Patents

Literature

54results about How to "Without compromising integrity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

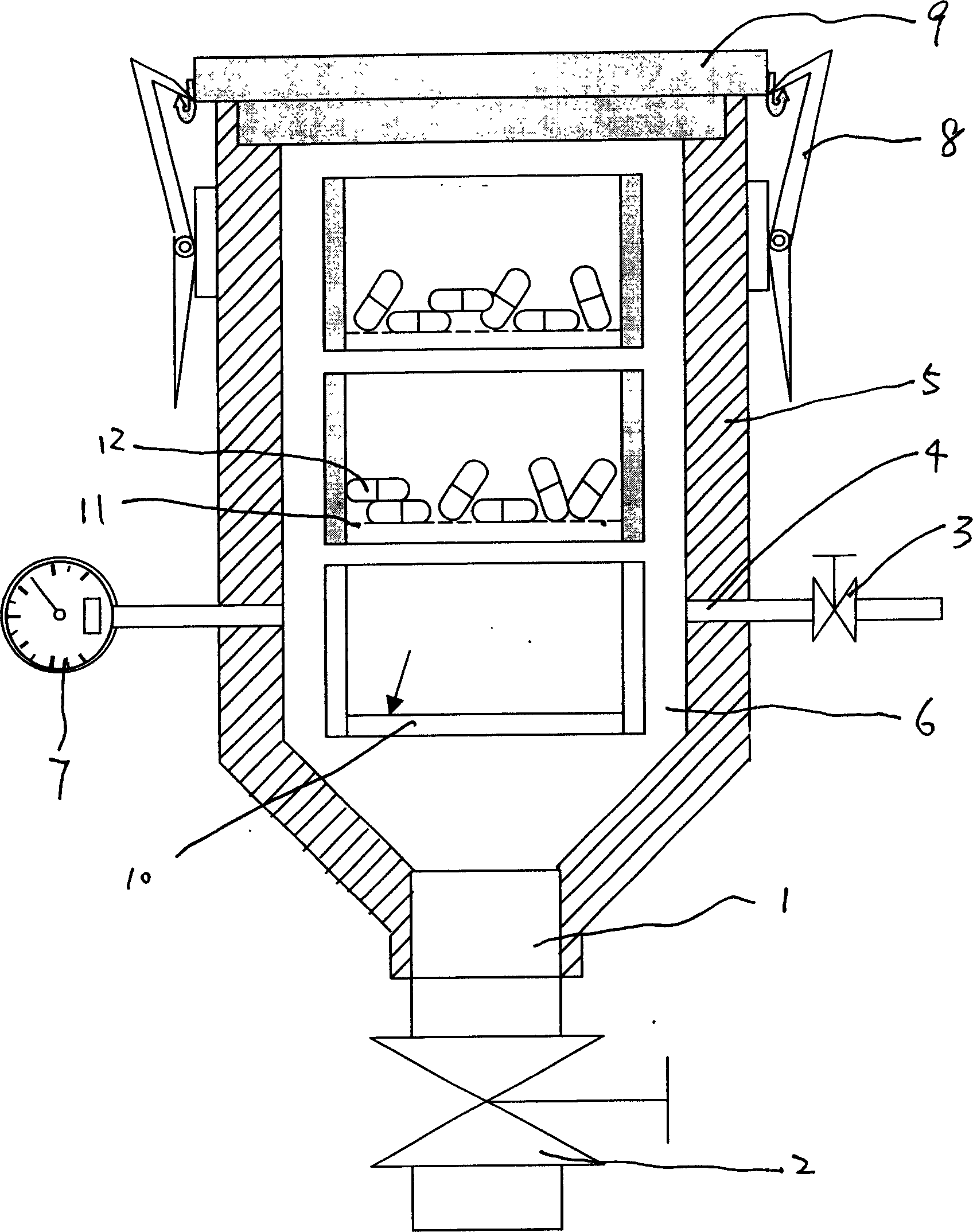

Capsule dismantling method and apparatus

InactiveCN1593370AFast separationReduce labor costsOpening closed containersBottle/container closurePhysical chemistryThin layer

The process for extraction consists the steps of, identifying the source of the raw material, extracting and concentrating the raw material, mixing the extractive with thin layer silica gel by the proportion of 1:1, loading column by the ratio of sample : thin layer chromatography silica gel = 1:0.5, and washing with expansion agent. The invention realizes an extraction process with an increased standard body purity.

Owner:韩杰

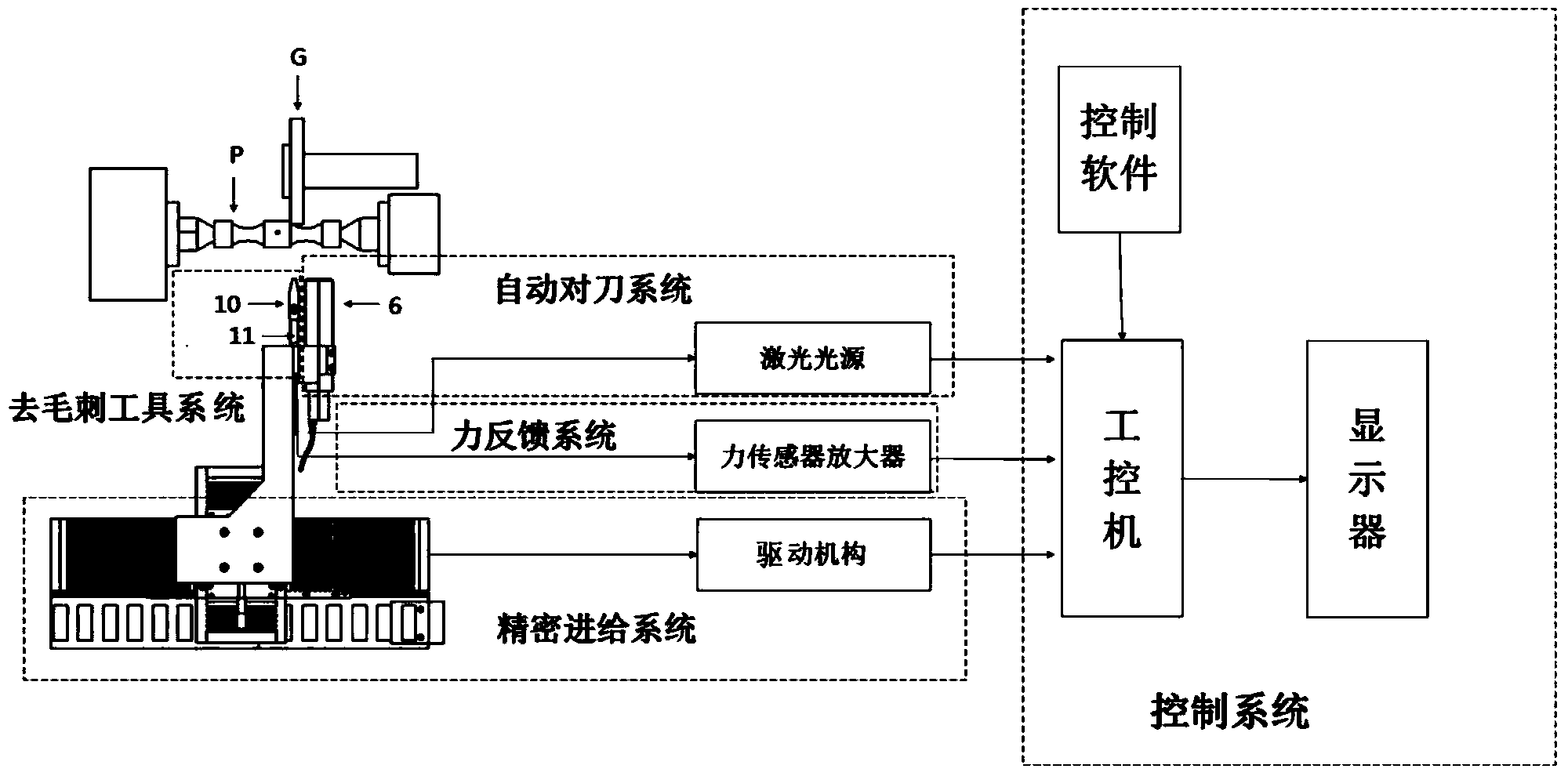

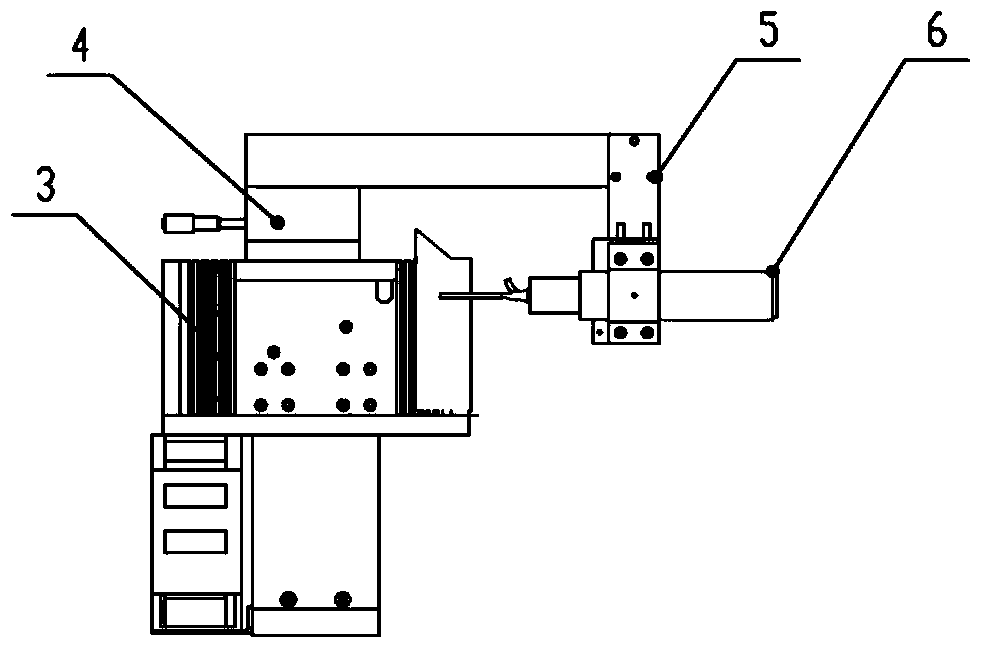

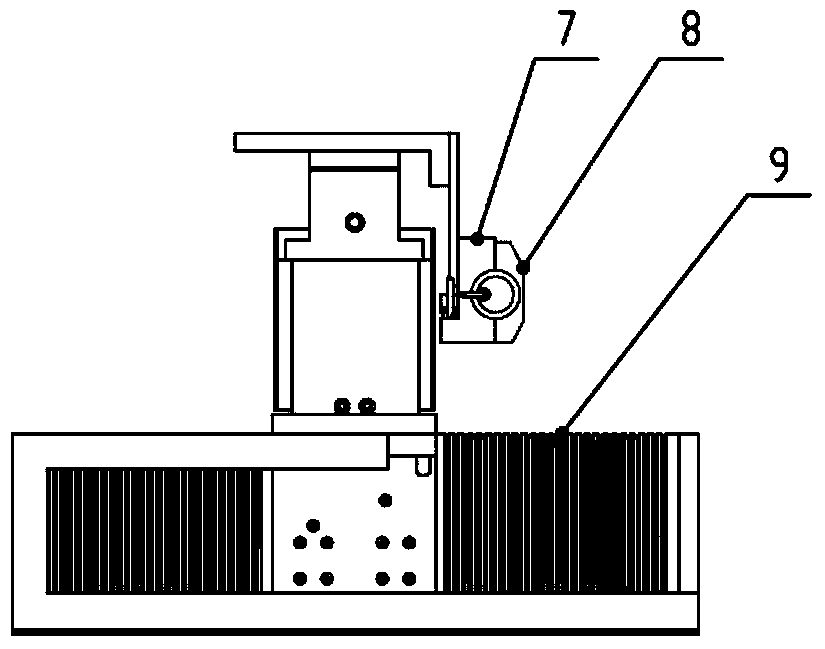

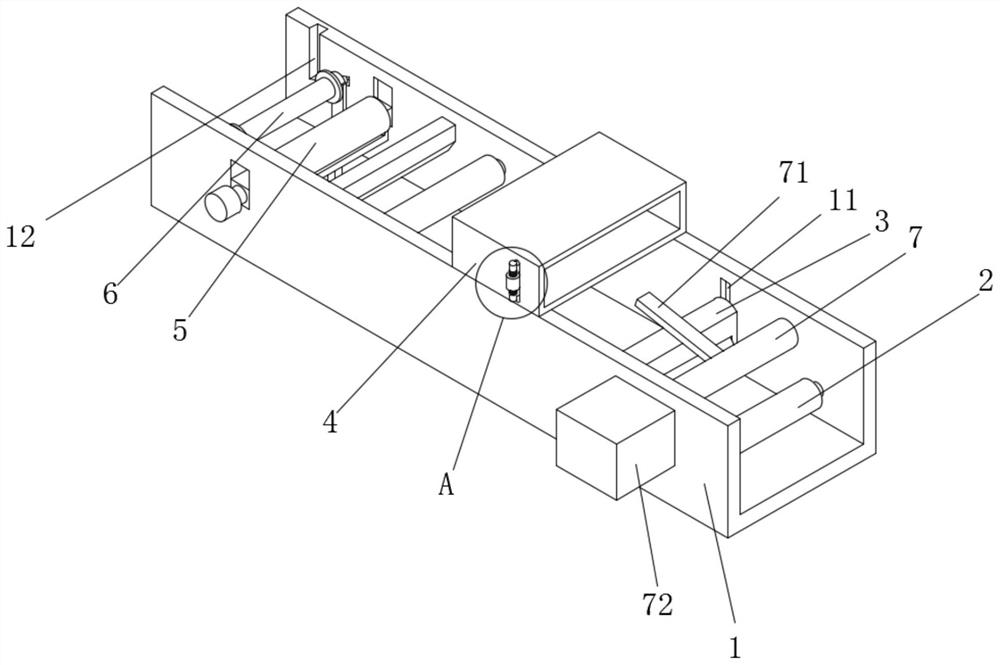

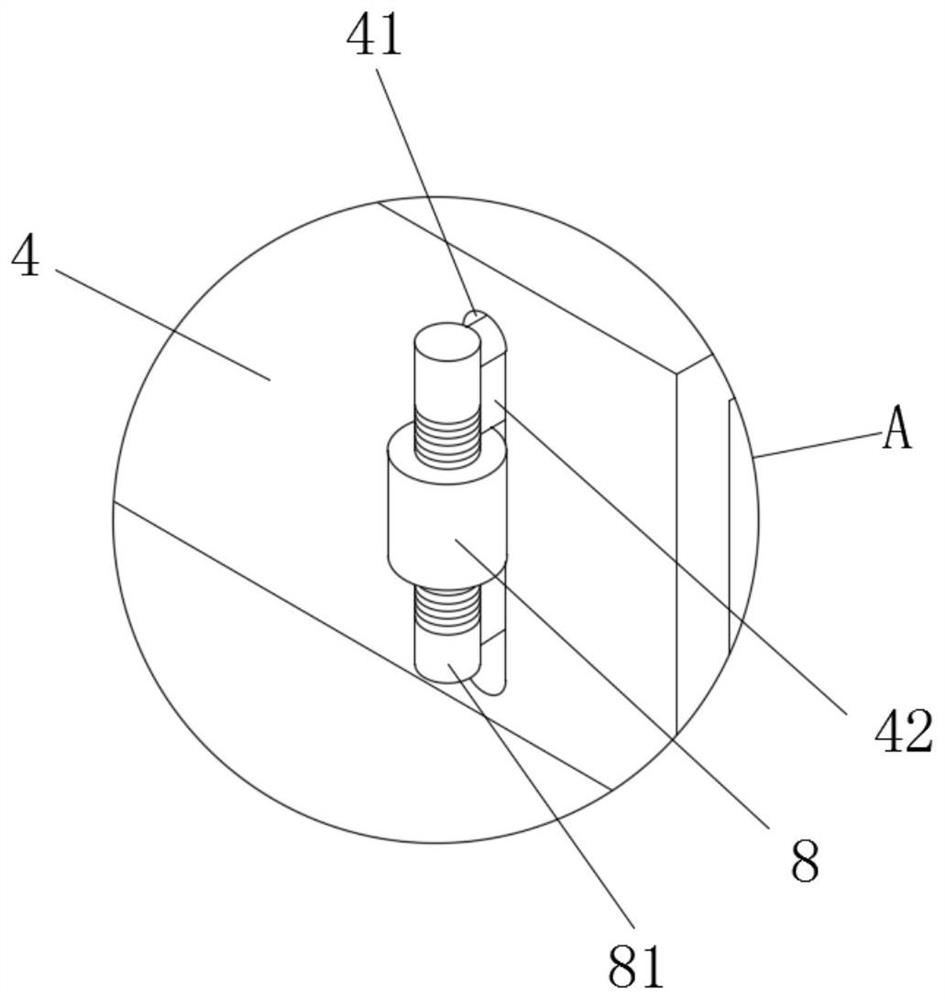

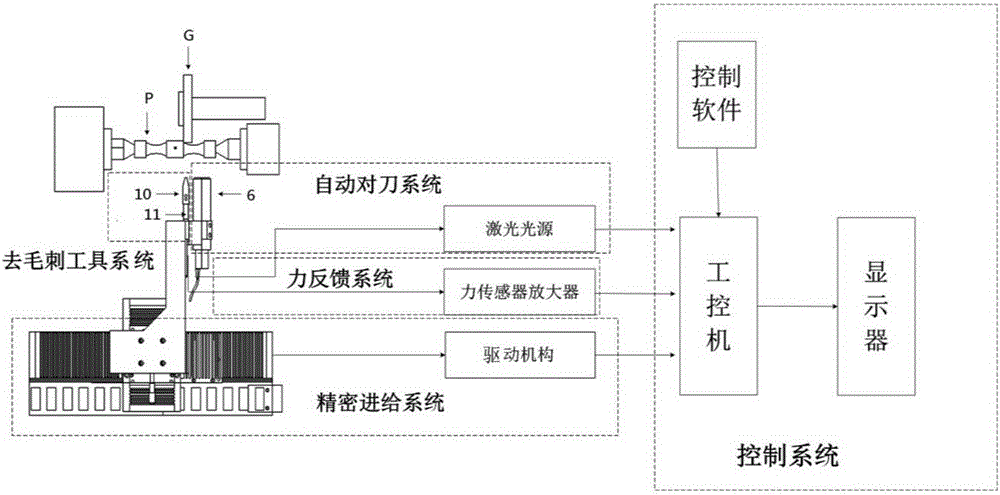

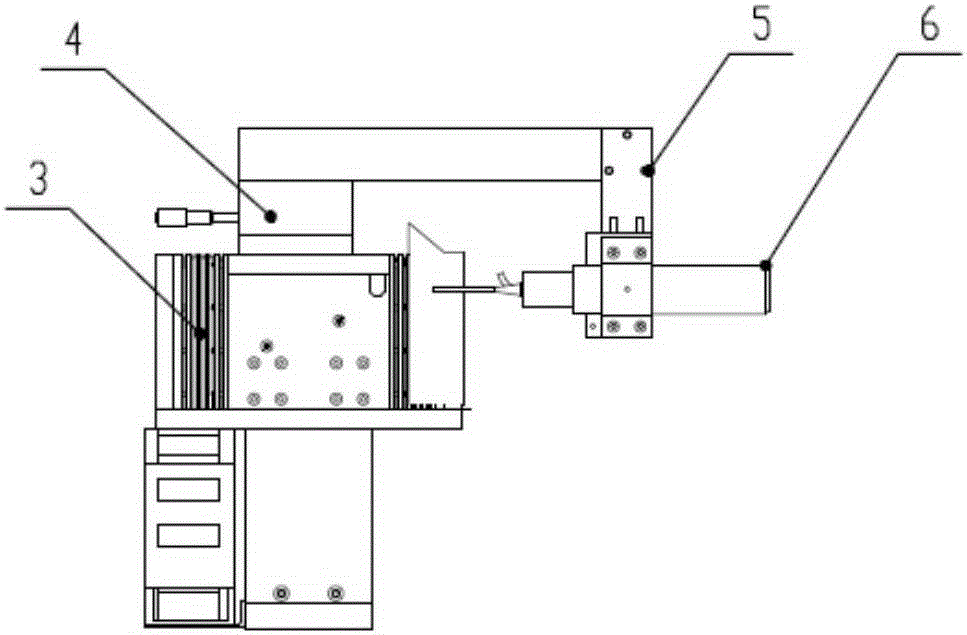

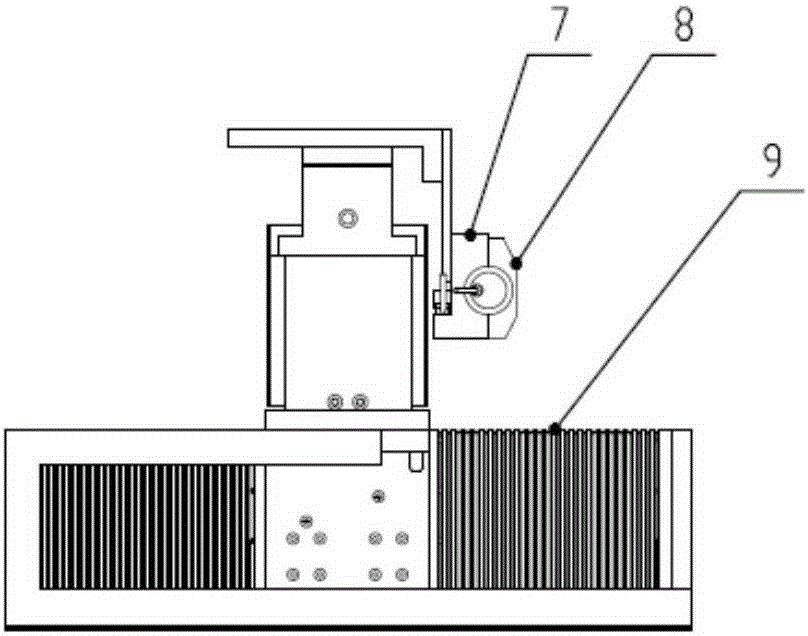

Automatic control device for online removing of tiny burrs on working edge of valve element of servo valve

ActiveCN104070183AGuaranteed stabilityGuaranteed accuracyAutomatic control devicesMeasurement/indication equipmentsAutomatic controlControl system

An automatic control device for online removing of tiny burrs on the working edge of a valve element of a servo valve comprises a deburring tool system, a precision feeding system, an automatic tool setting system, a force feedback system and a control system, wherein the deburring tool system mounted on a Z-axis lifting table comprises a deburring turning tool, a force sensor and a fixture, the precision feeding system used for controlling the feeding of the deburring tool system comprises an X-axis feeding mechanism, a Y-axis feeding mechanism and the Z-axis lifting table, the automatic tool setting system comprising a displacement sensor fixed on the fixture can achieve precise tool setting and complete radial runout measurement and working edge scanning detection of a workpiece, the force feedback system used for monitoring the degree of the deburring force in real time comprises a force sensor which is arranged below the deburring turning tool and connected with the fixture, and the control system used for monitoring the feeding movement, automatic tool setting, deburring, force feedback alarm retraction and online deburring effects of the automatic control device comprises an industrial personal computer connected with the precision feeding system, the force feedback system and the automatic tool setting system. The automatic control device for the online removing of the tiny burrs on the working edge of the valve element of the servo valve achieves the online automatic removing of the tiny burrs on the working edge and has the advantages of low rejection rates, high efficiency and low costs.

