Patents

Literature

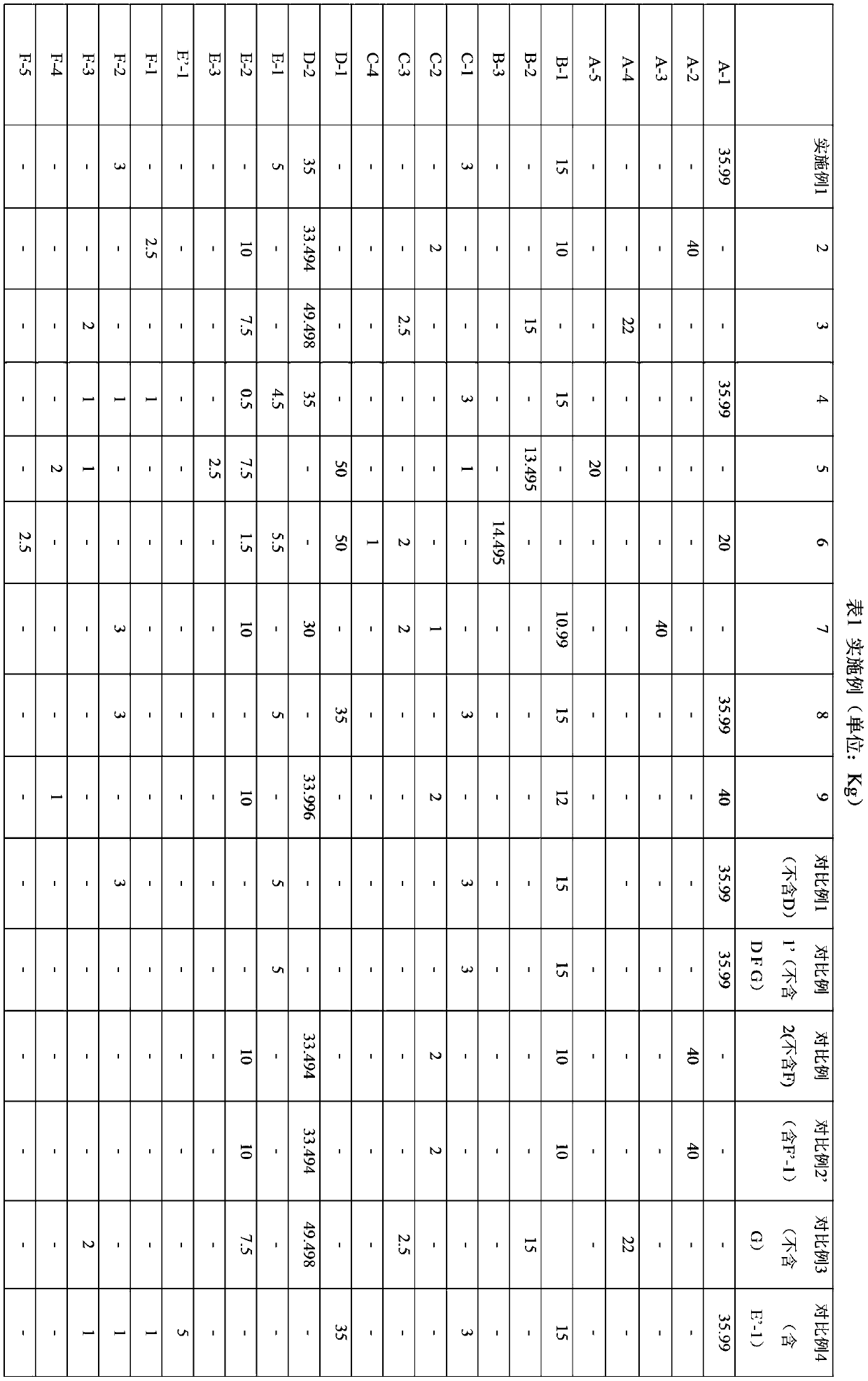

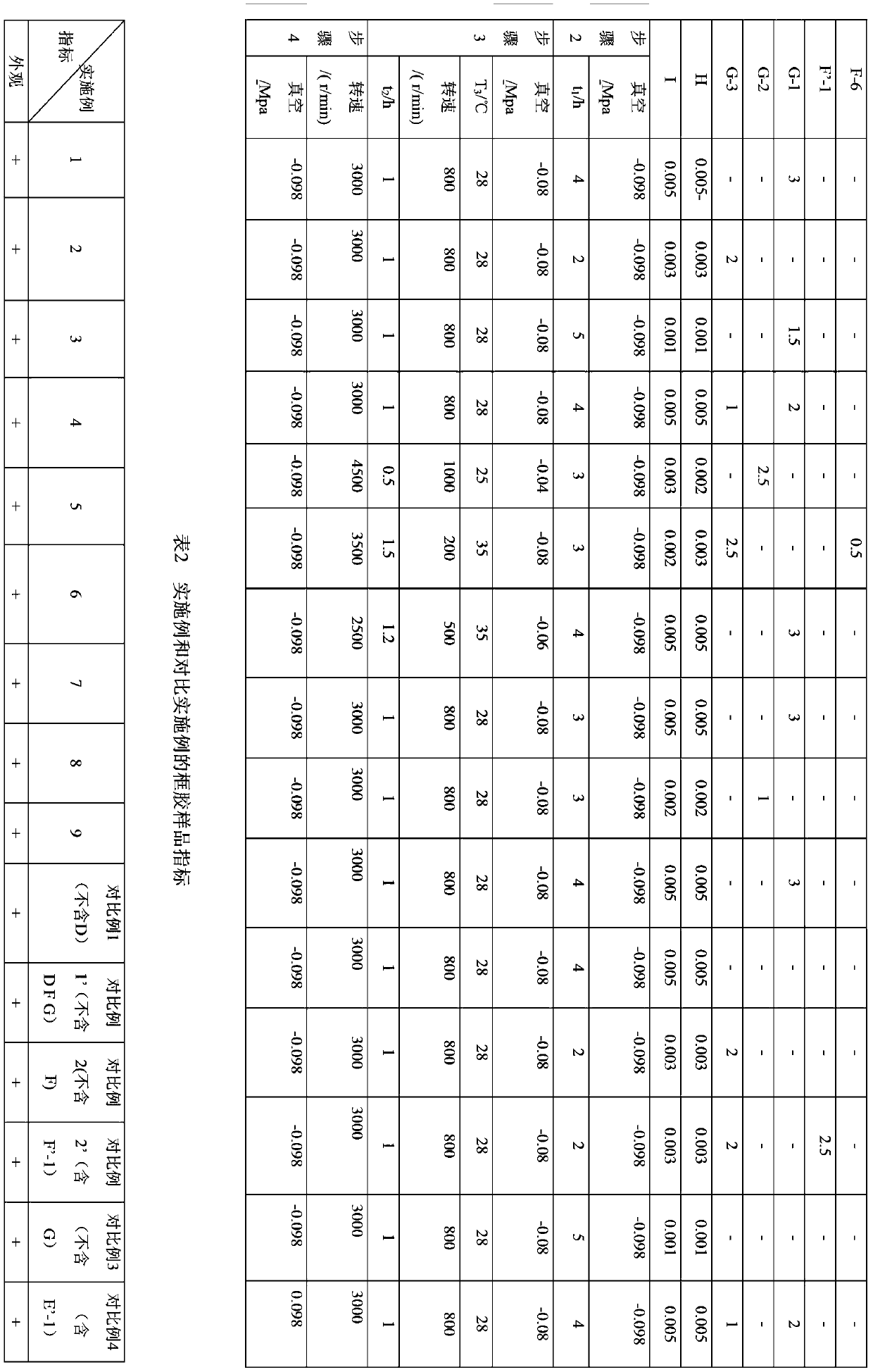

78results about How to "There will be no collapse" patented technology

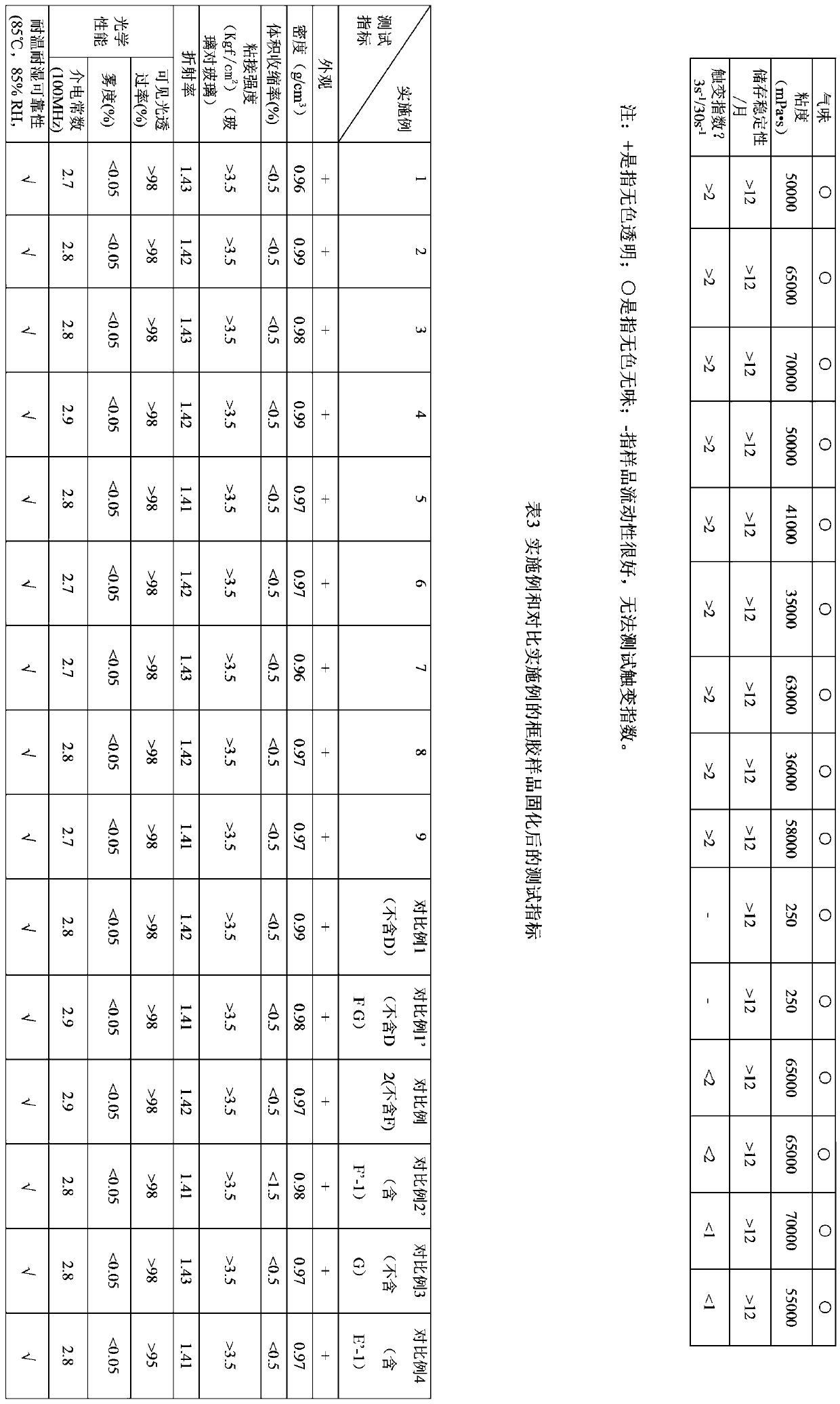

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

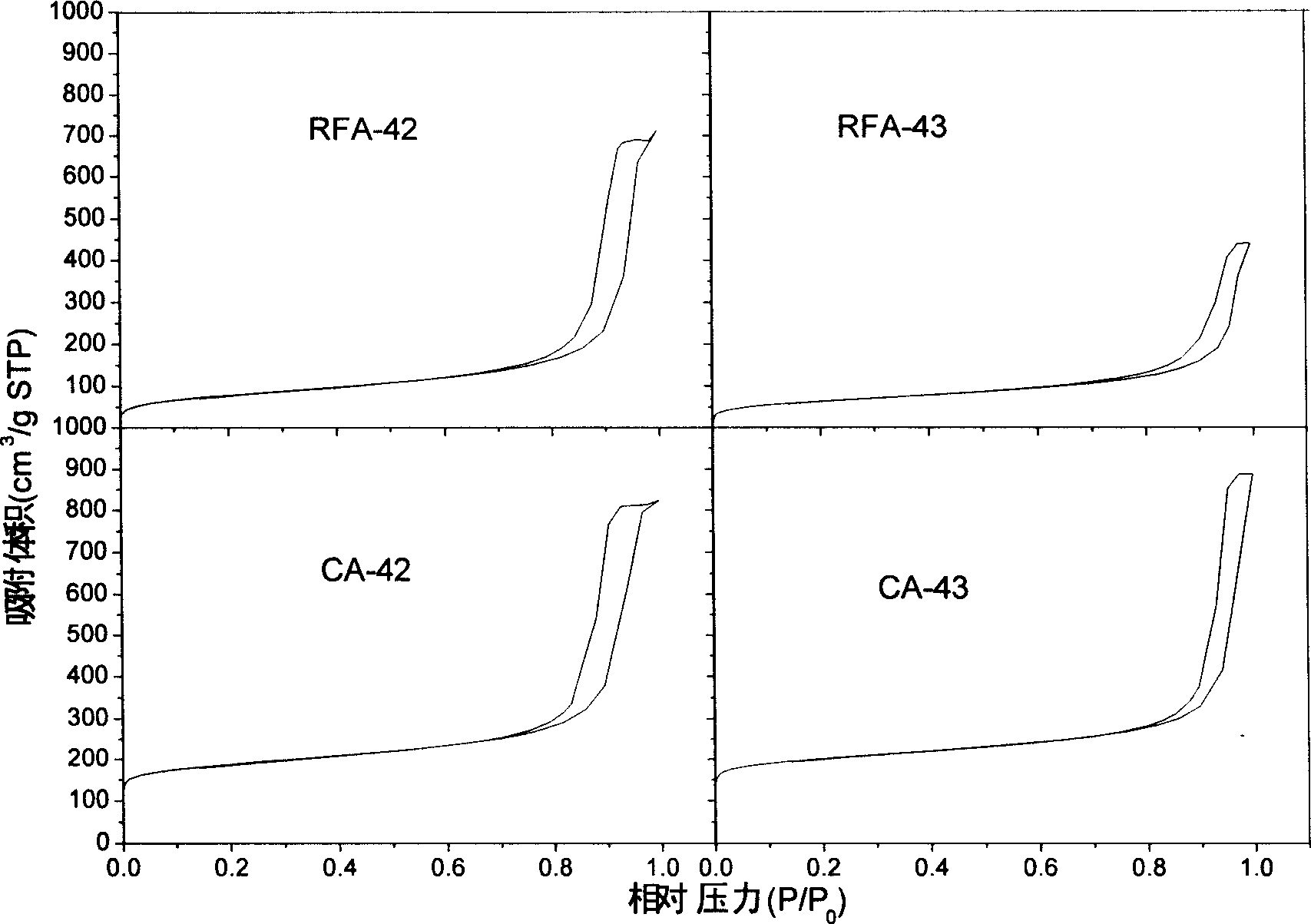

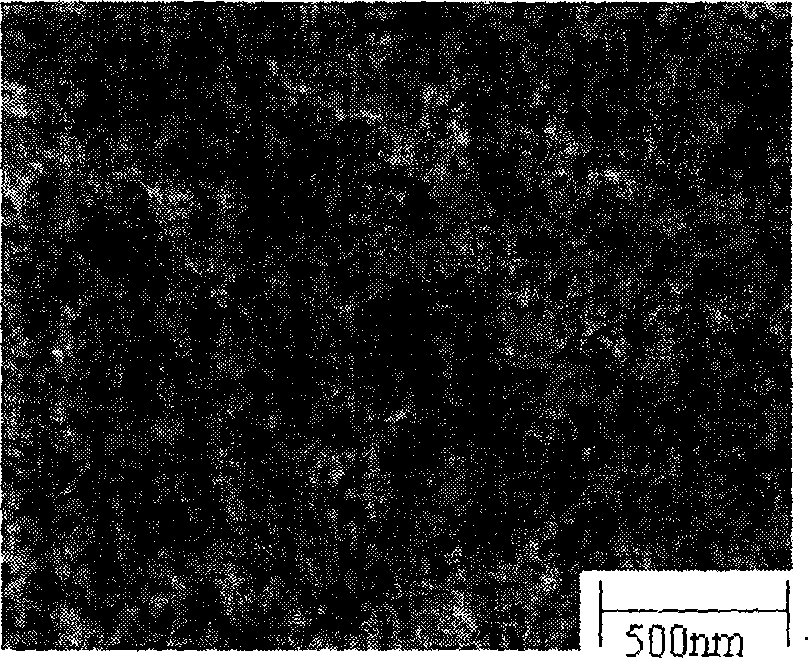

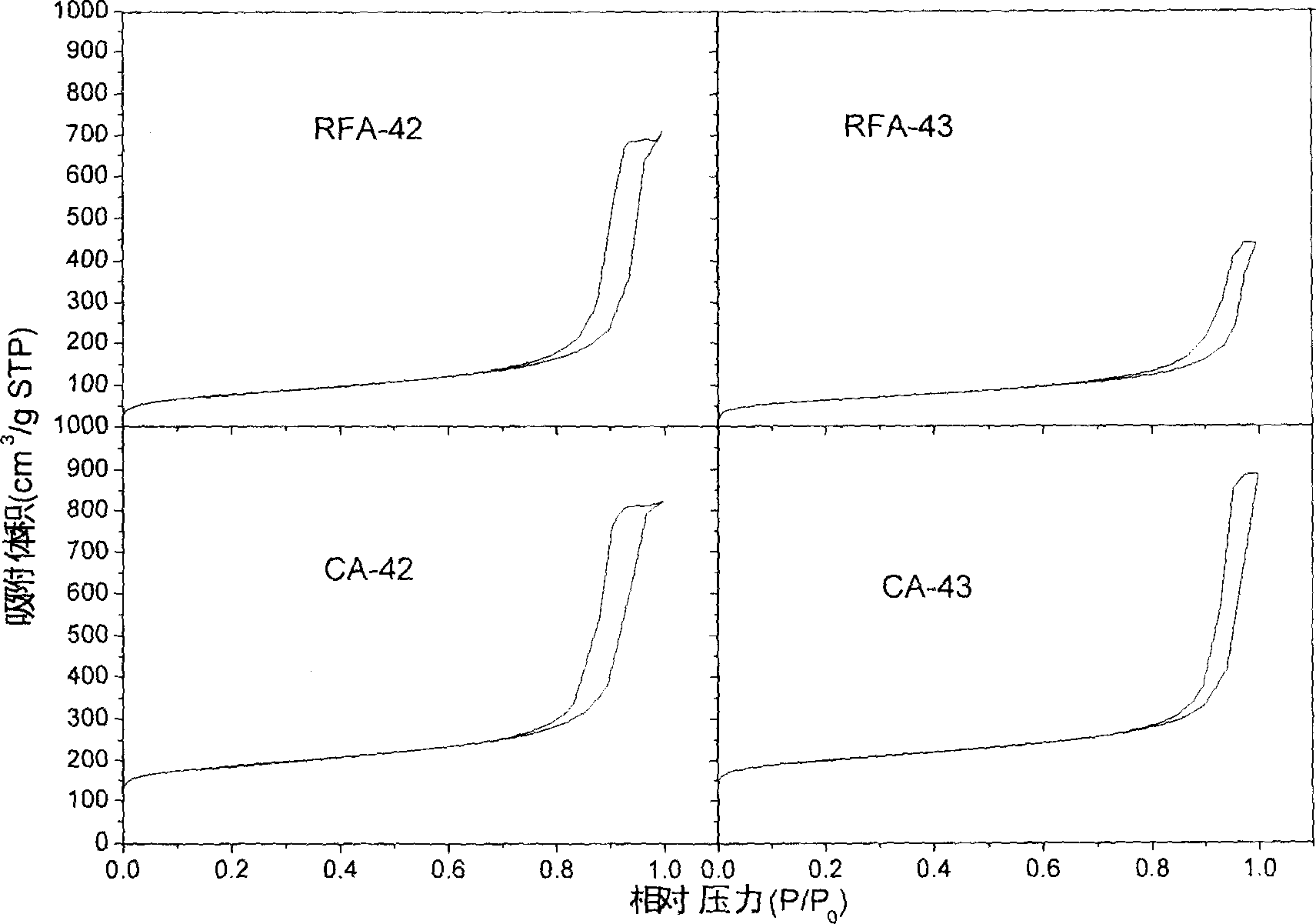

Method for preparing carbon gas gel

A process for preparing the organic aerogel and its carbon aerogel includes such steps as reaction between resorcin, formaldehyde, organic surfactant and catalyst in water, thermal solidifying to obtain organic gel, natural cooling or baking to obtain organic aerogel, and charring in inertial gas to obtain carbon aerogel.

Owner:SUN YAT SEN UNIV

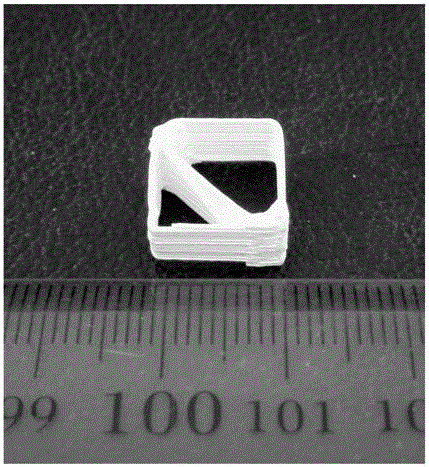

Lean ceramic powder size for direct-forming 3D ceramic printing as well as preparation method and application of lean ceramic powder size

ActiveCN106278201AAvoid post processingGood thinning performanceAdditive manufacturing apparatusRoom temperatureSolid content

The inventiondiscloseslean ceramic powder size for direct-forming 3D ceramic printing. The lean ceramic powder size is prepared from lean ceramic powder, a composite thixotropic agent, a dispersing agent, a thickening agent, a levelling agent and deionized water in a mass ratio being (65-75):(0.2-0.6):(0.9-1.3):(2.0-5.0):(0.5-1.5):(15-30); the lean ceramic powder is one or combination of Al2O3, ZrO2, SiC and Si3N4. The invention further discloses a preparation method and an application of the lean ceramic powder size. The lean ceramic powder size has high solid content and high shear thinning performance, is suitable for preparation of 3D printing ceramic devices with direction forming process and can be gradually dried and cured in a 3D printing process at the room temperature, and accordingly, a set structure is obtained without collapse, the printing precision is high, and the requirement for 3D printing direct-forming can be well met.

