Integrated breathing bag and manufacturing method thereof

A manufacturing method and technology of breathing bags, which are applied in the field of medical equipment, can solve the problems of easily causing medical accidents, numerous manufacturing processes, and difficult operation, and achieve the effects of avoiding the emission of irritating odors, avoiding human allergic reactions, and simplifying the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

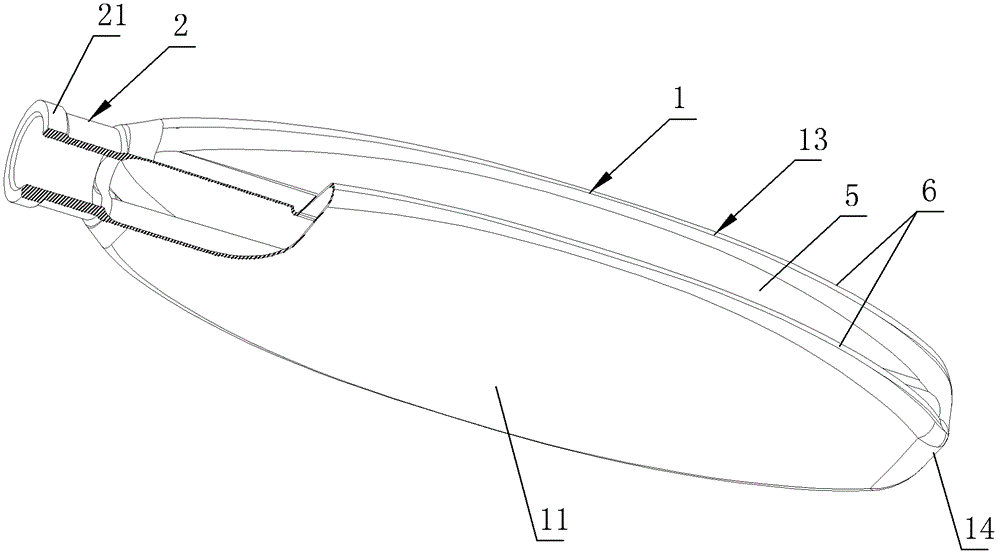

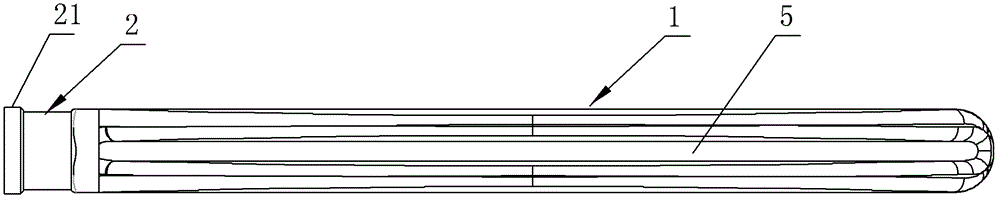

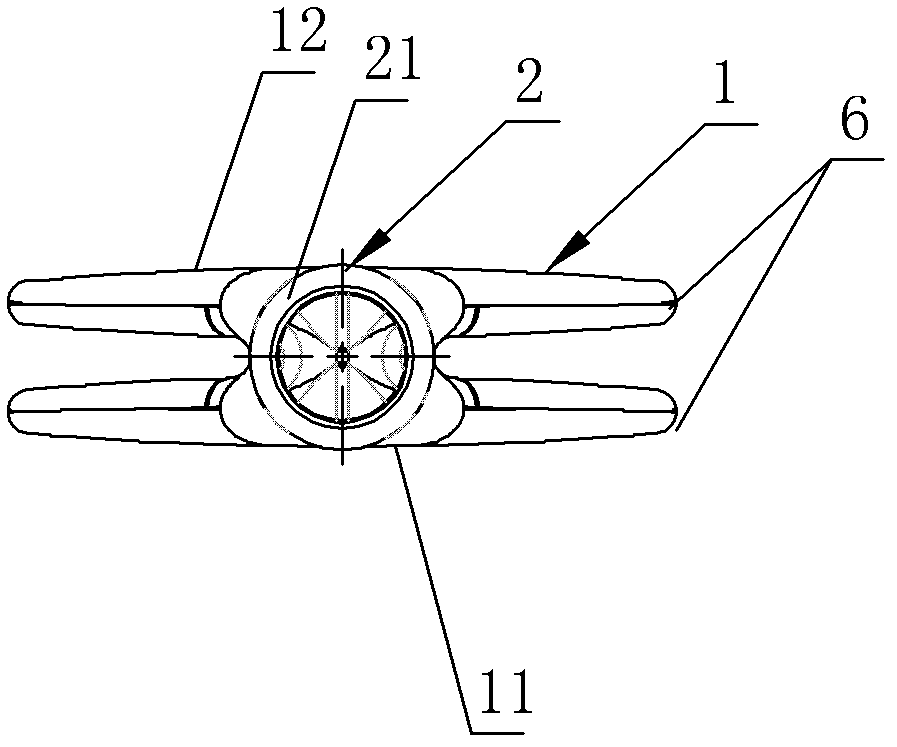

[0050] Such as Figure 1~4 As shown, a kind of integrated breathing bag of the present invention, comprises hollow bag body 1 and the joint 2 that is arranged on bag body 1 interface, and bag body is the flat bag that 1 section is ellipse, and joint 2 is a short tube, and this short The wall thickness of the tube is greater than that of the cavity wall of the capsule body 1; the tube wall thickness of the short tube is 3-4.5mm, and the cavity wall thickness of the capsule body is 0.2-1.0mm. The through hole of the joint 2 communicates with the inside of the capsule body 1, and the capsule body 1 and the joint 2 are integrally formed in the mold cavity by gluing and heating and forming.

[0051] In this embodiment, the capsule 1 and the joint 2 are made of safe and reliable liquid medical polymer materials. The medical liquid polymer material adopts PU material. The head of the joint 2 has a boss 21 for connecting with the supporting device. The boss 21 is located in the conn...

Embodiment 2

[0064] The difference between this embodiment and Embodiment 1 lies in that: the liquid medical polymer material used in this embodiment is made of PVC material; the process of vacuum removing air bubbles is added.

