the underframe and the bogie, can solve the problems such as the inability of the anti-roll torsion bar system to adapt, and achieves simple molding, reduced process, and reduced cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

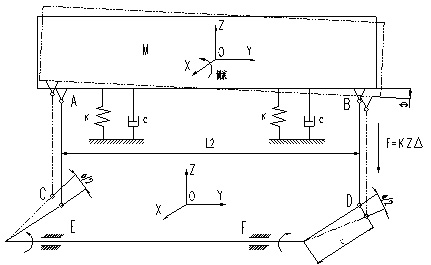

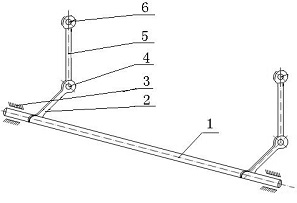

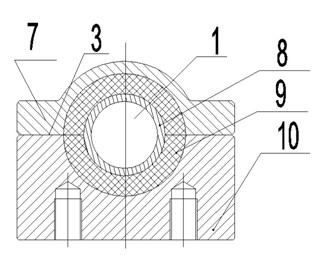

[0028] attached image 3 An embodiment of the present invention is given, and it can be seen from the accompanying drawings that the present invention relates to a new type of support method for a rail vehicle anti-roll torsion bar system, which uses a multi-layer composite sleeve support method to support a rail vehicle Anti-rolling torsion bar system; the support method of the multi-layer composite sleeve is to cover the torsion bar shaft with a layer of steel sleeve with lower hardness than the material of the torsion bar shaft through interference fit, and the torsional friction generated during use The force is borne by the steel sleeve. Since the steel sleeve is made of relatively low hardness material, it can effectively protect the torsion bar shaft (the torsion bar shaft has high hardness and is very sensitive to surface defects. If it is scrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com