Scattered tile sorting machine for small and medium-sized ceramic tiles and its sorting method

A finishing machine, small-scale technology, applied in the direction of packaging, packaging item types, special packaging items, etc., can solve the problems of reducing the efficiency of ceramic tile packaging, inconvenience in sorting and packaging, and cluttered arrangement, achieving small deformation, flexible installation, and reduction of ceramic tiles. superimposed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and examples, but the embodiments of the present invention are not limited thereto. In this paper, the side of the tile outlet is the front side, and the side of the tile packaging position is the rear side.

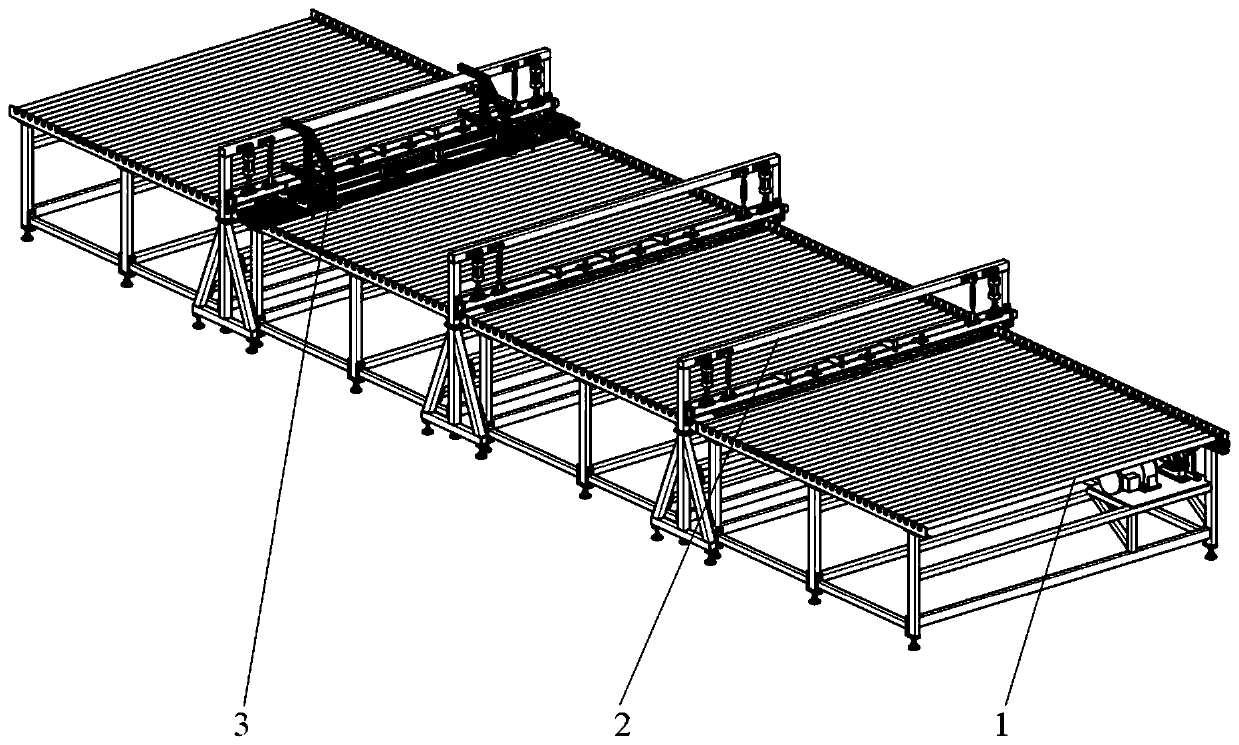