[0065] The manufacturing method of the above-mentioned integrated breathing bag comprises the following specific steps:

[0066] (1) Gluing: apply glue to the mold cavity of the capsule mold by sloshing the glue, sloshing the glue means gluing unevenly in the way of sloshing, and the material of the sloping glue is PVC material;

[0067] (2) Low temperature leveling: Leveling in a closed and clean oven for 5 minutes at a temperature of 70°C;

[0068] (3) Shaping: under the condition of the temperature in the oven at 180°C, heat the mold for 1 minute so that the capsule body in the mold in the obtained step (2) is shaped;

[0069] (4) Clamping mold injection: clamping the joint mold and the capsule mold, and leveling after injecting glue into the mold cavity of th...

Embodiment 3

[0077] The difference between this embodiment and Embodiment 2 is: the following specific steps are included:

[0078] (1) Gluing: apply glue to the mold cavity of the capsule mold by sloshing the glue, and sloshing the glue means that the glue is applied unevenly in the way of swaying;

[0079] (2) Low temperature leveling: Leveling in a closed and clean oven for 5 minutes at a temperature of 70°C;

[0080] (3) Shaping: under the condition of the temperature in the oven at 170° C., heat the mold for 1.5 minutes so that the capsule body in the mold in the obtained step (2) is shaped;

[0081] (4) Clamping mold injection: clamping the joint mold and the capsule mold, and leveling after injecting glue into the mold cavity of the joint mold;

[0082] (5) Vacuum removal of bubbles: Remove bubbles for 10 minutes at a temperature of 80°C and a vacuum of -0.1MPa;

[0083] (6) Plasticizing: plasticizing for 20 minutes at a temperature of 220°C;

[0084] (7) Cooling: Cool the mold w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com