Owner:JINGDEZHEN CERAMIC INSTITUTE

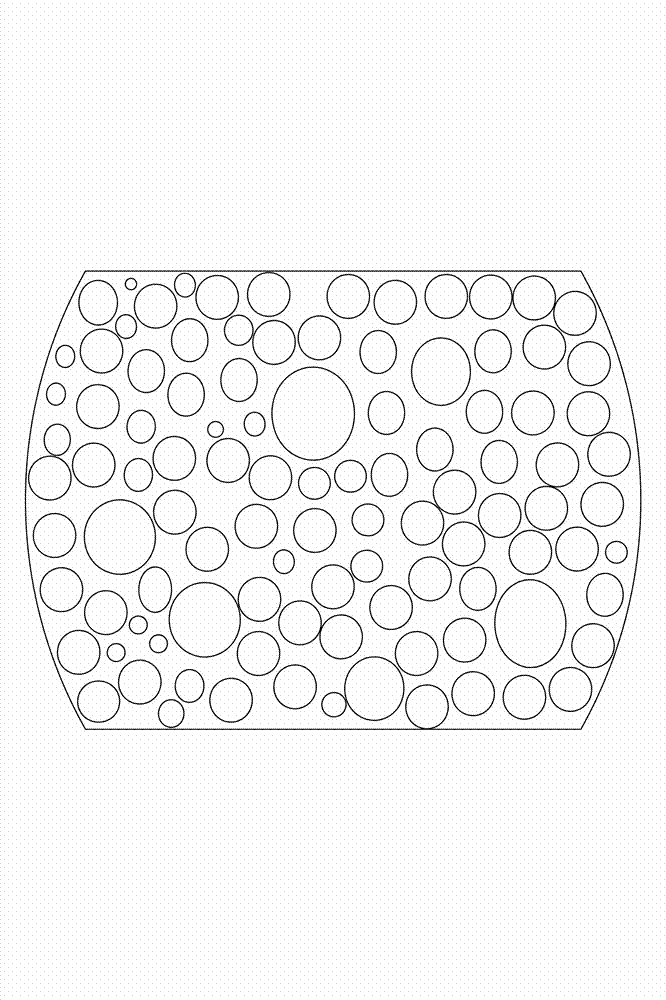

Bi-components for manufacturing polyurethane sole materials

The invention relates to bi-components for manufacturing polyurethane sole materials, wherein the raw material formula of a polyol component comprises polyester polyol, micromolecular polyol as a chain extender, a catalyst, a foaming agent and a foam homogenizing agent, wherein the foaming agent comprises water and azobisisobutyronitrile; the polyester polyol comprises polyglycol diethylene glycol sebacate polyol and polyglycol diethylene glycol succinate polyol; the micromolecular polyol is glycol; the catalyst is triethylene diamine; and the foam homogenizing agent is dimethyl siloxane. In the polyol component, the azobisisobutyronitrile and water are used together as the foaming agent, and the special combination of the polyester polyol, the chain extender, the foam homogenizing agent, the catalyst and the like is adopted, thus the problem of surface crusting of the polyurethane sole materials can be better solved; the surface of a manufactured sole is smooth, and the edges of the sole have thicker crusts to prevent the currency of sagging; and moreover, the sole has good and uniform elasticity and is soft and comfortable.

Owner:XUCHUAN CHEM KUNSHAN

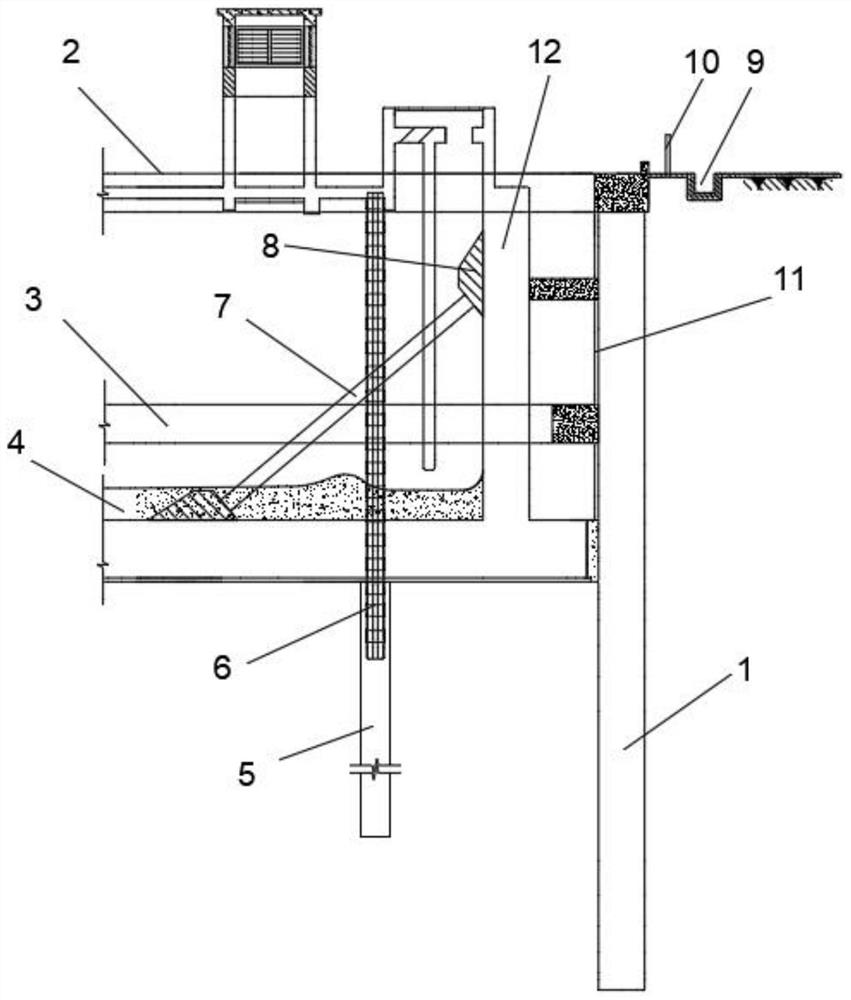

City road rainwater recovery system and method thereof

InactiveCN108221547AImprove resource utilization efficiencyAlleviate water scarcityFatty/oily/floating substances removal devicesSewerage structuresRoad surfaceEngineering

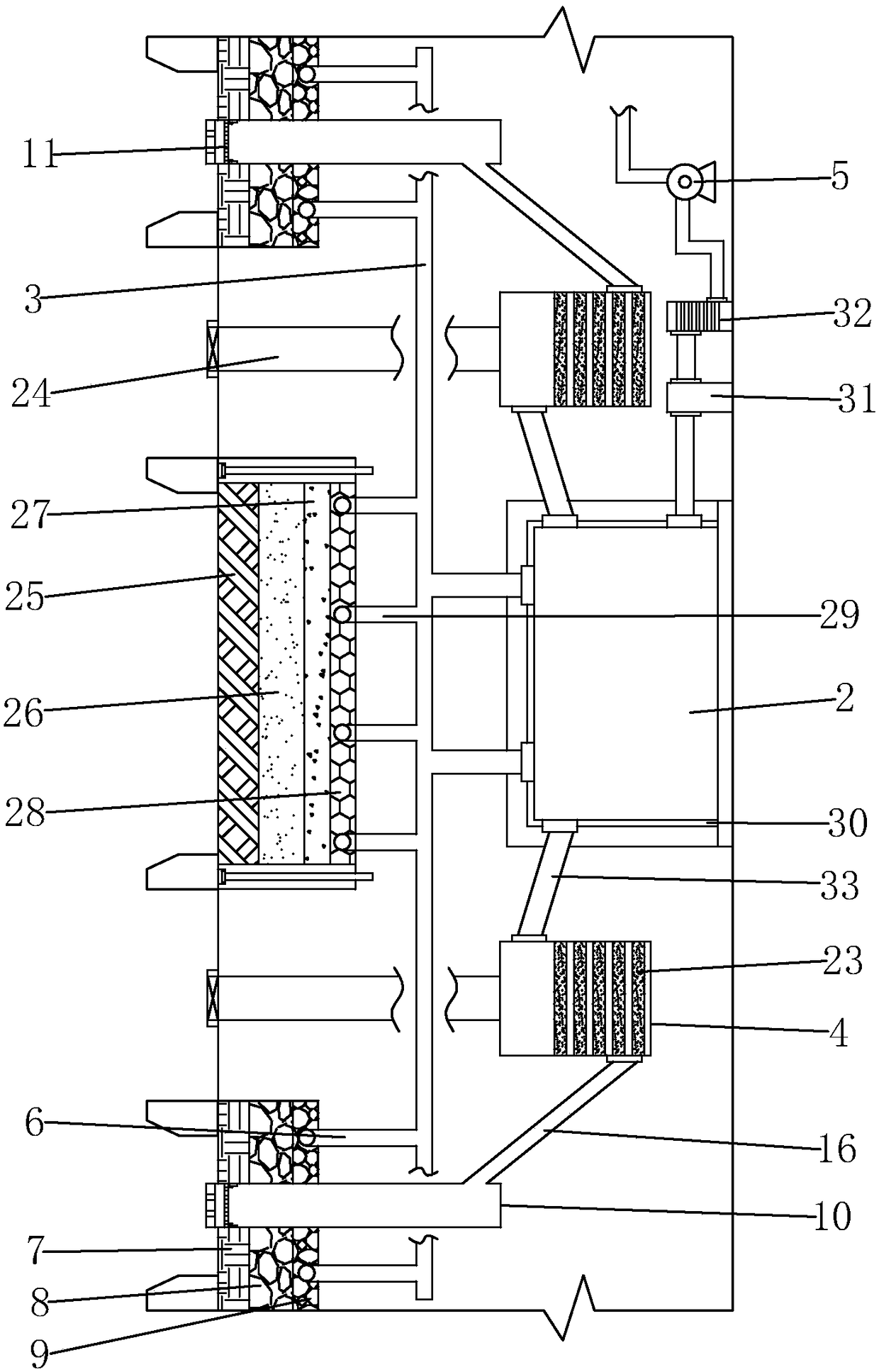

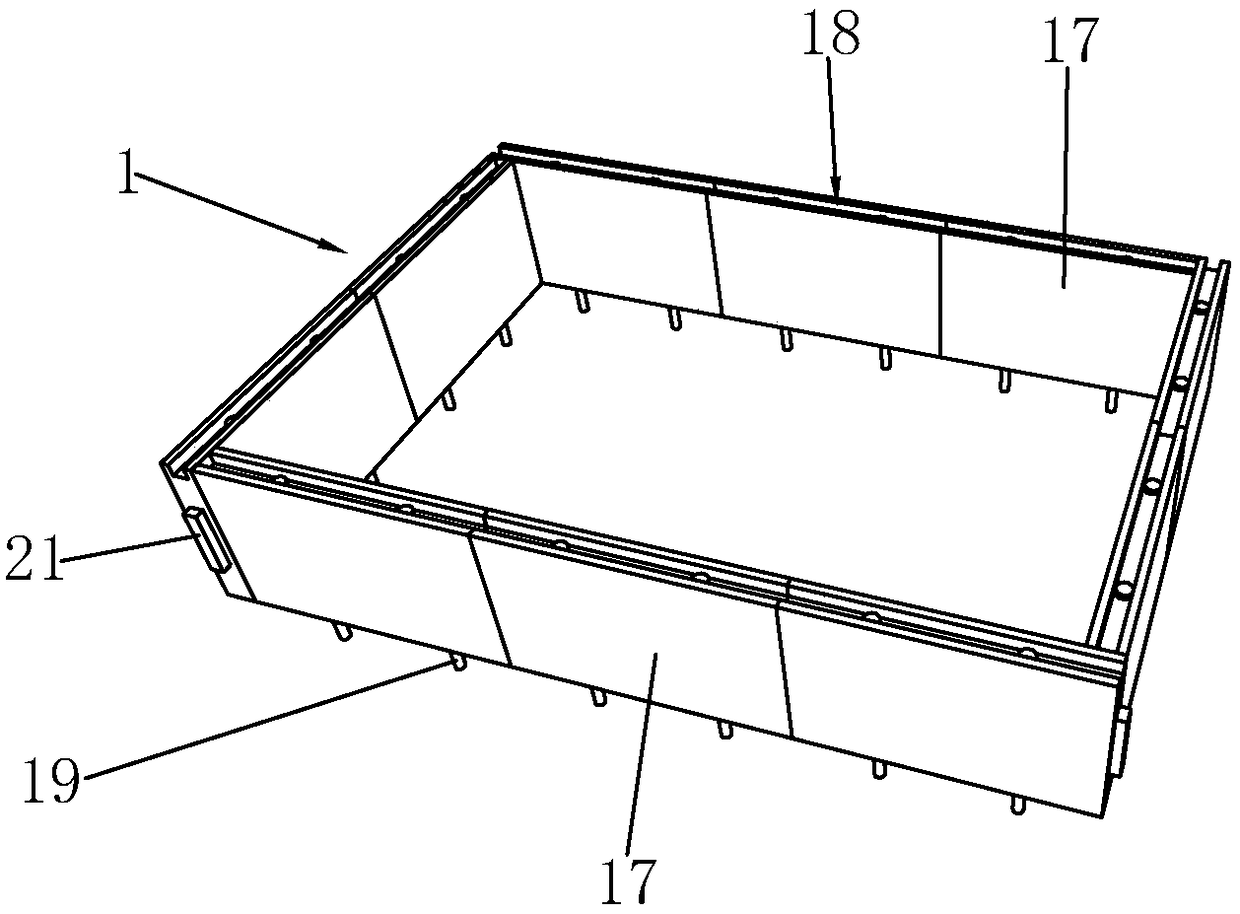

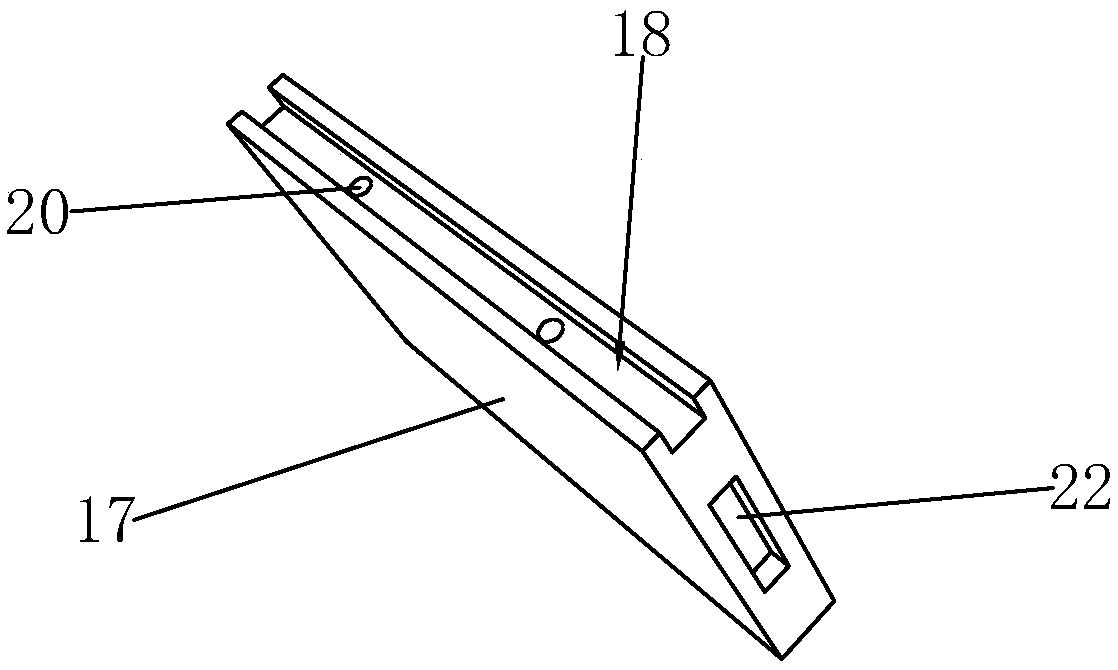

The invention discloses a city road rainwater recovery system and a method thereof. The recovery system comprises a soil-retaining frame, a bioretention zone, an ecological trench, a reservoir, a catchment main pipe, an adsorption pool, a water purification assembly, and an elevator pump, the water purification assembly is connected with the elevator pump, the catchment main pipe and the water purification assembly are communicated with the reservoir, an overflow well is arranged in the ecological trench, a filter sieve plate is arranged in the overflow well, sieve apertures are uniformly distributed on the filter sieve plate, and the bioretention zone is arranged in the soil-retaining frame. The method comprises the following steps: a) draining along a transverse direction; b) draining along a vertical direction; c) extraction and utilization; and d) regular maintenance. Through draining along the transverse direction and the vertical direction, the road draining speed is accelerated,the water amount accumulated on the road surface is reduced, appearance of a flood peak is avoided, waterlogging in the city can be effectively controlled, the rainwater can be filtered layer by layer and purified, and is stored in the reservoir, then the rainwater is lifted to ground through the elevator pump, secondary usage is carried out, and waste can be changed to valuables.

Owner:ZHEJIANG COLLEGE OF CONSTR

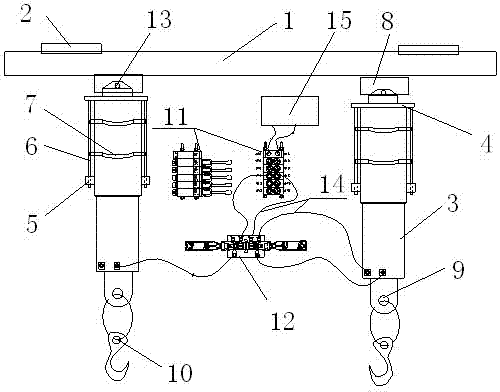

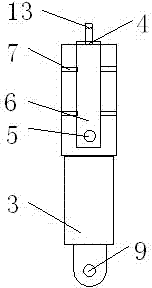

Convenient and fast hydraulic support lifting device

InactiveCN102756999AEasy to operateSave human resourcesLifting devicesHoisting equipmentsEngineeringJackscrew

The invention discloses a convenient and fast hydraulic support lifting device. The convenient and fast hydraulic support lifting device comprises two I-steel beams, wherein the upper parts of two ends of each I-steel beam are provided with fixed pallets, and the bottom of each I-steel beam is provided with two lifting ears which are symmetrically distributed. The convenient and fast hydraulic support lifting device is additionally provided with a pushing jack, wherein a telescopic part of the pushing jack is downward, the end of the telescopic part of the pushing jack is provided with a hook-headed pin hole, the hook-headed pin hole is connected with a lifting hook head, the top of the pushing jack is provided with a fixed seat, the fixed seat is provided with pin holes, through pins of the lifting ears pass through the pin holes, and a fixed ear of the pushing jack and the fixed seat are connected with each other through a fixed pull rod. The convenient and fast hydraulic support lifting device adopts the structure that the pushing jack is connected to the I-steel beams to enable the pushing jack to be used as a lifting tool, so that in the whole lifting process, a fixed 6.8-ton support can be lifted through a control button only by a driver skilled in an emulsion pump, and the convenient and fast hydraulic support lifting device is convenient in operation, saves a large number of human resources, and is safe and reliable.

Owner:GUIZHOU YONGRUN COAL IND

Gabion retaining wall construction method applied to bank slope protection

ActiveCN107859055AReduce construction costsSimple technologyArtificial islandsCoastlines protectionEngineeringGabion

The invention discloses a gabion retaining wall construction method applied to bank slope protection. The method comprises the steps of (a) excavation of a foundation pit, (b) reinforcement of the foundation pit, (c) gabion rock filling, (d) backfilling, (e) afforesting and (f) monitoring and measurement. The method includes few construction procedures and is convenient to operate, low in cost, high in environmental affinity, high in overall construction efficiency and easy in quality and safety control, the construction progress can be accelerated through cooperation of manpower and machinery, the good economic benefit can be obtained, and the method is suitable for more projects, has the broad application prospect and is worthy of popularization and application.