Owner:SHANGHAI JIAO TONG UNIV +1

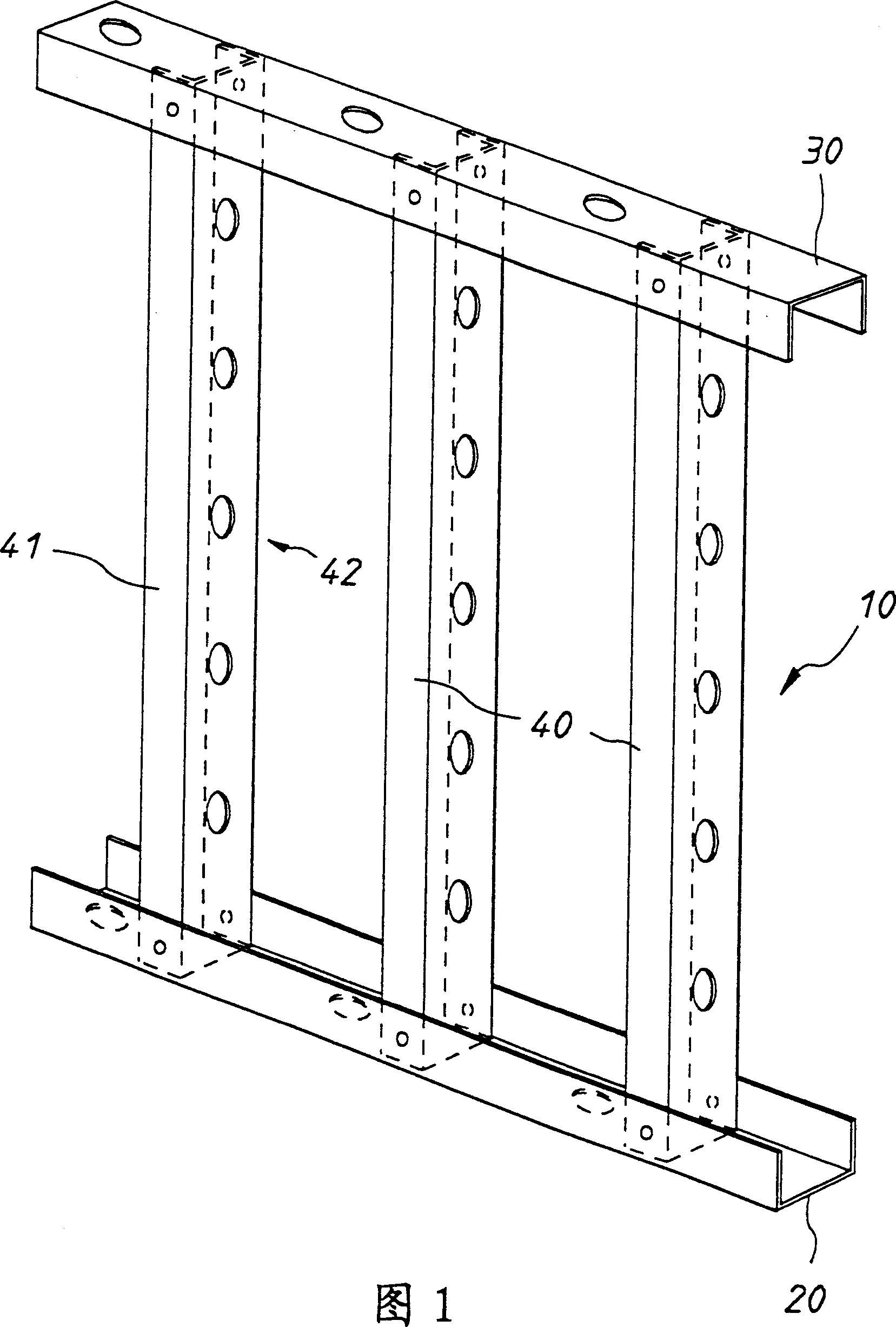

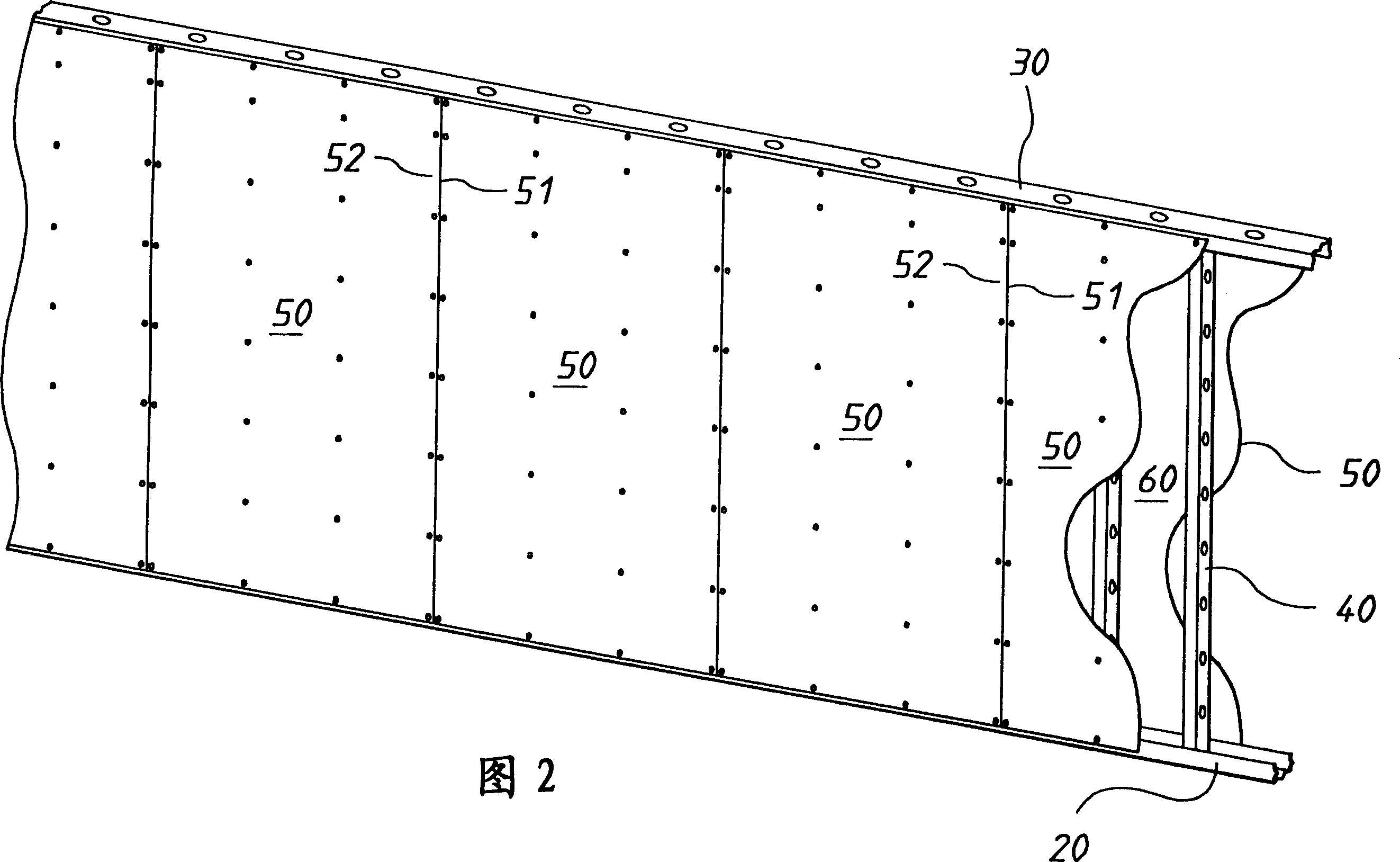

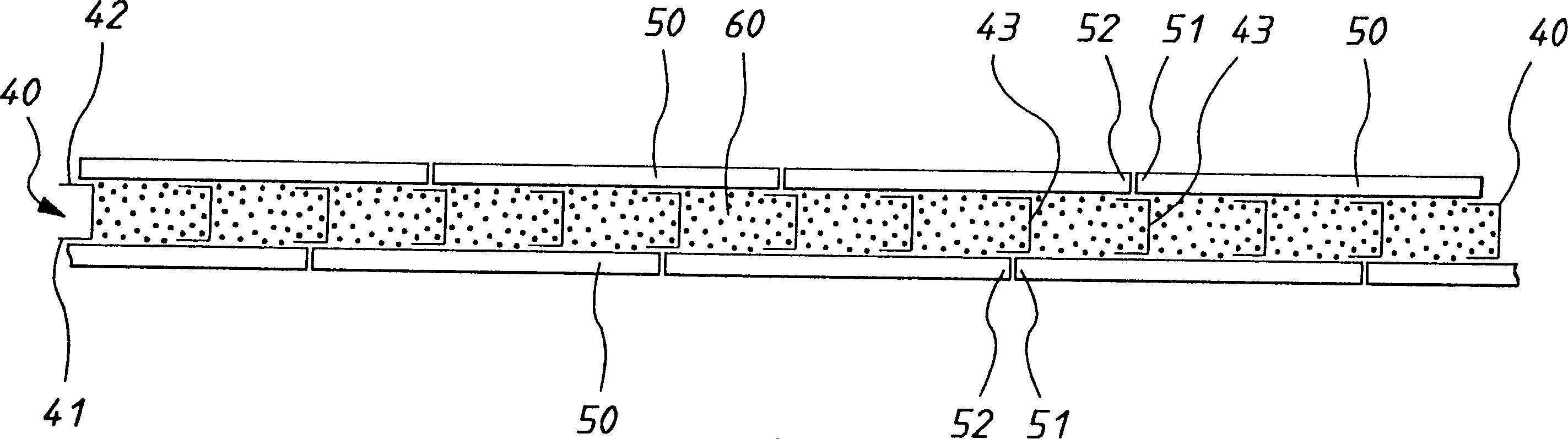

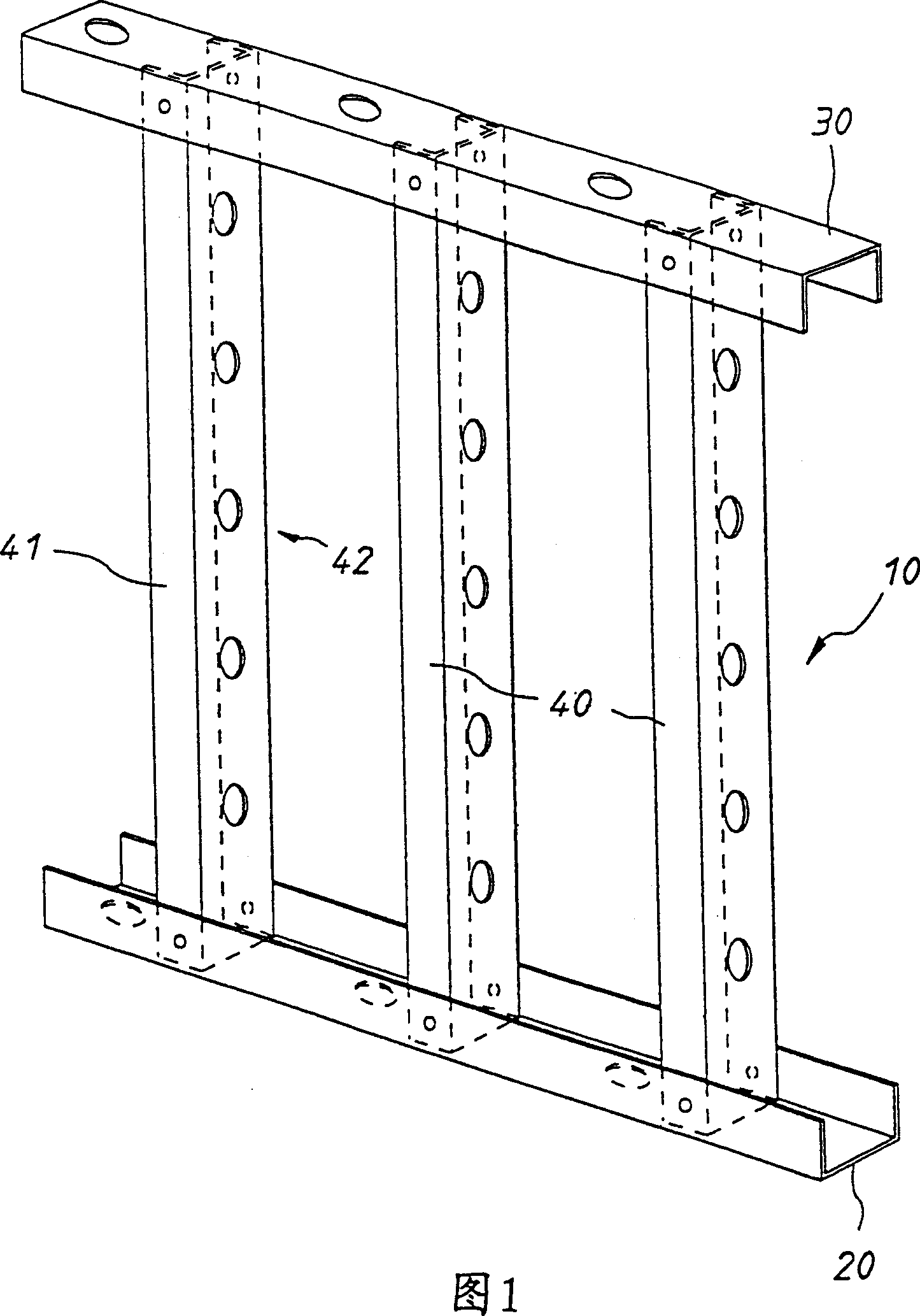

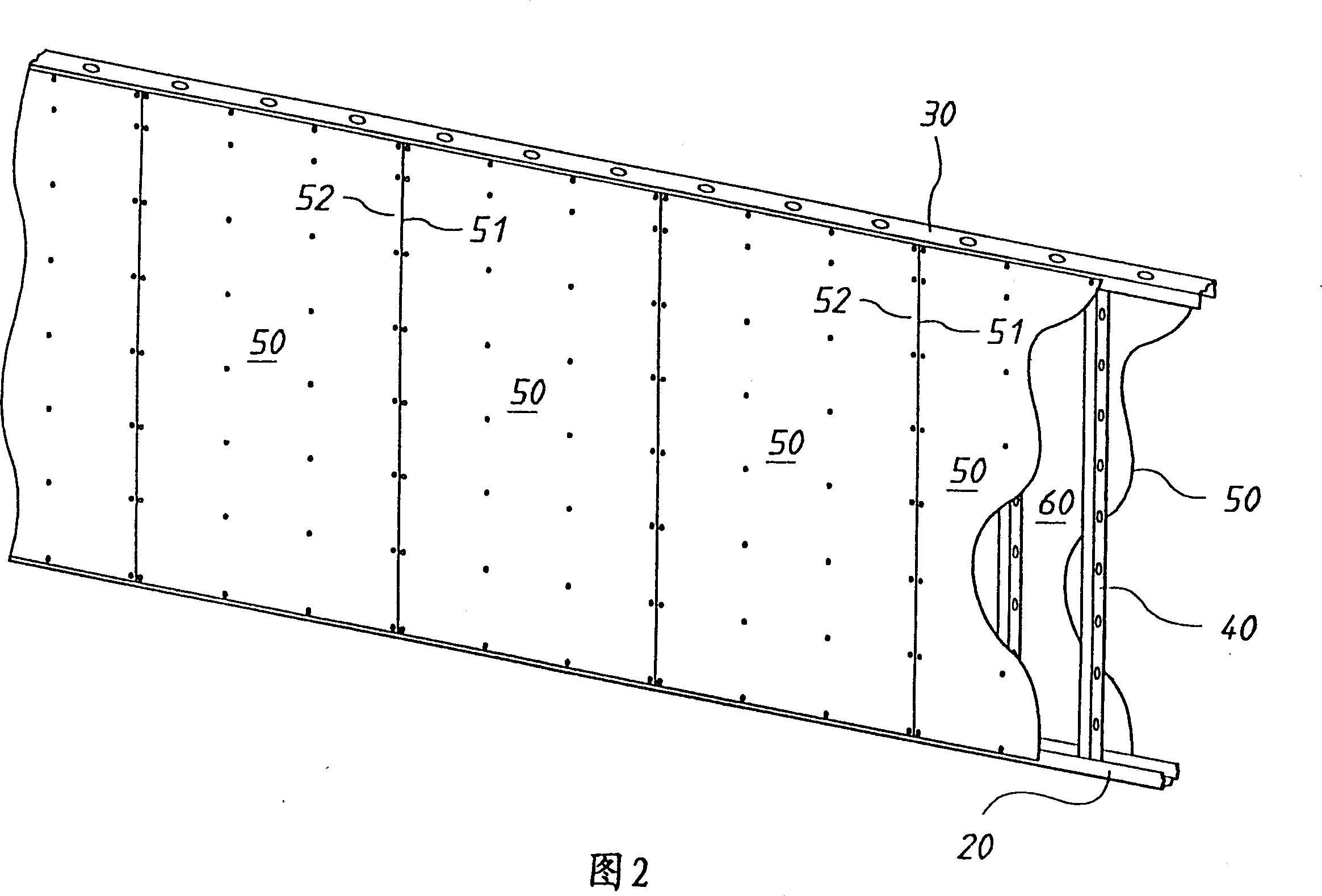

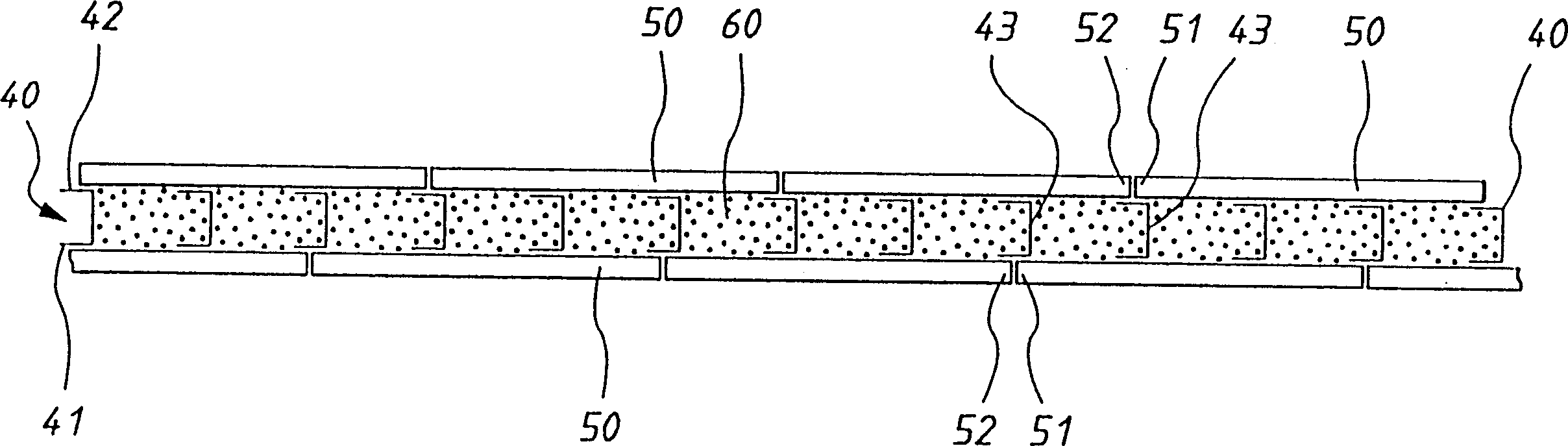

Wall element and its manufacturing method

InactiveCN1412396AIncrease flexibilitySimple and fast operationWallsFloorsSlurryMechanical engineering

A process for constructing a wall, floor or ceiling in situ. The process includes the steps of erecting a substantially rigid frame (10) and attaching fiber reinforced cementitious sheets (50) to the front and rear faces of the frame to form a void (60) therebetween. This void (60) is then filled with a lightweight aggregate concrete slurry and allowed to cure. The sheets are adapted to absorb sufficient moisture from the lightweight aggregate slurry to provide natural adherence of the concrete slurry to the sheets without substantially losing their structural integrity during setting and curing of the concrete slurry. Further, The invention provides a wall produced by the same process.

