Crusher and absorber manufacturing device applying same

A pulverizer and pulverizing blade technology, applied in the direction of absorbing pads, papermaking, applications, etc., can solve the problems of large mechanical vibration, pulp fiber clogging, large vibration noise, etc., to achieve convenient automatic control, reduce the number of maintenance, convenient processing and Assembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

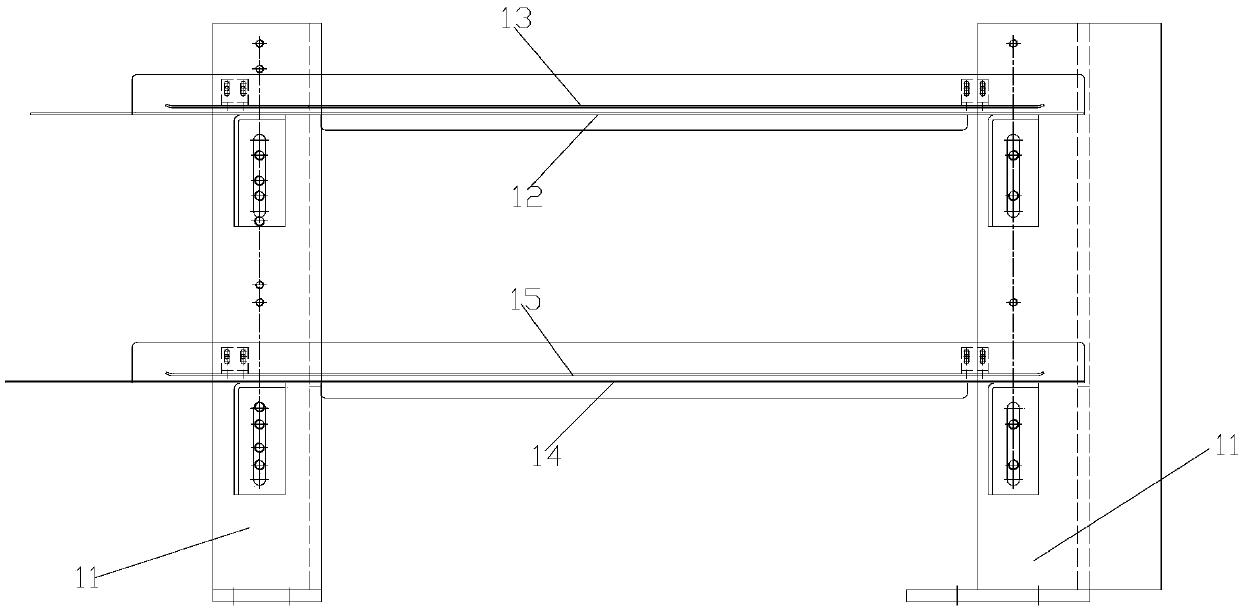

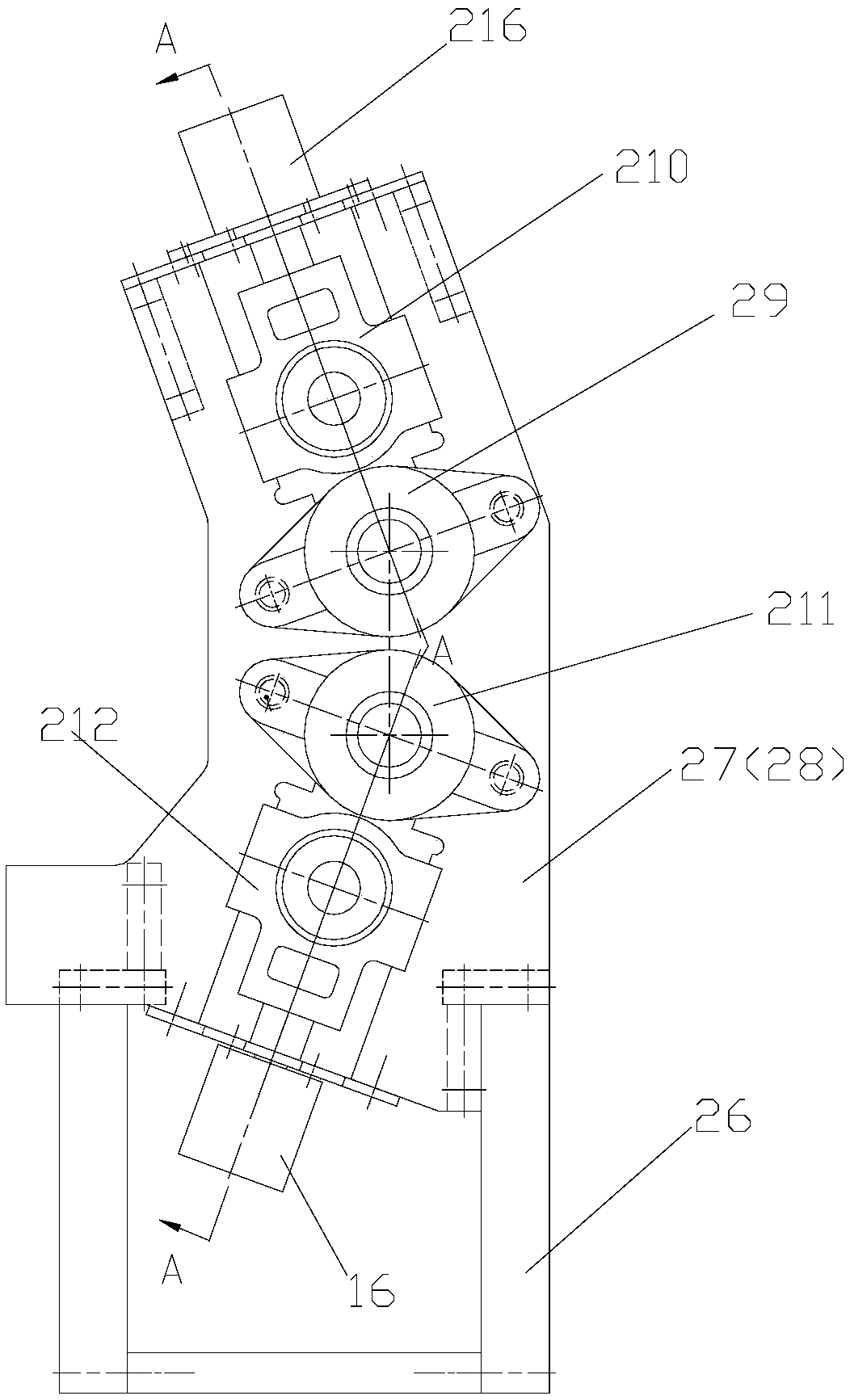

