Heat treatment process for parts for automobile shock absorption system and heat treatment support frame

A technology of automobile shock absorption and shock absorption system, which is applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of uniform distribution of unfavorable heat conduction, damage to the integrity of materials, and disorderly placement, and achieve improved mechanical strength and hardness. Improve the metallographic structure and promote the effect of heat flow up and down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not limited to these examples.

[0018] A heat treatment process for parts used in an automobile shock absorbing system, the heat treatment process comprising:

[0019] (1) Solid solution: Heat the parts used for the shock absorber system to 525-535°C, keep them warm for 90 minutes, then quench the parts for 5-6 minutes (water temperature 15-50 degrees Celsius), take them out and cool them naturally for 6-48 hours, then carry out artificial aging ;

[0020] (2) Artificial aging: Heat the components of the shock absorbing system to 165-185°C, keep them warm for 10 hours, take them out and cool them down to room temperature naturally.

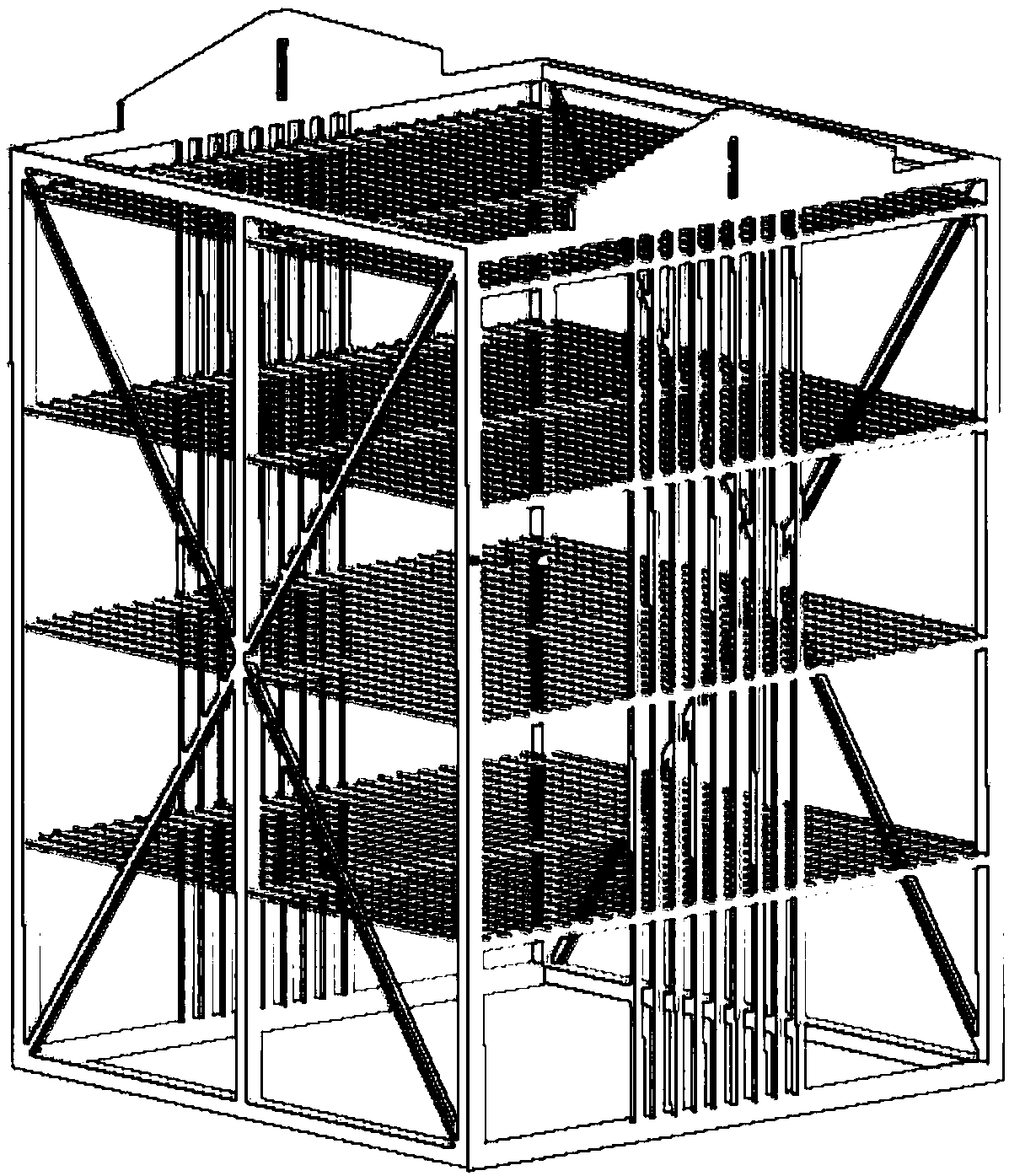

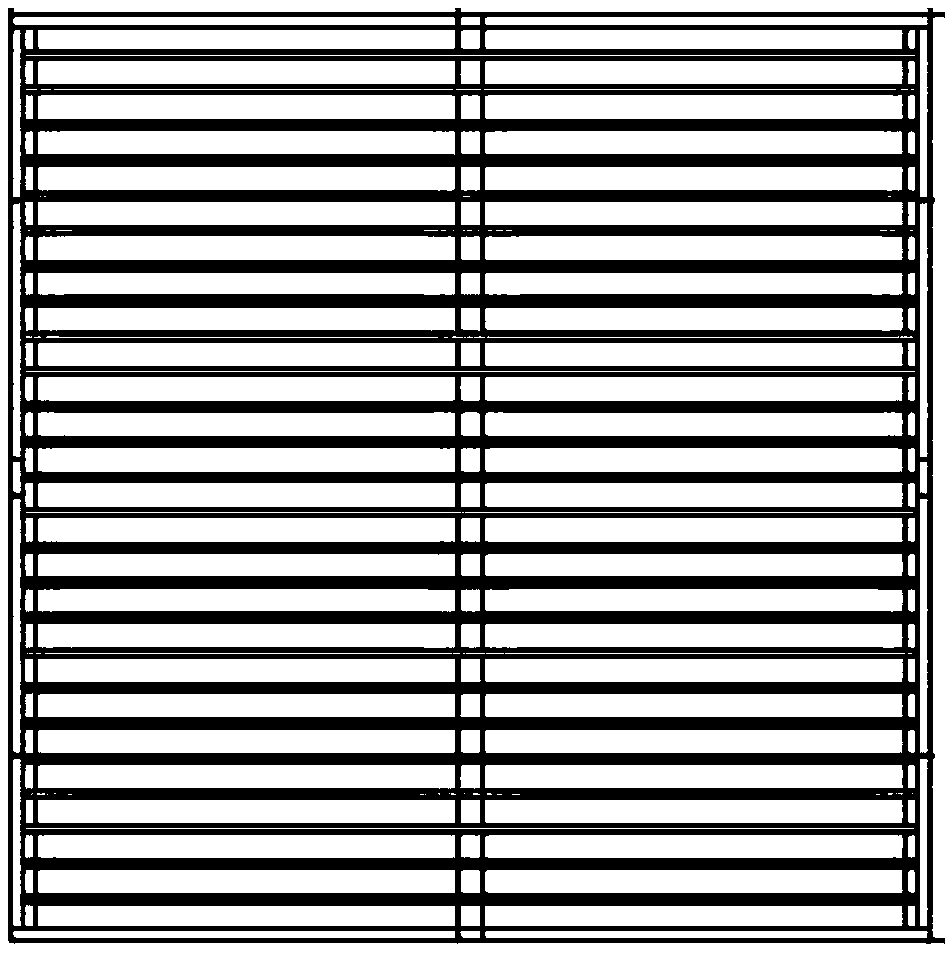

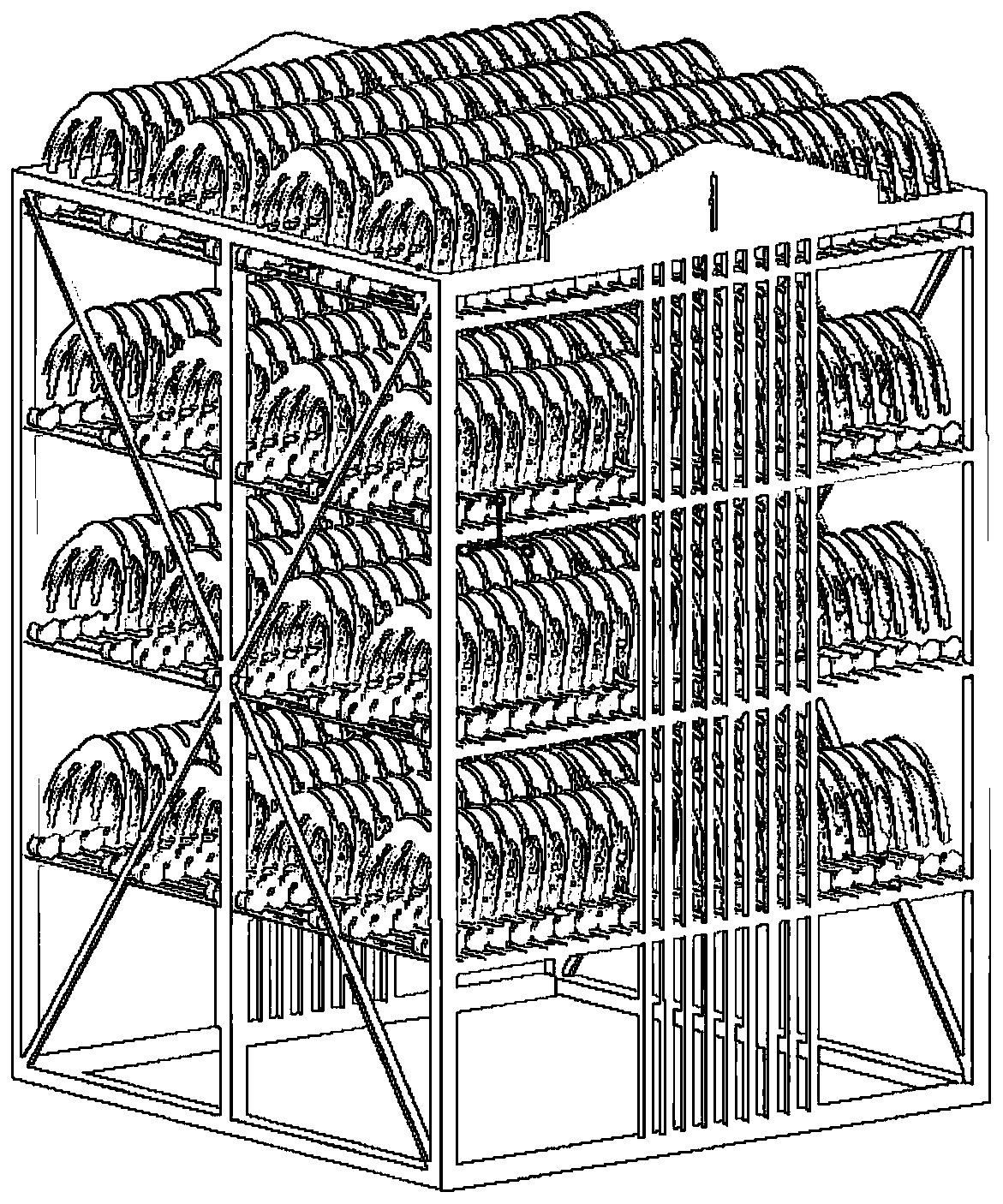

[0021] The above-mentioned heat treatment support frame for the heat treatment of parts of the automobile shock absorp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com