Method for processing surface of non quicksilver basicity zincium manganese and zincium silver button cell cathode cover

A technology of zinc-silver button type and battery negative electrode, which is applied in the manufacture of electrodes and electrodes of primary batteries. Effect of reducing pollution and high uniformity

Active Publication Date: 2008-11-05

SOUTH CHINA NORMAL UNIVERSITY

View PDF10 Cites 9 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

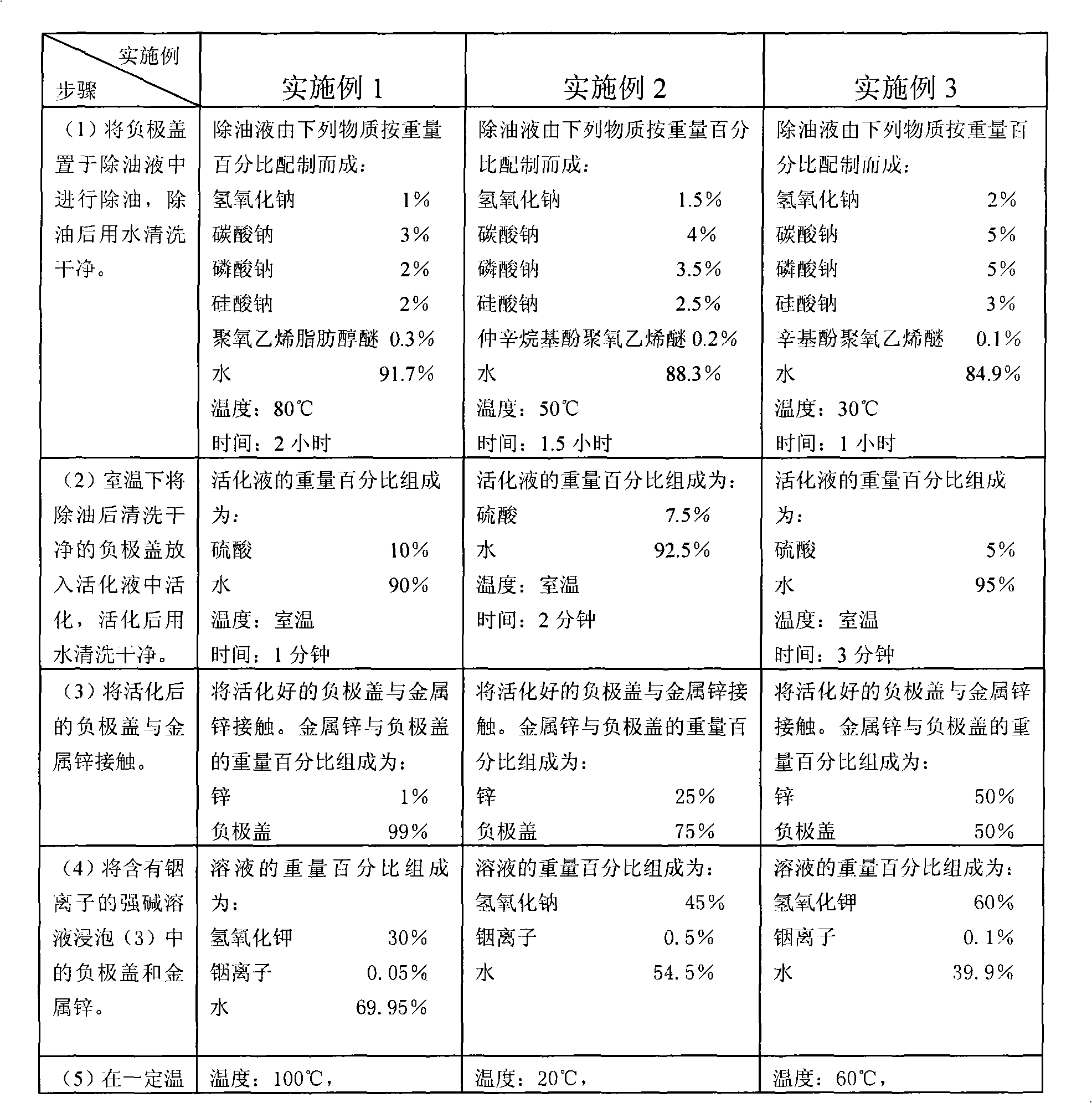

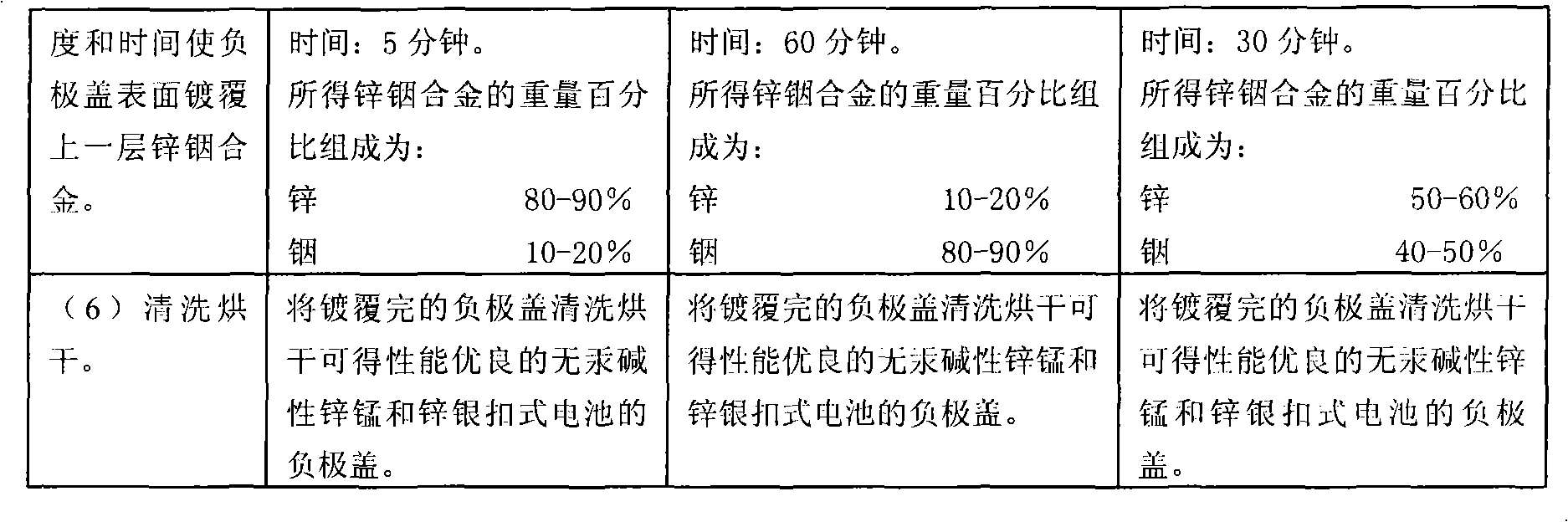

Embodiment

[0036]

[0037]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a cathode cover surface treatment method of the Hg-free alkaline zinc manganese and the zinc silver button cell, including the following steps: 1. deoiling the cathode cover of the commodity and cleaning by water; 2. putting the cleaned cathode cover into the activate fluids for activation, then cleaning by water after activation; 3. contacting the metallic zinc with the activated cathode cover; 4. putting the cathode cover and the metallic zinc in the strongly alkaline solution soaking step (3) containing the indium ion; 5. coating a layer of zinc indium alloy on the surface of the cathode cover under certain temperature and time; 6. cleaning and drying the coated cathode cover. The invention uses the contact coating theory and the replacement coating theory to directly prepare the zinc indium alloy of the hydrogen-eduction overpotential with good property on the cathode cover without the DC source and the reducer, which saves the resource and reduces the pollution, the metallic zinc with lower cost is adopted to partially replace indium with higher expensive, and the reclaimed bath and the metallic zinc can be used again to reduce the production cost.

Description

technical field [0001] The invention relates to the button battery manufacturing technology, in particular to a method for treating the surface of the negative electrode cover of the mercury-free alkaline zinc-manganese and zinc-silver button battery. Background technique [0002] my country is a big producer and consumer of alkaline zinc-manganese button batteries and zinc-silver button batteries. The mercury-free button battery is an inevitable trend. Because the button battery cannot reserve an air chamber, if certain measures are not taken to reduce the hydrogen gas generated by the self-discharge of the negative electrode zinc powder after the button battery is mercury-free, the battery will easily swell or even explode after manufacture, thus making the button battery The battery is dead. Extensive research has been done on how to reduce or prevent the self-discharge of negative electrode zinc powder, such as patent No. ZL200410026985.1, patent application No. 200610...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/08H01M4/04

Inventor 李伟善黄启明蔡宗平梁英肖秀华陈锦清

Owner SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com