Owner:JAMES HARDIE INT FINANCE BV

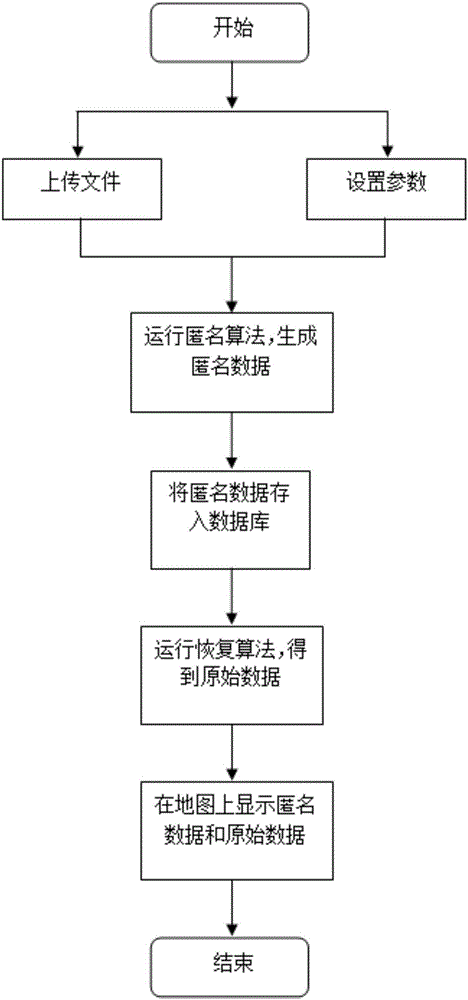

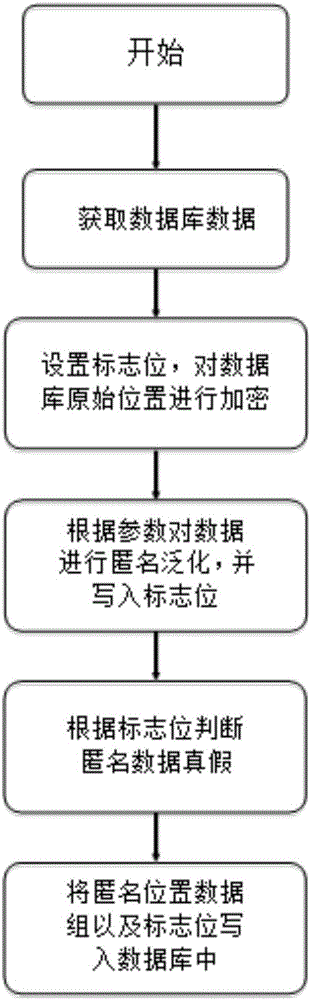

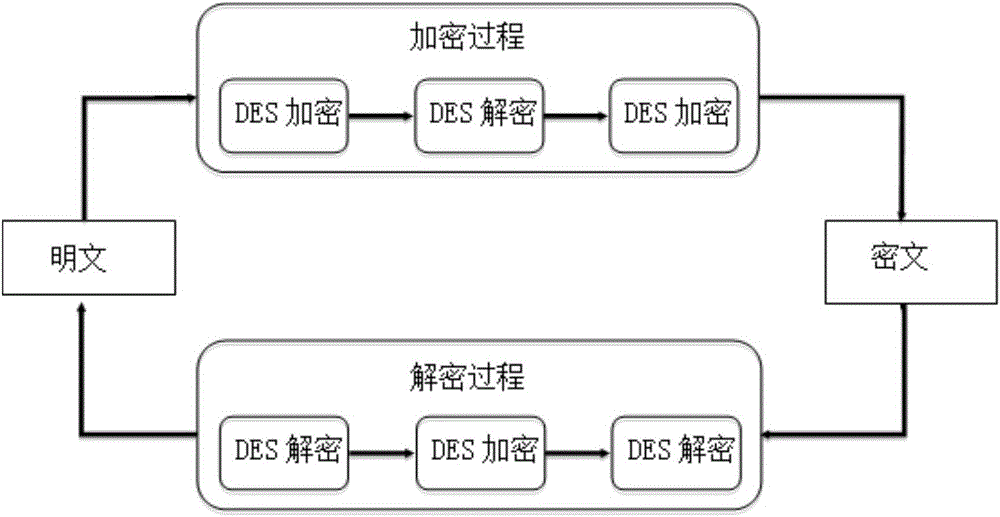

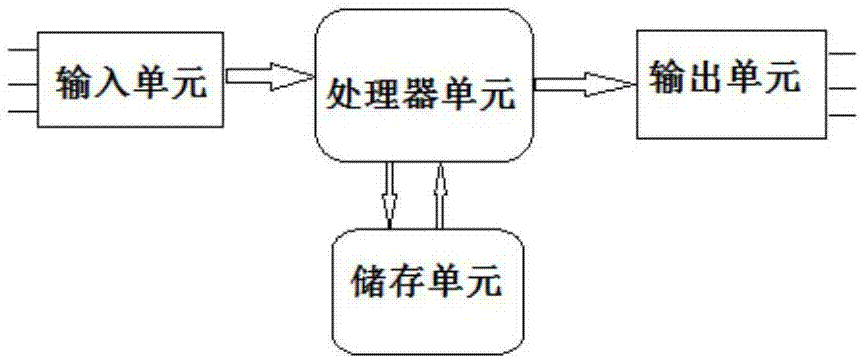

K-anonymization based motion track data privacy protection method and system

ActiveCN105160266AImprove scalabilityAdaptableDigital data protectionData privacy protectionOriginal data

The invention discloses a K-anonymization based motion track data privacy protection method and system. A K-anonymization technology is adopted for generalizing motion track data and hiding real data, the generalized data is encrypted at the same time by establishing a database trigger mechanism, and the generalized data is decrypted and recovered into original data by utilizing a design data recovery algorithm, so that privacy protection of the motion track data is realized. According to the K-anonymization based motion track data privacy protection method and system, a K-anonymization generalization algorithm is improved, so that the generalized track privacy data can be recovered, it is ensured that the original data can be recovered while the privacy data is hidden, and the data completeness is realized.

Owner:NANJING NORTH OPTICAL ELECTRONICS

Board surface leveling method of loop-free blind hole high-density interconnection printing circuit board

InactiveCN101716744AWithout compromising integrityImprove routing densityLapping machinesConductive pattern polishing/cleaningAcid etchingHigh density

The invention relates to a board surface leveling method of a loop-free blind hole high-density interconnection printing circuit board, which has the technical key point that the outer layer of a high-density interconnection printing circuit board is performed with whole board plating and is put into a scrubbing machine with the transmission speed of 1.5-2.0m / min; the pressure of a brush roll cooling water nozzle is 1.0-1.5 kg / cm<2>, the temperature of cooling water is 20-30 DEG C, brush roll grinding current is 0.8-1.2A, the horizontal swinging amplitude of the brush roll is 5mm, and the swinging frequency is 350 times / min; and the board surface of the high-density interconnection printing circuit board is ground and levelled. As the board surface of the printing circuit board is ground to be levelled, blind hole surface and surface copper are on the same horizontal plane; when a dry film is pasted, the blind hole can be tightly stuck with the dry film without adding a welding ring; during acid etching, blind hole integrity is not damaged, thus effectively improving the wiring density of the board surface of the printing circuit board.

Owner:BOMIN ELECTRONICS CO LTD

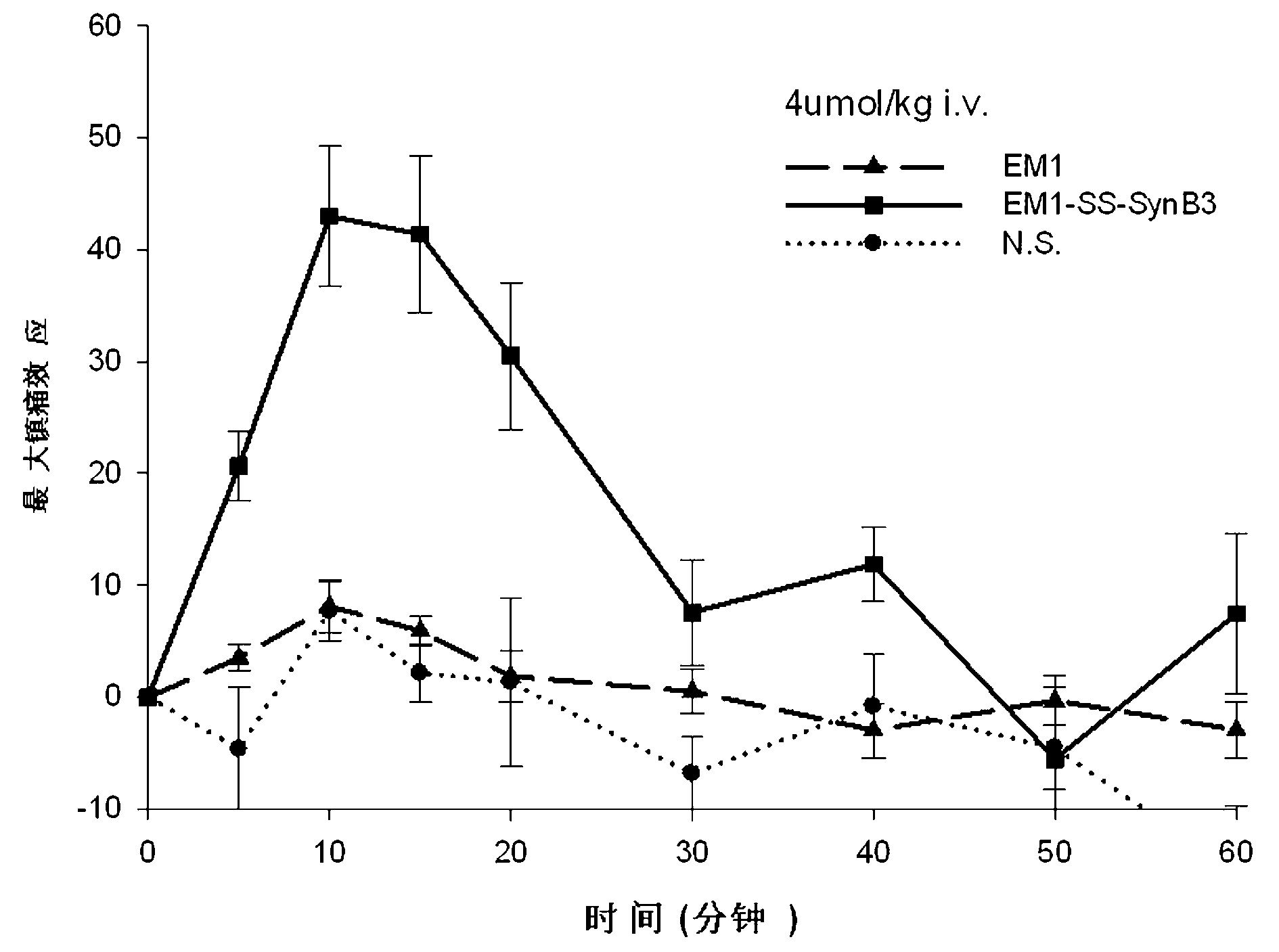

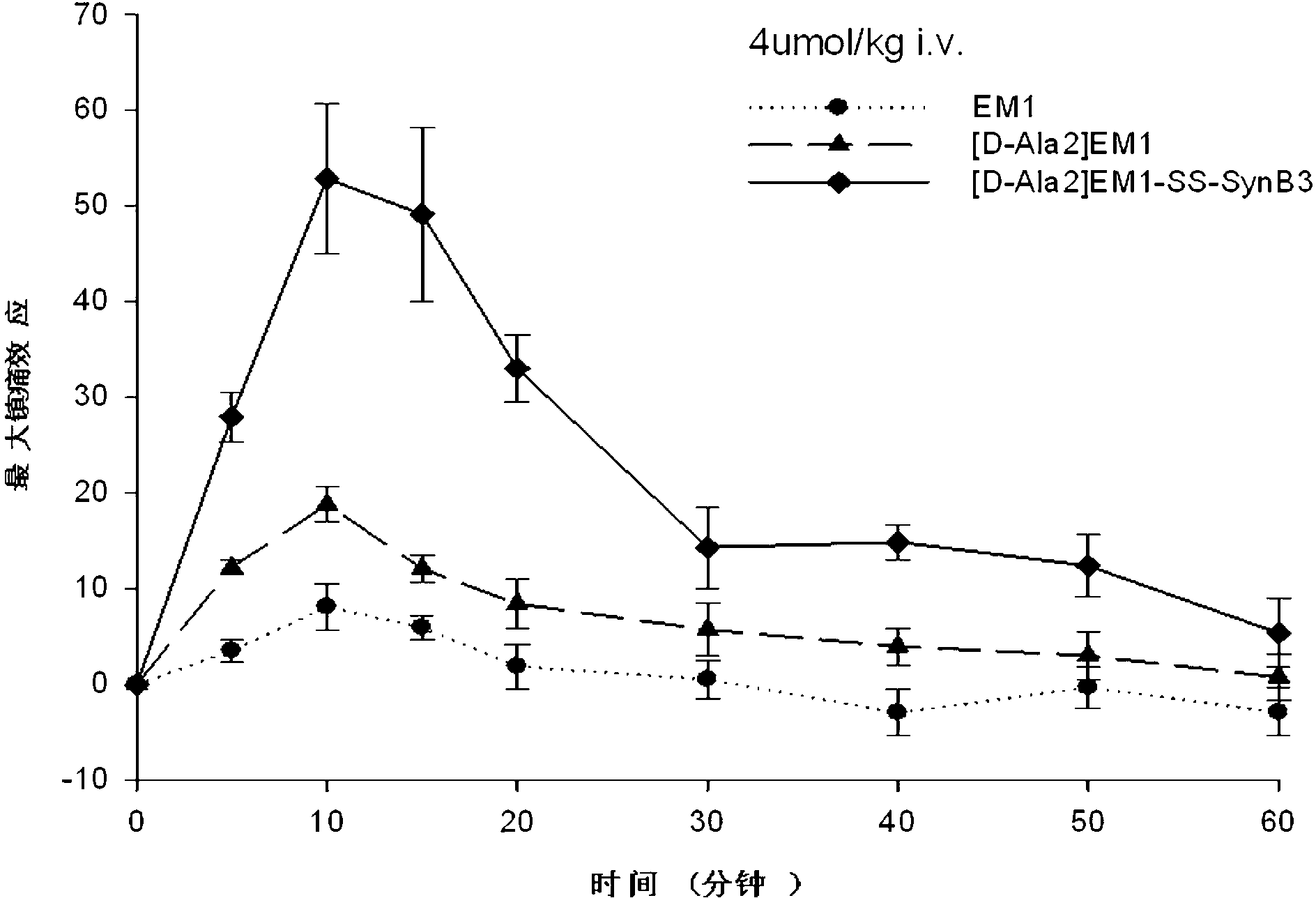

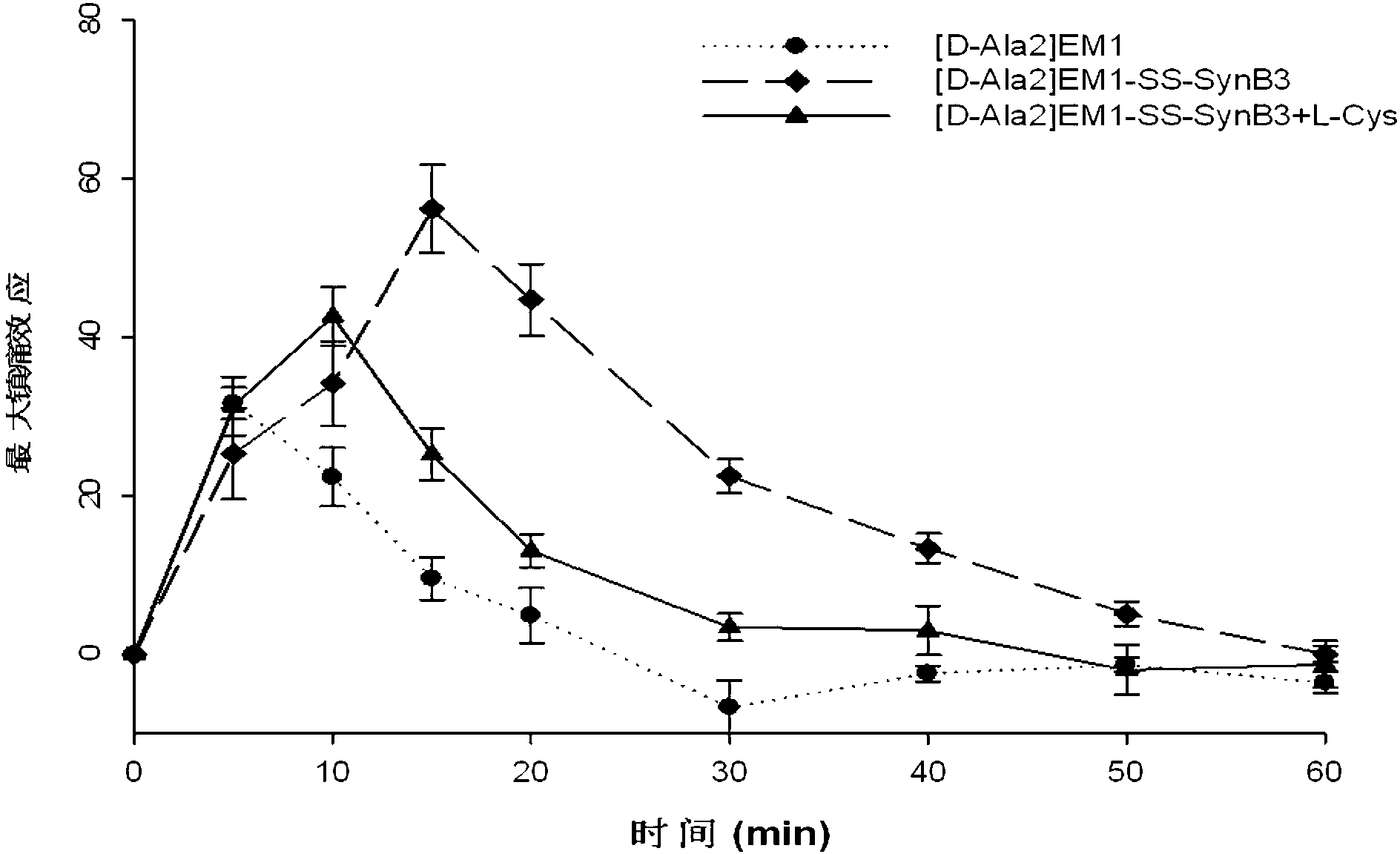

Endomorphin-derived peptide with blood-brain barrier permeability as well as synthesis and application of endomorphin-derived peptide

ActiveCN103012596AIncreased Brain UptakeWithout compromising integrityNervous disorderTetrapeptide ingredientsMeningesAdsorption effect

The invention discloses endomorphin-derived peptides with blood-brain barrier permeability. The endomorphin-derived peptides are formed by connecting cell-penetrating peptide SynB3 with the carbon terminal of EM1 (Endomorphin1) and analogue (D-A1a2) EM1 through a disulfide bond; good BBB (Blood-Brain Barrier) permeability of the SynB3 is used to mediate the EM1 and the analogue (D-A1a2) EM1 to permeate the blood-brain barrier to reach the center by means of adsorption effect; and the characteristics that the disulfide bond is stable in blood and is easily reduced to break in meninx are utilized, the disulfide bond is broken under the action of a meningeal reductase to release free endomorphin-derived peptide so that the pain killing effect of the endomorphin-derived peptide can be exerted. A pharmacodynamic experiment proves that the endomorphin-derived peptides can be peripherally administrated besides the obviously improved pain killing activity to provide a wide prospect for developing clinical application of a neuropeptide medicine.