Owner:浙江永安工程咨询集团有限公司

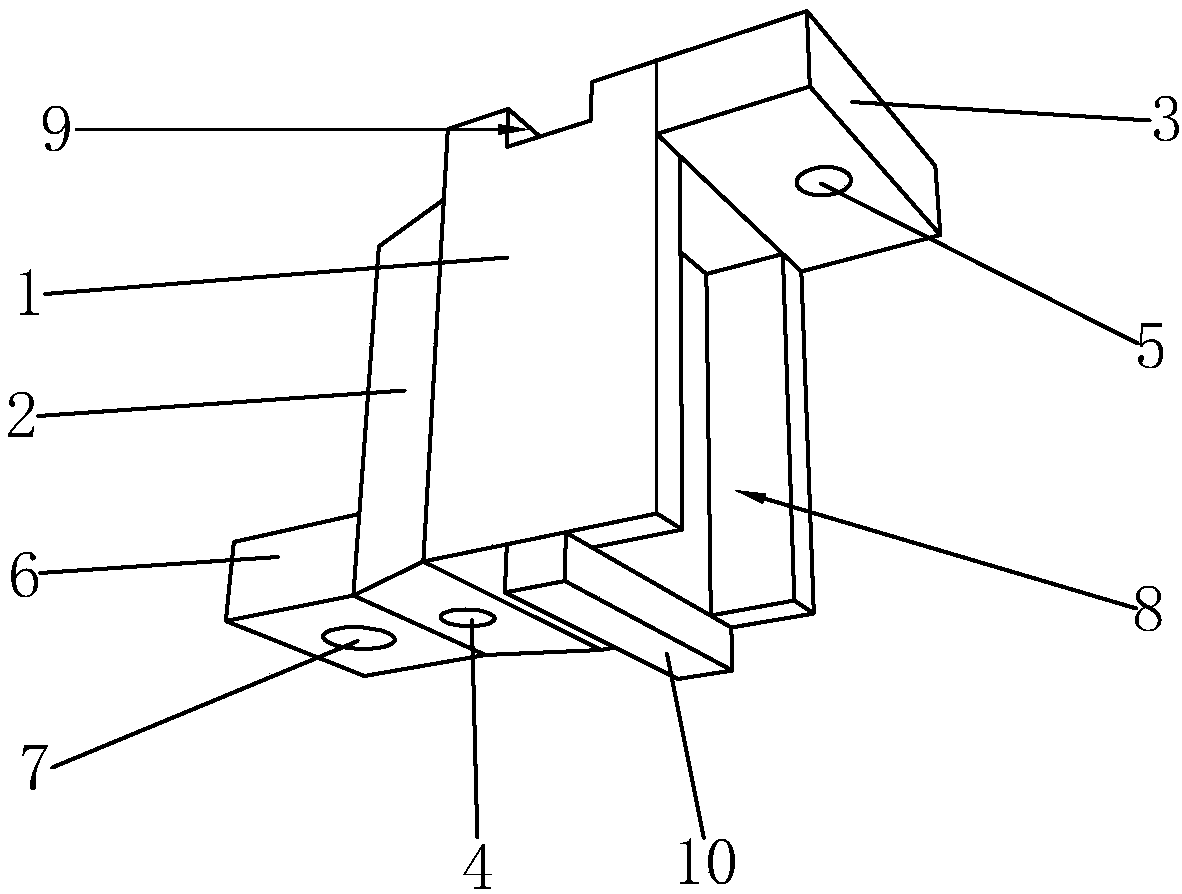

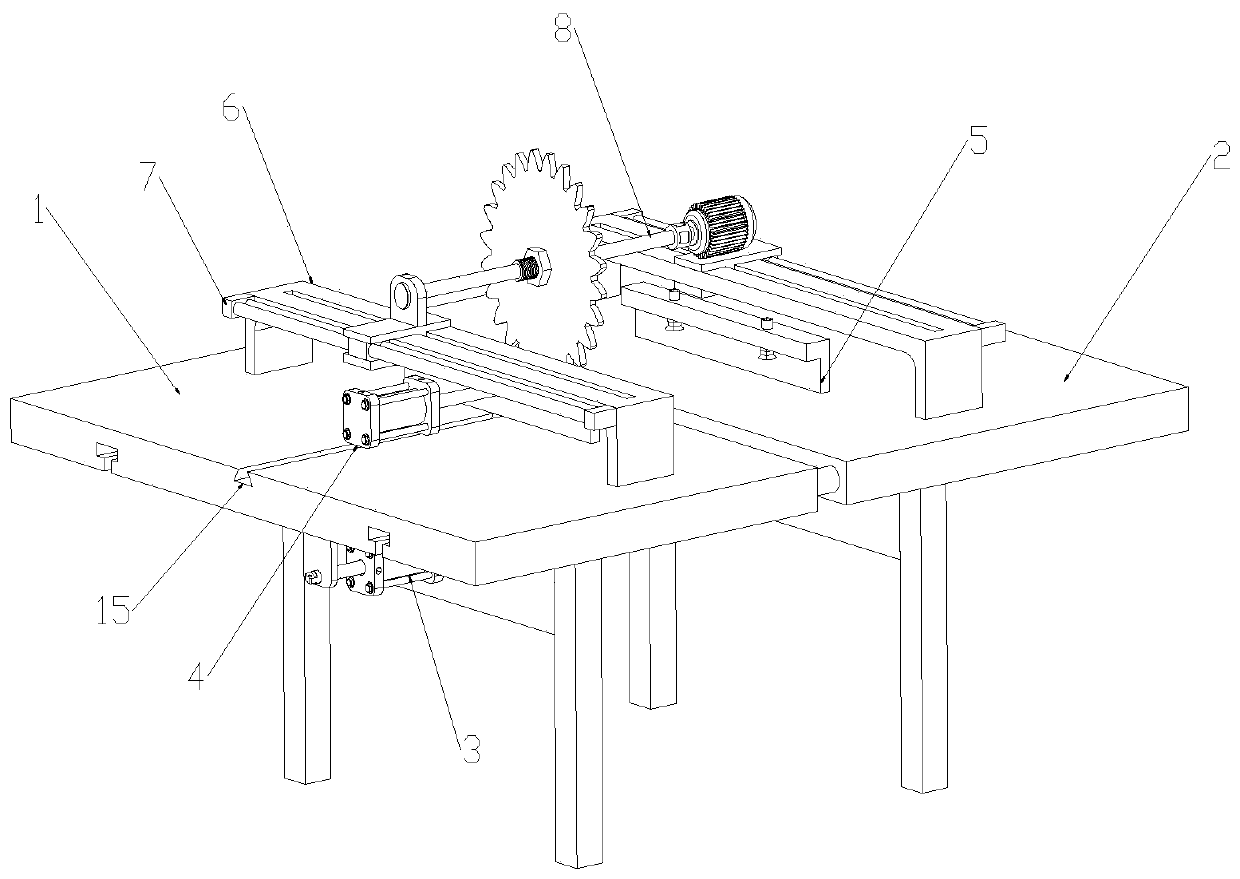

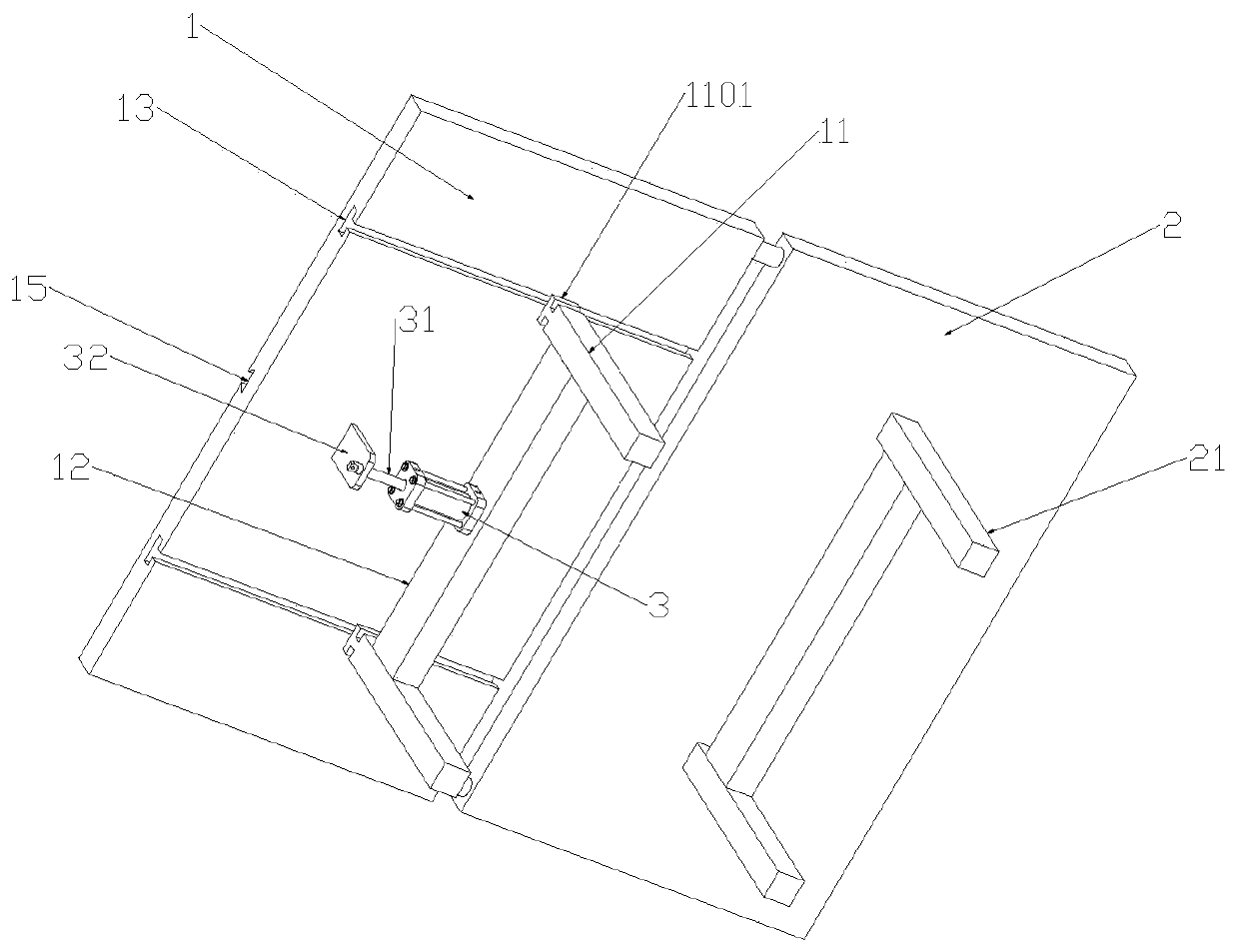

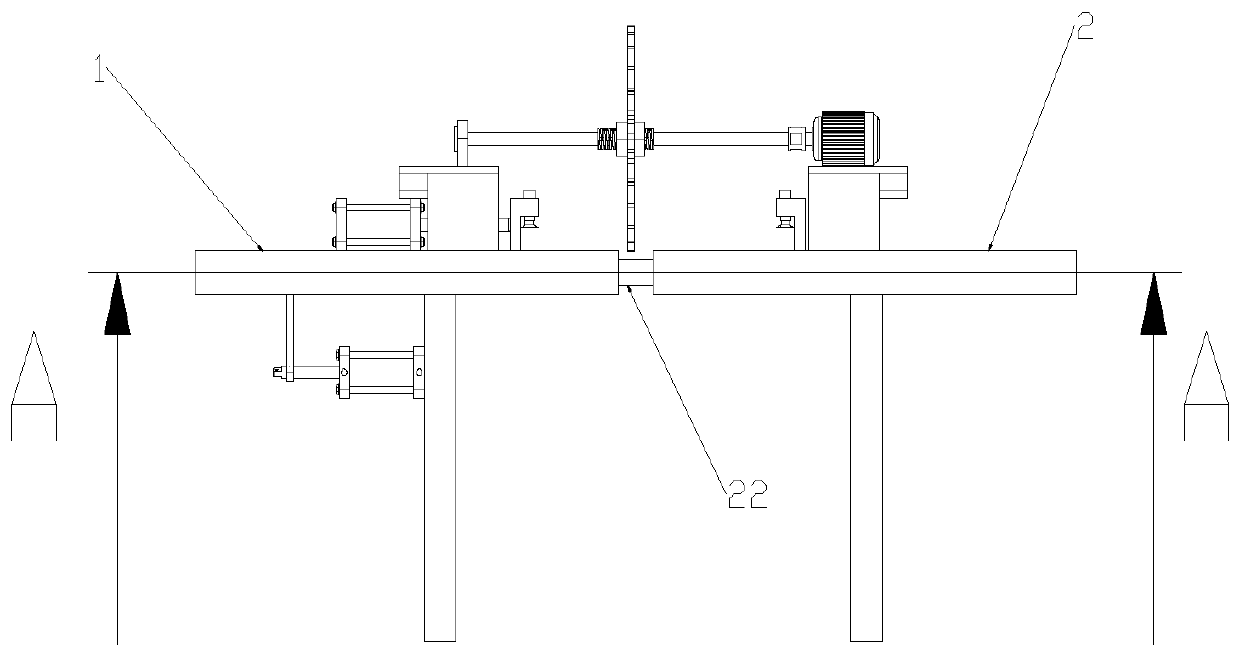

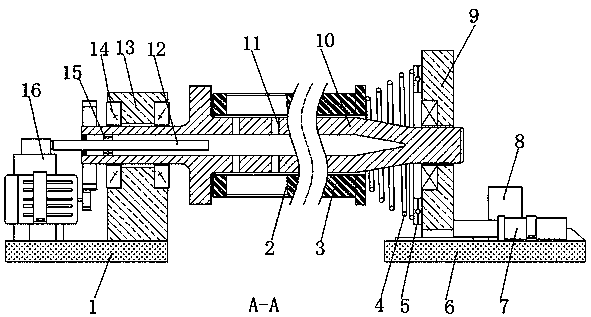

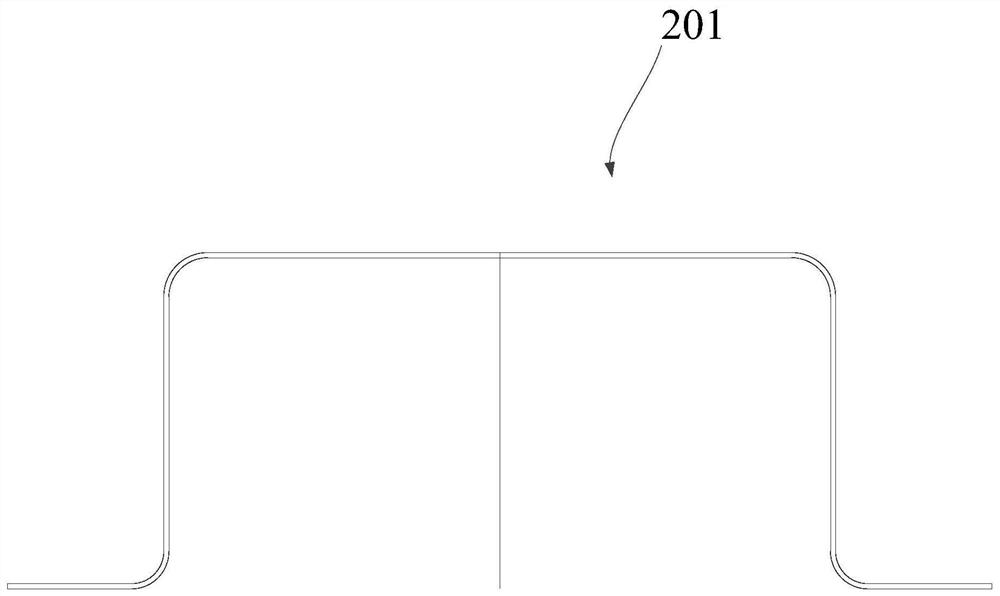

Automatic cutting device for producing and processing plate material through mold

ActiveCN109968425AEasy to operateThere will be no collapseMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic cutting device for producing and processing a plate material through a mold. The automatic cutting device comprises a first platen and a second platen, a dovetailgroove is formed in the middle position of the upper surface of the first platen, the upper end of the dovetail groove is provided with a second cylinder fixed to the upper end of the first platen, and one end of the second cylinder is connected with a clamping piece. Support frames provided with limiting grooves in the middle portions are fixed to the upper ends of the first platen and the secondplaten, linear electric cylinders are fixed to the side ends of the support frames, I-shaped bodies are fixed to the side ends of electric cylinder sliders, the upper ends of the I-shaped bodies arefixedly provided with cutting mechanisms. After cutting is completed, transverse positioning disappears, longitudinal positioning does not change, the plate material does not collapse, and the personal safety of an operator is not threatened; and meanwhile, when the width of the cut plate material needs to be changed, the position of a fastening nut is adjusted, the appropriate distance between acutting wheel and a clamping plate is obtained through measurement, the desired width of the plate material after cutting is obtained, and operation is convenient.

Owner:铜陵中锐电子科技有限公司

Textile use coiling block facilitating fabric winding

The invention discloses a textile use coiling block facilitating fabric winding. The textile use coiling block facilitating fabric winding comprises a fixed bottom plate; a perpendicular vertical plate is welded to the outer wall of the side, close to a track base plate, of the upper surface of the fixed bottom plate; the middle portions of the outer walls of the two sides of the perpendicular stand plate are each provided with a counter bore; conical roller bearings are embedded in the two counter bores; a same driving roller is rotationally connected between the inner circles of the two conical roller bearings, and is of a cylindrical structure internally provided with a cavity, and an opening is reserved in one end of the driver; a centripetal bearing is connected to the circumferentialinner wall of the position, close to the opening, of the driving roller in a clamped manner; a gas sucking pipe is inserted and connected to the inner ring of the centripetal bearing; the circumferential outer wall of the driving roller is sleeved with a sleeve; and rectangular holes are formed in the circumferential outer wall of the sleeve and distributed alternately at equal intervals. According to the textile use coiling block facilitating fabric winding, the cloth head of to-be-wound fabric can be closely adsorbed in a strip-shaped hole, the fabric can be closely attached to the circumferential outer wall of a coiling block at the starting end of fabric coiling, it is guaranteed that a finished fabric coil is more close, and the using amount of the coiling block is reduced.

Owner:盐城融凡纺织制衣有限公司

Method for rehabilitation and preservation of exsiccate specimen of large-sized marine fishes

InactiveCN1996431AEasy to fixEasy to storeSpecial ornamental structuresDead animal preservationEpoxySurface ocean

The rehabilitation and storage method for large scale sea fishes dry specimen is proceeded with the cleaning of the specimen, unsaturated epoxide resin to stick the incomplete position, polishing the notch, stuffing the inside with PVC aggregates, using unsaturated sticking the notch, making up the color, and lubricating it. This method is easy in rehabilitation, with easy preservation, firm and elegant.

Owner:SOUTH CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

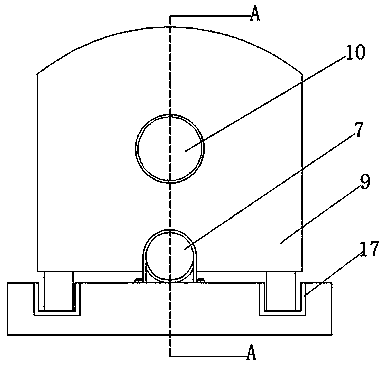

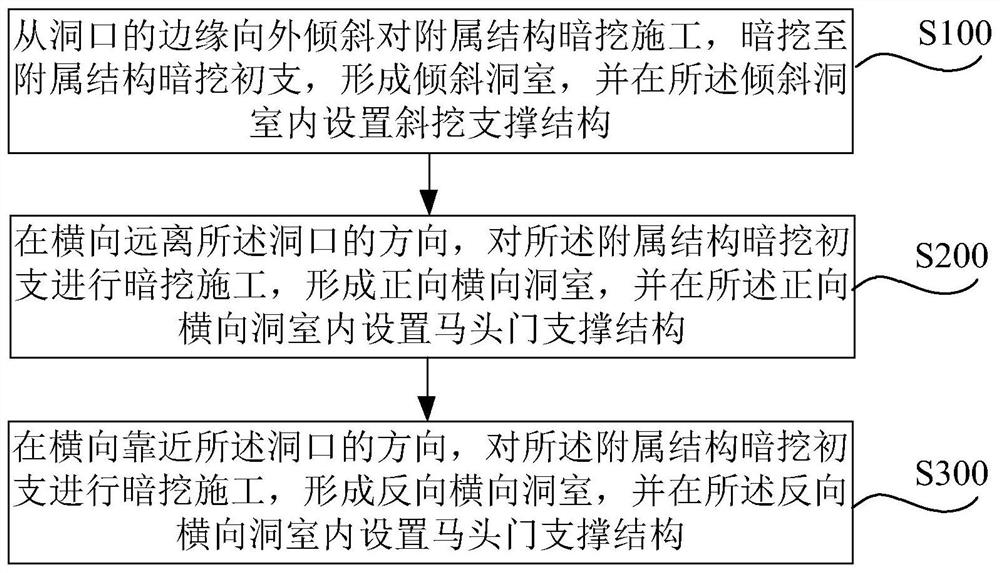

Underground excavation tunnel ingate construction method

InactiveCN111720126ANo collapseThere will be no collapseUnderground chambersTunnel liningAccessory structureArchitectural engineering

The embodiment of the invention provides an underground excavation tunnel ingate construction method. The method comprises the following steps that underground excavation construction is carried out on an accessory structure in a manner of inclining outwards from the edge of an opening, underground excavation is carried out until an accessory structure underground excavation primary support to form an inclined cavern, and an inclined excavation supporting structure is arranged in the inclined cavern, wherein the opening is adjacent to the accessory structure, a section of the accessory structure is larger than a section of the opening, and the accessory structure underground excavation primary support is located on the periphery of the accessory structure; underground excavation construction is carried out on the accessory structure underground excavation primary support in a direction away from the opening transversely, a forward transverse cavern is formed, and an ingate supporting structure is arranged in the forward transverse cavern; and underground excavation construction is carried out on the accessory structure underground excavation primary support in a direction close tothe opening transversely, a reverse transverse cavern is formed, an ingate supporting structure is arranged in the reverse transverse cavern, and an underground excavation primary support space is formed in the transverse direction. According to the method, the technical problem that traditional underground excavation tunnel ingate construction is not suitable for forming an ingate from a small section to a large section is solved.

