A solid-state hydrogen storage device with high heat transfer characteristics

A technology of hydrogen storage device and thermal characteristics, applied in fixed-capacity gas storage tanks, geometry/arrangement/size of container structure, hydrogen technology, etc., can solve stress concentration, uneven dispersion of hydrogen storage materials, and damage to the internal structure of the tank and other problems, to achieve the effect of reducing damage, ensuring service life, and uniform heat distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

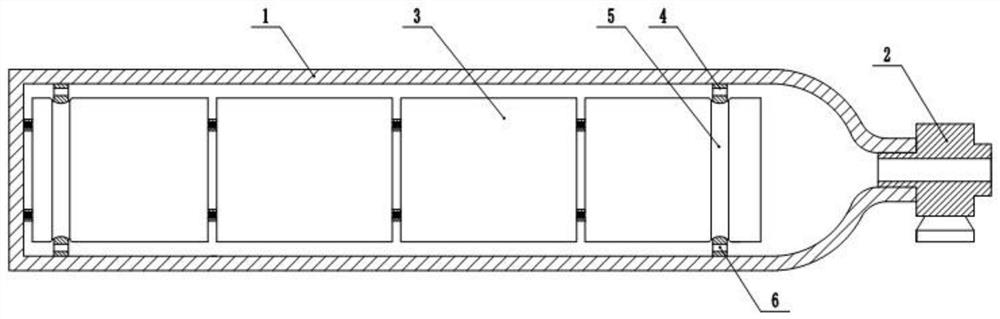

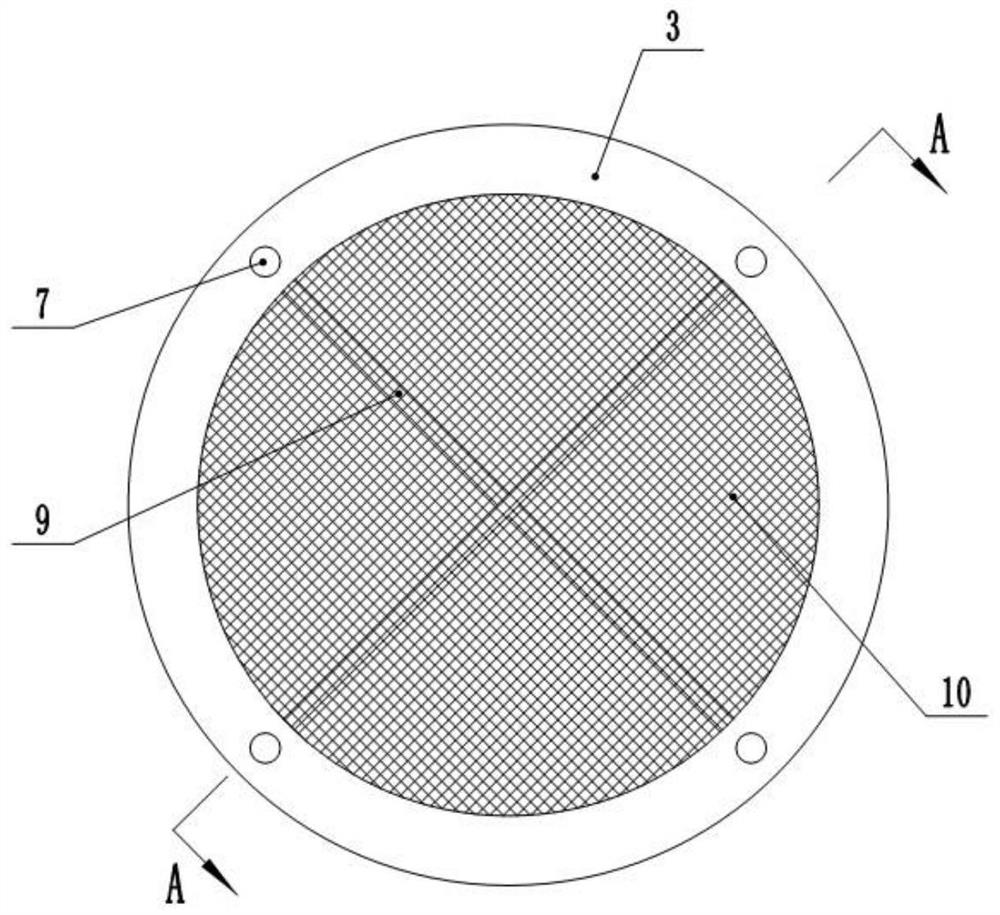

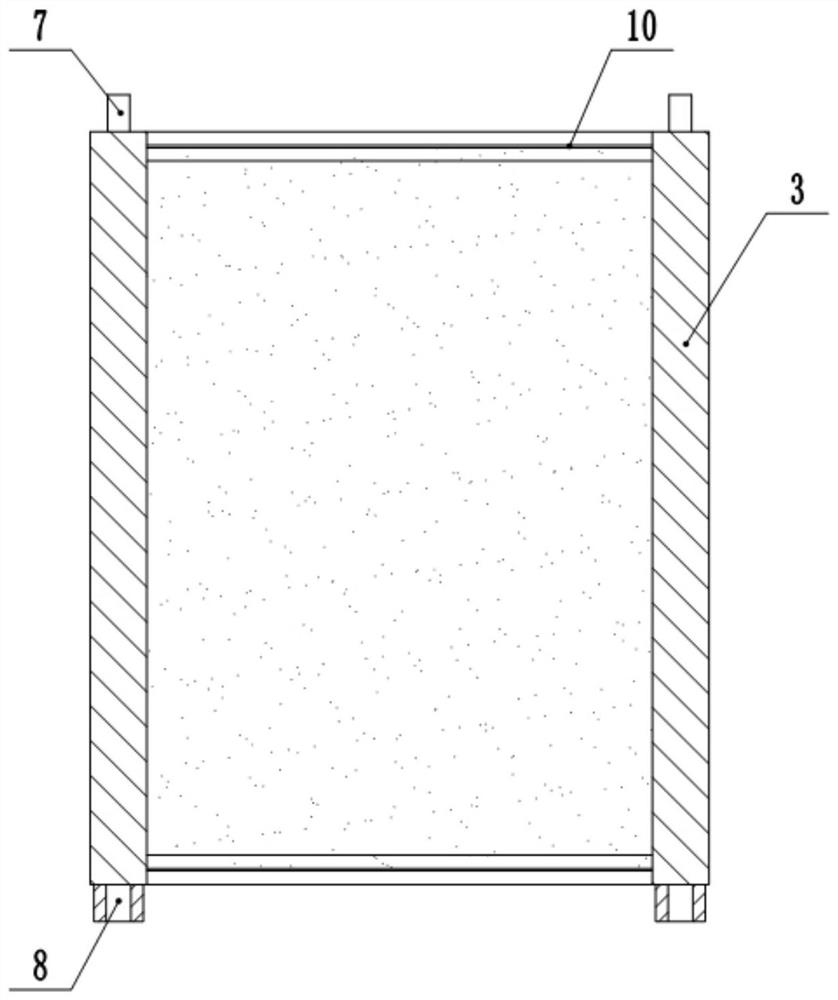

[0035] Embodiment 1 is basically as attached figure 1 and figure 2 Shown:

[0036] A solid-state hydrogen storage device with high heat exchange characteristics, comprising an outer tank 1, figure 1 The middle and outer tanks 1 are placed horizontally, the left end of which is the bottom of the outer tank 1, and the right end is the top of the outer tank 1. The hydrogen storage device is placed vertically when in use, and an air inlet and outlet valve 2 is provided at the right end of the outer tank 1, wherein the outer tank 1 The tank 1 is made of aluminum alloy, carbon steel or stainless steel, with a thickness of 2-5 mm, a length of 200-300 mm, and an outer diameter of 50-80 mm.

[0037] 4 to 10 hydrogen storage cylinders 3 are fixed inside the outer tank 1. In this embodiment, there are 4 hydrogen storage cylinders 3, and the four hydrogen storage cylinders 3 are connected sequentially from left to right, and the central axis of each hydrogen storage cylinder 3 is in li...

Embodiment 2

[0041] Embodiment 2 is basically as Figure 4 Shown:

[0042] The difference between Embodiment 2 and Embodiment 1 is that a sleeve 12 is provided outside the outer tank 1, and a plurality of heat transfer fins 11 are integrally formed on the outer wall of the sleeve 12. The heat transfer fins 11 are evenly distributed along the axial direction of the sleeve 12, the thickness of the heat transfer fins 11 is 0.5-3mm, the heat transfer fins 11 are made of aluminum alloy, and the outer wall of the outer tank 1 is coated with heat-conducting glue, The sleeve 12 is bonded on the outer tank 1 by heat-conducting glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com