Owner:LANZHOU UNIVERSITY

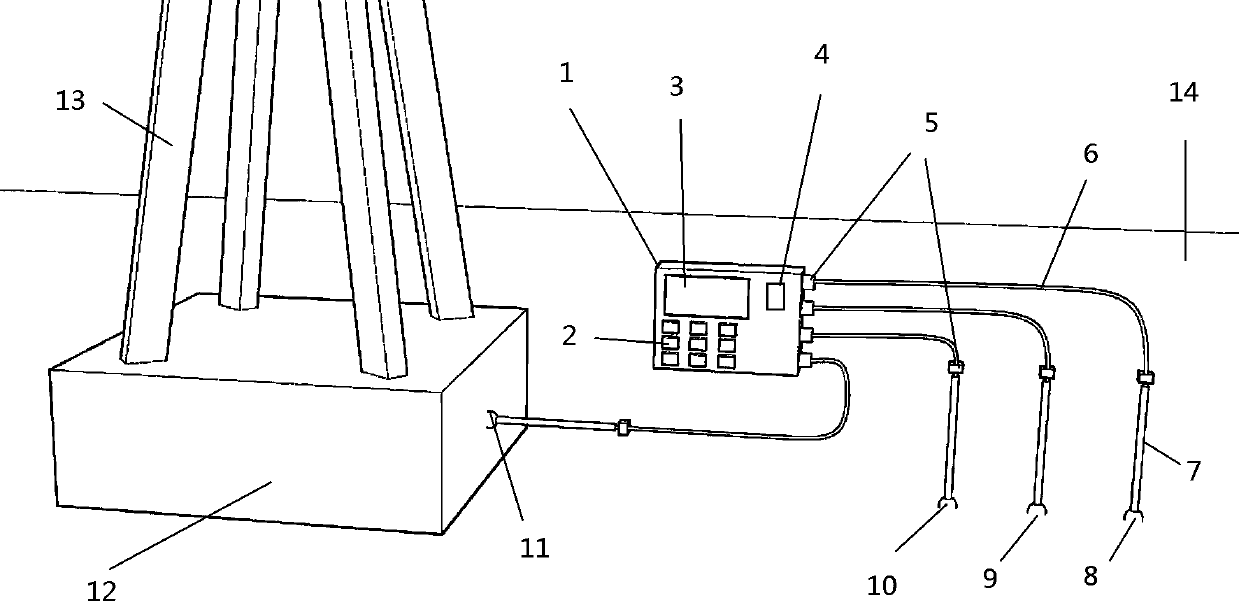

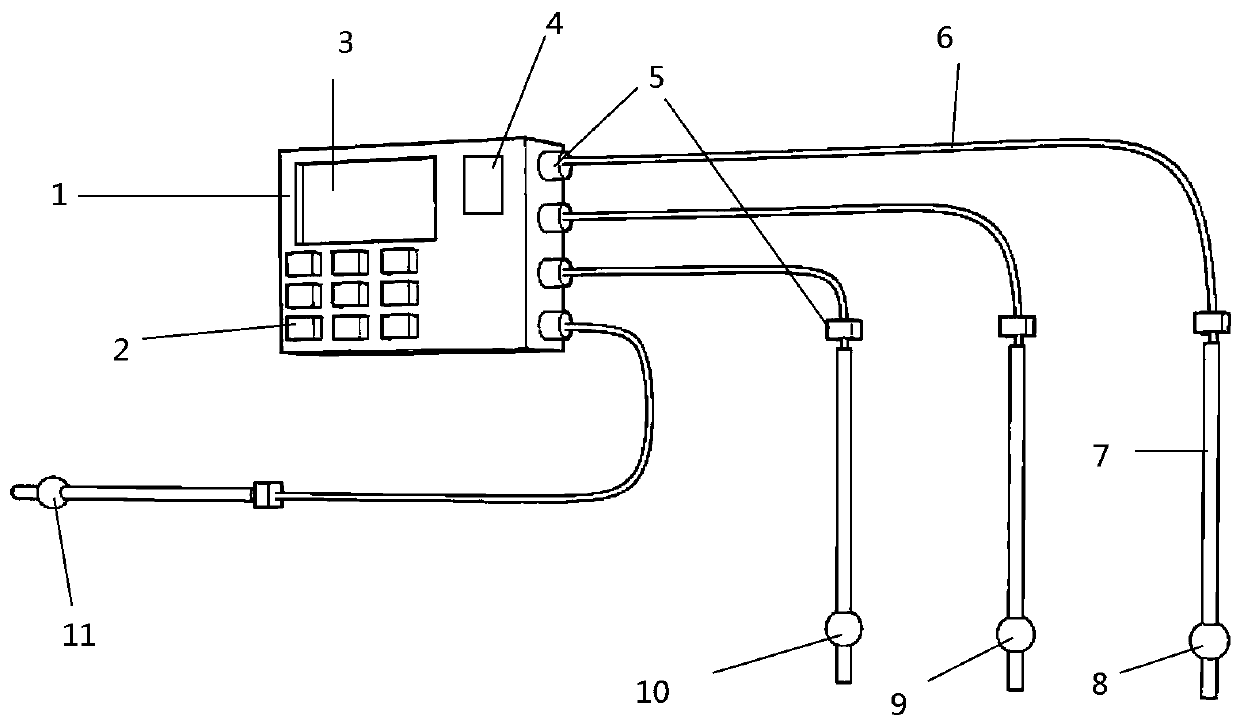

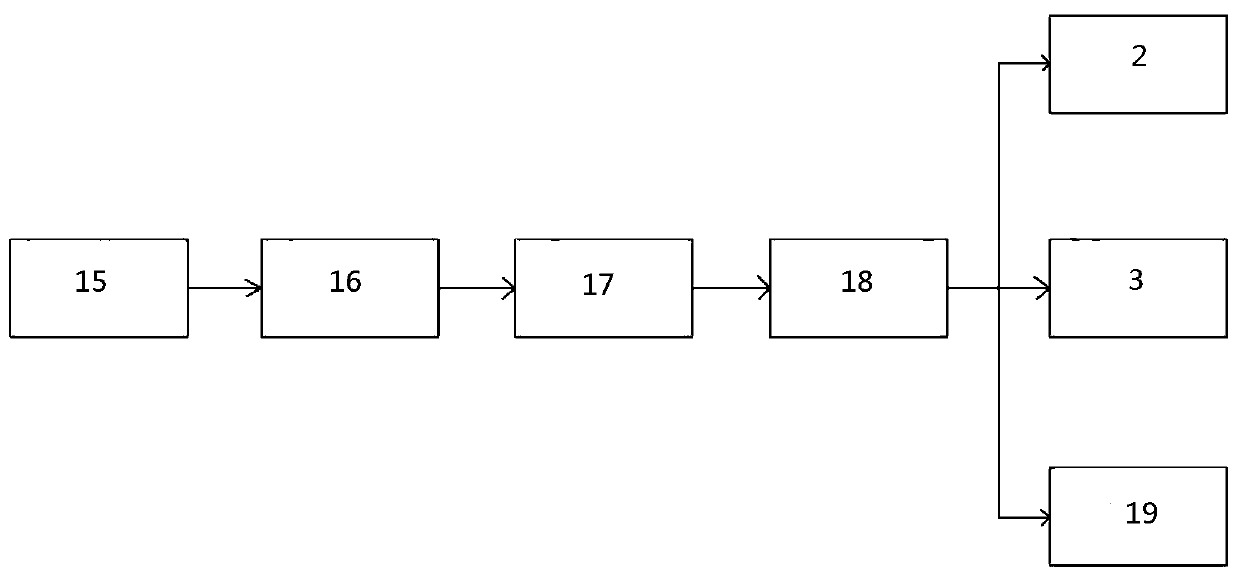

Device and method for detecting corrosion degree of steel bars of reinforced concrete foundation of iron tower

PendingCN108680490ACheck the degree of corrosionWithout compromising integrityWeather/light/corrosion resistanceMicrocontrollerRebar corrosion

The invention relates to a device and a method for detecting corrosion degree of steel bars of a reinforced concrete foundation of an iron tower. The device comprises an operation panel, a single chipmicrocomputer and sensors, wherein an AD (analog to digital) conversion module, a microprocessing module and an execution module are arranged in the single chip microcomputer; a display module, a press key input module, the single chip microcomputer and a storage module are arranged on the operation panel; the sensor comprise a soil temperature and humidity sensor, a soil pH (potential of hydrogen) value sensor, a soil chloride ion sensor and a resistivity detector. By adopting the structure, the device has the advantages that on one hand, the corrosion degree of the steel bars in the concrete tower foundation can be detected without excavating the soil and destroying the concrete tower foundation structure; on the other hand, the corrosion degree of the steel bar can be quickly analyzedat site.

Owner:CHINA THREE GORGES UNIV

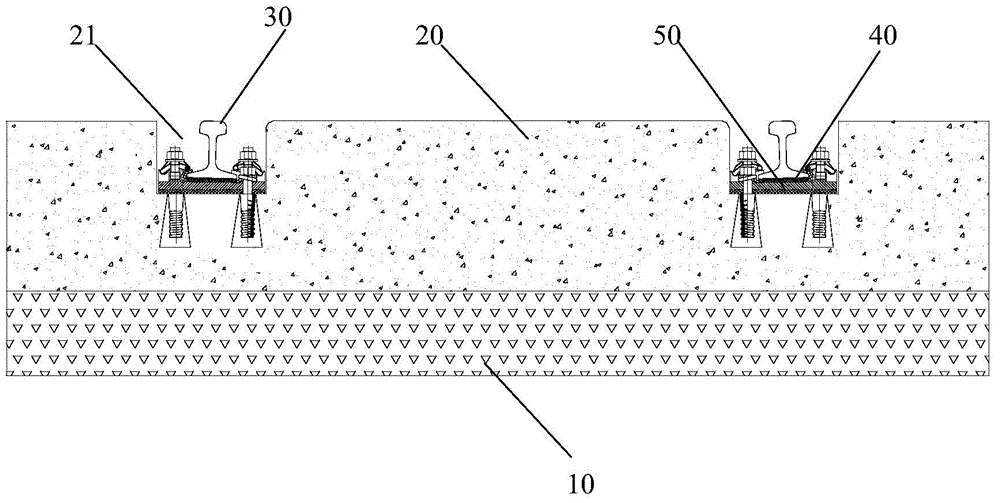

Assembled grade crossing

InactiveCN104947566AReduce the number of potting jointsImprove stabilityTemporary pavingsBuilding construction

The invention provides an assembled grade crossing with compact structure, good integrity, stress uniformity, simplicity in construction, long maintenance cycle and low maintenance cost. The assembled grade crossing comprises a graded broken stone layer, an integral road bed and a track, wherein the graded broken stone layer is laid on a foundation of the railroad grade crossing; the integral road bed is arranged on the graded broken stone layer, and two grooves used for mounting the track are formed in the upper surface of the integral road bed; and the track is mounted in the grooves used for mounting the track. The assembled grade crossing is simple to construct, construction speed is high, construction time is shortened, normal traffic can be restored in the shortest time, and construction cost is reduced; meanwhile, the problems that a circuit is hung on a plate, mud pumping is caused and a grade crossing plate is broken can be solved.

Owner:TIANJIN PORT FACILITIES MANAGEMENT SERVICE

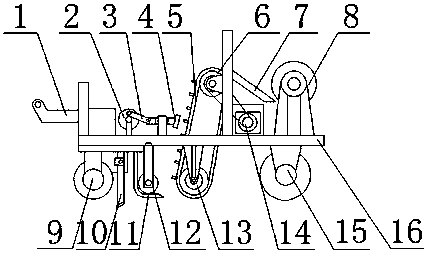

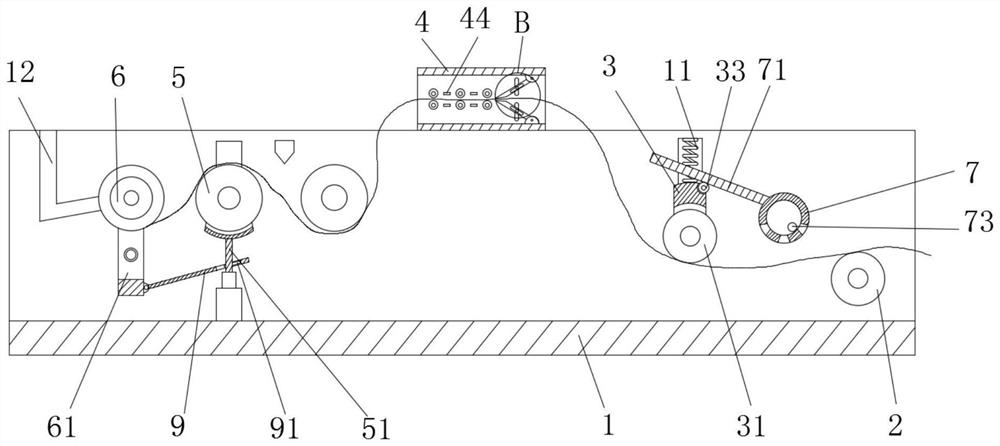

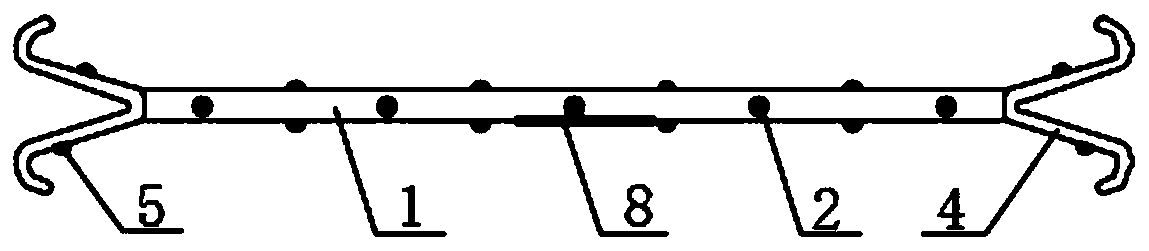

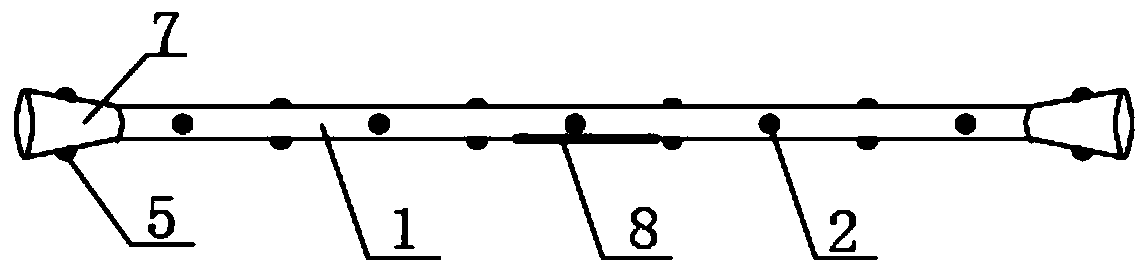

Mulching film strip collecting device

InactiveCN108496430AReduce residual film rateWithout compromising integrityGatherer machinesAgricultural engineeringPlough

The invention relates to a mulching film strip collecting device, and belongs to the technical field of agricultural equipment. The mulching film strip collecting device mainly comprises a rack, a delivering device, a collecting roller and the like. Through a film pulverator plough shovel, mulching film embedded in soil is ploughed out, the ploughed mulching film arrives at a delivering device through a delivering packing auger bottom support, and under traction of the delivering device, the mulching film moves upwards; then a cam rotates to drive a hammerhead to reciprocate, the hammerhead hammers the mulching film to make the mulching film vibrate, and the mulching film is effectively separated from impurities like soil on the mulching film through vibrating. The residual film rate is effectively lowered, and meanwhile, the cleanliness after the mulching film is recycled is guaranteed.