Owner:CHINA RAILWAY FIFTH SURVEY & DESIGN INST GRP

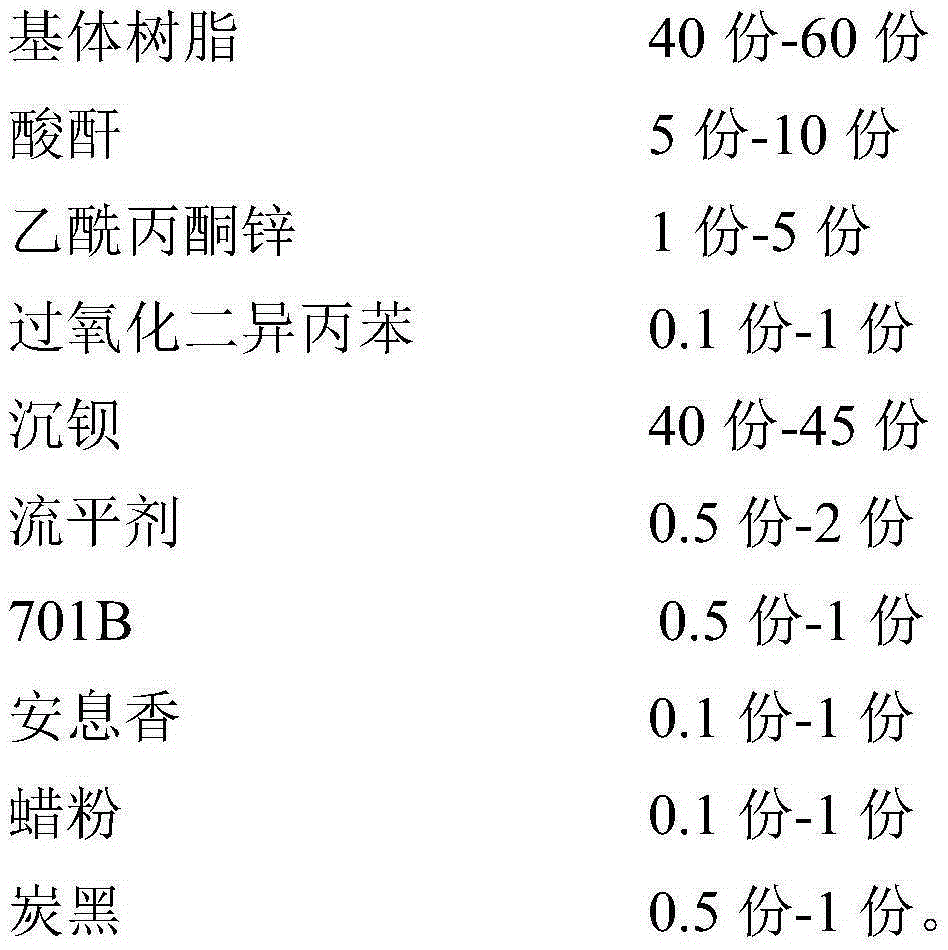

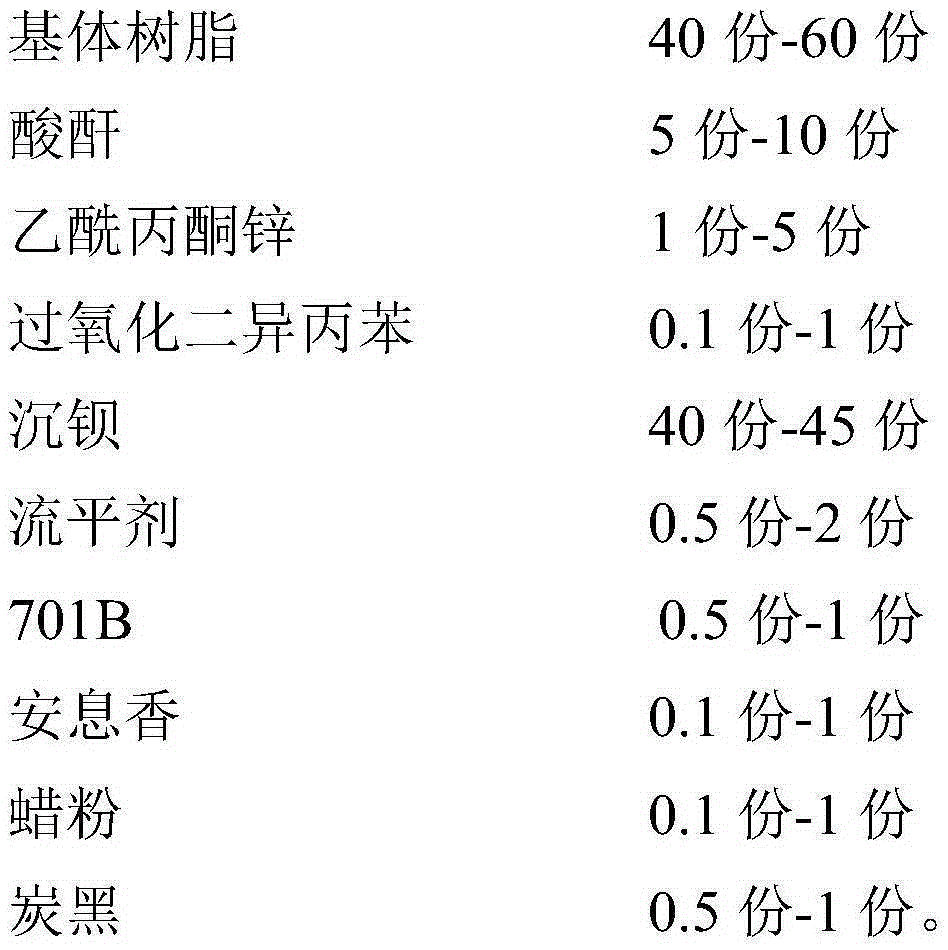

Epoxy powder coating with self-repairing function and preparation method thereof

ActiveCN105400377AImprove mechanical propertiesLong storage periodAntifouling/underwater paintsPaints with biocidesGlass transitionRaw material

The invention discloses an epoxy powder coating with a self-repairing function and a preparation method thereof. The epoxy powder coating is prepared from the following raw materials (by weight): 40-60 parts of matrix resin, 5-10 parts of acid anhydride, 1-5 parts of zinc acetylacetonate, 0.1-1 part of dicumyl peroxide, 40-45 parts of precipitated barium, 0.5-2 parts of a leveling agent, 0.5-1 part of 701 B, 0.1-1 part of benzoin, 0.1-1 part of wax powder and 0.5-1 part of carbon black. The matrix resin is matrix resin with an allyl structure. Free radical polymerization is initiated through the allyl structure and dicumyl peroxide to raise crosslinking density and glass transition temperature of epoxy resin, and self-repairing performance of the epoxy powder coating is improved through ester group dynamic crosslinking. The preparation method of the epoxy powder coating is simple to operate, is low-cost and is suitable for industrial production.

Owner:南通南京大学材料工程技术研究院

Method for preparing carbon gas gel

The invention relates to a normal-pressure drying preparation method of organic airgel and carbon airgel thereof. This method takes resorcinol and formaldehyde as reaction monomer, organic surfactant (for example, hexadecyltrimethylammonium bromide, sodium laurylsulfonate) as emulsifier and catalyst, water is solvent, The hydrogel is cured by heating; then, the organic aerogel can be obtained by directly drying naturally or by heating. Moreover, the carbonized aerogel with high specific surface area can be obtained by carbonizing the organic aerogel in an inert atmosphere. The preparation process of the organic aerogel and the carbon aerogel proposed by the invention is simple and fast, requires low equipment and is environmentally friendly, and is expected to realize the industrialized production of the carbon aerogel.

Owner:SUN YAT SEN UNIV

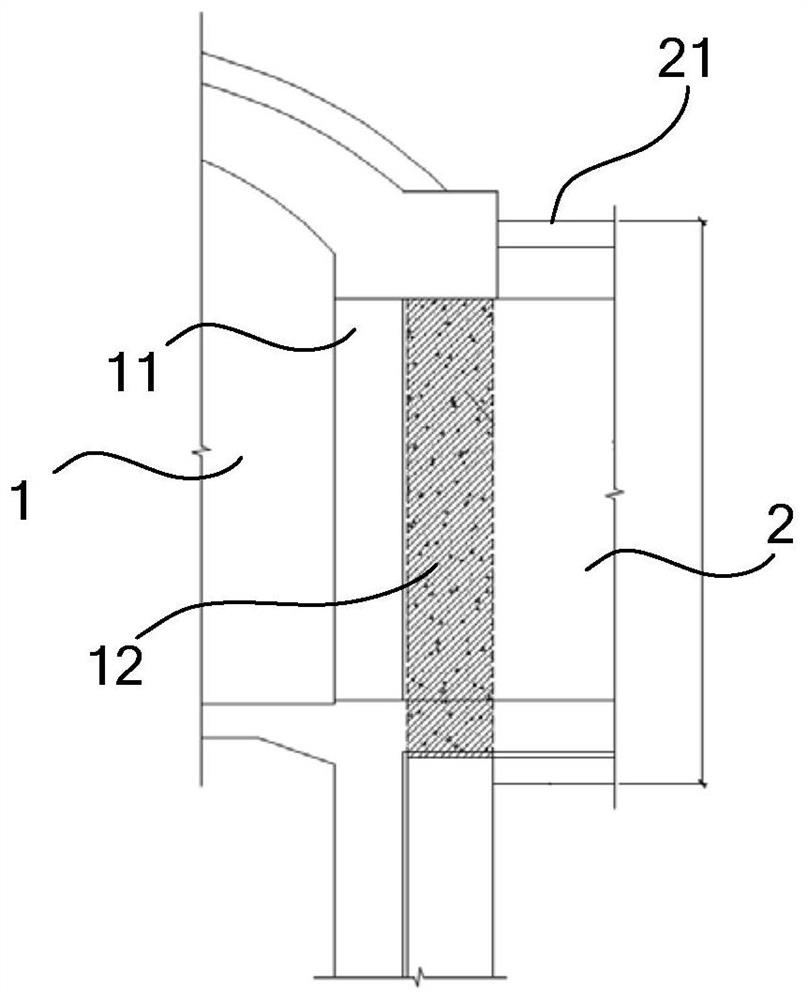

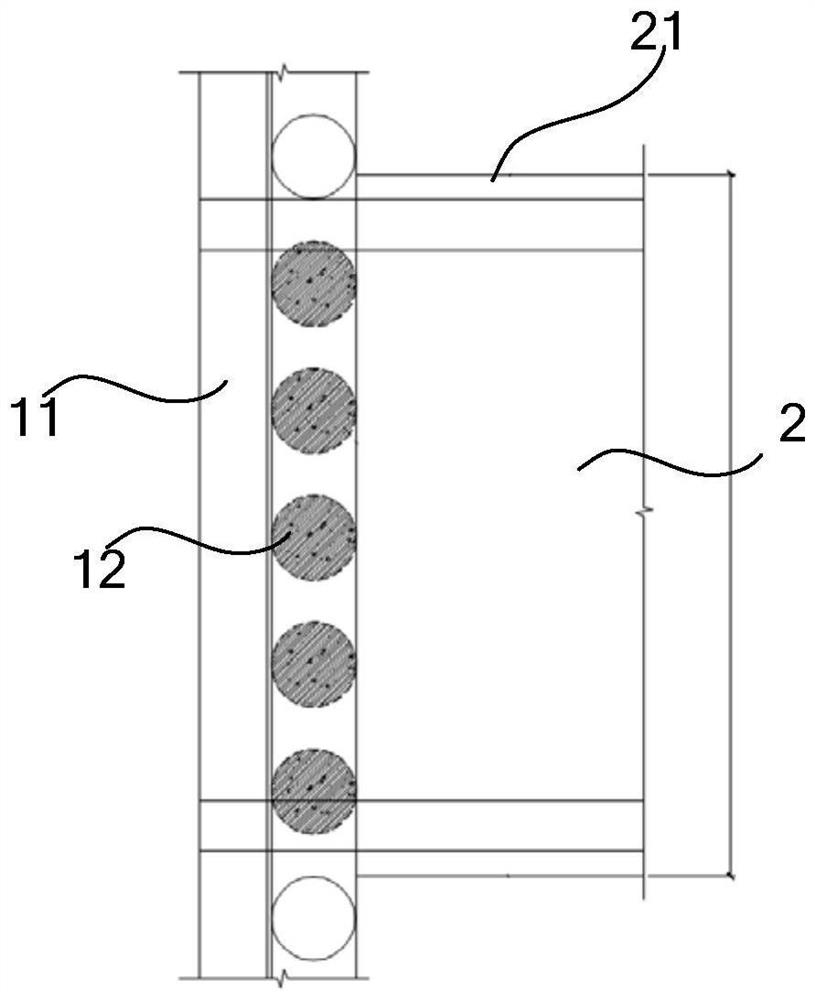

Dust collector filtering bag component and cloth bag dust collector

InactiveCN106731294AThere will be no collapseReduce volumeDispersed particle filtrationMembrane filtersFiltrationBaghouse

The invention discloses a dust collector filtering bag component and a cloth bag dust collector. The dust collector filtering bag component comprises filtering bags and a cage framework, wherein the filtering bags comprise an external filtering bag body, an inner filtering bag body and a connecting bag body, so that four cylinder-shaped filtering surfaces are formed; the cage framework comprises an upper flange cylinder, an outer support rod, an inner support rod and an inner sleeve rod; the outer support rod is inserted between the external filtering bag body and an outer connecting bag wall; the inner support rod is inserted between the inner filtering bag body and an inner connecting bag wall; a circular pressing plate is fixed at the upper end part of the inner sleeve rod; the upper end of the inner sleeve rod penetrates through the inner sealing plate and is fixed through a screw nut; the pressing plate is matched with an inner sealing plate part to press the upper sealing part of the inner filtering bag body; the lower end of the inner sleeve rod is bent upwards to form a support rod section; the support rod section is used for supporting the inner connecting bag wall of the connecting bag body. Compared with a conventional filtering bag component, the dust collector filtering bag component has the advantages that the filtration area is increased and the filtration efficiency is improved.

Owner:苏州海蓝环保科技有限公司

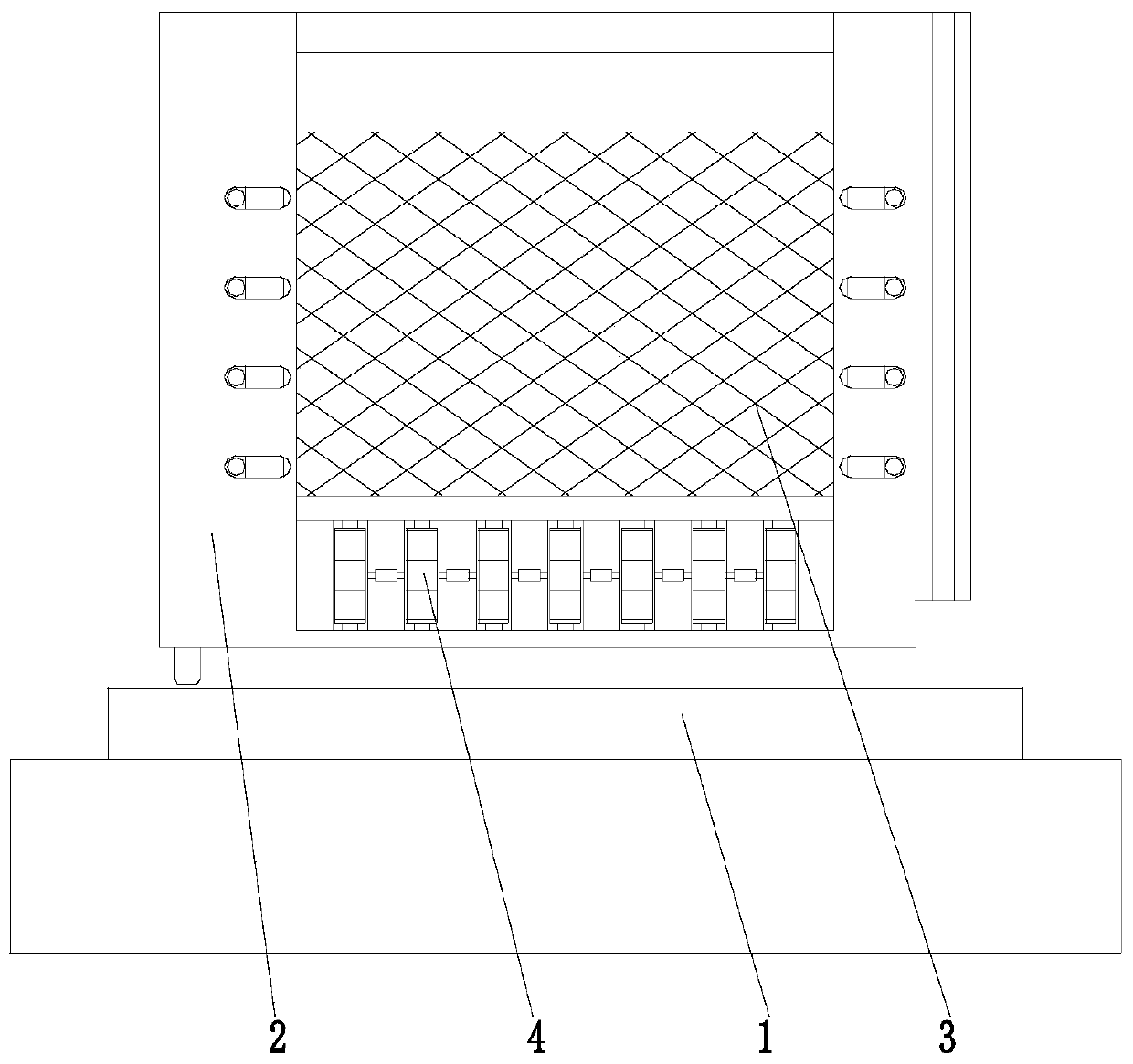

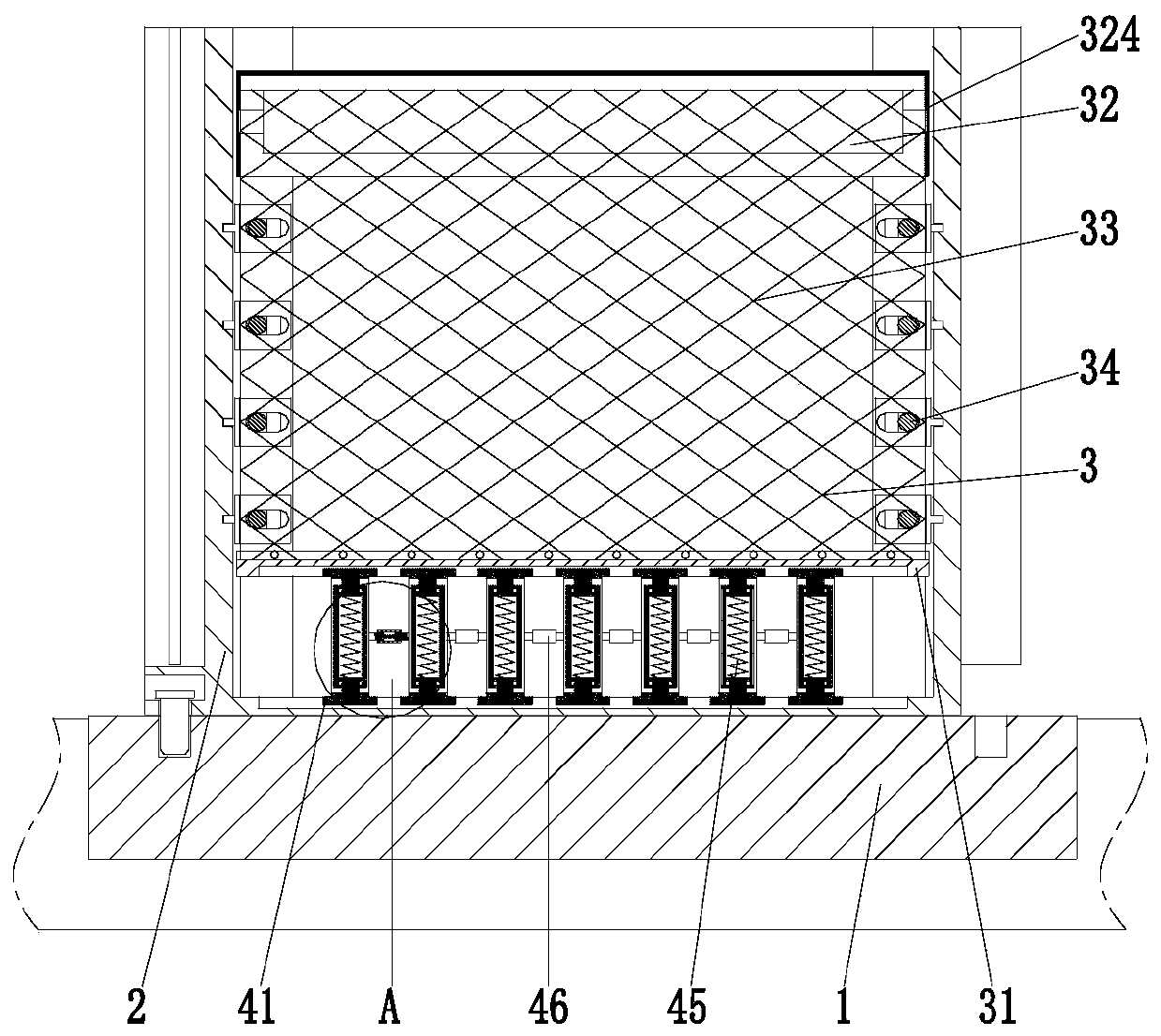

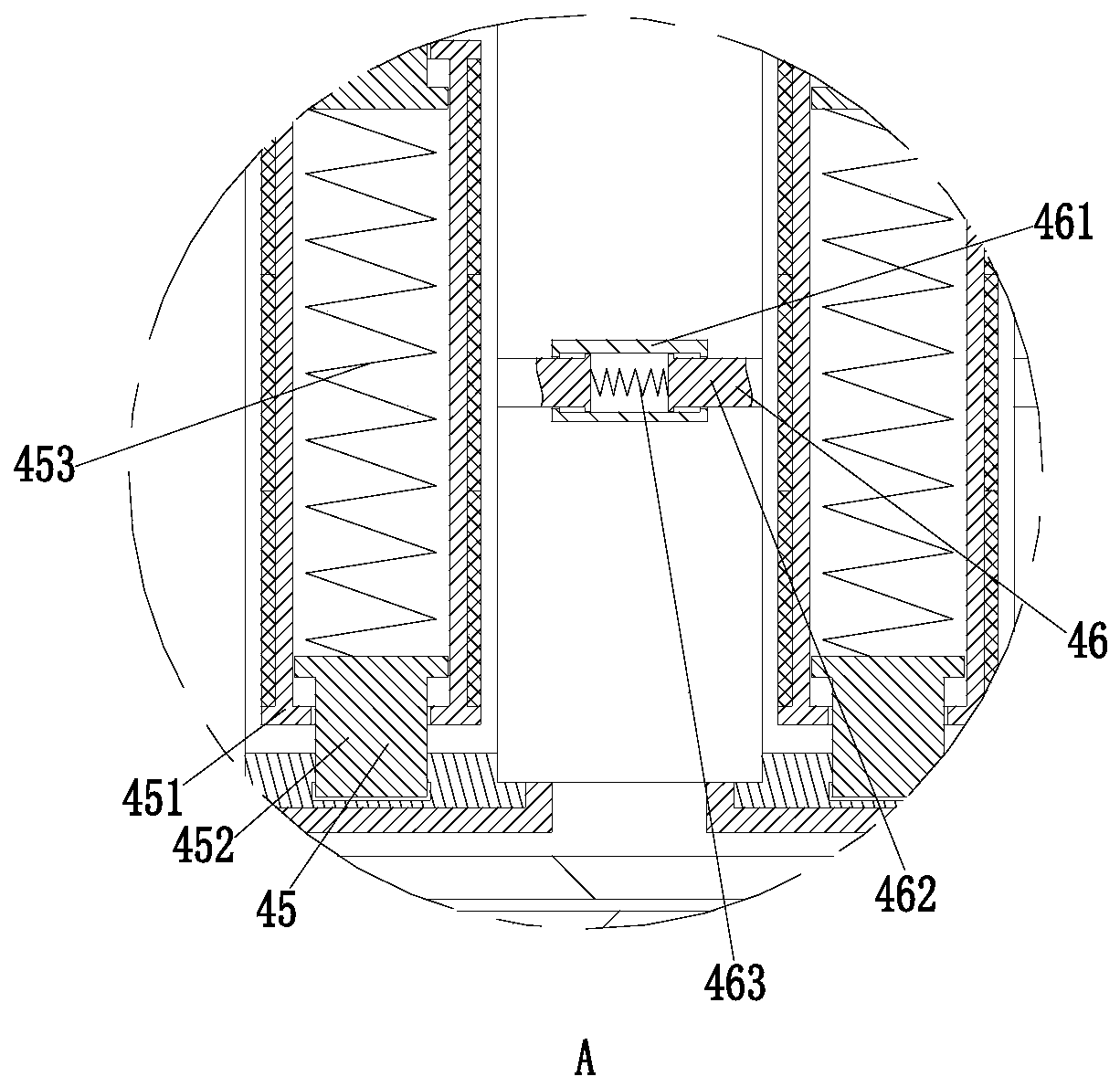

Highway municipal guardrail and construction method thereof

ActiveCN110528424ASolve the prone to collapseAdjustable distanceRoadway safety arrangementsTraffic accidentEngineering

The invention provides a highway municipal guardrail and a construction method thereof. The guardrail comprises a base, a frame, a grid unit and an anti-collision unit. The guardrail can solve the problems that existing guardrails are easy to collapse, the fixed guardrails are most poured with cement so as to be inconvenient to move, and the guardrail which is damaged due to traffic accidents is inconvenient to replace; protective nets of the guardrails used for a long time can be damaged, the damaged guardrails need to be replaced integrally, replacement is troublesome on the other hand, andthe replacement cost is high on the other hand; and in addition, the existing guardrails are made of steel materials, and the damage to automobiles and the damage to drivers and passengers caused by collision between the automobiles and the guardrails are very large.

