Pipe network multi-section division pipe laying process

A multi-stage, pipe network technology, applied in sewer systems, waterway systems, buildings, etc., can solve problems such as low work efficiency, achieve the effects of improving efficiency, reducing impact, and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

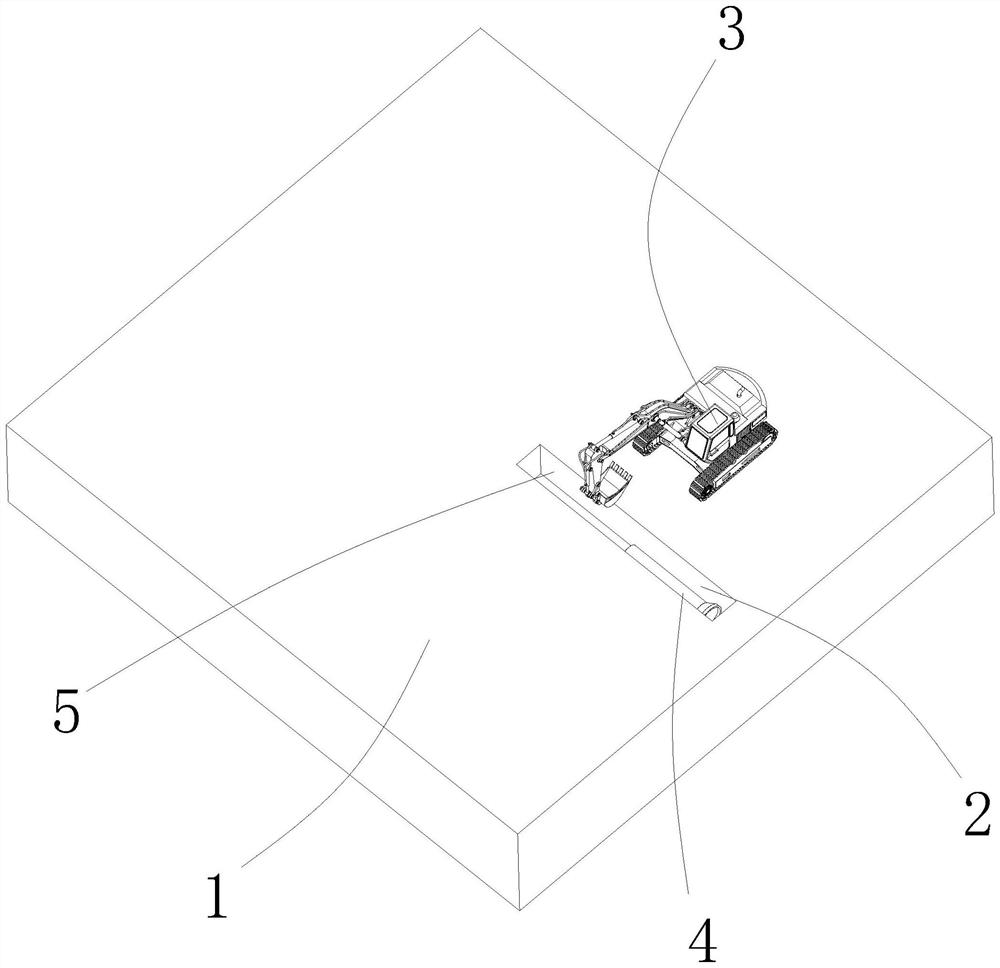

[0040] The multi-section division of labor and pipe laying process of the pipe network includes the following steps:

[0041] Step 0.5, confirm the pipe network path according to the BIM building model.

[0042] Step 1: Divide the pipe network path into several construction sections by adding 50-100cm to the length of the integral multiple of the ductile iron pipe 4 .