Owner:王景硕

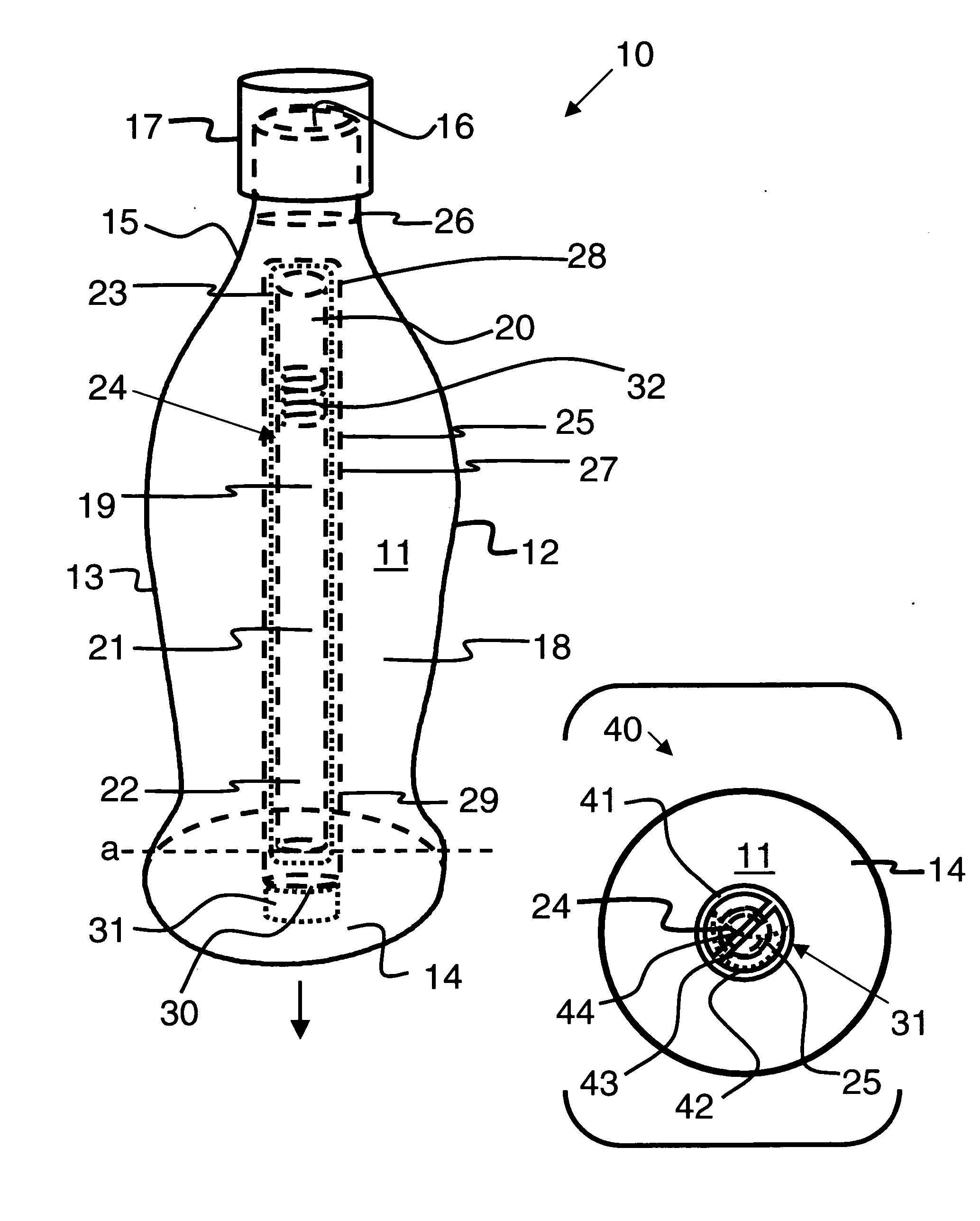

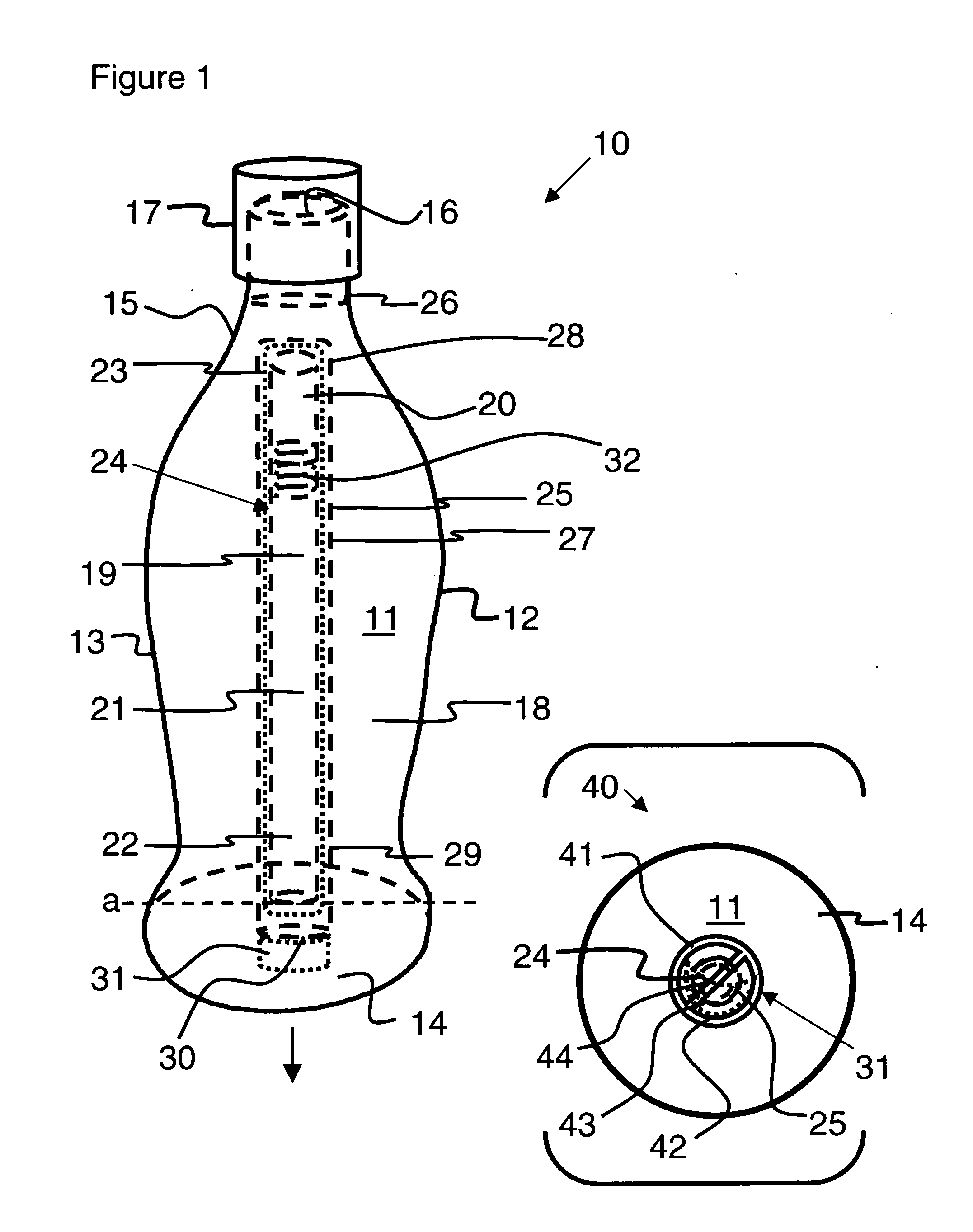

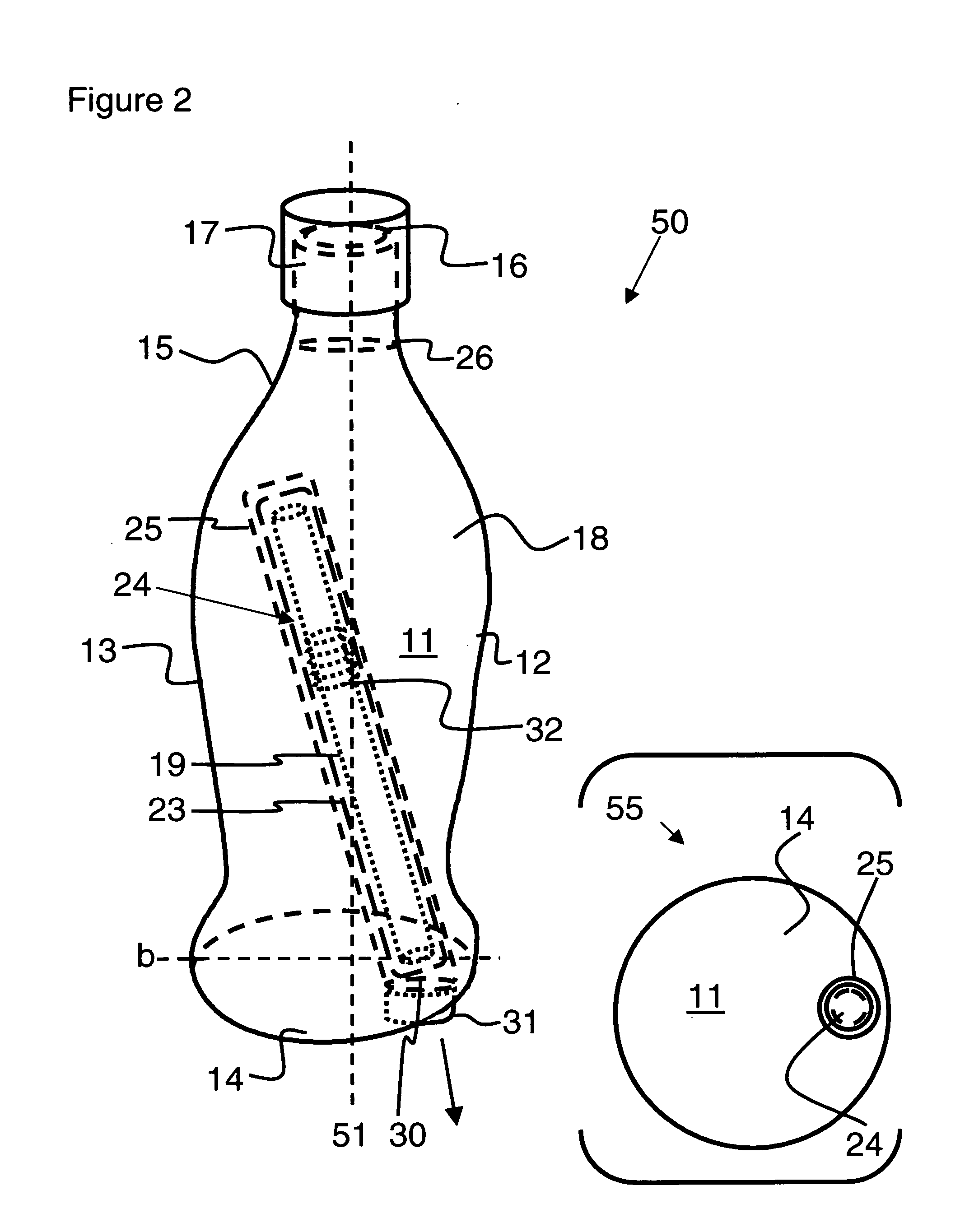

Liquid containing vessel having aseptic straw housing and method for manufacturing the same

InactiveUS20070125744A1Without compromising integrityDispensing apparatusContainer/bottle contructionDrinking strawEngineering

A liquid containing vessel has an aseptic straw housing. The vessel includes a beverage container having a liquid chamber and a separate, dry, straw housing chamber adapted for housing a straw enclosed in an aseptic environment. The arrangement of the internal chamber, the liquid and the straw housing chamber prevents contact between the aseptic straw and the liquid. An external outlet aperture in the aseptic straw housing chamber affords access to the aseptic straw from points outside of the container. The dual chamber construction provides a dry environment for housing the aseptic straw. Contemporaneous presentment of a straw with a beverage is accomplished in a convenient and reliable manner without compromising the integrity of the beverage or the straw.

Owner:SAMMAN JOHN M

Anti-wrinkle non-woven fabric winding device and using method thereof

PendingCN113307076ASolve the problem of wrinkles in windingWithout compromising integrityCleaning using toolsElectrostatic chargesEngineeringNonwoven fabric

The invention discloses an anti-wrinkle non-woven fabric winding device and a using method thereof, and relates to the field of non-woven fabrics. The anti-wrinkle non-woven fabric winding device comprises a workbench, wherein a conveying roller is rotatably mounted in the workbench, a supporting frame is slidably mounted in the workbench, a pressing roller is rotatably mounted at the bottom of the supporting frame, and a processing box with an opening inside is fixedly mounted in the middle of the upper portion of the workbench; two symmetrical and inclined scraping plates are rotatably mounted inside the processing box; and a plurality of transmission rollers are rotatably mounted inside the processing box. According to the anti-wrinkle non-woven fabric winding device and the using method thereof, the two scraping plates are symmetrically arranged, so that fluff on the surface of a non-woven fabric is scraped away at a time; and then the fluff on the surface of the non-woven fabric is thermalized and ironed in a heating plate ironing mode, so that the the problem that in the prior art, gaps exist in the rolled non-woven fabric due to the fluff in the rolling process, and wrinkles are generated in the rolling process as certain fluff still exists on the surface of the non-woven fabric in the rolling process is solved.

Owner:安徽苏博伦服饰有限公司

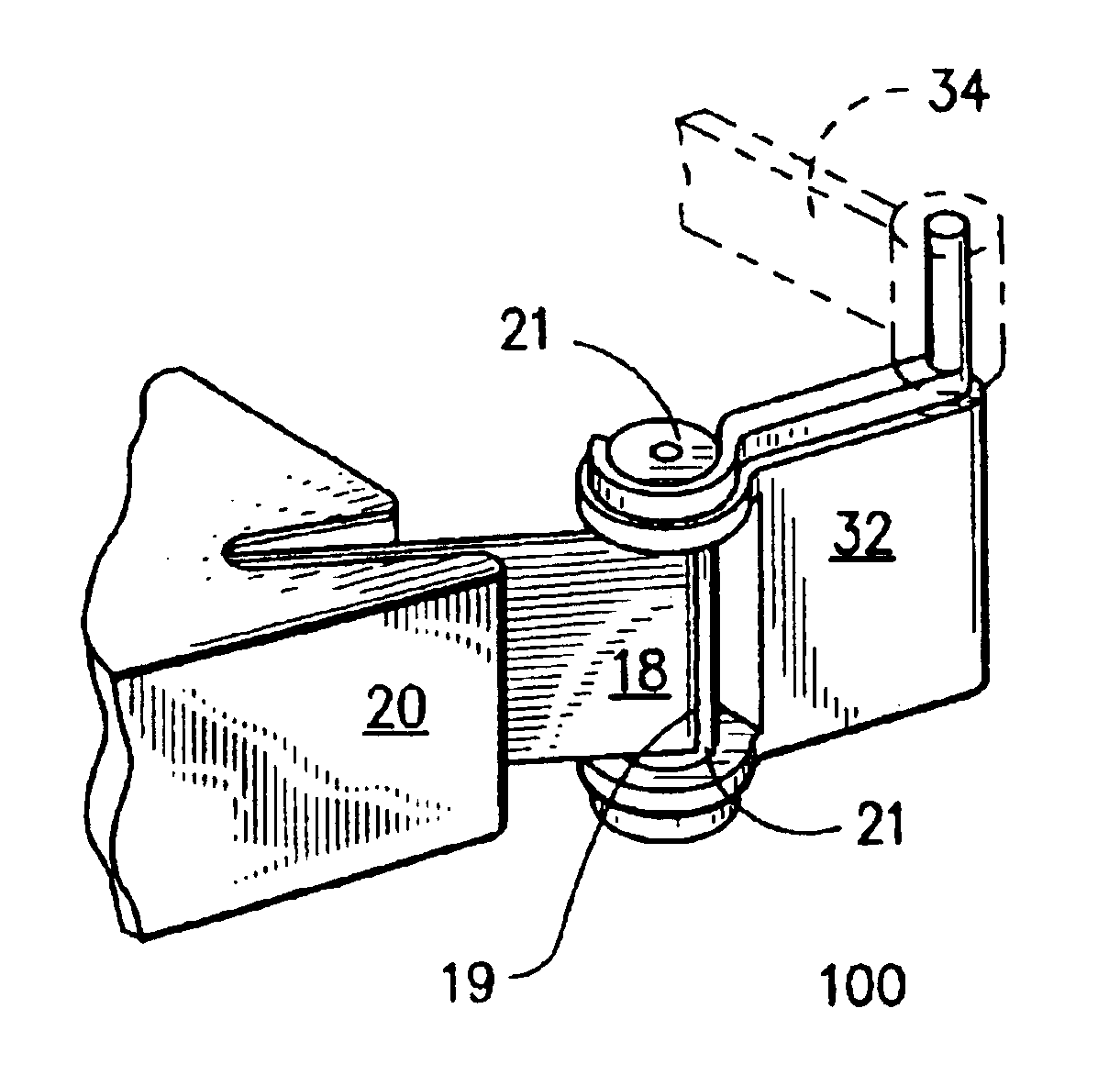

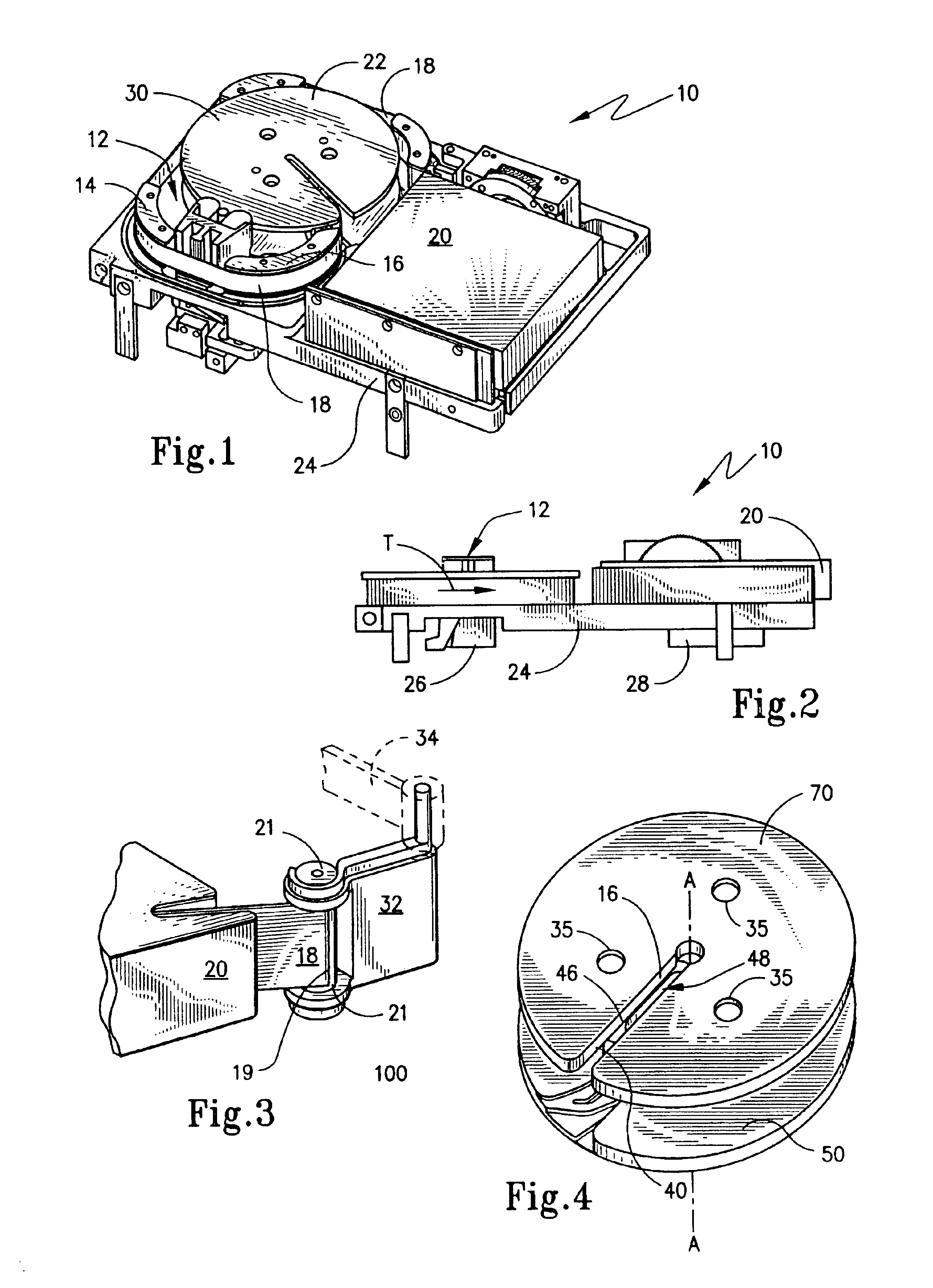

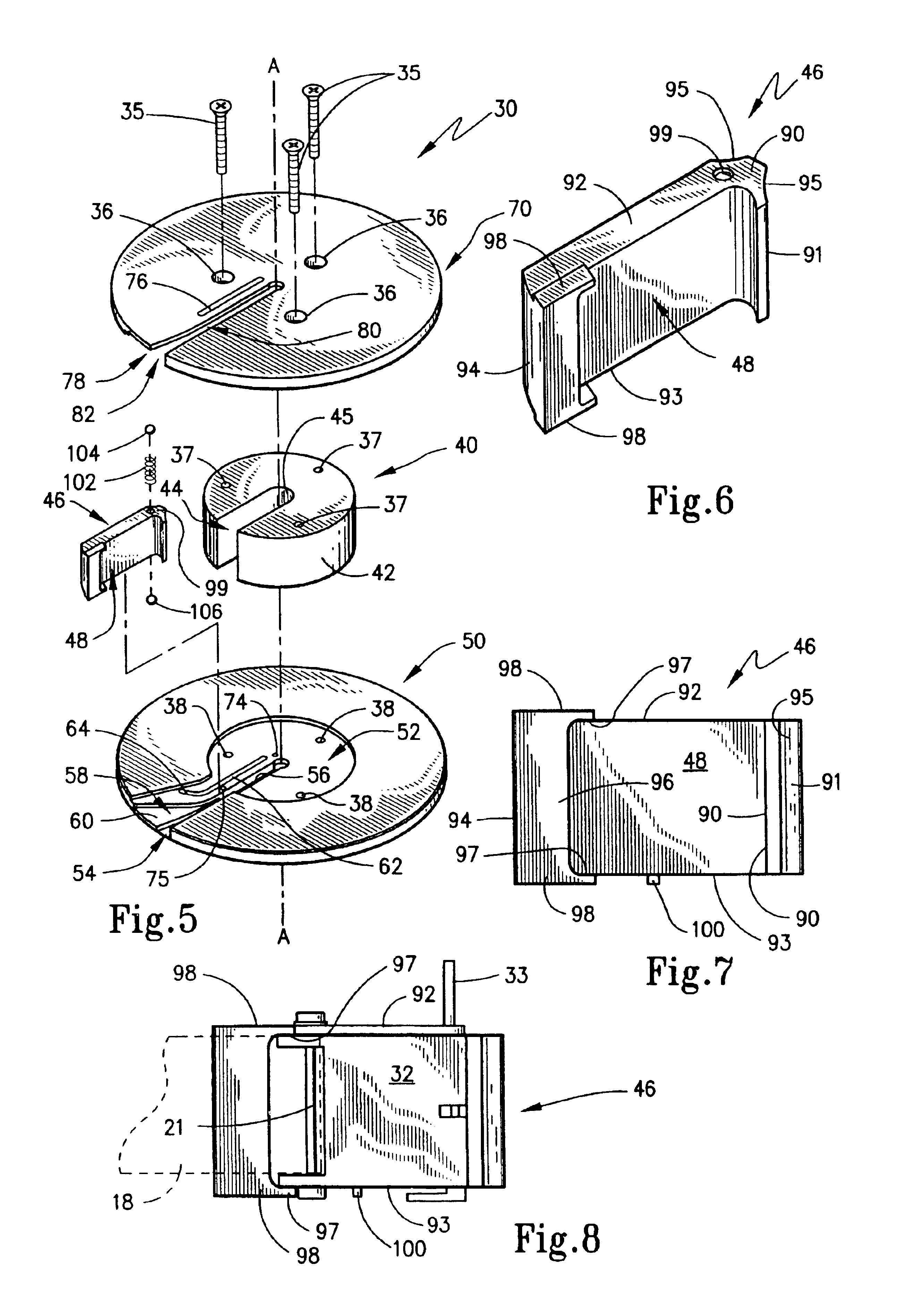

Tape threading apparatus having take-up hub with gap filling block for data storage systems and method therefor

InactiveUS6889927B2Avoid damageControl UniformityProjector film strip handlingCamera film strip handlingMagnetic tapeEngineering

A take-up mechanism for a read / write recording apparatus includes a hub with an outer surface about which a tape medium is to be wound. A recess is formed in the outer surface, and a receiver block is reciprocally movable between an extended position and a retracted position. When retracted, an end surface of the receiver block registers with the outer surface of the hub to form a smooth winding surface for the tape. The receiver block has a bay sized to engage the leader block on the tape such that the leader block is enclosed within the hub when the receiver block is retracted. A rotatable drive rotates the hub to wind the tape thereon. This mechanism may be incorporated into a read / write apparatus including a read / write recording head, bearing members to support the tape during transport and a threading assembly to thread the tape through the device.

