T-shaped self-support structure suitable for curved surface friction stir welding

A self-supporting structure, friction stir technology, applied in welding equipment, non-electric welding equipment, edge parts of workpieces, etc., can solve the problem of inability to ensure the gap between two curved surfaces and the amount of misalignment, and can reduce the gap between assembly and fit , The effect of improving production efficiency and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings.

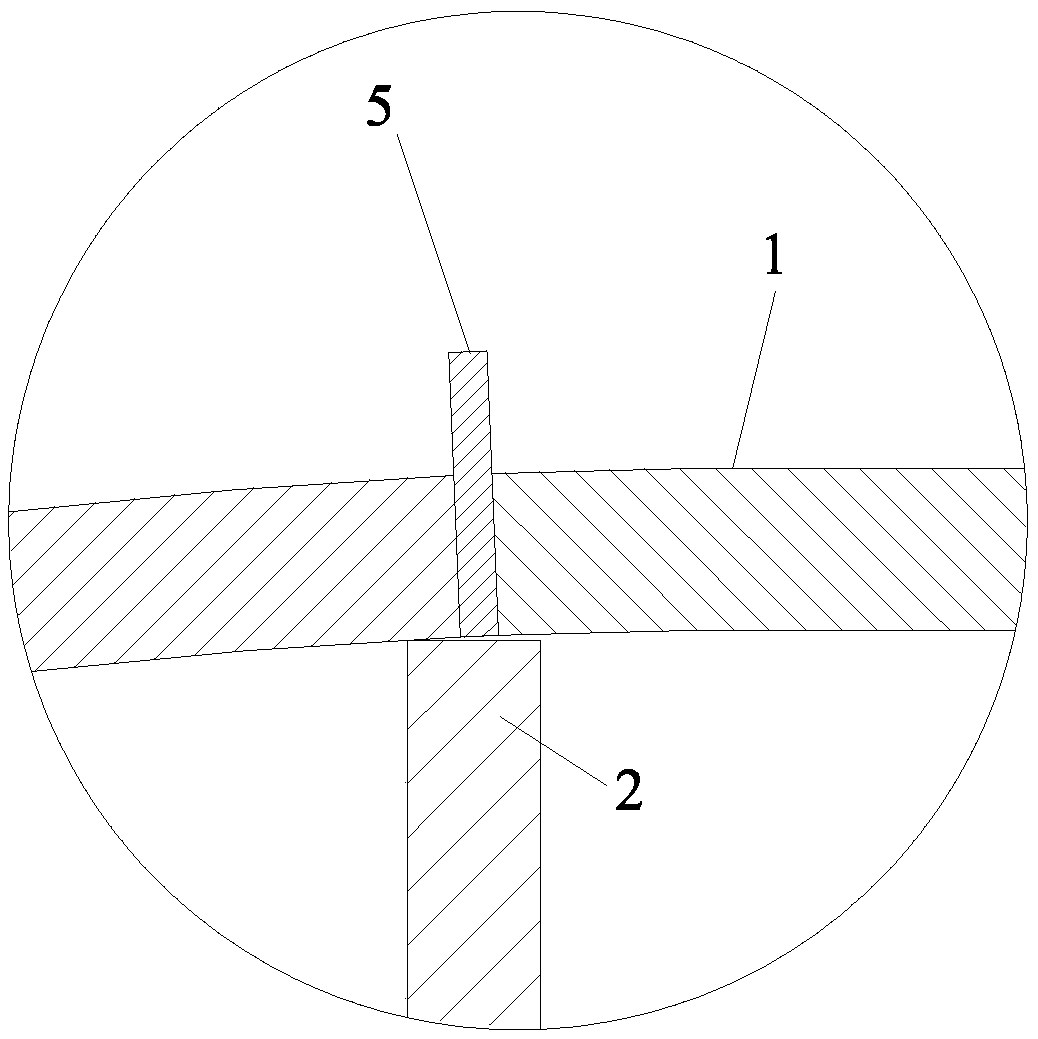

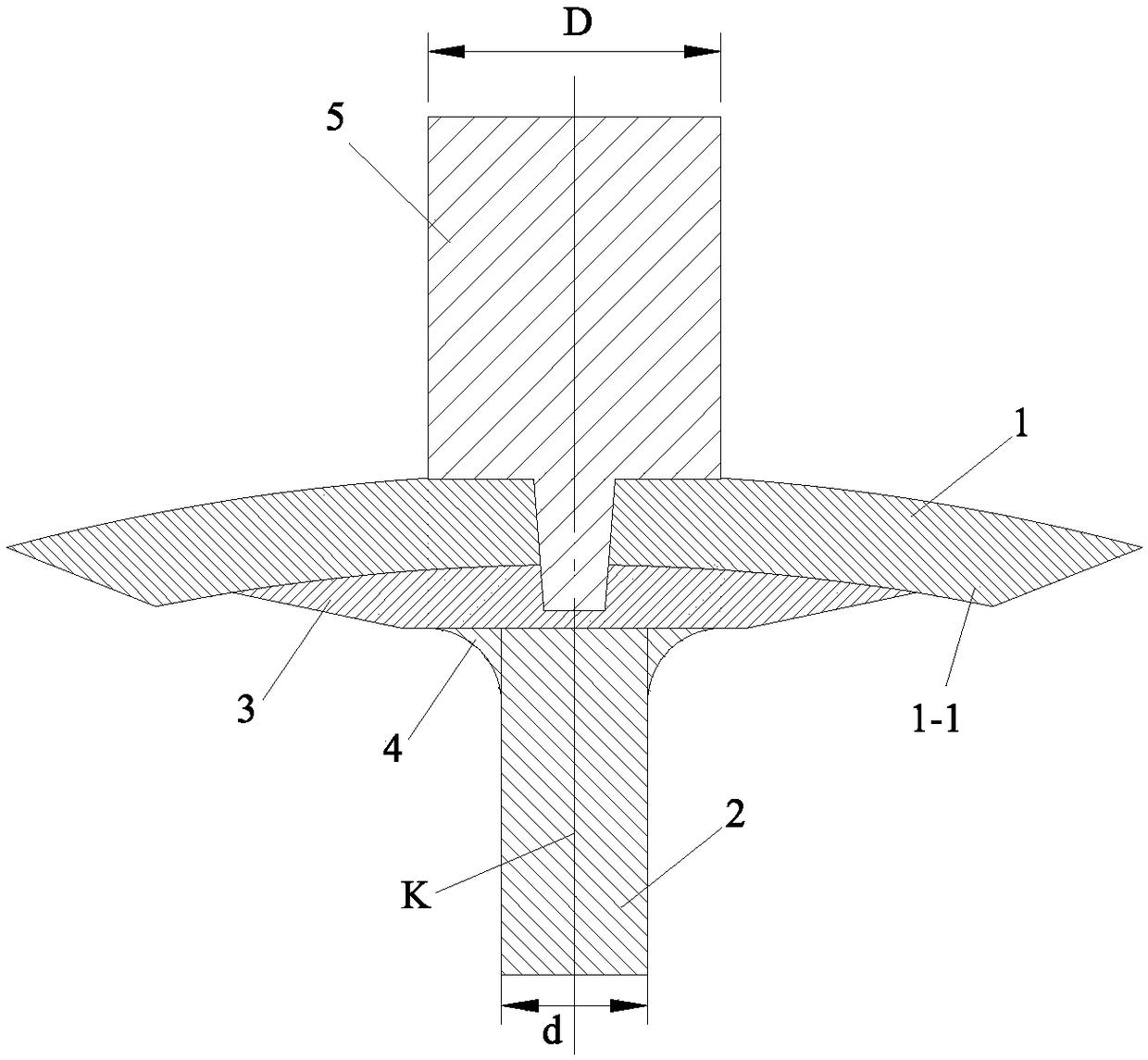

[0013] Such as figure 1 and figure 2 As shown, the T-shaped self-supporting structure suitable for curved surface friction stir welding in the present invention includes: a rib plate 2, a profiled curved panel 3 and two chamfers 4, the curvature of the profiled curved panel 3 and the curvature of the curved skin panel 1 Equal, the width of the profiled curved panel 3 is greater than or equal to the shoulder diameter D of the stirring head 5, the length of the profiled curved panel 3 is equal to the length of the curved surface skin panel 1; the top end surface of the rib plate 2 is fixed on the profiled curved panel 3, and the extension line K of the central line of the rib plate 2 passes through the highest point of the profiled curved panel 3; two chamfers 4 are fixed at the connection position between the rib plate 2 and the profiled curved panel 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com