Owner:武汉精杰重型工程有限公司

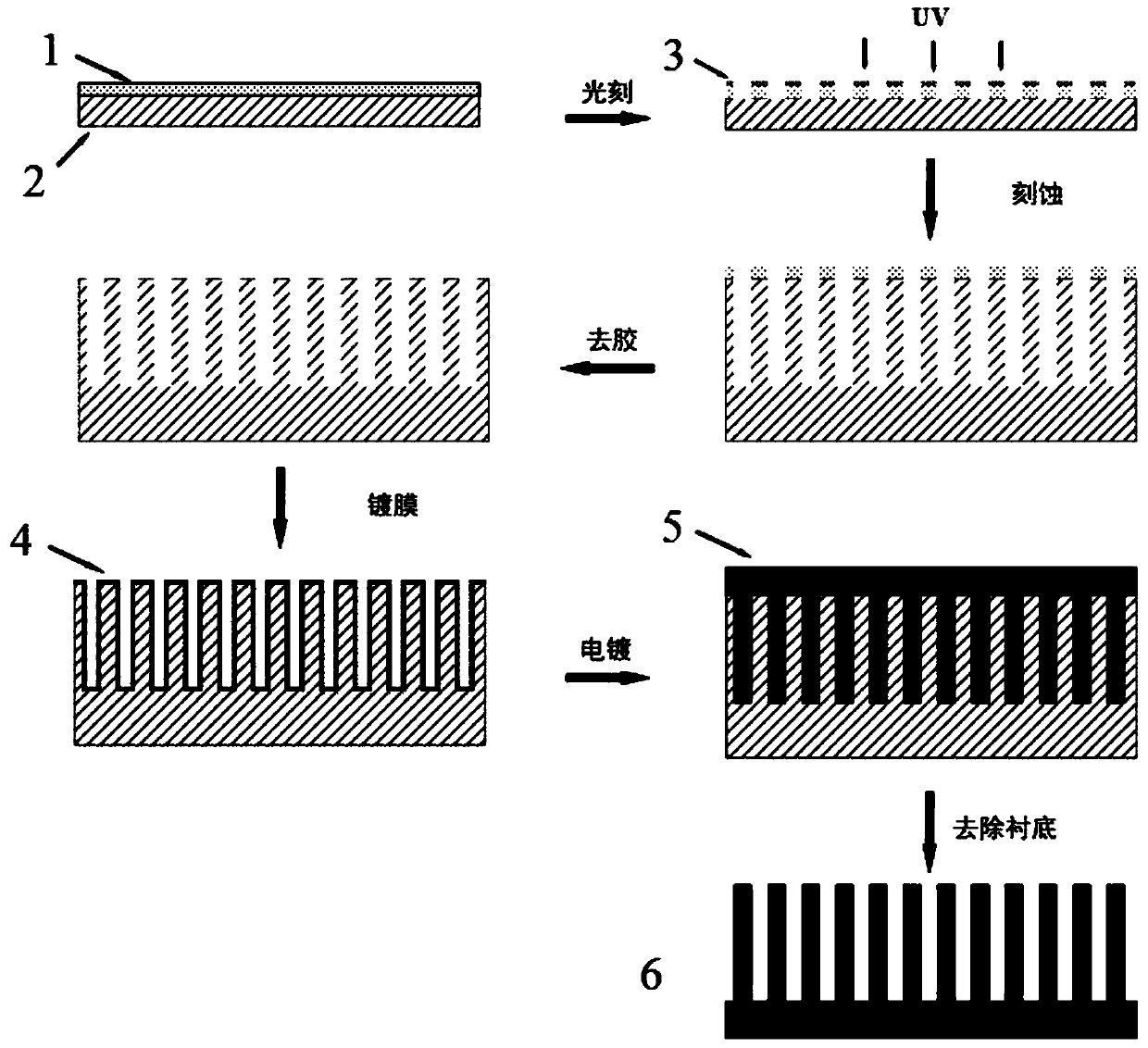

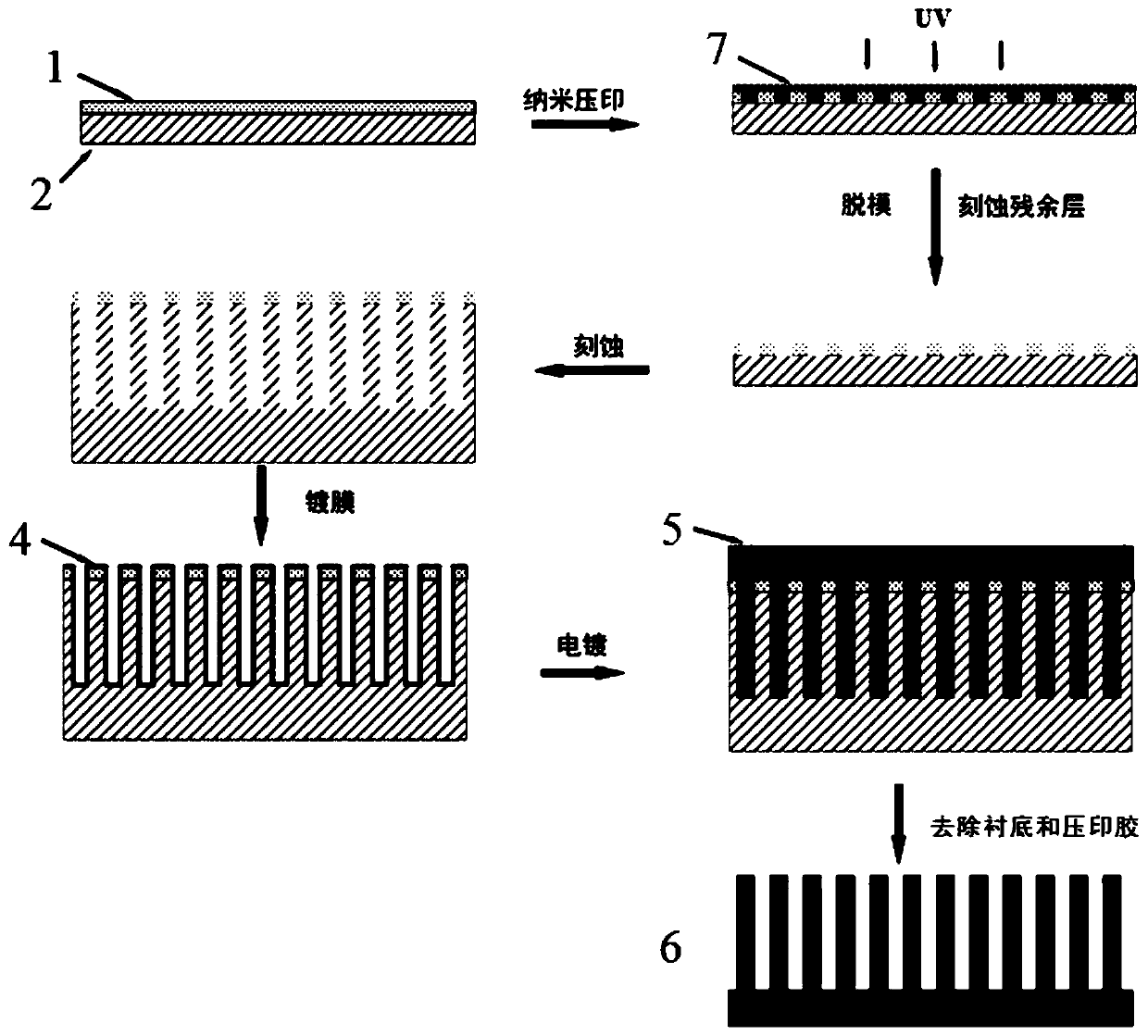

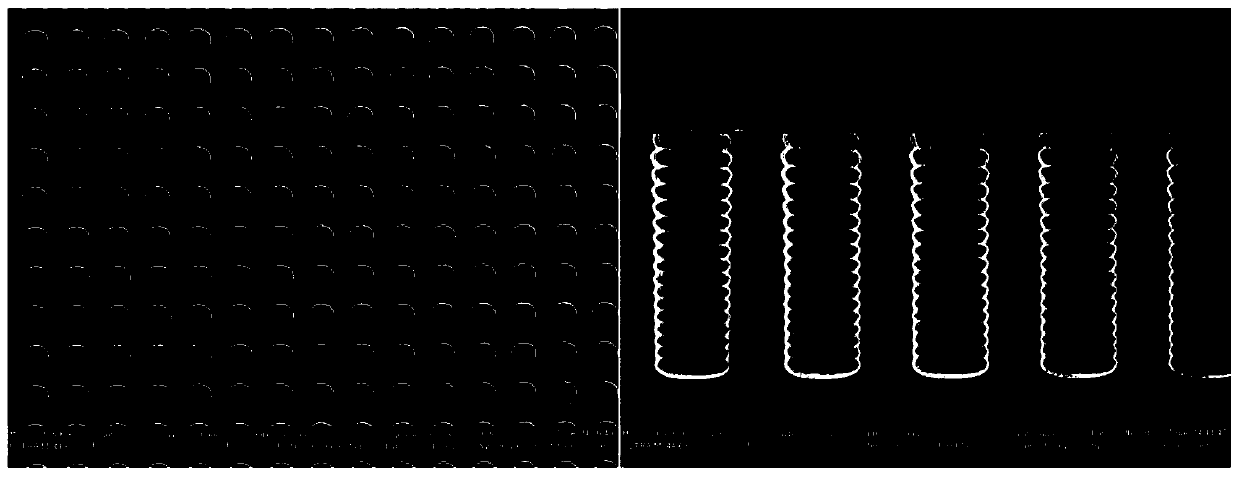

Metal micro/nano wire array and preparation method thereof

InactiveCN109795975AHigh aspect ratioHigh reuse rateDecorative surface effectsChemical vapor deposition coatingMicro nanoNano-device

The invention belongs to the technical field of micro-nano machining, and particularly relates to a metal micro / nano wire array and a preparation method thereof. The metal micro / nano wire array comprises a supporting layer metal sheet and metal micro / nano wires erected on the metal sheet. The metal micro / nano wire array has a large depth-to-width ratio, and the diameter and height of the metal micro / nano wire and the thickness of the metal sheet can be accurately controlled; The metal micro / nano wires are directly erected on the metal sheets and are not crossed and overlapped with one another,so that the specific surface area and the repeated utilization rate are increased; The metal micro / nano-wire array can be applied to preparation of a flexible nano device with a large depth-to-widthratio. According to the preparation method, a material with relatively good rigidity and etching stability is used as a substrate, so that the problems of collapse and the like in an etching process can be avoided, and a micro / nano wire array with a high depth-to-width ratio is obtained; In addition, according to the method, the height of the micro / nano wire can be accurately controlled by controlling the etching time.

Owner:NANJING UNIV

Low-cost and high-strength waterproof desulfurized gypsum board and production method thereof

The invention discloses a low-cost and high-strength waterproof desulfurized gypsum board and a production method thereof. The gypsum board is produced from a main material, an auxiliary material anda proper amount of water, the main material is composed of desulfurized gypsum, aluminate cement, white Portland cement and ordinary Portland cement, and the content of the desulfurized gypsum in themain material is 65-80 wt%; and the auxiliary material comprises expanded perlite, a gypsum retarder, fibers, a water reducer, a dispersant and a water retaining agent. The gypsum board and the production method have the following advantages: (1) after the aluminate cement, white Portland cement and ordinary Portland cement are blended together, the gypsum board does not collapse after being soaked in water, the waterproof property of the gypsum board is improved, and the problem of poor waterproof property of an existing gypsum board is solved; (2) the expanded perlite and the fibers are added, so that the density of the gypsum board is reduced, the strength and the crack resistance of the gypsum board are improved, and the cost is also reduced; and (3) the water reducer is added, so that the later viscous phenomenon of the gypsum board is improved, and the strength of the gypsum board is increased.

Owner:SHIHEZI UNIVERSITY

Guide wall adopting steel structure

InactiveCN104863085ASimple construction processNot easy to damageStream regulationUnderwater structuresTerrainBasement

The invention discloses a guide wall adopting a steel structure. The guide wall comprises a guide wall body, wherein prefabricated plates are arranged on the two sides of the guide wall body; the prefabricated plates are connected with the guide wall body through fixing bolts; the lower surface of the guide wall body is connected with a protection wall; steel bar connection strips are embedded between the protection wall and the guide wall body; two side surfaces of the protection wall and the guide wall are positioned on the same horizontal line; two guide plates are vertically mounted between the protection wall and the guide wall; the tops of the guide plates extend to the outer side of the upper surface of the guide wall; the bottoms of the guide plates are detachably connected with two guide seats; a ground beam is transversely connected between the two guide seats; the two ends of the ground beam are fixed on the guide seats; a steel pipe is embedded in the ground beam. The guide wall adopting the steel structure is simple in construction process, low in possibility of being damaged, suitable for being used underwater and basements with smooth terrain and different water depths, and convenient to replace, has a good guide effect, does not collapse, shortens the construction time and improves the construction efficiency.