Owner:SEGWAY SYST

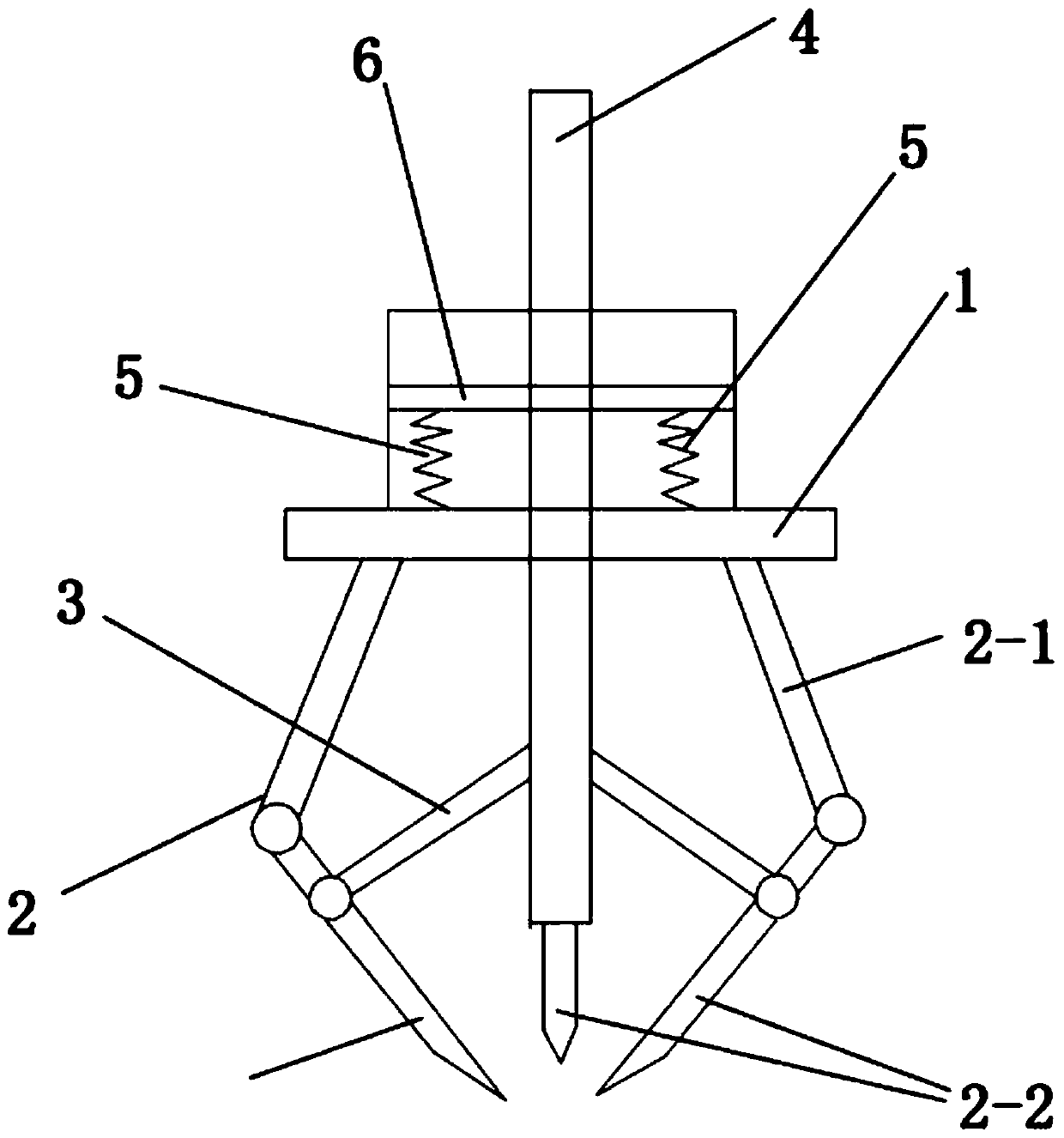

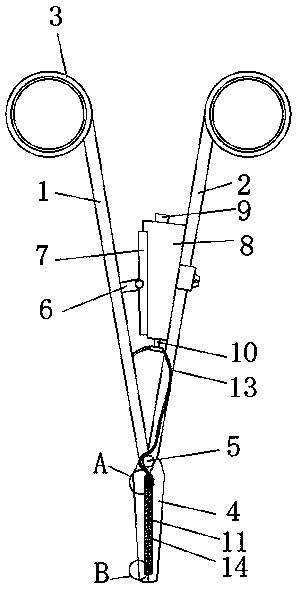

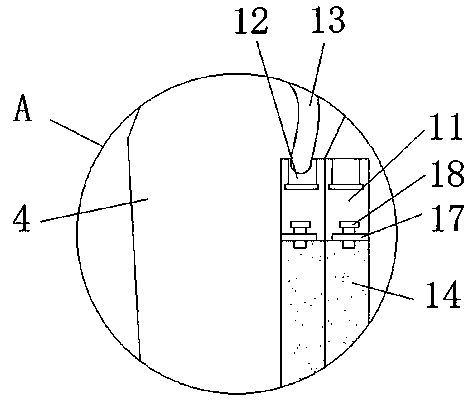

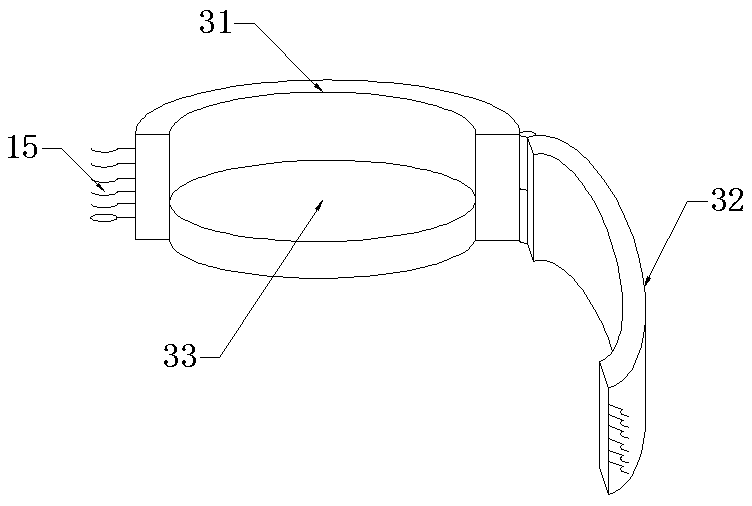

Coupler sealing ring sleeving and taking device for metro vehicle

InactiveCN110788797AWithout compromising integrityEasy to operateMetal-working hand toolsStructural engineeringMechanical engineering

The invention discloses a coupler sealing ring sleeving and taking device for a metro vehicle. The coupler sealing ring sleeving and taking device comprises a mounting seat. The mounting seat is fixedly connected with a grabbing part. The grabbing part is movably connected with a supporting rod through a connecting rod. The supporting rod vertically penetrates through the mounting seat and is in sliding connection with the mounting seat. According to the coupler sealing ring sleeving and taking device for the metro vehicle, the sealing ring is taken and is arranged on a coupler connecting groove through a simple manipulator design, time and labor are saved, the operation is convenient, it can be ensured that the sealing ring can be rapidly arranged in place on the premise that the surfaceintegrity and the performance of the sealing ring are not damaged, and the maintenance efficiency is improved.

Owner:樊帅

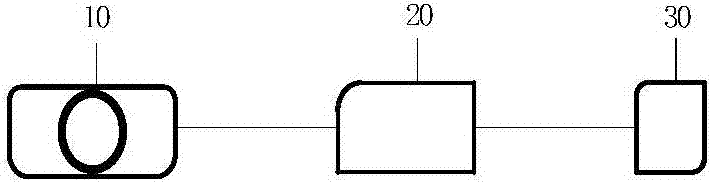

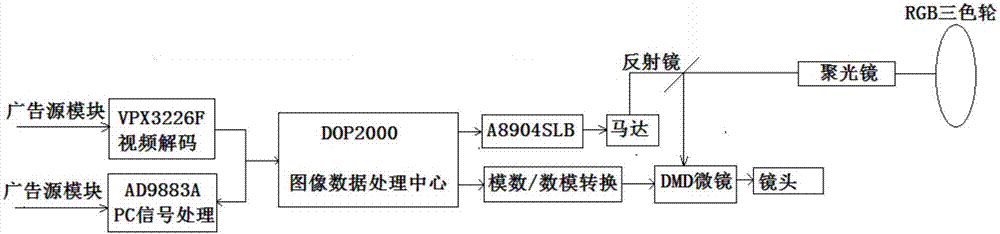

Vehicle body advertisement putting device and vehicle equipped with vehicle body advertisement putting device

InactiveCN107154231AAvoid pollutionAvoid modificationDisplay meansMobile visual advertisingEngineeringElectric control

The invention belongs to the technical field of vehicle body advertisements and particularly relates to a vehicle body advertisement putting device and a vehicle equipped with the vehicle body advertisement putting device. The vehicle body advertisement putting device comprises a projection module, an advertisement source module and a power module, wherein the power module is used for supplying power for the projection module and the advertisement source module; the advertisement source module is electrically connected with the projection module and is used for supplying advertisement content needed by the projection module; the projection module is arranged outside a vehicle body and is used for projecting the advertisement content in the advertisement source module onto the external surface of the vehicle body. The vehicle body advertisement putting device is integrated with the projection module and corresponding electric control modules; the purpose of putting advertisements can be achieved under the precondition that advertisement stickers, advertisement pictures or advertisement boxes are not used; various technical problems in the existing vehicle body advertisements are solved; the market vacancy is filled up; the vehicle body advertisement putting device has the characteristics of convenience in washing, no damage to vehicle bodies, freely-customized advertisement putting time, safety and reliability.

Owner:黄群战

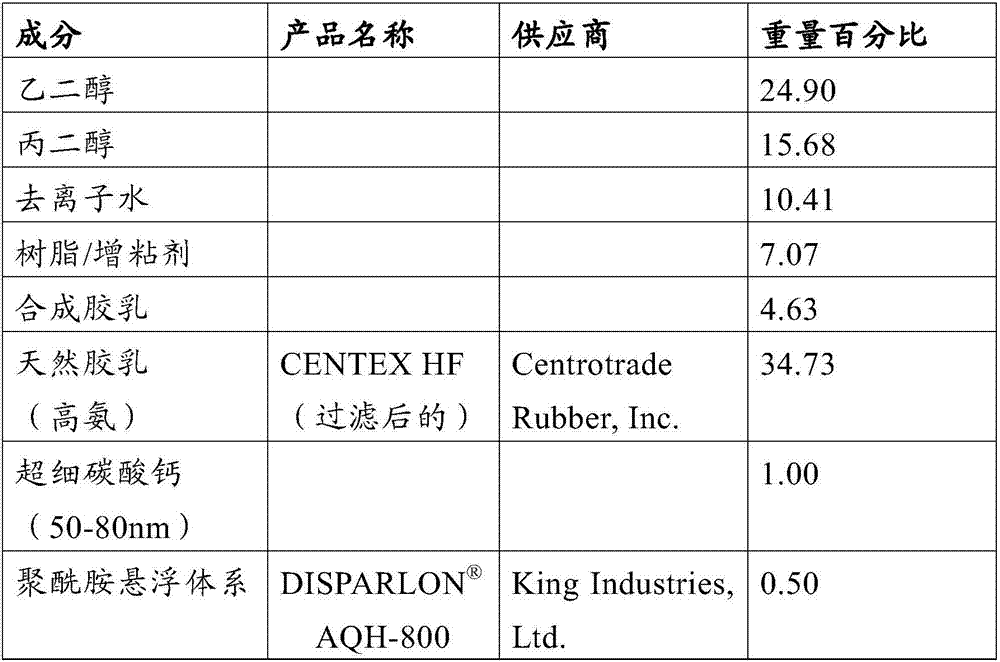

High performance sealant composition for tire repair

A high performance sealant for repairing punctures in tires includes a highly filtered natural rubber latex, an ultra-fine inorganic powder, a polyamide suspension, and an antifreeze agent that includes water and at least one of ethylene glycol and propylene glycol. The high performance sealant can readily pass through a valve stem of a tire without removing the core and seal, and provides a strong and durable sealing of the puncture.

Owner:ILLINOIS TOOL WORKS INC

Antibacterial automatic-disinfection type towel forceps

InactiveCN110141305ARealize self-disinfection functionImprove work efficiencyChemicalsSurgical forcepsForcepsEngineering

The invention discloses an antimicrobial automatic-disinfection type towel forceps. The antimicrobial automatic-disinfection type towel forceps comprises a first forceps handle and a second forceps handle, the top of the first forceps handle and the top of the second forceps handle are fixedly connected with finger rings, the bottom of the first forceps handle and the bottom of the second forcepshandle are fixedly connected with forceps heads, a rivet is hinged between the two forceps heads, the first forceps handle is fixedly connected with a connecting rod close to one side of the second forceps handle, the connecting rod is vertically hinged with a pressing plate, the second forceps handle is installed with a disinfectant bottle close to one side of the first forceps handle, the top ofthe disinfectant bottle is fixedly connected with a bottle mouth, the bottom of the disinfectant bottle is fixedly connected with a shunt pipeline, both of the forceps heads are provided with groovesat the opposite side of each other, the top of the inner wall of each groove is fixedly connected with a spray head, and an infusion rubber tubing is fixedly connected between the shunt pipeline andthe two spray heads. The invention can quickly disinfect the clamped towel and improve work efficiency, and is not prone to damaging the integrity of the towel and good in using effect.