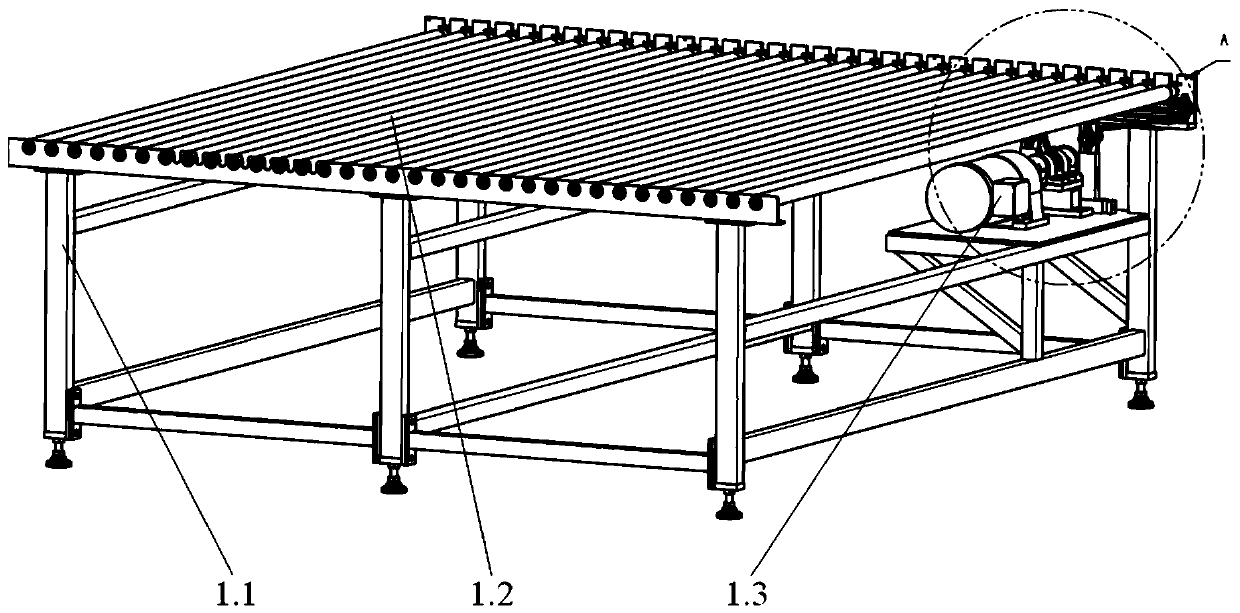

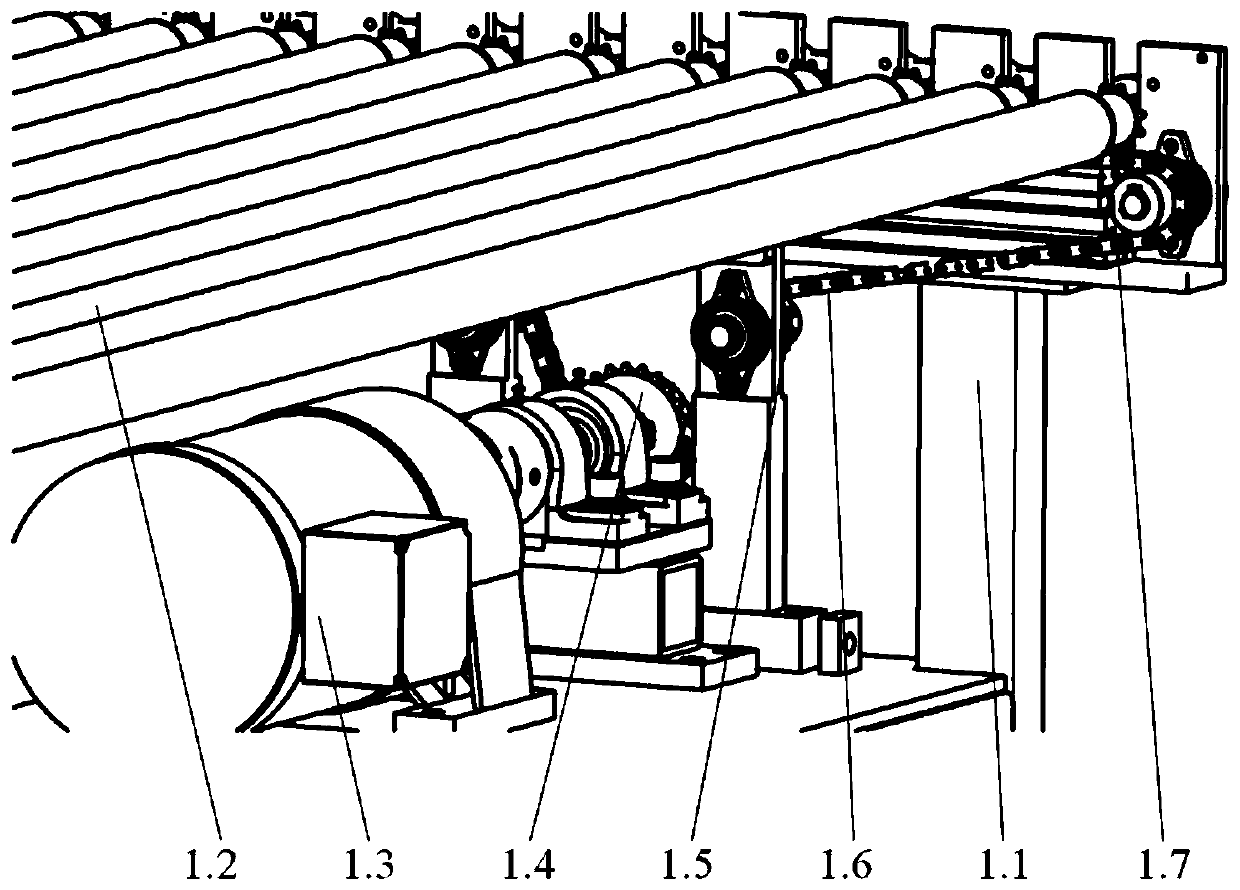

[0037] like Figure 1-Figure 7 As shown, the small and medium-sized ceramic tile loose brick sorting machine of the present invention includes three parts, which are respectively a conveying roller table 1, a segmented and regular blocking mechanism 2 and a whole row of tile clamping mechanism 3. The conveying roller table 1 is divided into multiple sections, It is continuously arranged between the tile outlet and the tile packaging position. The segmented and regular blocking mechanism 2 is arranged at the junction of two adjacent conveying rollers 1 where the tiles tend to be scattered. The entire row of tile clamping mechanisms 3 is installed on the On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com