Owner:CHENGDU XUNDE SCI & TECH

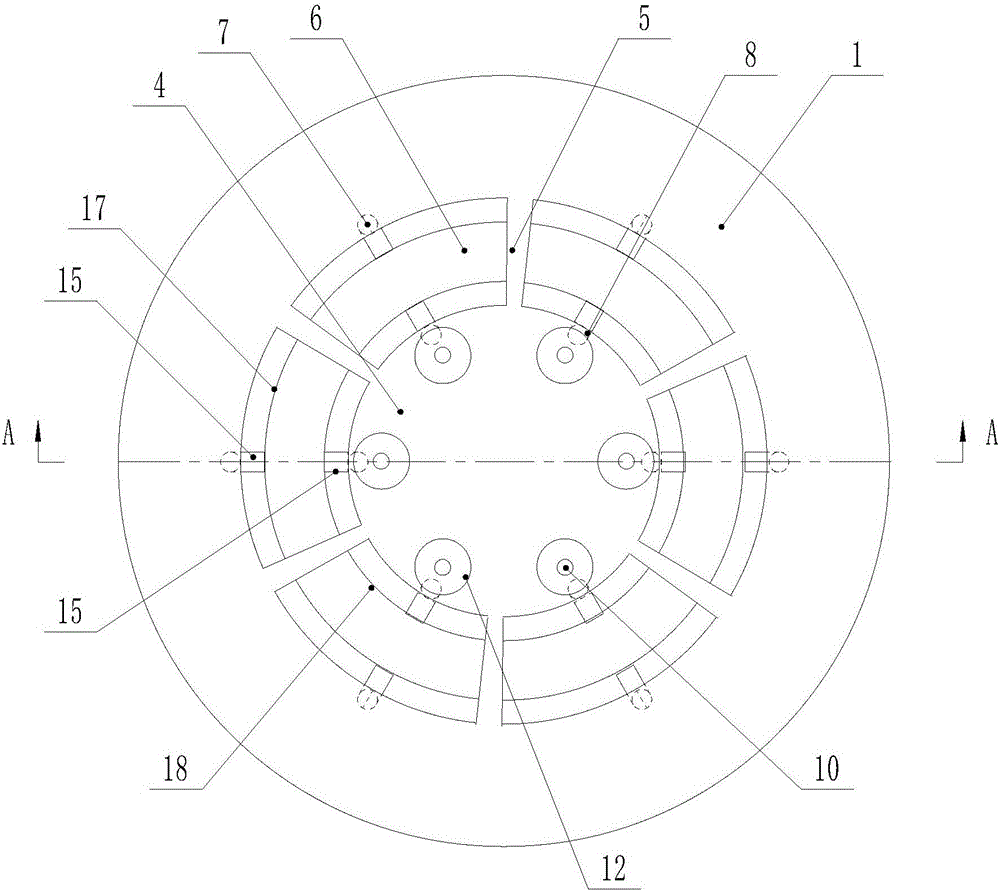

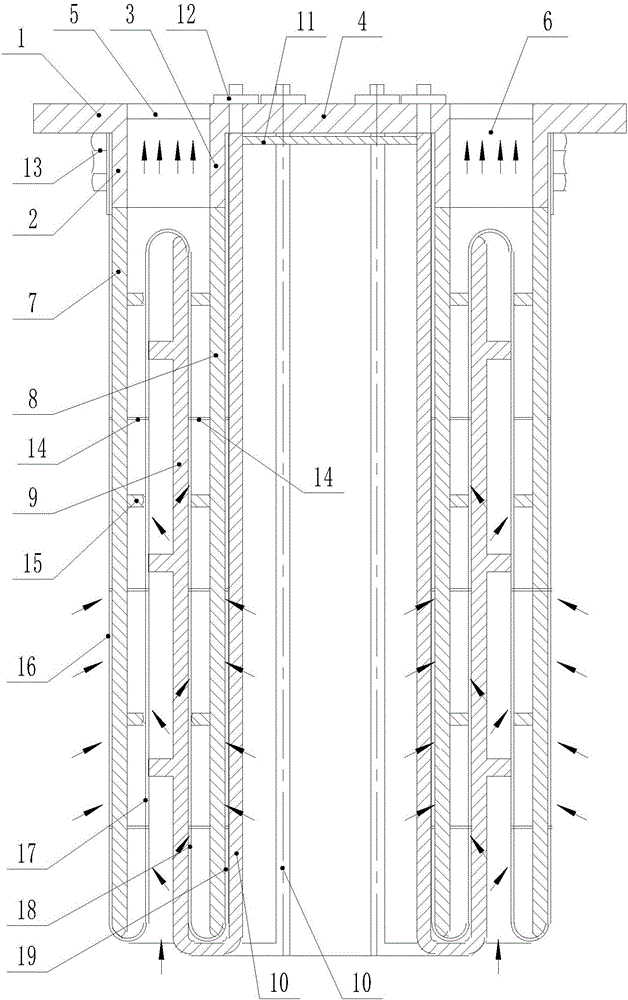

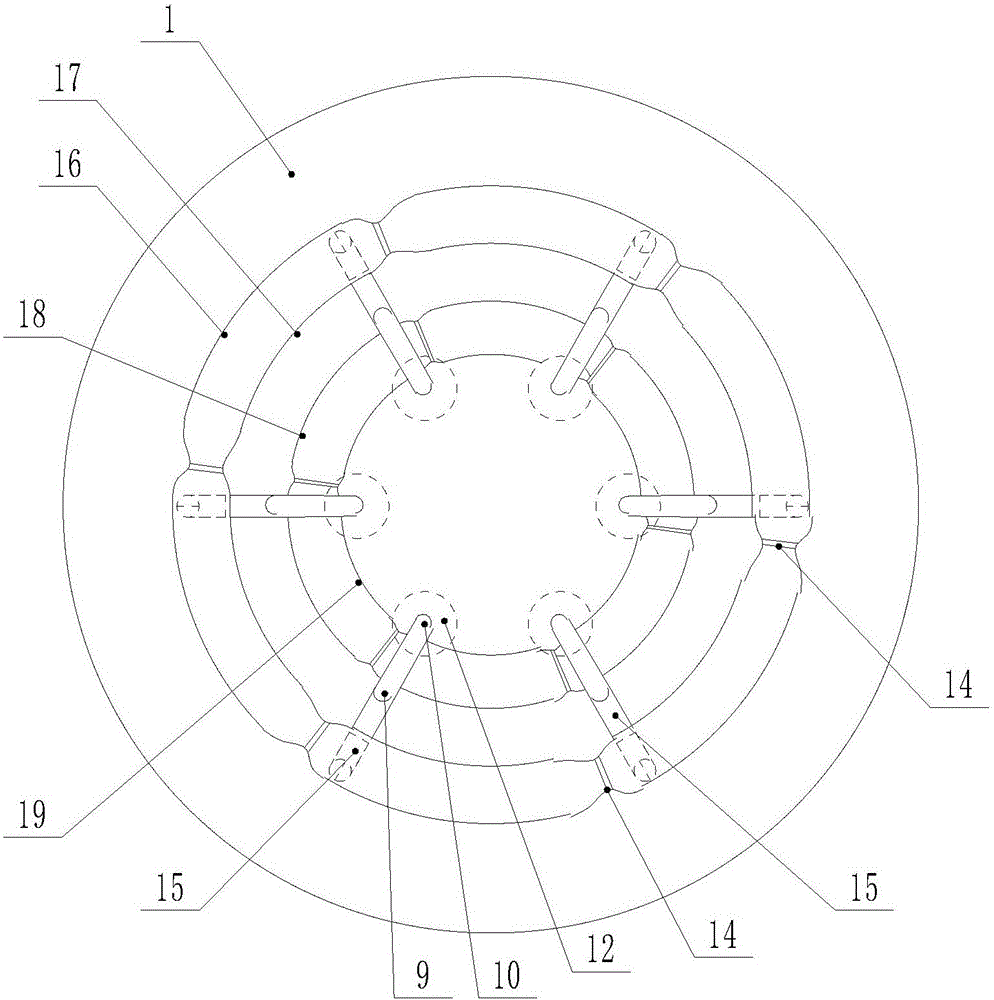

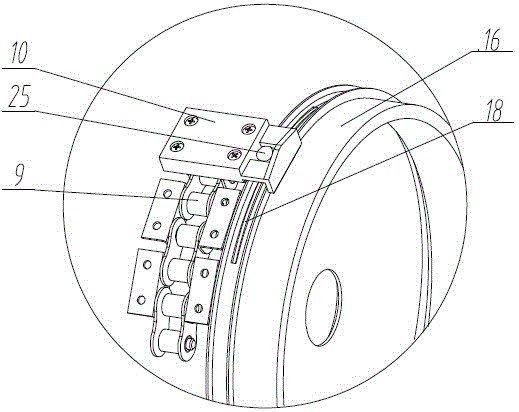

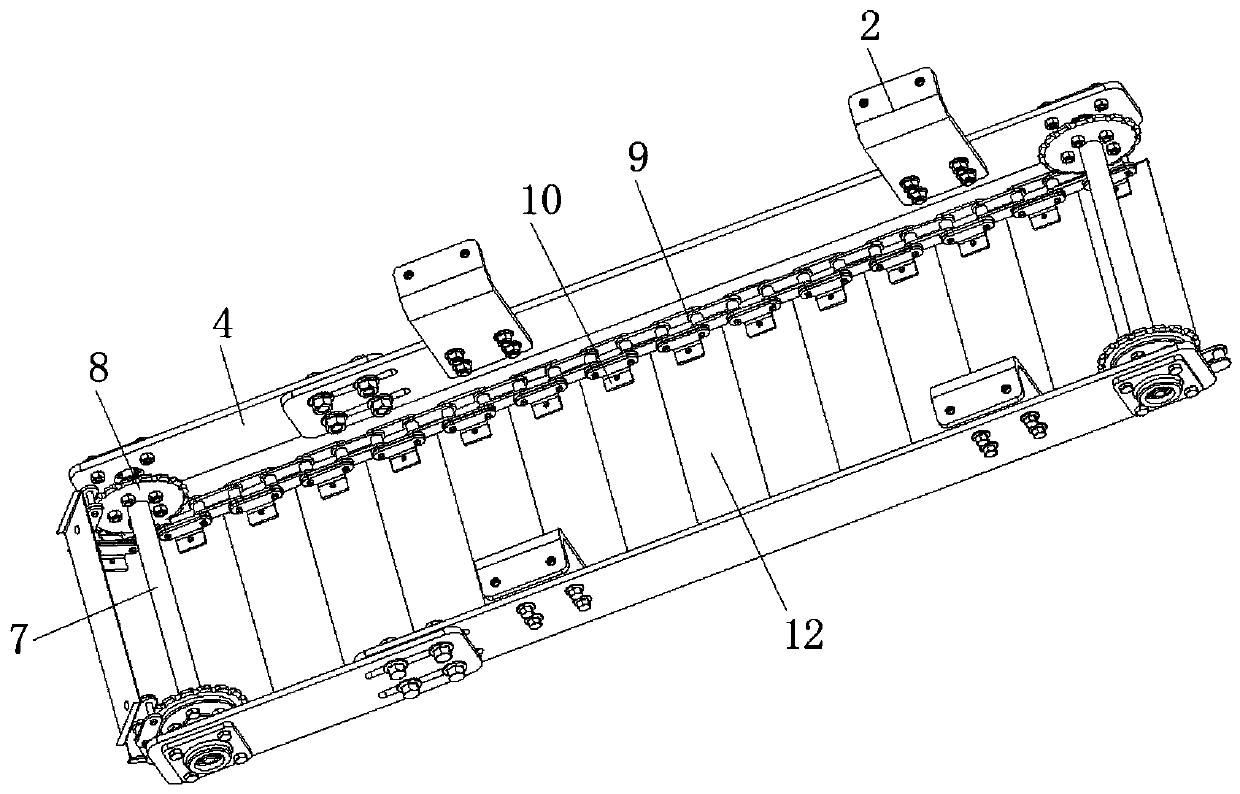

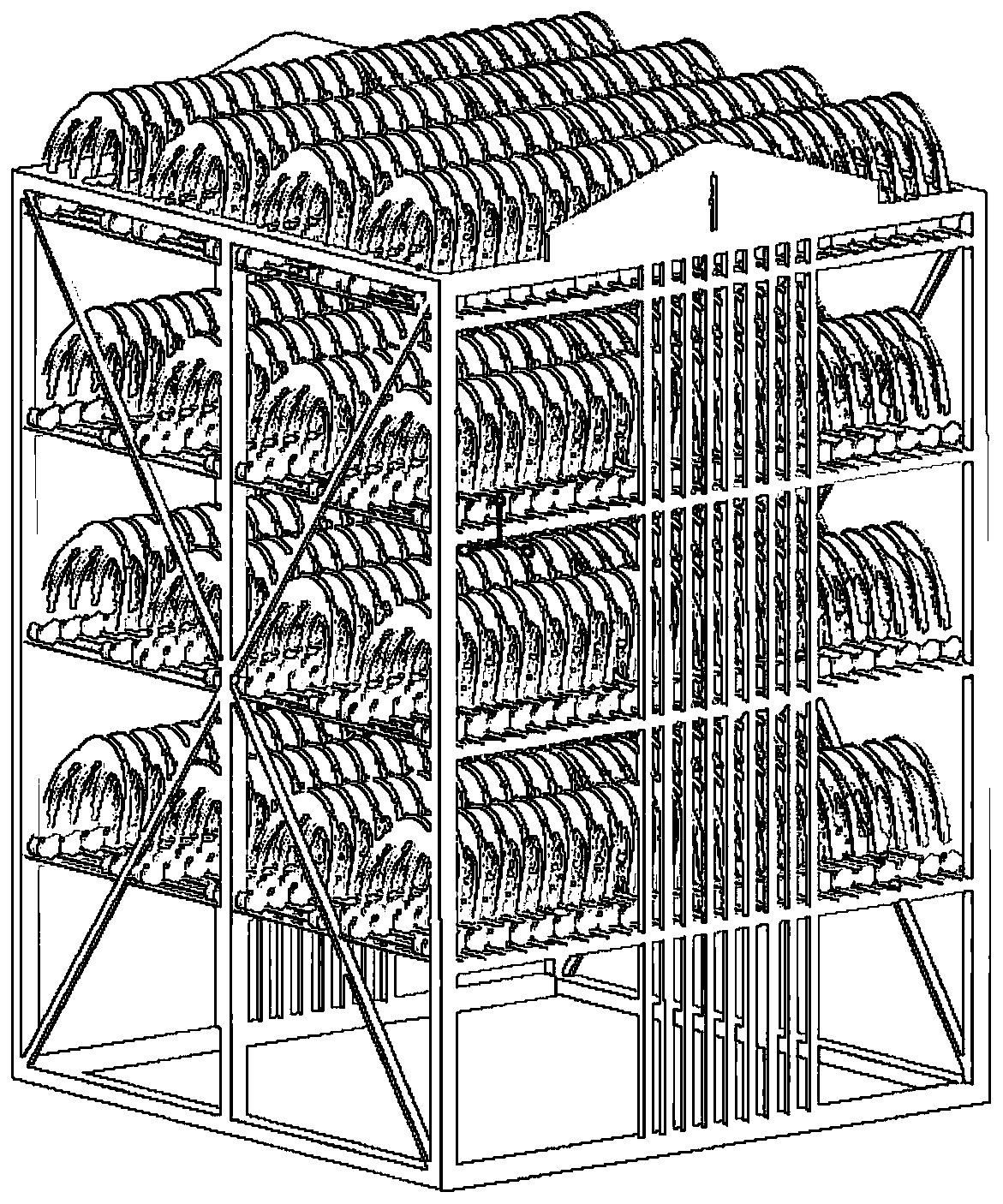

Caterpillar-type lotus seed shellershelling machine

The invention relates to food processing equipment, and especially discloses a caterpillar-type lotus seed shellershelling machine. A bearing base support and a driving motor is installed under the front end of the machine frame, a driving shaft is installed on the bearing base support, one end of the driving shaft is connected to the driving motor, and a synchronous belt is installed on the driving shaft; and the caterpillar-type lotus seed shellershelling machine comprises at least one shelling mechanism. The caterpillar-type Lotus seed shellershelling machine has the following advantages: the shellershelling machine is capable of controlling cutting depths into the lotus seed shells as well as effectively fixing the lotus seeds according to different sizes of the lotus seeds; moreover, the shellershelling machine is capable of carrying out high-efficiency shelling operations on the lotus seeds of various sizes without encountering the phenomenons of failed peeling or broken lotus seeds, so that the qualities of the shelled lotus seeds are improved. In addition, the caterpillar-type lotus seed shellershelling machine is safe and reliable in operations, as well as not easy to leak; two sets of shelling mechanisms are combines, so that the production efficiency is greatly improved and the floor area is reduced. The caterpillar-type lotus seed shellershelling machine is suitable for large-scale, automatic and high-quality lotus seed shelling operations in lotus-seed processing enterprises.

Owner:XIANGTAN UNIV

A kind of full-fit frame glue for touch screen and preparation method thereof

ActiveCN107286901BHigh light transmittanceGood refractive indexNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention provides a frame adhesive for full attachment of touch screens. The frame adhesive is prepared from components in percentage by mass as follows: 20%-40% of vinyl silicone oil, 1%-15% of hydrogen-containing silicone oil, 1%-3% of a coupling agent, 30%-50% of 110 raw rubber, 5%-10% of a thixotropic agent, 1%-3% of a hardness regulator, 1%-3% of a construction aid, 0.001%-0.05% of a catalyst and 0.001%-0.05% of an inhibitor. The frame adhesive has good extrusion performance, thixotropy and adhesion and has very good compatibility with organosilicone LOCA (liquid optical clear adhesive), the refractive index between the frame adhesive and the LOCA is smaller than 0.003, and the defect of black edges can be overcome after curing attachment. The frame adhesive is packaged and used in a single-component manner, the procedures can be simplified, the operation requirement of automatic equipment in the attachment process can be met, and bubbles and impurities in the organosilicone LOCA can be prevented. The invention further provides a preparation method of the frame adhesive. The method is simple in process, safe, environment-friendly and prone to industrialization.

Owner:新纶光电材料(深圳)有限公司

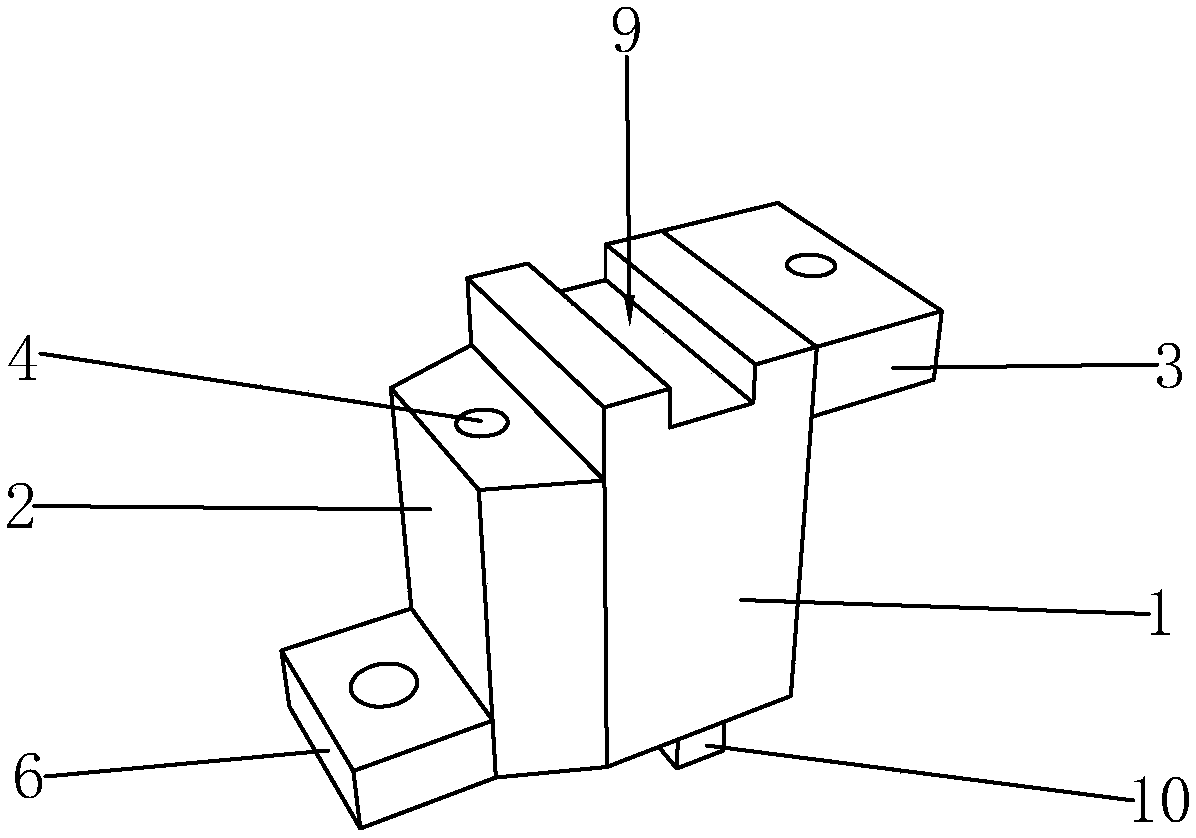

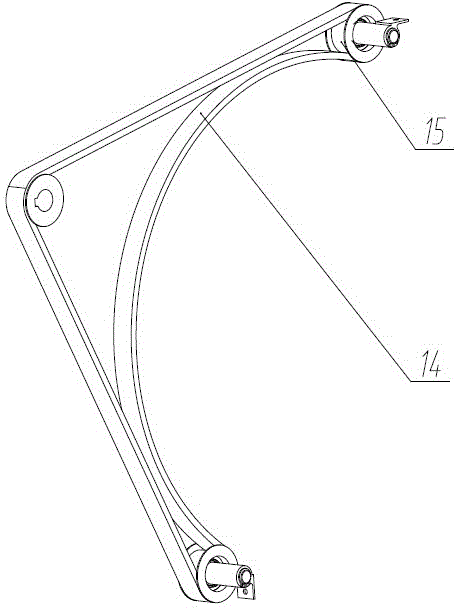

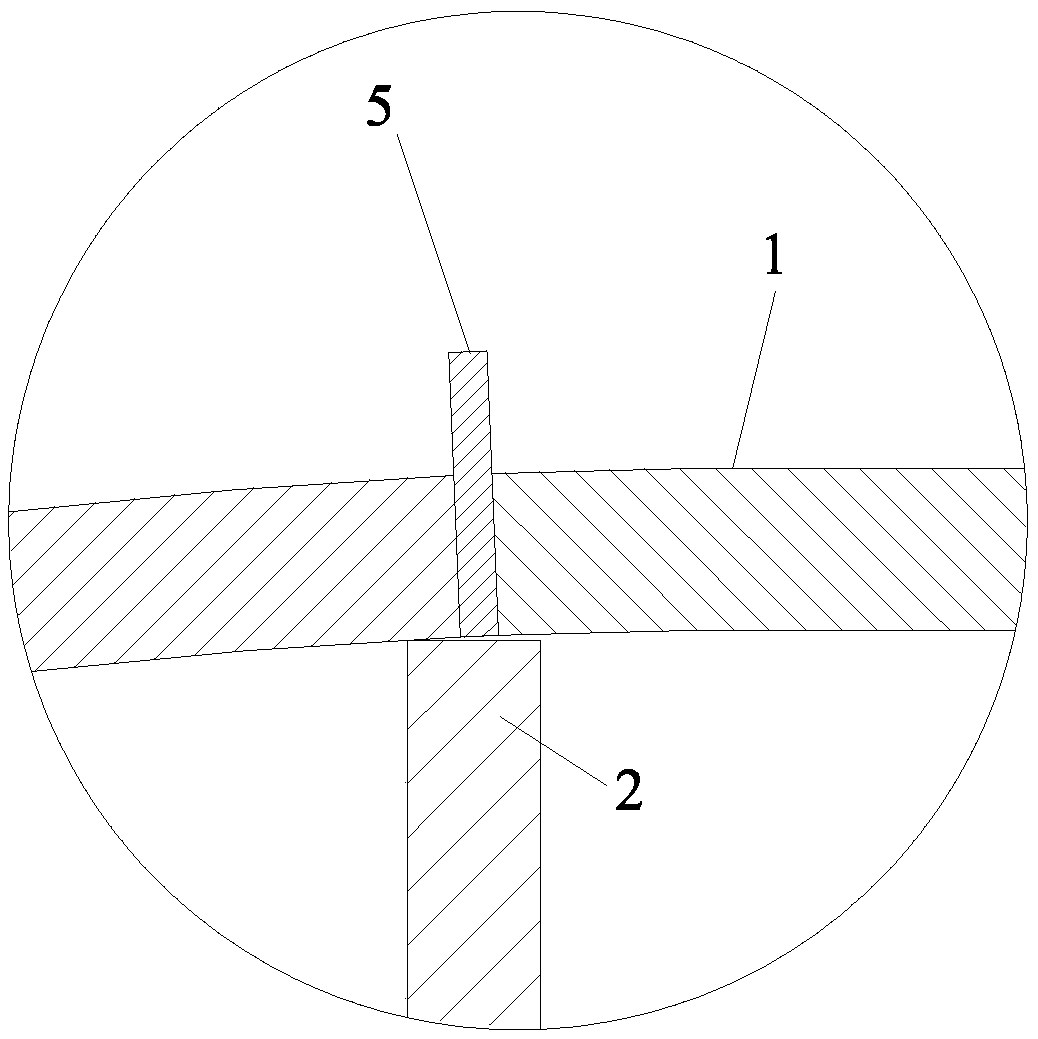

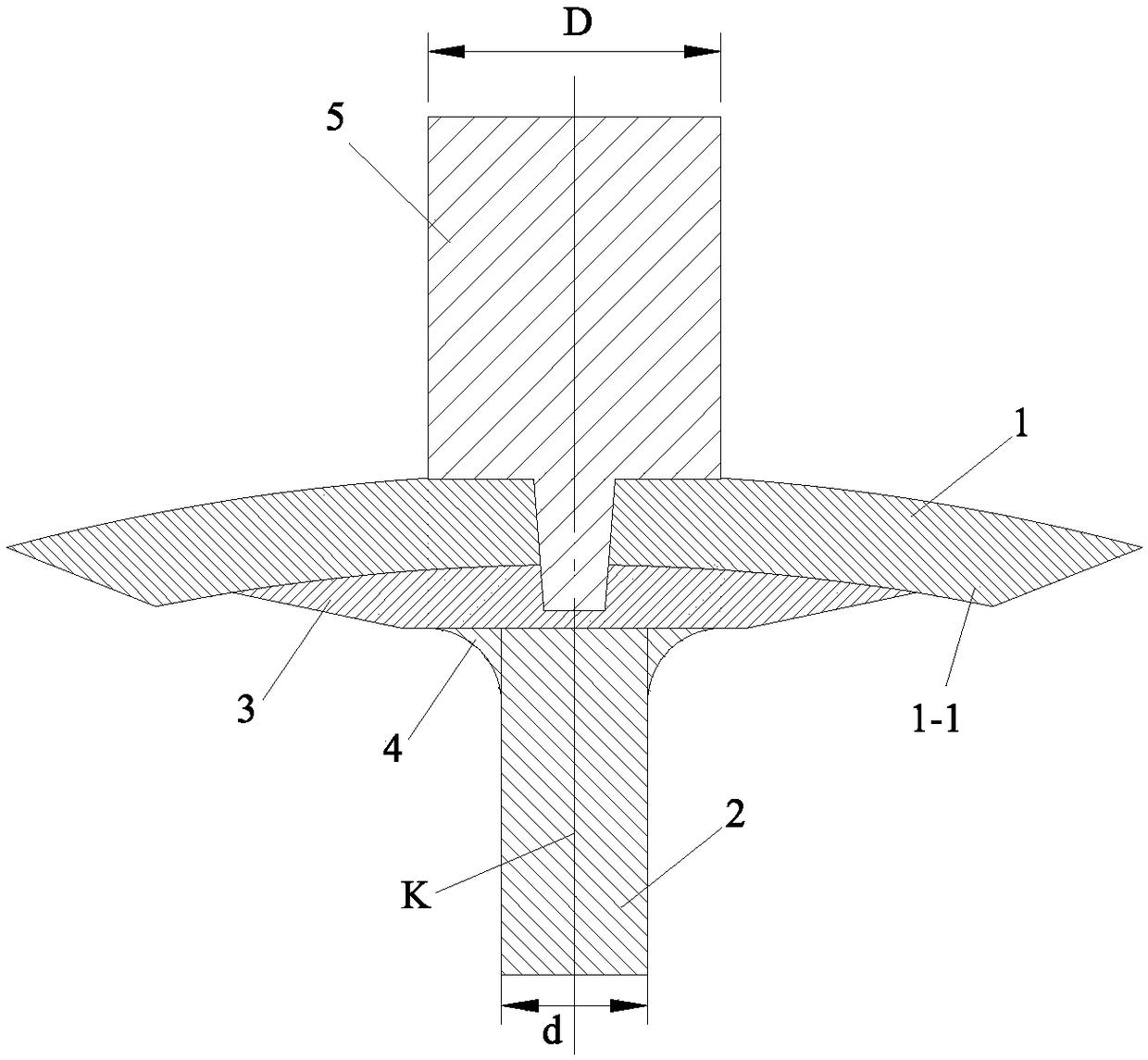

T-shaped self-support structure suitable for curved surface friction stir welding

InactiveCN109483079AAchieving back self-supportThere will be no collapseWorkpiece edge portionsNon-electric welding apparatusEngineeringSoldering process

The invention discloses a T-shaped self-support structure suitable for curved surface friction stir welding, and relates to the technical field of friction stir welding of curved surface metal structures. The structure comprises a ribbed plate, a profile curved surface plate and two chamfering angles; the curvature and the length of the profile curved surface plate are the same with the curvatureand the length of a curved surface cover plate; the width of the profile curved surface plate is higher than and equal to the shaft shoulder diameter D of a stirring head; the top end surface of the ribbed plate is fixedly connected to the inner side concave surface of the profile curved surface plate; the extension line of the center line of the ribbed plate passes through the highest point of the profile curved surface plate; the two chamfering angles are both fixedly connected with the ribbed plate and the profile curved surface plate; and the radiuses (FORMULA) d of the chamfering angles are the thickness of the ribbed plate. The profile curved surface plate fitted with the inner side concave surface of the curved surface cover plate and the chamfering angles are additionally providedon the ribbed plate, so that assembly fit gaps are greatly reduced; and through the chamfering angles, enough materials are supported under a shaft shoulder of the stirring head in the welding process, the axial top forging force can be smoothly transferred to the ribbed plate during welding, and the complexity of needing additional tools to support the back part under the shaft shoulder is prevented.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

