Preparation method for high-performance water-based environmentally-friendly anticorrosive paint used for metal base material

A technology for anti-corrosion coatings and metal substrates, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor shielding performance of water-based coatings, achieve strong metal chelating ability, improve water resistance and salt spray resistance Performance, the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

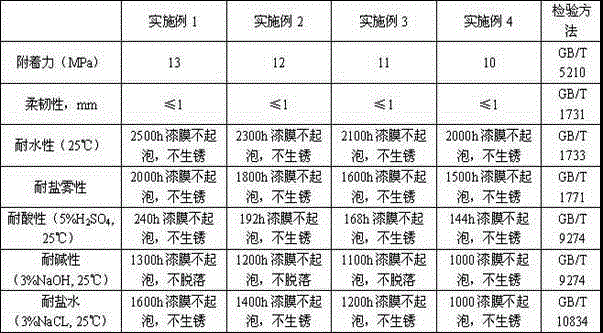

[0035] The invention is a method for preparing a high-performance water-based environmental protection anti-corrosion coating for metal substrates. The prepared high-performance water-based environmental protection anti-corrosion coating can reach more than 10MPa in adhesive force and more than 1500h of water resistance at 25°C. , Its salt spray resistance can reach more than 1500h, and the coating film does not blister or rust.

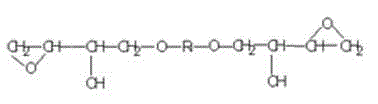

[0036] The present invention relates to the preparation of component A and component B. The component A contains water-based epoxy curing agent, non-heavy metal anti-rust pigment, deionized water, filler, thickener, dispersant, leveling agent, disinfectant Foaming agent, PH regulator, film-forming aid, component B contains water-based epoxy resin, mussel adhesion protein.

[0037] The above-mentioned non-heavy metal antirust pigment can form an organic complex with mussel adhesion protein, increase the compactness of the coating, and improve the prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com