Owner:江苏旭辉医疗器械有限公司

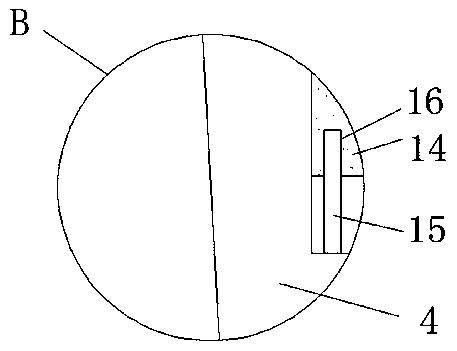

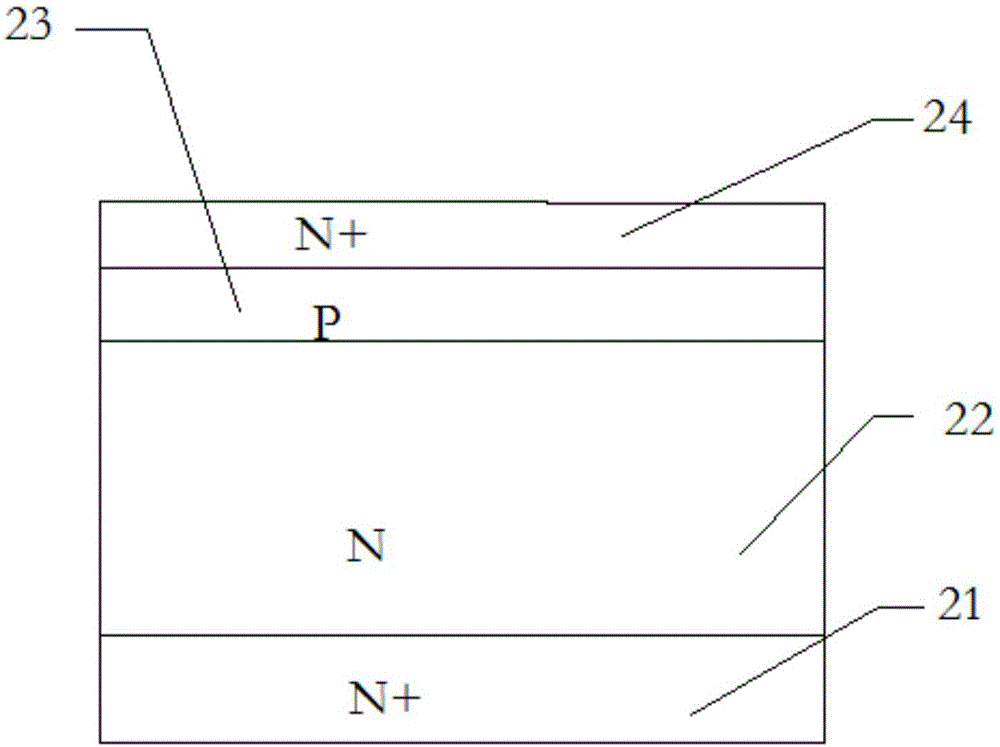

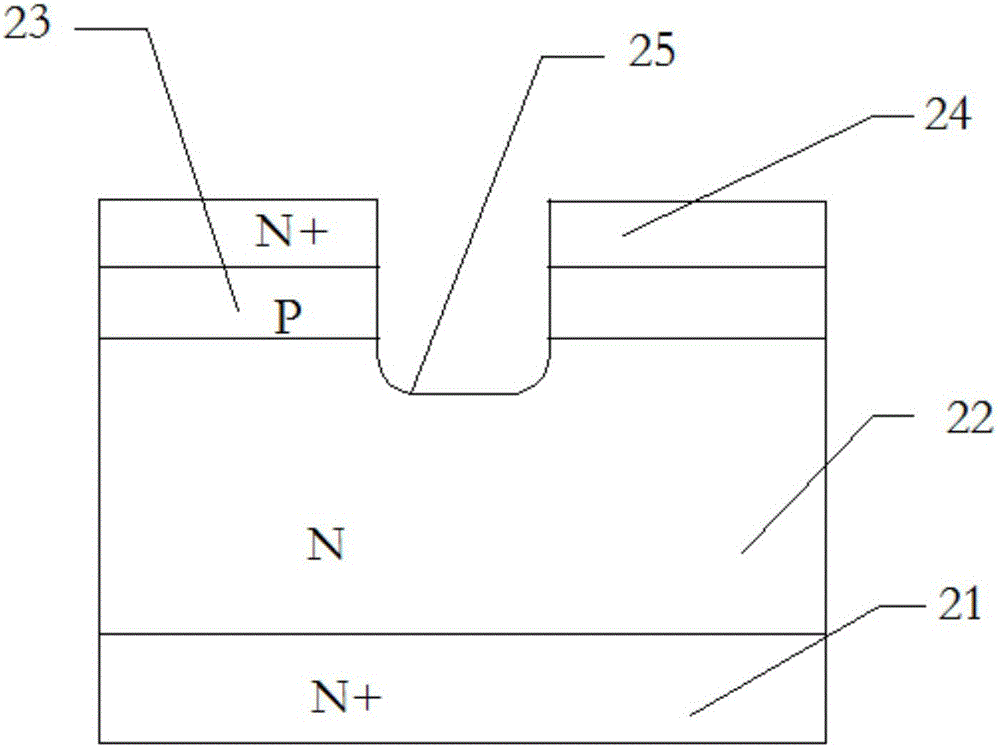

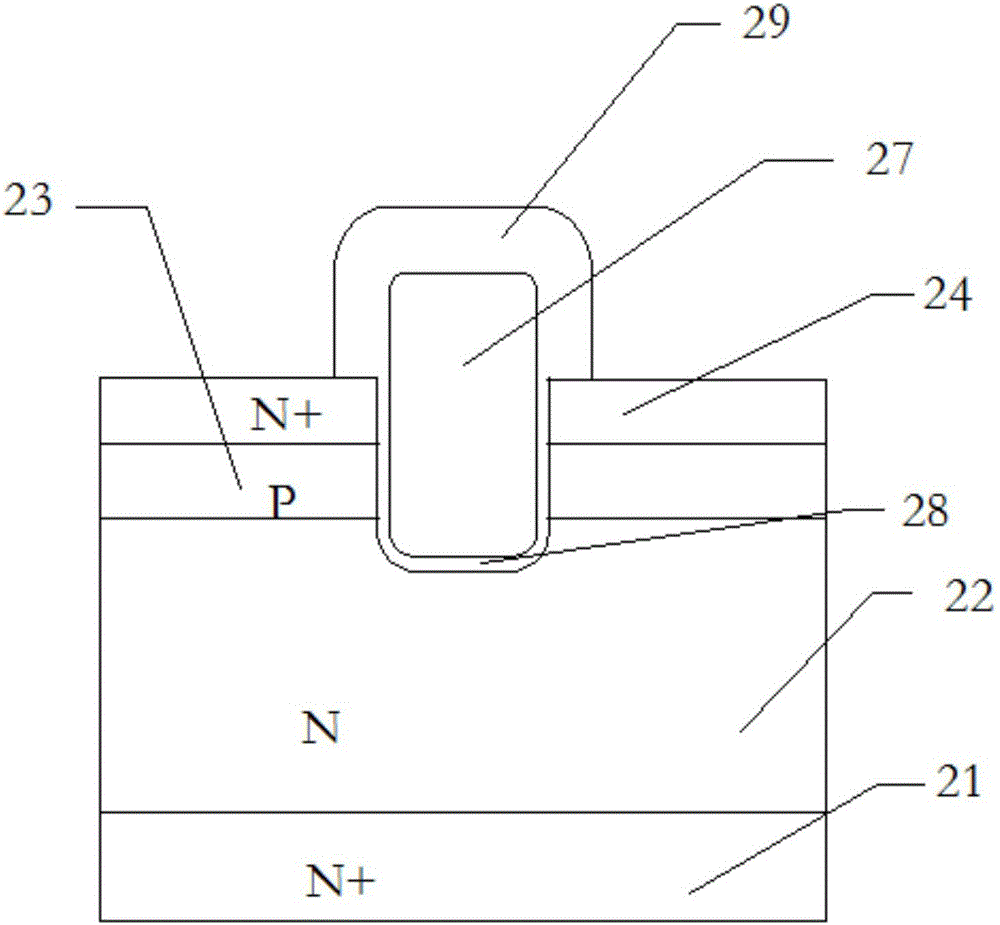

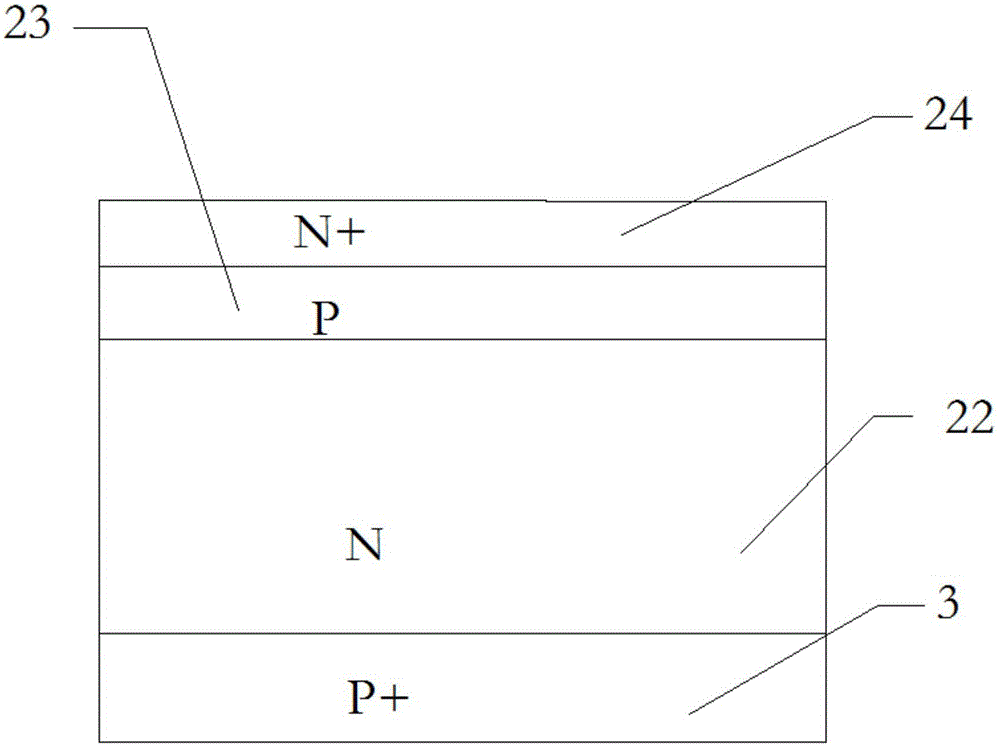

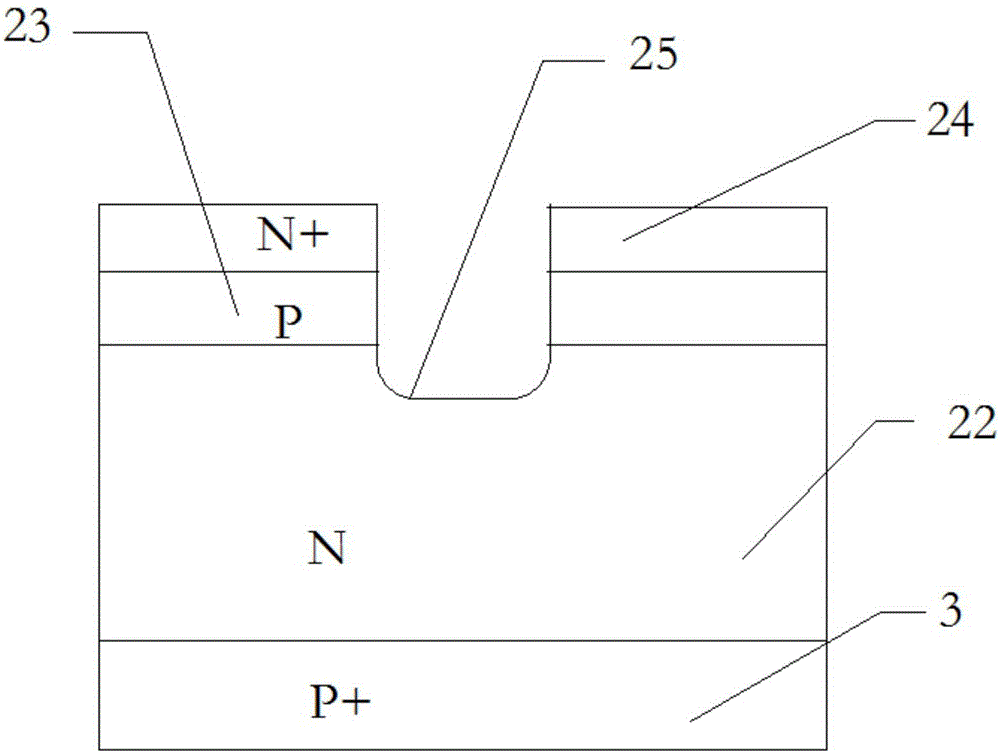

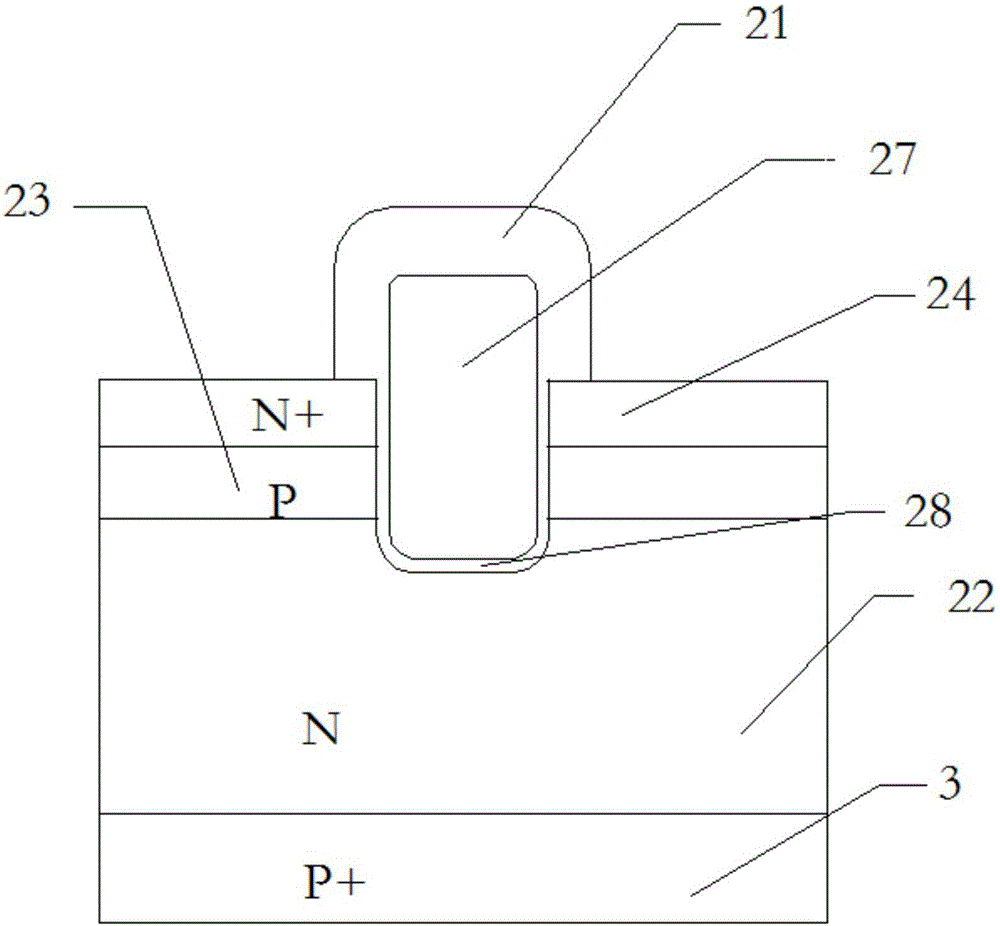

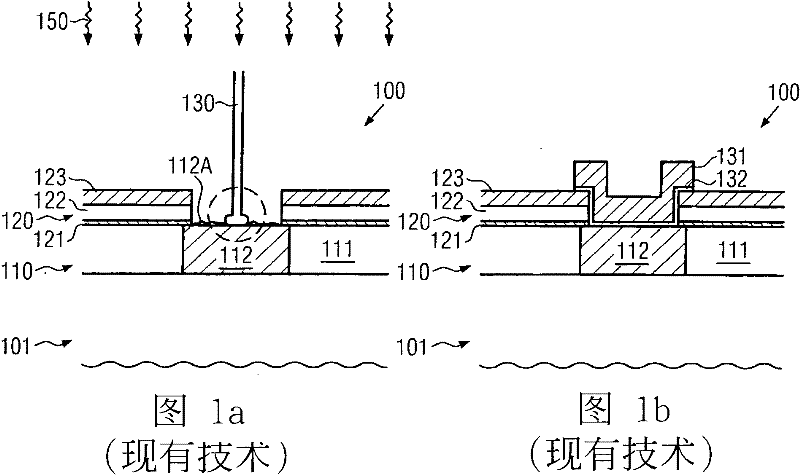

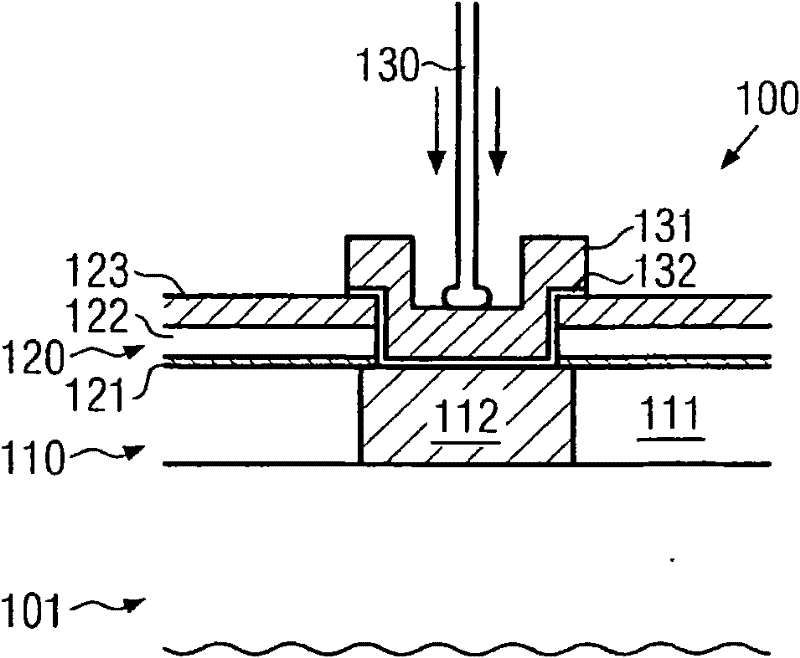

MOSFET device manufacturing method and MOSFET device

PendingCN106098561AOvercome dopingOvercoming Diffusion DifficultiesSemiconductor/solid-state device manufacturingSemiconductor devicesMOSFETSchottky barrier

The invention relates to the technical field of semiconductors and specifically relates to an MOSFET device manufacturing method and an MOSFET device. According to the method, epitaxial technologies are adopted, heavily doped N type wide-gap semiconductor material is used as a substrate; a voltage withstanding drift zone, a P type body zone epitaxial layer and an N+ source zone epitaxial layer are orderly formed via homoepitaxial operation, and a matrix is formed; photoetching and etching technology technologies are used for forming a gate zone groove and a Schottky groove on the matrix; a gate oxide layer is formed on an inner wall of the gate zone groove via thermal oxidization; a gate electrode is formed on an inner wall of the gate oxide layer via depositing, photoetching and etching operation; an outer surface of the gate electrode is subjected to passivation layer deposition operation, and a gate electrode insulation protective layer is formed through the photoetching and etching operation; a Schottky diode is formed after a surface of the Schottky groove is subjected to Schottky barrier metal deposition operation and annealing operation; the MOSFET device is finally obtained. Via use of the MOSFET device manufacturing method and the MOSFET device that are provided in the invention, impurity doping and diffusion technologies are not required, and reliability of the gate oxide layer can be improved.

Owner:JILIN SINO MICROELECTRONICS CO LTD

Tanning method in manufacturing beast stufffed specimen

ActiveCN104388601AEfficient and safe tanning methodEasy to stretchTanning treatmentPre-tanning chemical treatmentBiotechnologyAluminium chloride

The invention discloses a tanning method in manufacturing a beast stufffed specimen. The tanning method comprises the following steps: removing meat, shaving, degreasing, acidizing for 4-50 hours by using sulfuric-acid pickling liquor with pH of 2-3, degreasing, acidizing for 4-50 hours by using citric-acid pickling liquor with pH of 2-3, neutralizing to enable the pH to be 6-7, immersing into tanning liquor prepared by a skin penetrating agent, ammonium sulfate, sodium chloride and aluminum chloride for 24-72 hours, cleaning and brightening. The tanned skin is complete in lip and tail ends of the four limbs, strong in plasticity, good in quality, easy in operation and available in needed materials, low in price, simple and convenient in operation method, is non-toxic and odorless, is safe and environment-friendly and has wide promotion and application values.

Owner:广州广宠生物科技有限公司

Automatic control equipment for online removal of tiny burrs on the working edge of the servo valve spool

ActiveCN104070183BGuaranteed stabilityGuaranteed accuracyAutomatic control devicesMeasurement/indication equipmentsAutomatic controlControl system

An automatic control device for online removing of tiny burrs on the working edge of a valve element of a servo valve comprises a deburring tool system, a precision feeding system, an automatic tool setting system, a force feedback system and a control system, wherein the deburring tool system mounted on a Z-axis lifting table comprises a deburring turning tool, a force sensor and a fixture, the precision feeding system used for controlling the feeding of the deburring tool system comprises an X-axis feeding mechanism, a Y-axis feeding mechanism and the Z-axis lifting table, the automatic tool setting system comprising a displacement sensor fixed on the fixture can achieve precise tool setting and complete radial runout measurement and working edge scanning detection of a workpiece, the force feedback system used for monitoring the degree of the deburring force in real time comprises a force sensor which is arranged below the deburring turning tool and connected with the fixture, and the control system used for monitoring the feeding movement, automatic tool setting, deburring, force feedback alarm retraction and online deburring effects of the automatic control device comprises an industrial personal computer connected with the precision feeding system, the force feedback system and the automatic tool setting system. The automatic control device for the online removing of the tiny burrs on the working edge of the valve element of the servo valve achieves the online automatic removing of the tiny burrs on the working edge and has the advantages of low rejection rates, high efficiency and low costs.

Owner:SHANGHAI JIAOTONG UNIV +1

IGBT device manufacturing method and device

PendingCN105977157AOvercome dopingOvercoming Diffusion DifficultiesSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierImpurity doping

The invention relates to the technical field of a semiconductor device, and especially relates to an IGBT device manufacturing method and device. The method comprises the following steps: carrying out epitaxy on a P+ substrate through epitaxy technology to obtain a voltage withstand drift region, a P-type body area epitaxial layer and an N+ source region epitaxial layer in sequence, which form a base body; through photoetching and etching technique, providing a gate trench and a Schottky groove in the base body; carrying out thermal oxidation on the inner wall of the gate trench to form a gate oxide layer; forming a gate electrode on the inner wall of the gate oxide layer through deposition, photoetching and etching; carrying out passivation layer deposition on the outer surface of the gate electrode, and forming a gate electrode insulation protection layer through photoetching and etching; lastly, carrying out Schottky barrier metal deposition and annealing on the surface of the Schottky groove to form a Schottky diode; and finally, obtaining an IGBT device. According to the IGBT device manufacturing method and device, impurity doping and diffusion processes are saved, and reliability of the gate oxide layer is enhanced.

Owner:JILIN SINO MICROELECTRONICS CO LTD

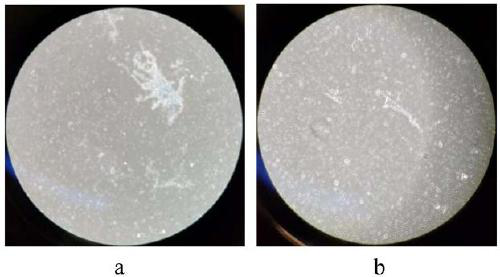

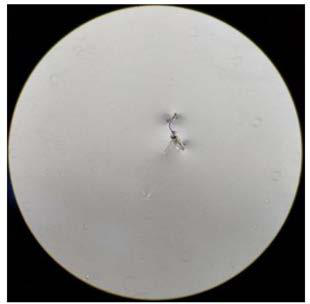

Method for separating and purifying brain micro-vessels

ActiveCN109055301AHigh separation purityWithout compromising integrityCell dissociation methodsCulture processProtein targetMagnetic bead

The invention discloses a method for separating and purifying brain micro-vessels. The method comprises the following steps: (1) taking fresh whole brain tissues of a mouse, and grinding up and down by a Dounce homogenizer for 12 to 15 times to prepare tissue homogenate; (2) performing double filtering on the tissue homogenate by sterile glass beads and a 70mum nylon cell filter to obtain cerebrovascular and microvascular tissues. By adopting the method disclosed by the invention, the separation integrity, quantity and purity of the brain micro-vessels can be improved effectively without affecting the content of target proteins in the brain micro-vessels.

Owner:HUNAN NORMAL UNIVERSITY

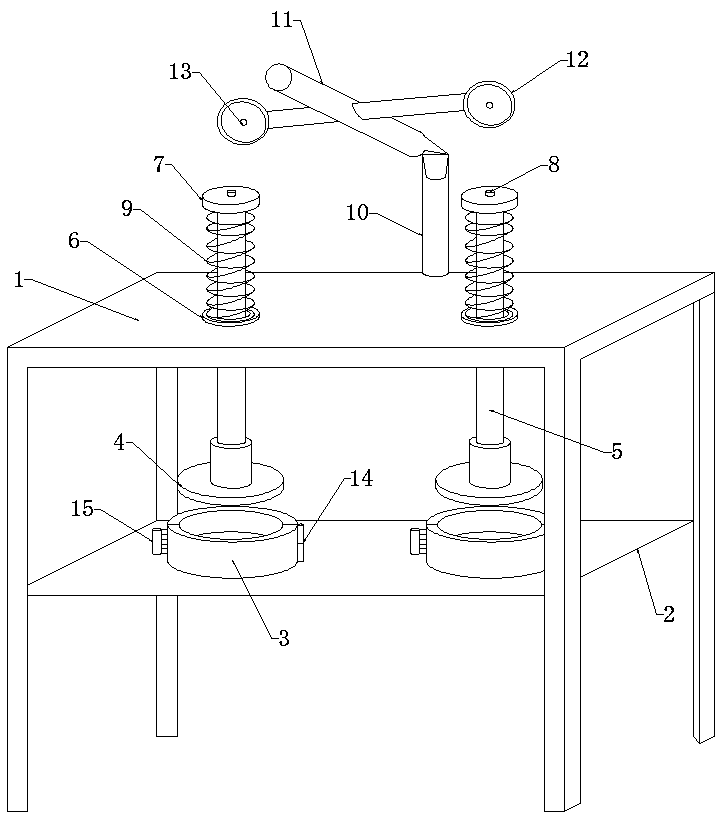

Manual spring tea press for white peony root tea

InactiveCN109198051AEasy to take outWithout compromising integrityPre-extraction tea treatmentFood shapingEngineeringTea leaf

The invention relates to a manual spring tea press for white peony root tea. The press comprises an operating frame and a workbench, wherein the workbench is arranged in the middle of the operating frame, a mold is arranged on the workbench, a clamping ring is arranged on the operating frame, a press rod is arranged on the clamping ring, a press block is arranged at the lower end of the press rod,a press cap is arranged at the top of the press rod, a spring is arranged between the press cap and the clamping ring, antiskid bulges are arranged on the press cap, a support rod is arranged on theoperating frame, a press arm rod is hinged on the support rod, a gland is arranged on the press arm rod, and a groove is formed in the gland. The press has the benefits as follows: the press is simplein structure and high in practicability, tea is processed according to the lever principle, time and labor are saved, pressed tea cakes are taken out by a left module and a right module, the integrity of the tea cakes cannot be damaged, power is not consumed, the production cost of the pressed tea can be reduced, and the demand of small-batch process or tea test processing and development can bemet.

Owner:SICHUAN BIAOYI TRADITIONAL CHINESE MEDICINE TECH CO LTD

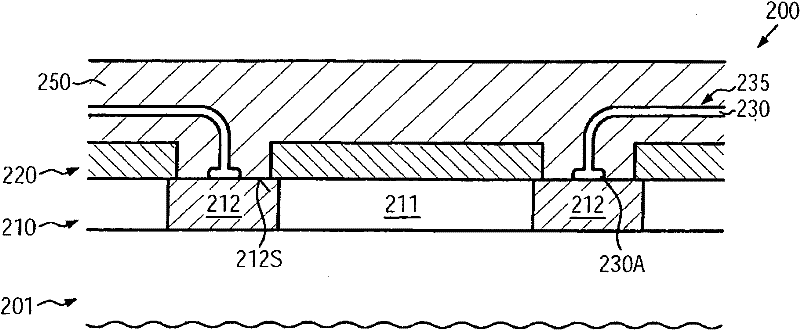

Enhanced wire bond stability on reactive metal surfaces of a semiconductor device by encapsulation of the bond structure

InactiveCN102132400ANo added complexityReduce equipmentSemiconductor/solid-state device detailsSolid-state devicesDevice materialStructural engineering

The wire bond structure of sophisticated metallization systems, for instance based on copper, may be provided without a terminal aluminum layer and without any passivation layers for exposed copper surfaces (212S) by providing a fill material (250) after the wire bonding process in order to encapsulate at least the sensitive metal surfaces (212S) and a portion of the bond wire (230). Hence, significant cost reduction, reduced cycle times and a reduction of the required process steps may be accomplished independently from the wire bond materials used. Thus, integrated circuits requiring a sophisticated metallization system may be connected by wire bonding to the corresponding package (260) or carrier substrate with a required degree of reliability based on a corresponding fill material (250) for encapsulating at least the sensitive metal surfaces (212S).