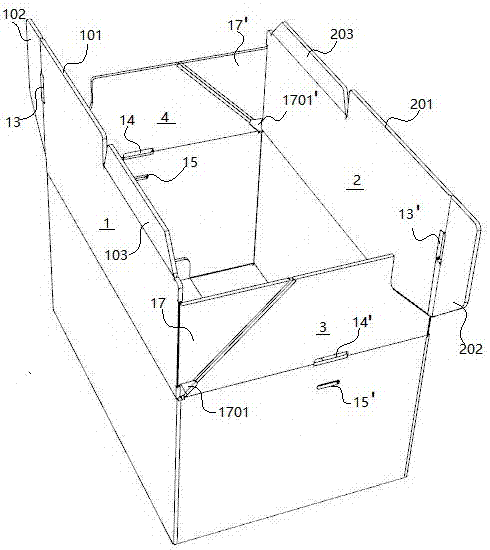

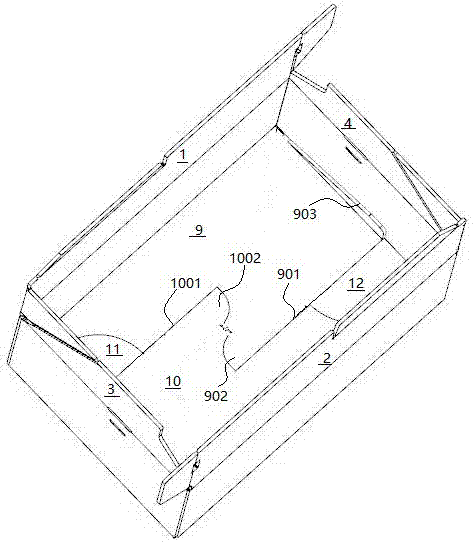

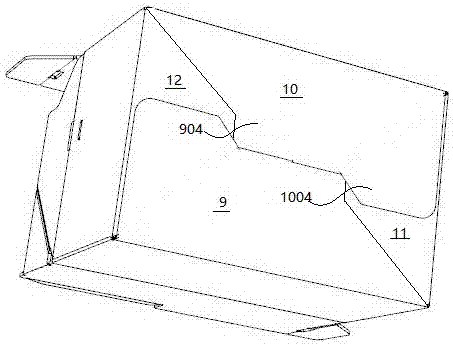

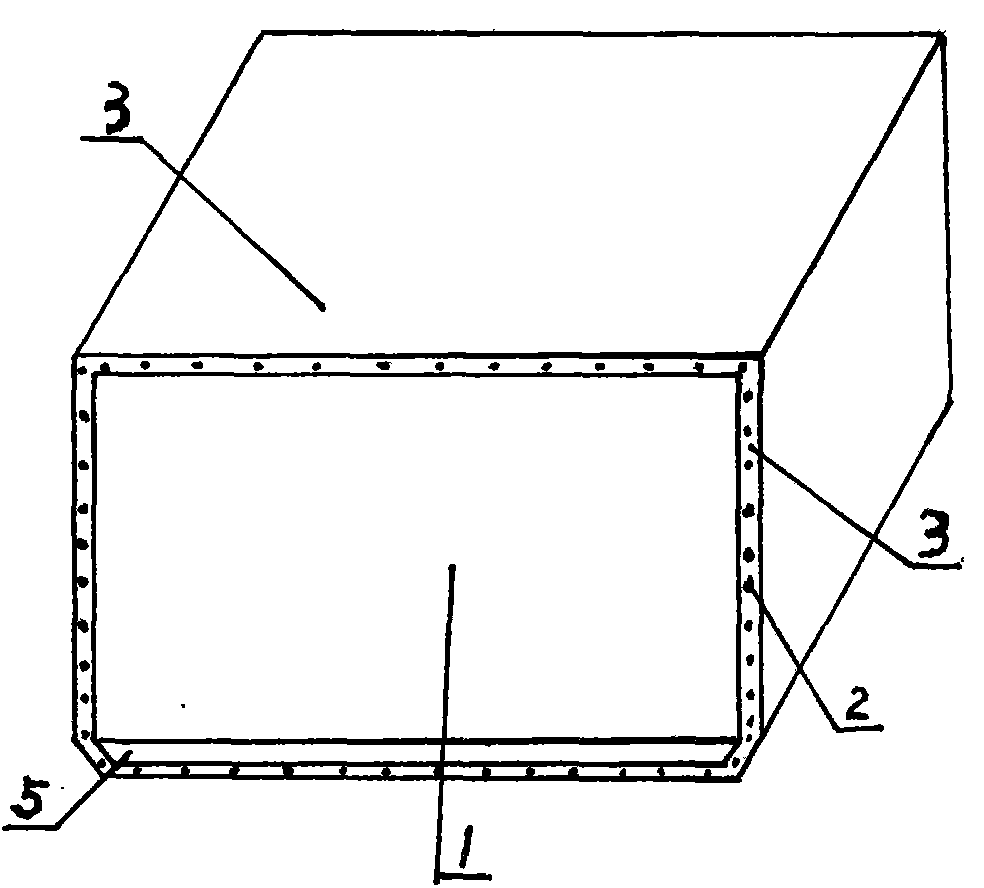

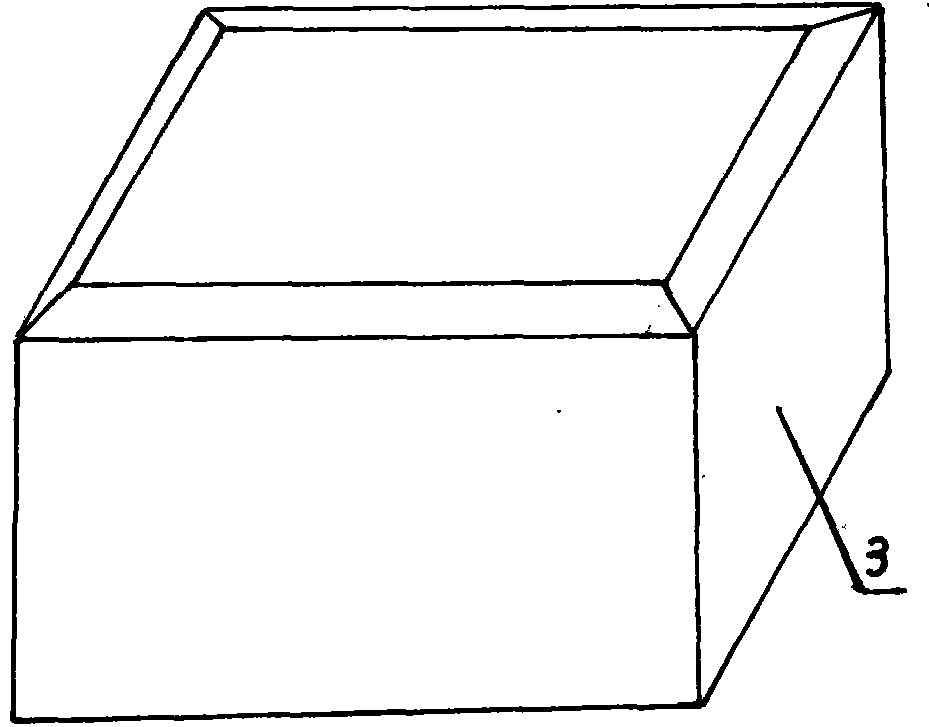

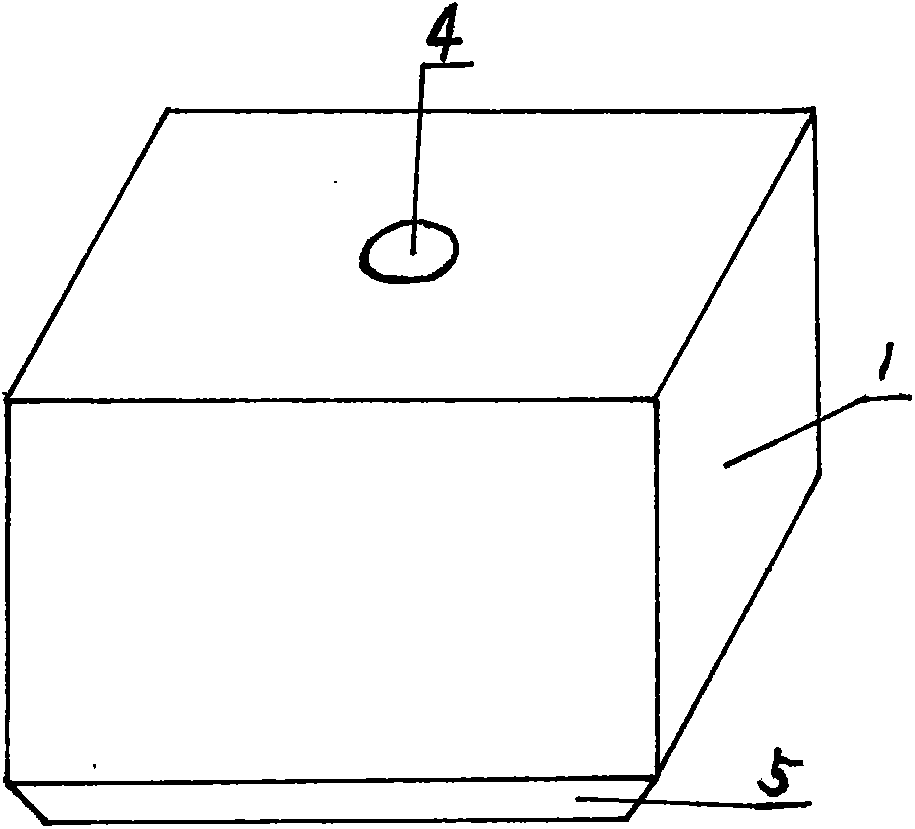

Reusable packaging box without needing tape sealing

ActiveCN107512454AEnables tape-free packagingEasy to openPackage recyclingRigid containersEngineeringMirror image

The invention discloses a reusable packaging box without needing tape sealing. The packaging box is composed of a box bottom, a box cover and side retaining surfaces. A box body is formed by enabling the box bottom to be connected with the box cover through the side retaining surfaces. The box cover comprises a first top surface and a second top surface which are oppositely arranged, and a third top surface and a fourth top surface which are oppositely arranged, and the first top surface, the second top surface, the third top surface and the fourth top surface can be folded inwards. A first top edge of the first top surface and a second top edge of the second top surface are each of a Z-shaped structure and are arranged in a mutual mirror image manner. When the first top surface and the second top surface are superimposed, meshing limit can be achieved through the Z-shaped structures in a pair. A first folded surface is arranged on one lateral side of the first top surface, a second folded surface is arranged on one lateral side of the second top surface, the first folded surface and the second folded surface are located on the different side surfaces, and when being superimposed, the first top surface and the second top surface can be detachably fixed to the side retaining surfaces through the first folded surface and the second folded surface correspondingly. When the packaging box provided by the invention is sealed, no tape needs to be used, and the packaging box can be reused in the transportation and delivery process.

Owner:上海易彬科技有限公司

Two-phase high-efficiency extraction method of eucommia ulmoides gum

The invention discloses a two-phase high-efficiency extraction method of eucommia ulmoides gum. The method takes any one or two or more of eucommia ulmoides leaves, eucommia ulmoides bark and eucommiaulmoides samara peel as the raw materials, and comprises the following steps of: mixing the raw materials with an inorganic compound aqueous solution with a mass fraction of 1-15%, adding an organicsolvent into the mixed solution to form a water phase-organic phase two-phase system, and performing heating and stirring on the two-phase system at a temperature of 50-110DEG C; and after heating isfinished, collecting the organic phase, and separating the eucommia ulmoides gum from the organic phase to obtain the eucommia ulmoides gum. According to the method, lignin in cell walls in the raw materials is decomposed through the inorganic compound aqueous solution, the permeability of cells is improved, dissolution of gum substances in the cells is accelerated, and high-purity eucommia ulmoides gum can be obtained in an environment-friendly mode.

Owner:BEIJING FORESTRY UNIVERSITY

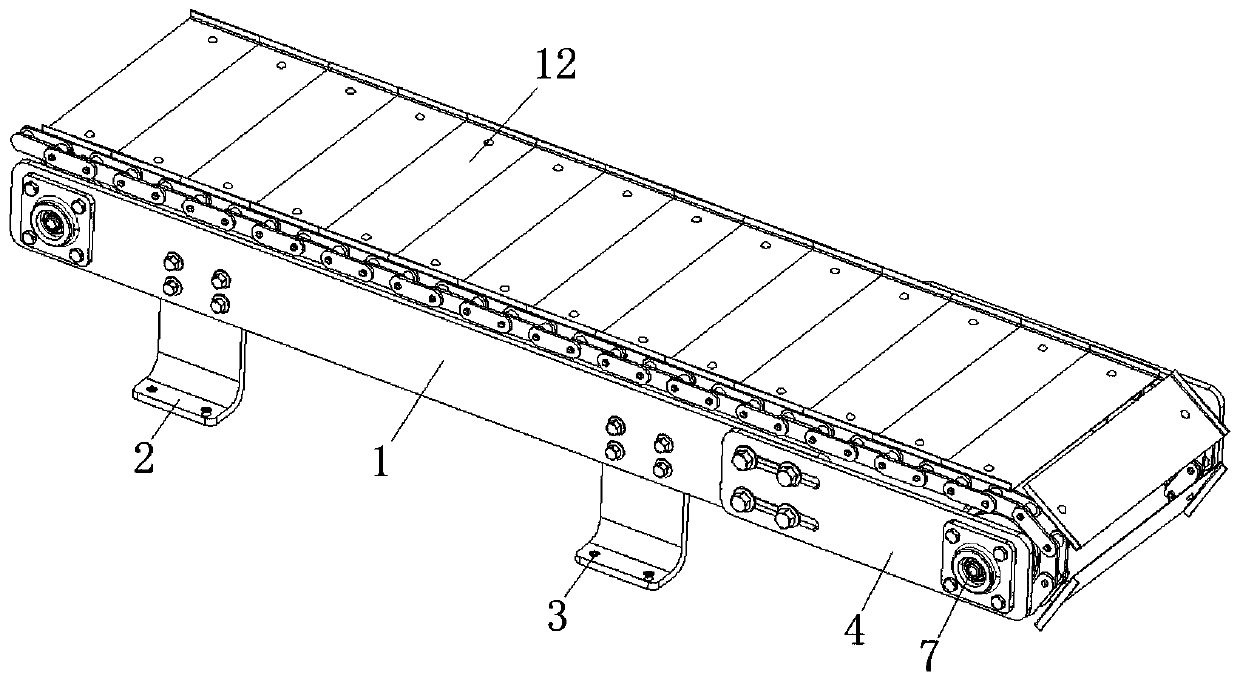

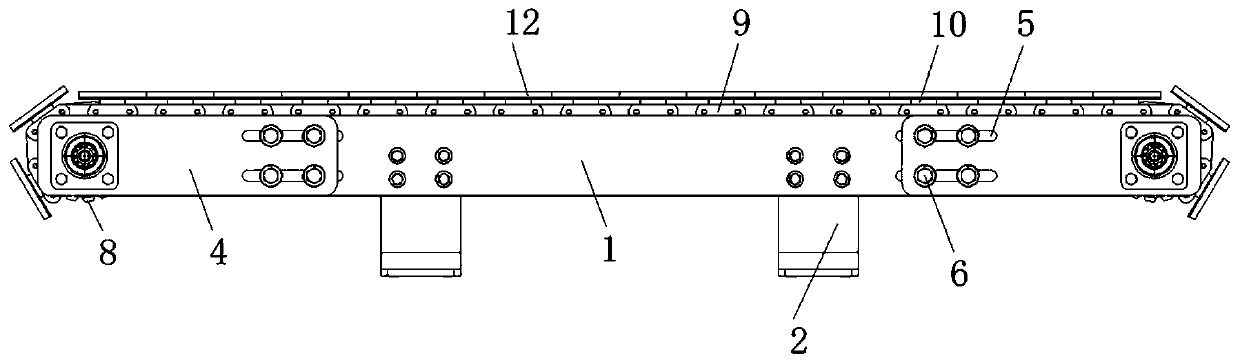

Conveying device used for food processing and being convenient to operate and maintain

InactiveCN111003424AEasy to operateEasy maintenanceConveyorsElectric machineryStructural engineering

The invention discloses a conveying device used for food processing and being convenient to operate and maintain. The device comprises a frame, two fixing bases are symmetrically and fixedly installedat the bottom of the frame, motor bases are fixedly installed on the outer sides of t two ends of the frame, horizontal adjusting grooves are formed in connecting positions of the motor bases and theframe, and the adjusting grooves are symmetrical up and down. A plurality of plates are spliced to replace a traditional conveying belt to convey foods, so the cleanliness is high, and food contamination is reduced; the plates are of a detachable structure, the plates can be disassembled in a targeted mode, then the internal of the device is maintained, so later maintenance is facilitated, production and machining are facilitated; and the whole structure is simple, so the cost is low, the overall stability is extremely high, operation is easy, the plates 12 can be cleaned conveniently in theworking process, and later device maintenance is facilitated.

Owner:合肥民祯健康科技有限公司

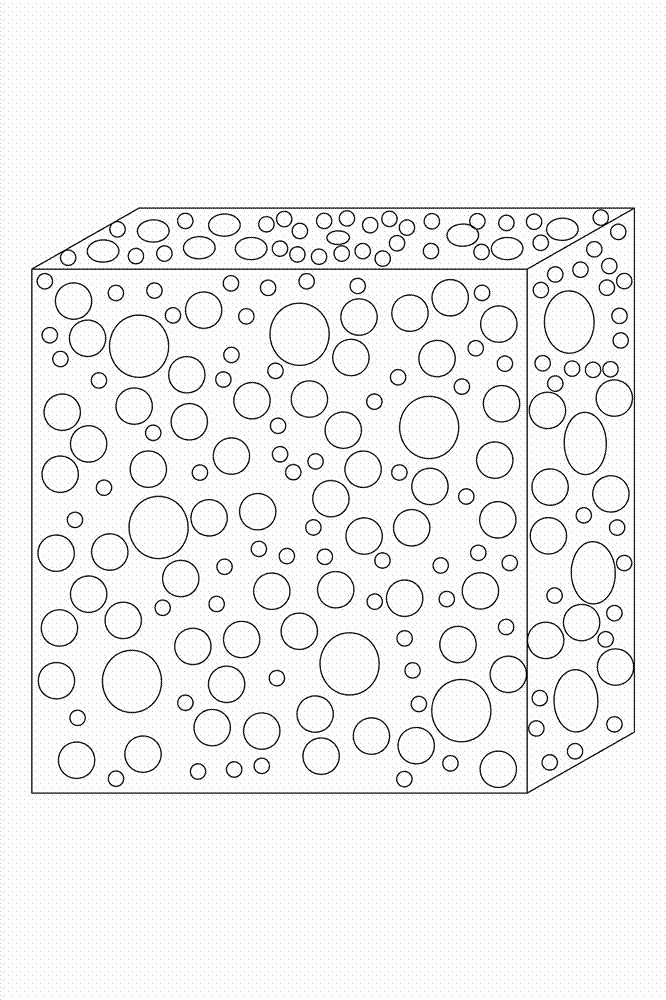

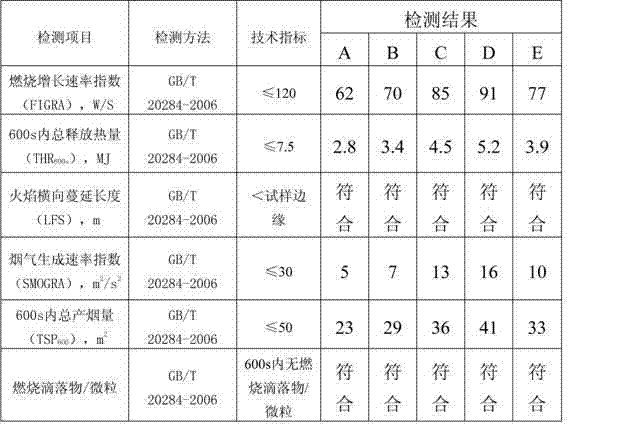

Modified polyphenolic aldehyde-urethane foam thermal insulation board and preparation method thereof

The invention discloses a modified polyphenolic aldehyde-urethane foam thermal insulation board with excellent fireproof thermal insulation performance and a preparation method thereof. The foaming particles are quickly foamed and expanded by use of the high heat released by the reaction between the modified polyphenolic aldehyde-urethane resin and a curing agent, and a foaming agent synchronously foams the modified polyphenolic aldehyde-urethane resin at high temperature before curing and forming. The modified polyphenolic aldehyde-urethane foam thermal insulation board comprises the following raw materials in parts by mass: 100 parts of modified polyphenolic aldehyde-urethane resin, 3-6 parts of surfactant, 5-9 parts of foaming agent and 0-6 parts of filler. The preparation method comprises the following steps of: mixing and stirring the modified polyphenolic aldehyde-urethane resin, the surfactant, the foaming agent and the filler according to the parts by mass; uniformly mixing the mixture obtained by mixing and stirring with 30-70 parts of foaming particles; mixing the uniformly mixed mixture containing the foaming particles with 6-12 parts of curing agent, and feeding into a continuous production line; and heating to 60-100 DEG C and pressurizing to 0.1-0.3MPa, foaming and curing for forming.

Owner:滕州市华海新型保温材料有限公司

Benzene board concrete floor block and manufacture method thereof

InactiveCN103967184ALow thermal conductivityLighten the loadConstruction materialFloorsGlass fiberBenzene

The invention discloses a benzene board concrete floor block and a manufacture method thereof. Each outer surface of the benzene board is coated and bonded with a concrete layer which is provided with a fiberglass mesh in the middle thereof. The concrete layers of each two adjacent surfaces are seamlessly adhered to form an overall block having an inner core of the benzene board and an outer layer of the concrete layer. The manufacture method thereof includes firstly, coating a first layer of concrete on a wood board, laying and bonding the fiberglass mesh on the first layer of concrete, coating a second layer of concrete on the fiberglass mesh, and then bonding the benzene board with the top surface downwards onto the second layer of concrete; secondly, coating the concrete which is added with the fiberglass mesh on each lateral side of the benzene board; thirdly, coating the concrete layer which is provided with a fiberglass mesh at the bottom of the benzene board; fourthly, drying and maintaining until solidification and drying of the concretes of the outer layer are achieved. The benzene board concrete floor block has the advantages of high strength, solid durability, light weight, energy-saving insulation and manufacturing and constructional simplicity.

Owner:方高松

Foundation pit supporting structure and construction method thereof

PendingCN112359844AHigh strengthImprove stabilityFencingExcavationsReinforced concreteArchitectural engineering

The invention relates to a foundation pit supporting structure and a construction method thereof. The foundation pit supporting structure comprises a B-class cast-in-place pile, a first reinforced concrete support, a second reinforced concrete support, a bottom plate, a cast-in-place bored pile and a latticed column. The B-class cast-in-place pile is vertically arranged in a foundation pit, the first reinforced concrete support and the second reinforced concrete support are horizontally arranged and sequentially connected with the B-class cast-in-place pile from top to bottom, the cast-in-place bored pile is vertically arranged, the top end of the cast-in-place bored pile is connected with the bottom plate, the latticed column is fixedly arranged on the cast-in-place bored pile, and an inclined throwing support is arranged between the bottom plate and the first reinforced concrete support. According to the foundation pit supporting structure, by arranging the inclined throwing support,the strength and stability of the whole supporting structure can be effectively improved, and it is guaranteed that no soil collapse phenomenon occurs; the latticed column can play a role in supporting the first reinforced concrete support and the second reinforced concrete support, so that the foundation pit is more stable; and the inclined throwing support is fixedly connected with the bottom plate and the pond wall of a storage pond through reinforced concrete brackets, so that the foundation pit is more stable.