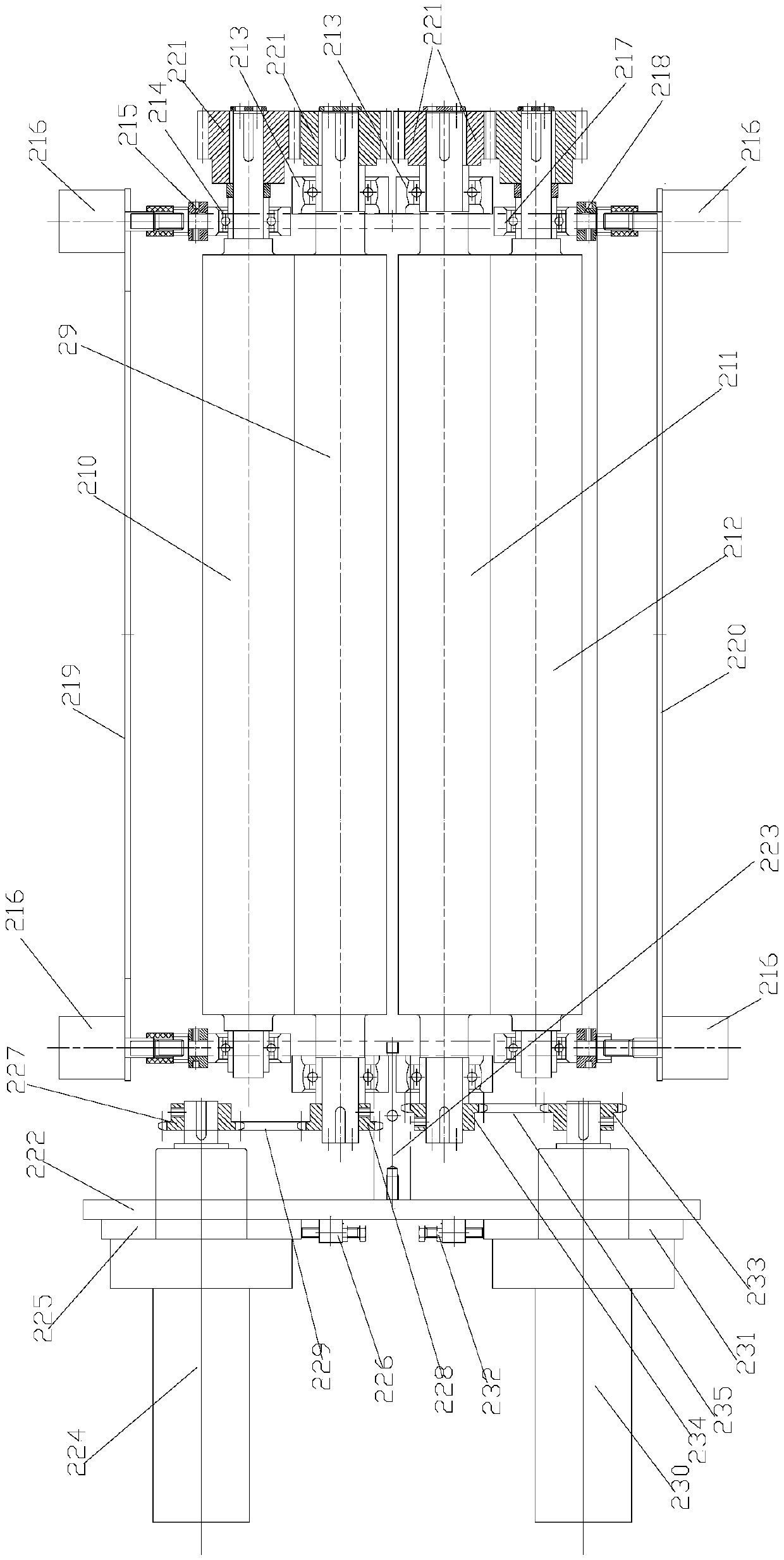

[0032] Embodiment, a pulverizer for pulverizing pulp sheets, such as Figures 8 to 11As shown, it includes a knife roll 1 for pulverizing pulp sheets into pulp fibers, the knife roll 1 is arranged in the horizontal direction, and a housing 2 covering the knife roll 1 is arranged on the outside of the knife roll 1, and the shell The body 2 has a cylindrical structure as a whole, and the two ends of the shell 2 are provided with sealing plates 319, and the two ends are sealed. One side of the housing 2 is provided with a pulp sheet inlet 3, and the other side of the housing 2 is provided with an export port 4 that leads out the pulp fiber from the housing 2, and a vertical wall is arranged below the export port 4. The discharge pipeline 5 that direction arranges. The upper end of the inner wall 5a of the discharge pipe 5 is airtightly connected with the bottom dead center 4a of the outlet 4 .

[0033] An adjustment plate 6 that can move up and down along the inner side wall 5a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com