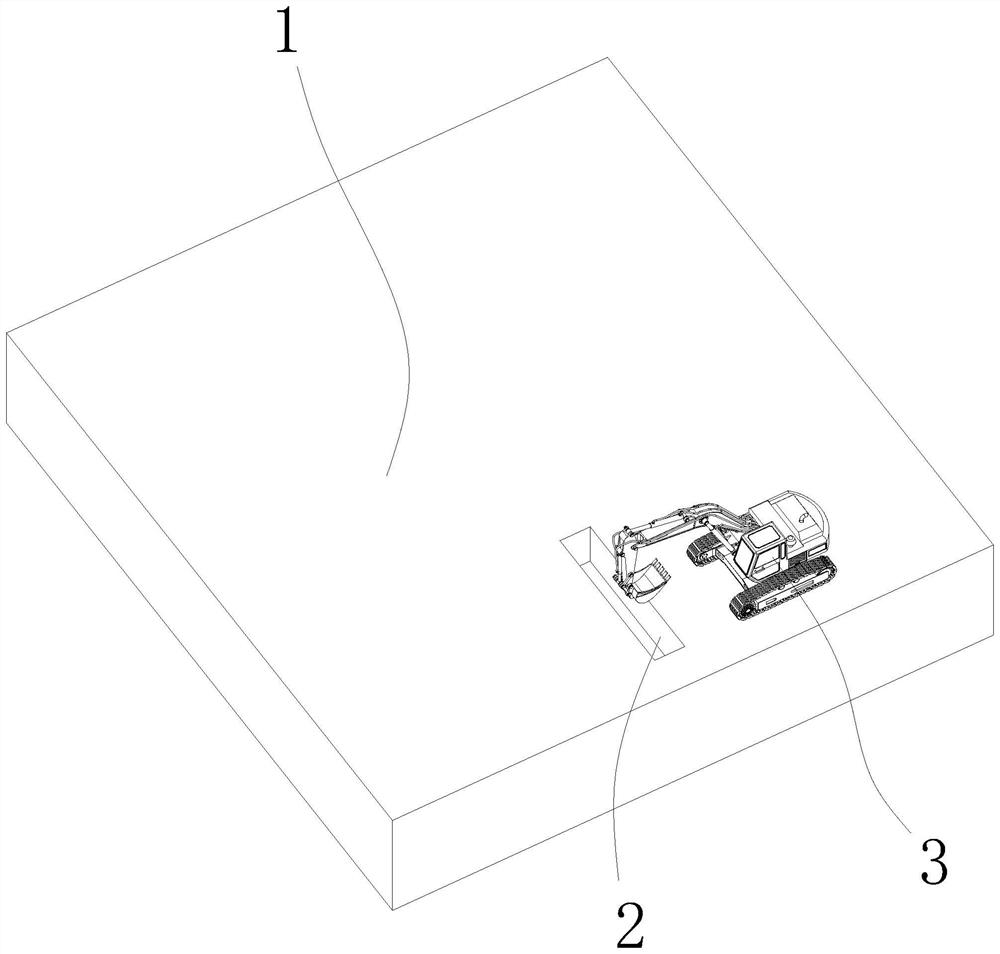

[0043] step 2, as figure 1 As shown, at the initial position of the construction section, the initial trench 2 is excavated on the earthwork 1 with a length of 1.2-1.6 times the length of the ductile iron pipe 4, and the excavated initial trench is only slightly longer than the ductile iron pipe 4. In case of rain, there will not be too much rainwater accumulated in the initial trench, which is convenient for construction.

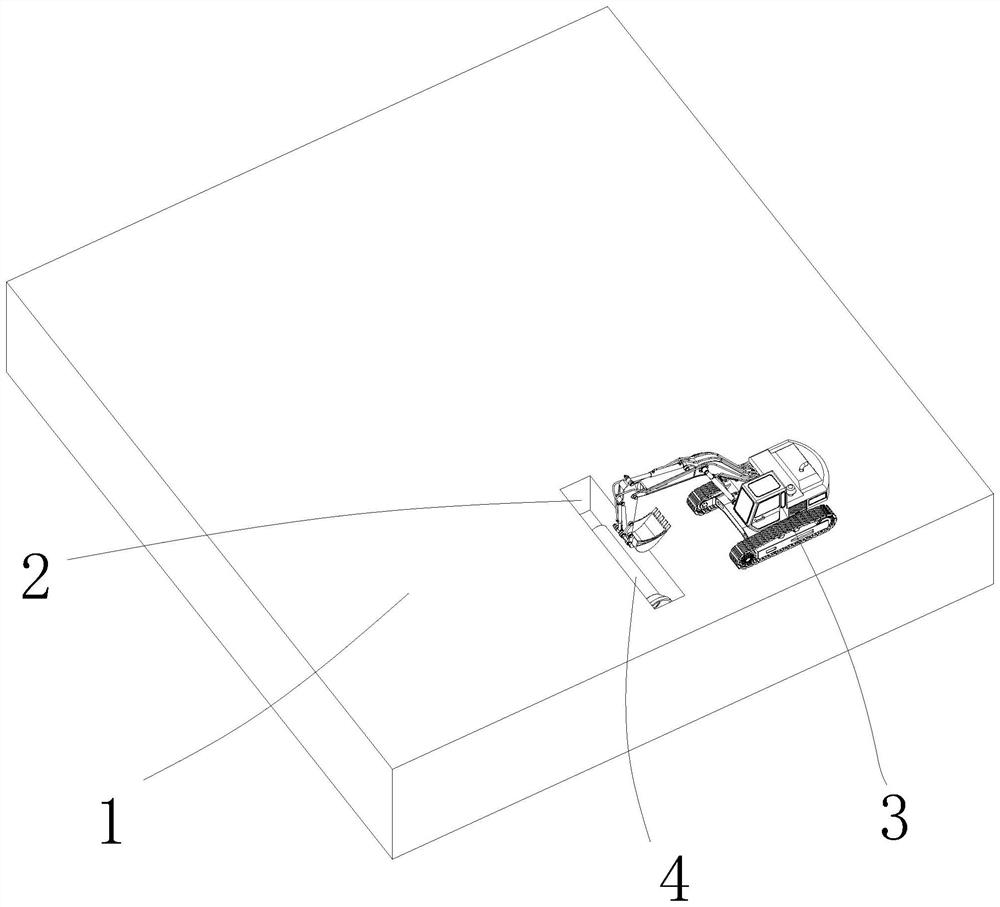

[0044] step 3, as figure 2 As shown, the ductile iron pipe 4 is placed in the initial trench 2 by the excavator 3, and there is a distance from the ductile iron pipe 4 to both ends of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com