Owner:JIANGXI THERMAL POWER CONSTR CORP

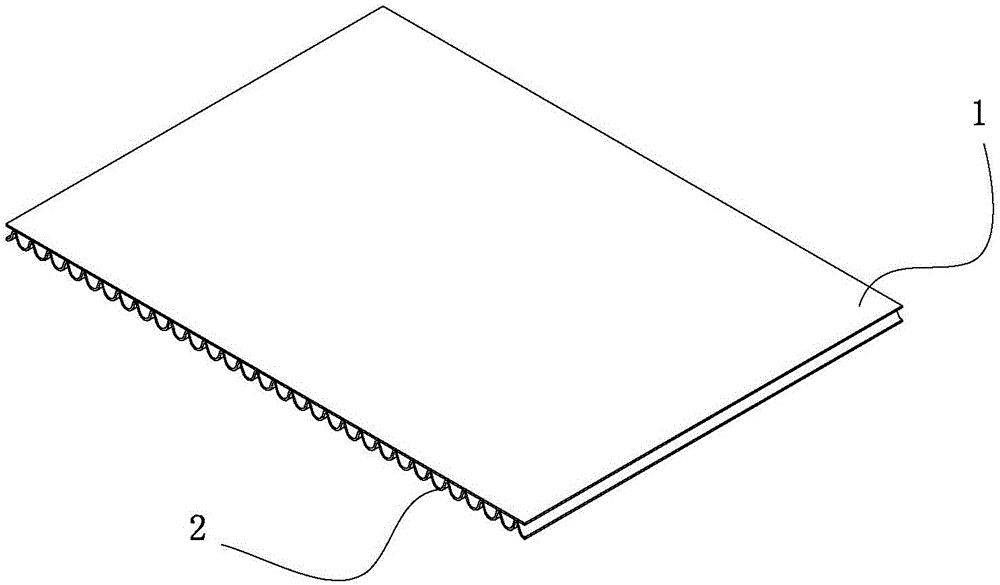

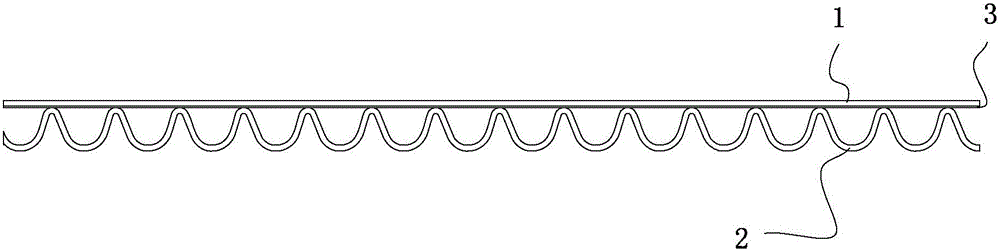

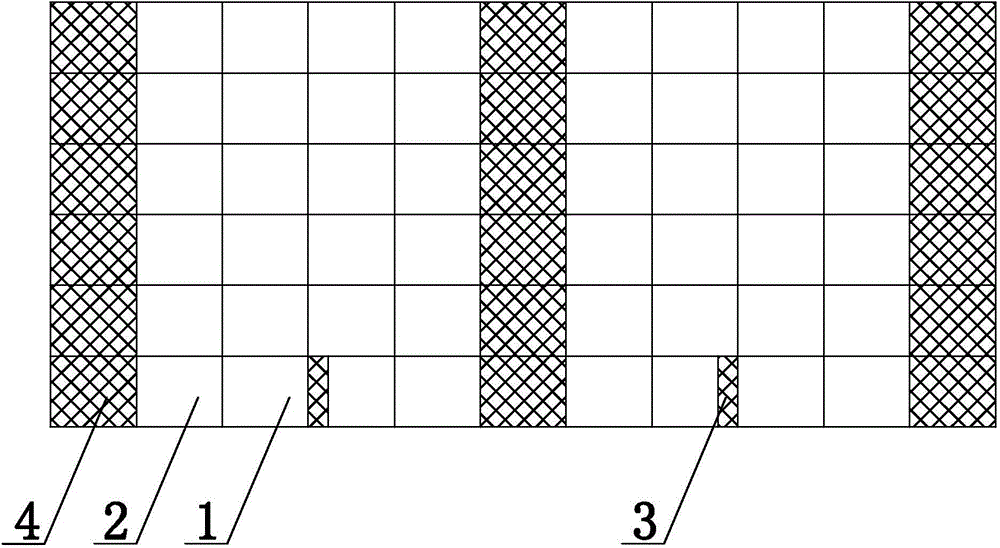

Filter paper structure and method for manufacturing same

InactiveCN105155352APlay a protective effectThere will be no collapsePaper/cardboardPaper/cardboard layered productsPulp and paper industryFilter paper

The invention discloses a filter paper structure which comprises structurally plate-shaped filter paper and structurally wavy filter paper. The wavy filter paper is adhered on the plate-shaped filter paper by hot-melt adhesive. The invention further discloses a method for manufacturing the filter paper structure. The method includes steps of applying pressures on filter paper by the aid of a wave press roll assembly to form the wavy filter paper; adhering the wavy filter paper with the plate-shaped filter paper by the hot-melt adhesive. The filter paper structure and the method have the advantages that wavy structures can be prevented from being collapsed when the filter paper is wound to form a filter element, the filter paper is high in mechanical strength and firm in structure, and accordingly the quality of products can be guaranteed.

Owner:深圳华盛过滤系统有限公司

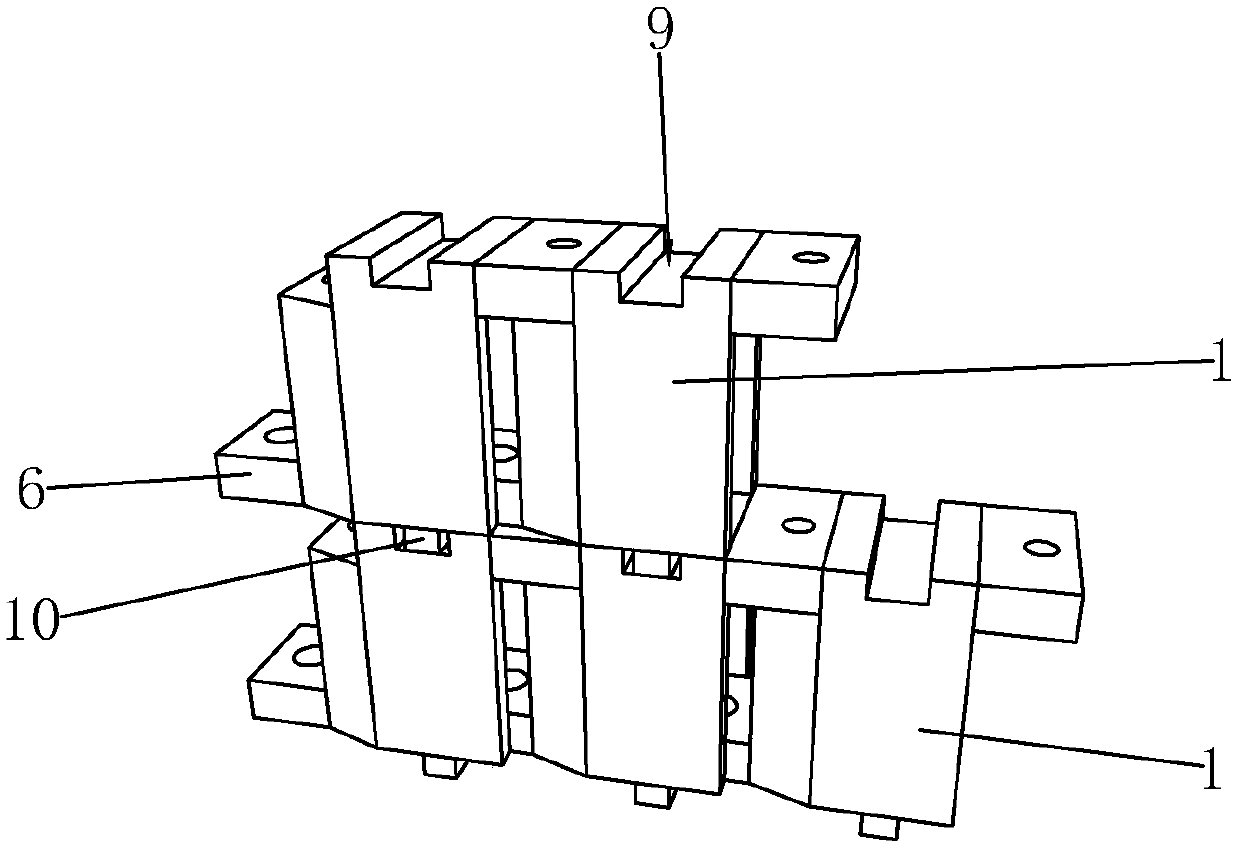

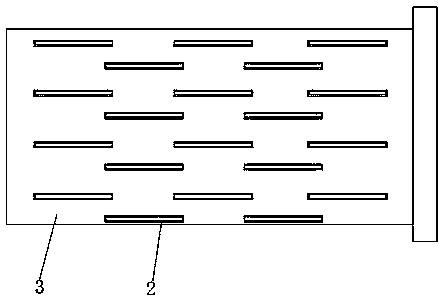

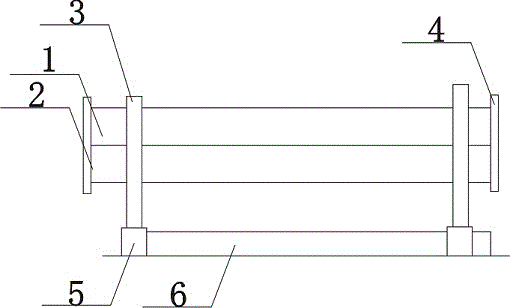

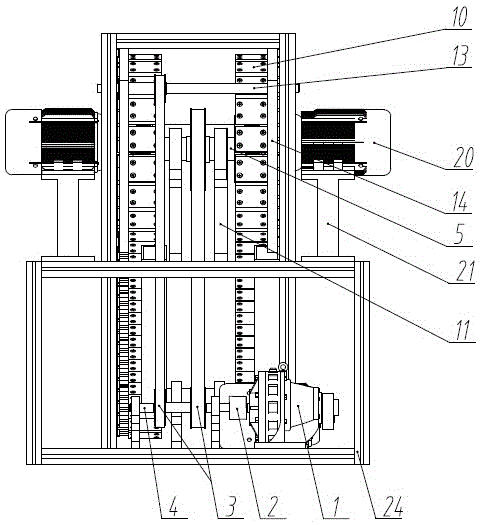

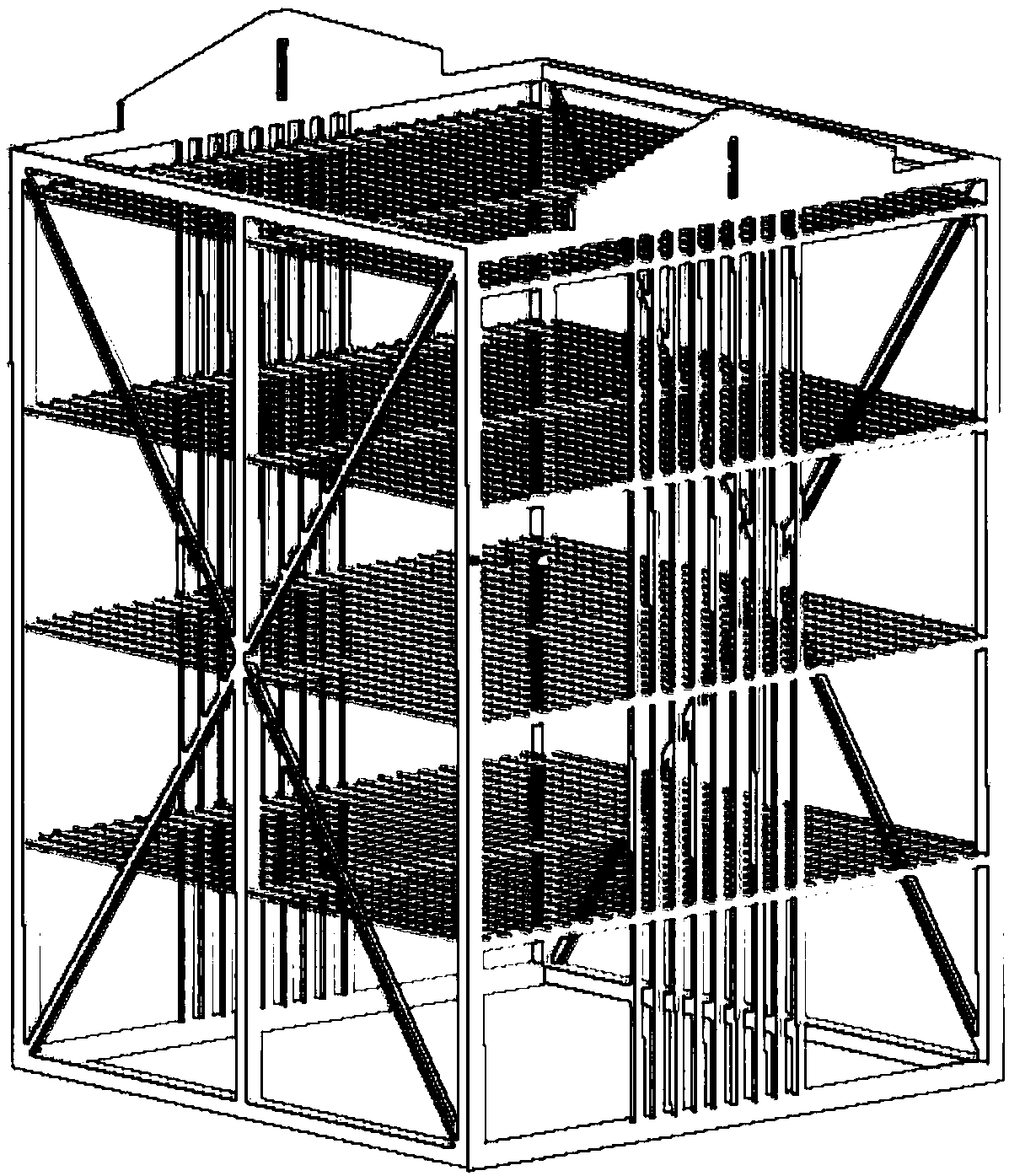

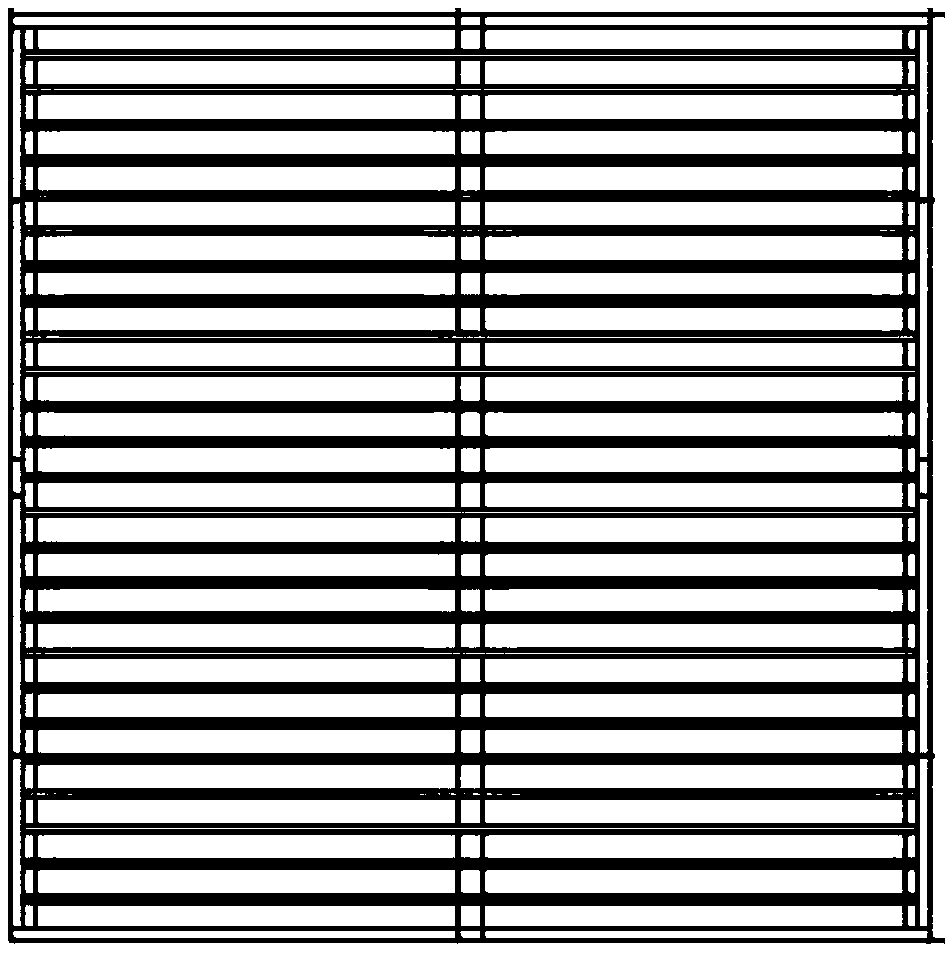

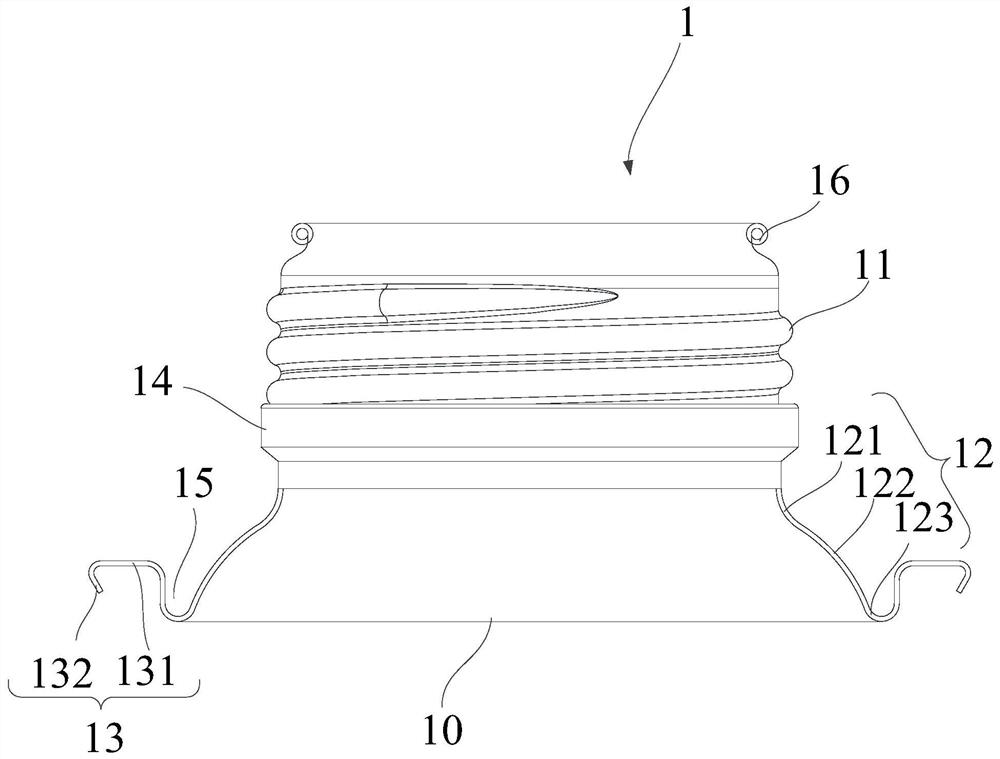

Heat treatment process for parts for automobile shock absorption system and heat treatment support frame

InactiveCN108929936AReasonable structureArrange neatlyFurnace typesHeat treatment furnacesHardnessEngineering

The invention discloses a heat treatment process for parts for an automobile shock absorption system and a heat treatment support frame, the heat treatment process comprises normalizing treatment, quenching treatment and tempering treatment; and the parts are placed in a heat treatment furnace for heat treatment by the heat treatment support frame. The heat treatment support frame comprises a frame body, the frame body is composed of a top square frame, intermediate layer square frames, a bottom square frame and a plurality of side frame pillars, the plurality of side frame pillars are vertically welded to the top corners of the top square frame and the bottom square frame, the intermediate layer square frames are sequentially in parallel ate intervals welded to the side frame pillars connecting the top square and the bottom square frame, and strip-like grilling are welded on the intermediate layer square frames. The heat treatment support frame is more reasonable in structure comparedwith that in the prior art, the parts can be placed neatly, the accommodation space is large without damaging the integrity of the parts, the heat conduction is more uniform, the heat treatment efficiency is improved; and the heat treatment process improves the mechanical strength and hardness of the parts, and improves metallographic structures.

Owner:ANHUI LUOSHI SHENGTAI AUTO PARTS

Pre-control roof medium-length hole mining method novel two-step stope room

InactiveCN105545308AThere will be no collapseImprove mining safety factorUnderground miningSurface miningEngineeringParallel arrangement

Owner:SHANDONG HUALIAN MINING

Metal screw cap, zip-top can and manufacturing method of metal screw cap

The invention provides a metal screw cap, a zip-top can and a manufacturing method of the metal screw cap, and relates to the technical field of packaging containers. The metal screw cap comprises a screw cap body, a channel used for liquid to flow out is defined by the inner wall of the screw cap body, the screw cap body comprises a threaded part, an arc-shaped part and an edge folding part, thearc-shaped part is provided with a plurality of arc-shaped sections connected end to end, at least two arc-shaped sections are different in radius, the threaded part is used for being in threaded sealing connection with a cap body, and the edge folding part is used for sealing of the edge folding part and a flanging of the can body in a coiled mode. The metal screw cap with the threaded part is arranged, so that the zip-top can can be sealed again after being opened, liquid in the zip-top can can be prevented from being polluted or wasted, when the arc-shaped sections are formed by the arc-shaped part of the metal screw cap by adopting a stamping mode or when the zip-top can is filled with the liquid with certain pressure, the metal screw cap can keep good stability, and therefore the yield of the zip-top can can be advantageously increased.

Owner:ORG TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com