A gradient variable temperature pyrolysis system for domestic waste treatment

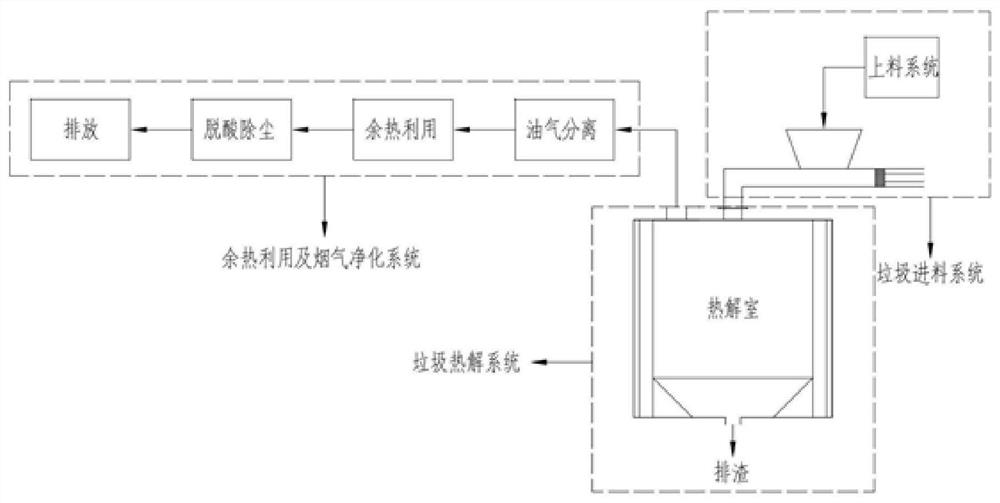

A technology for domestic garbage and garbage, applied in the field of harmless disposal of solid waste, can solve the problems of complex flue gas treatment process, easy generation of waste water, water pollution, etc., achieve stable and continuous anaerobic or oxygen-limited pyrolysis and combustion, improve Working environment, the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

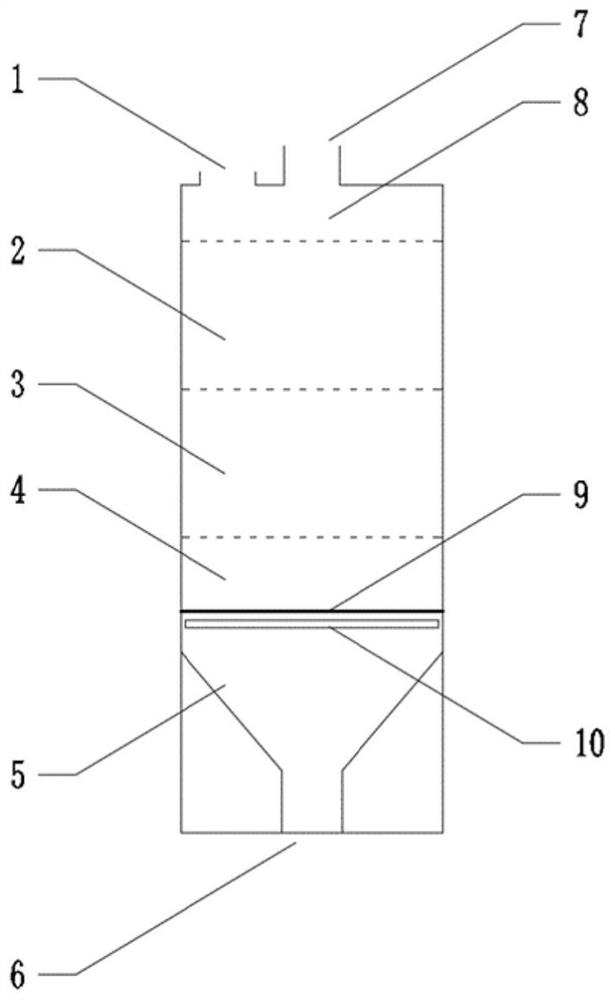

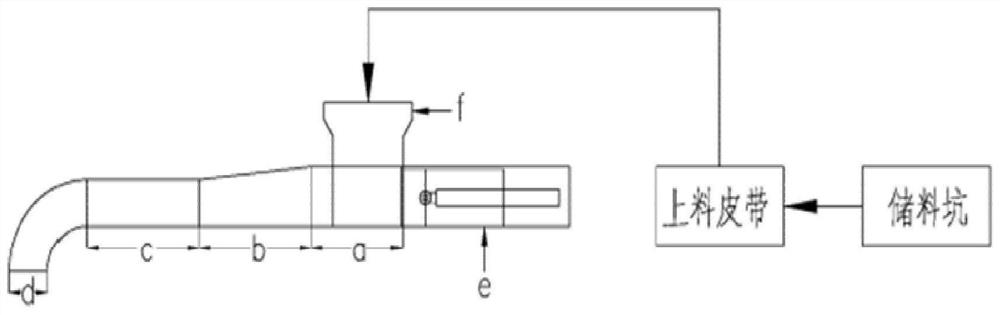

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0035] Through a large amount of investigation and analysis of existing technologies, it is concluded that the current small-tonnage pyrolysis system mainly has the following specific problems and possible countermeasures:

[0036] (1) For small-scale (less than 10 tons per day) domestic waste low-temperature pyrolysis system, a complete system solution is required, which can reduce investment and operating costs, and has complete flue gas purification and waste heat utilization supporting equipment;

[0037] (2) It is necessary to realize the continuous and stable pyrolysis of waste through the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com