Owner:GLOBALFOUNDRIES INC

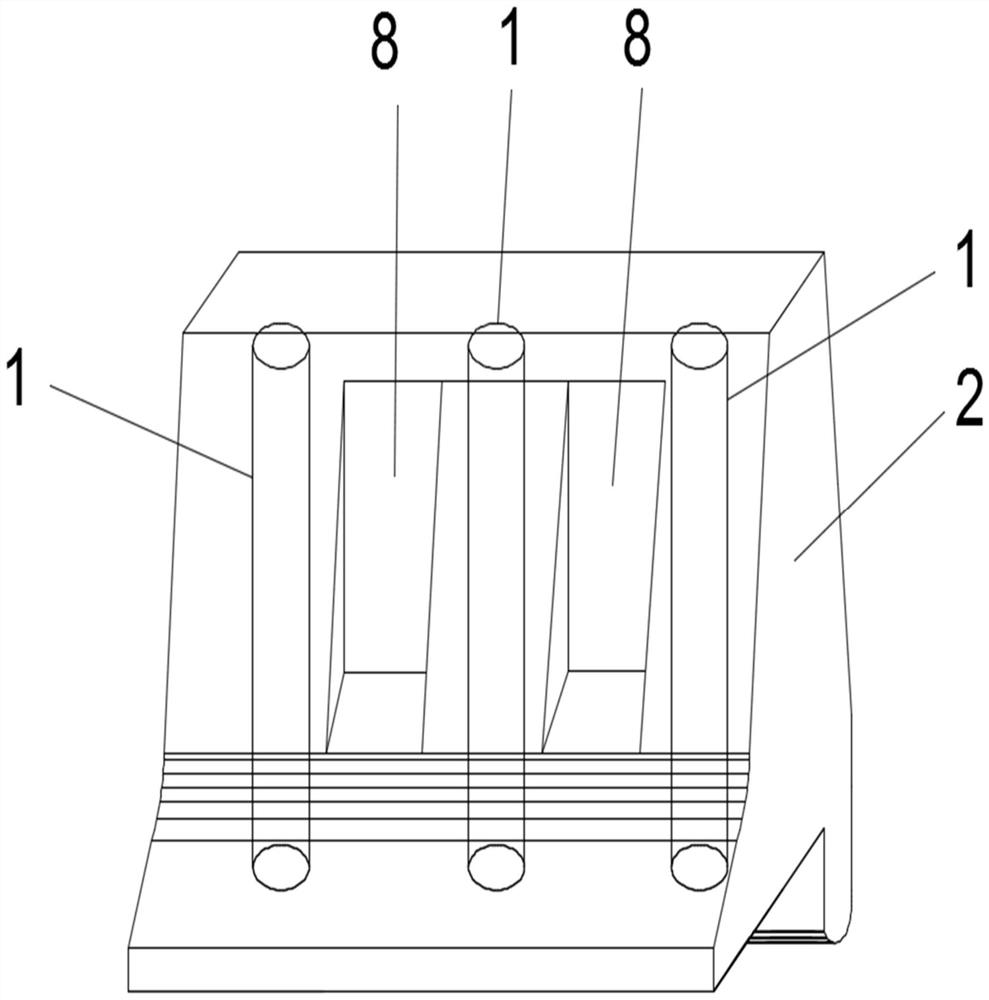

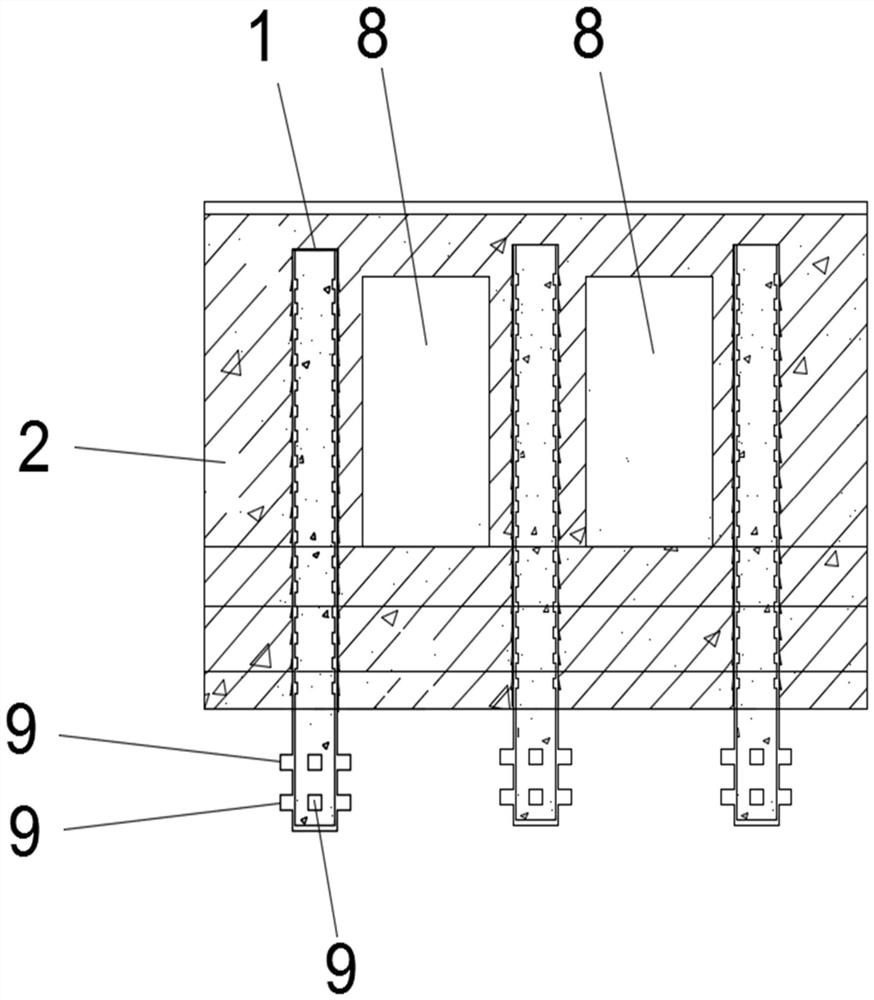

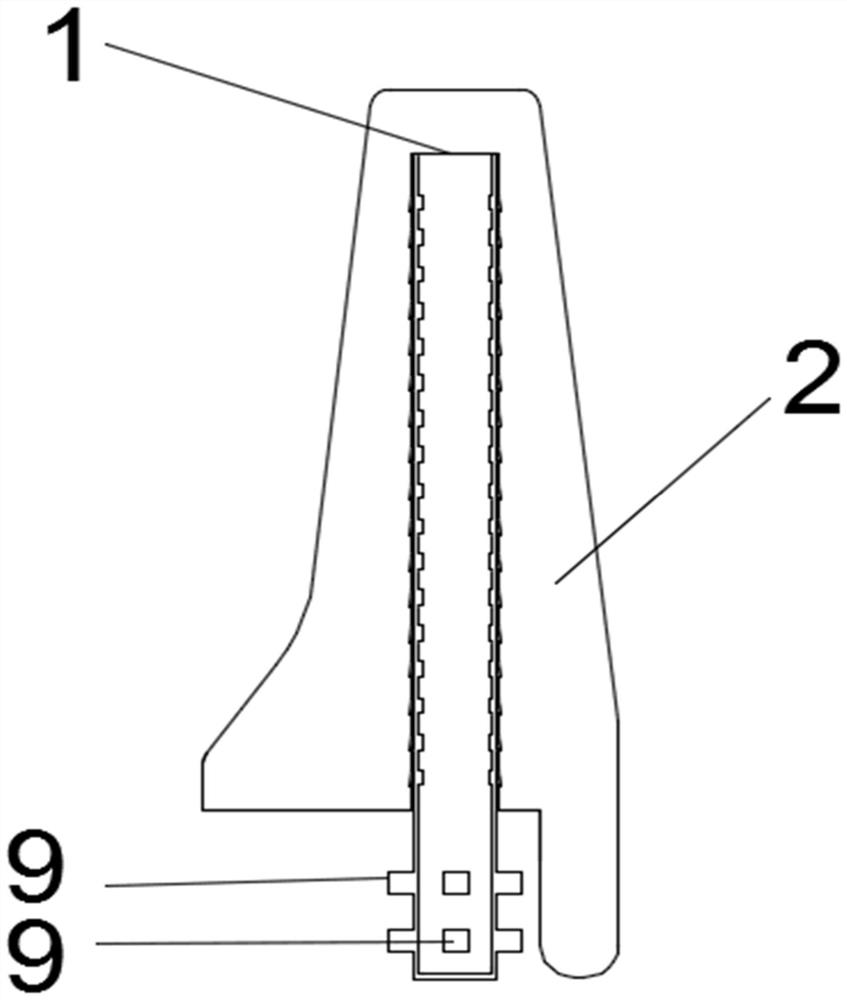

A prefabricated anti-collision wall and its installation method

ActiveCN110344317BSimplify the construction periodShorten the construction periodBridge structural detailsBridge erection/assemblyFoam concretePolystyrene

Owner:GUANGZHOU UNIVERSITY

Finger ring size-adjusting device and method for adjusting finger ring sizes

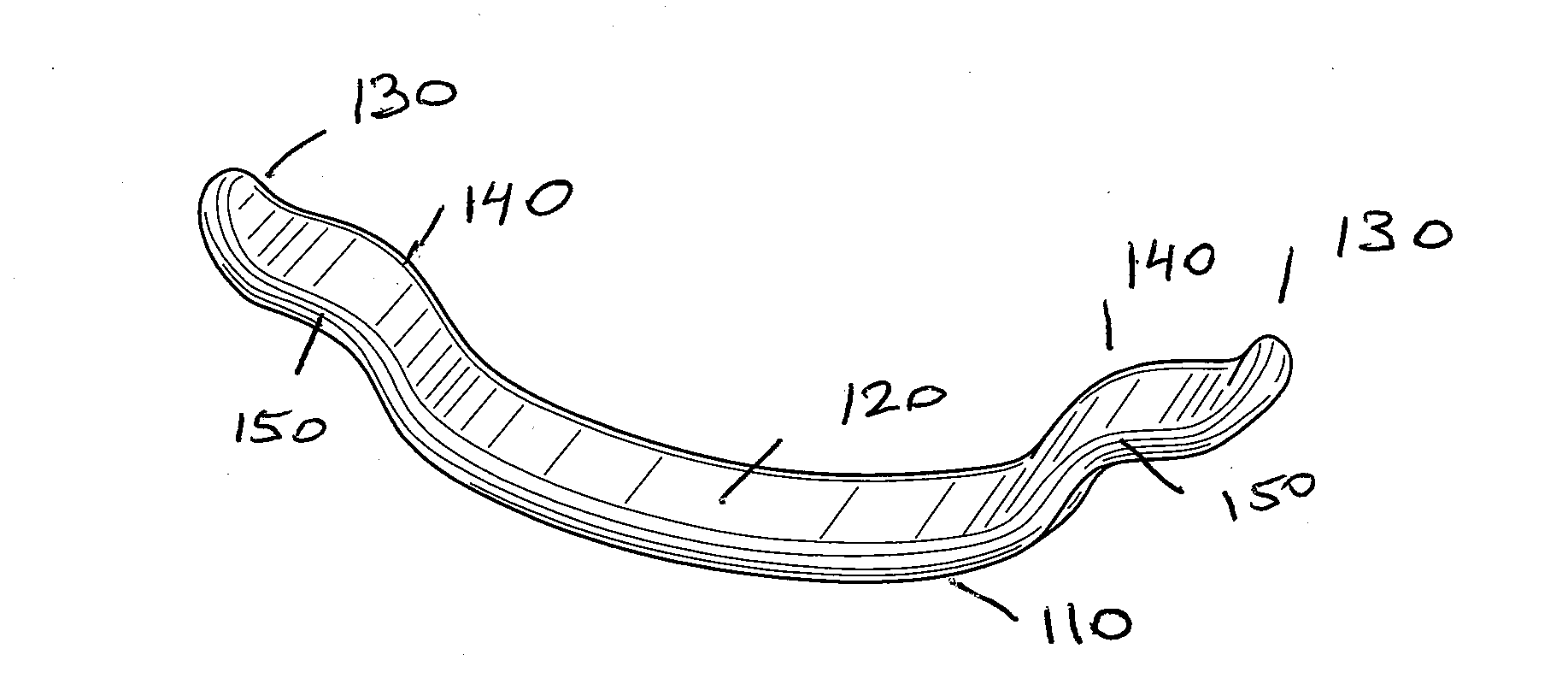

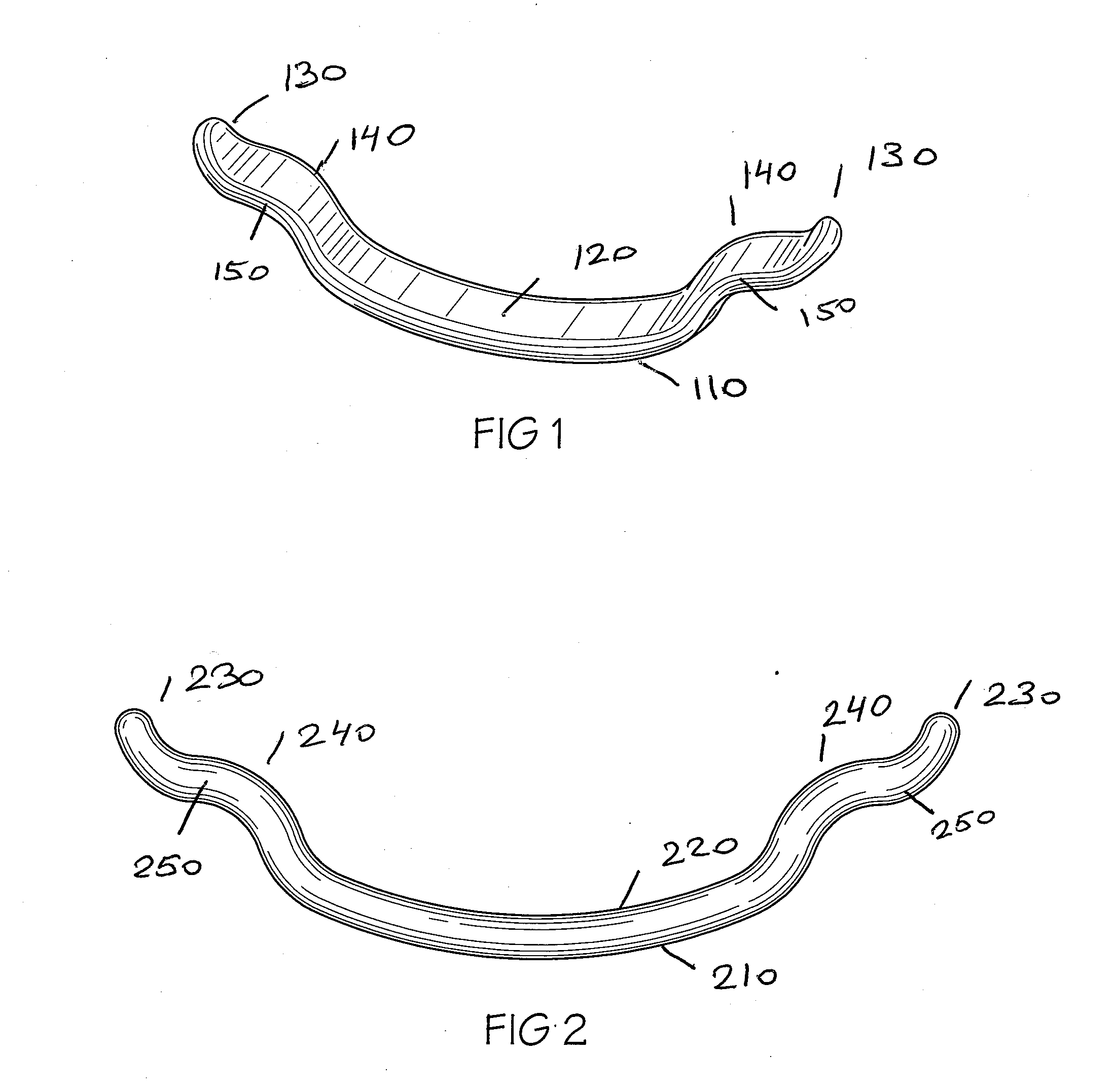

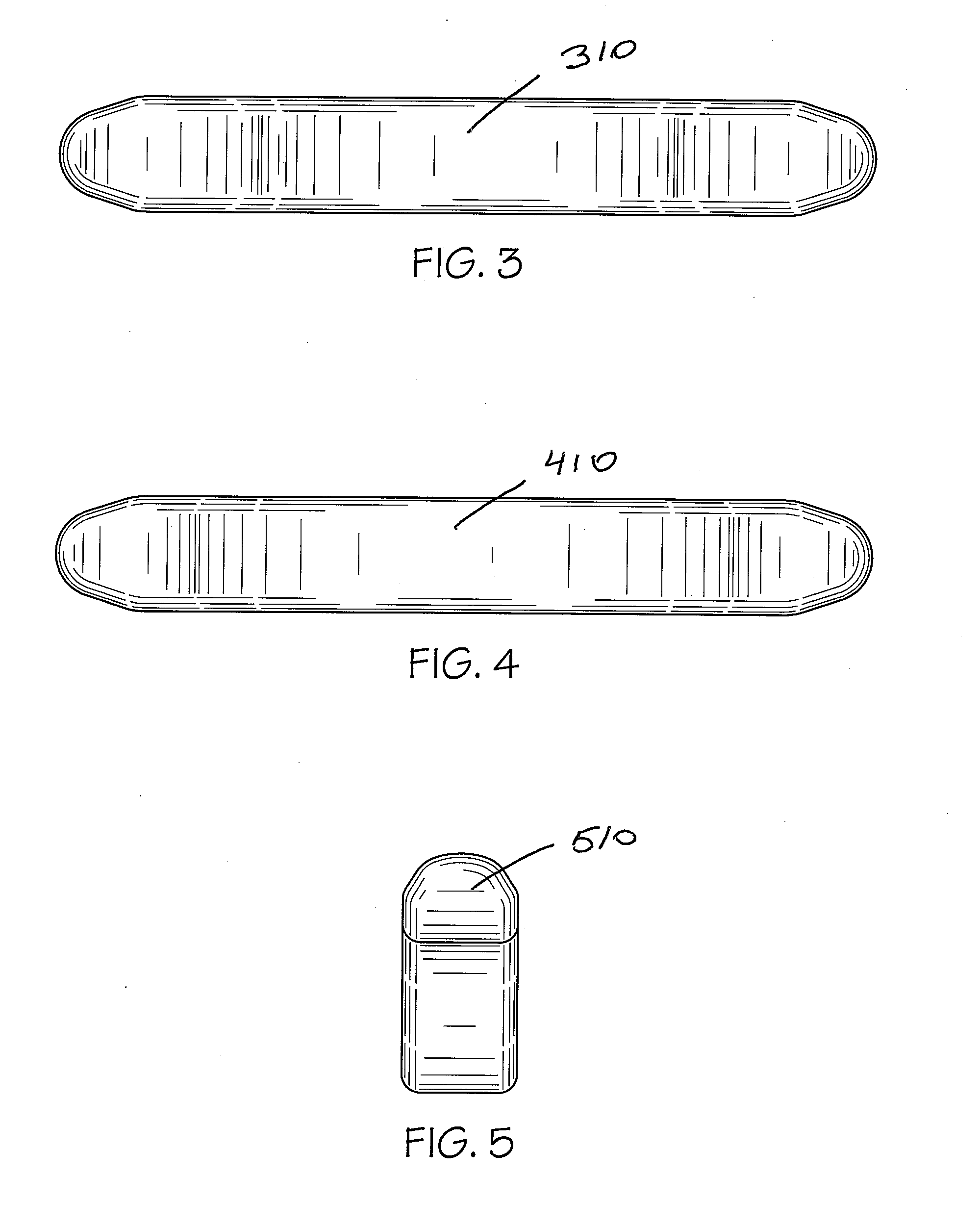

The present invention concerns generally with devices and methods for adjusting a finger ring size, and, more particularly, with a finger ring size-adjusting device that comprises no moving parts, and a method for adjusting the size of said finger ring using said device without a need for cutting or otherwise altering said ring. The device and the method of its use allow performing size adjustments without compromising the integrity of the ring. The device can be quickly added, adjusted or removed by any jeweler and without cutting, drilling or modifying the original design of the ring.

Owner:NISGURETSKY BARRY

Wall member and method for construction thereof

InactiveCN1093902CIncrease flexibilitySimple and fast operationWallsFloorsMoistureConstruction aggregate

A method of fabricating a wall, floor, or ceiling on site. The method includes the following steps: installing a strong rigid frame (10) and fixing fiber reinforced cement sheets (50) to the front and rear of the frame to form an inner cavity (60) therebetween. Then, light aggregate concrete mud is injected into the above-mentioned inner cavity (60) and allowed to cure. The sheet is a moisture absorber that absorbs enough moisture from lightweight aggregate concrete mud to allow the concrete mud to naturally bond with the sheet during its curing and curing period without substantially reducing the integrity of its structure. The invention also provides walls produced by this method.

Owner:JAMES HARDIE INT FINANCE BV

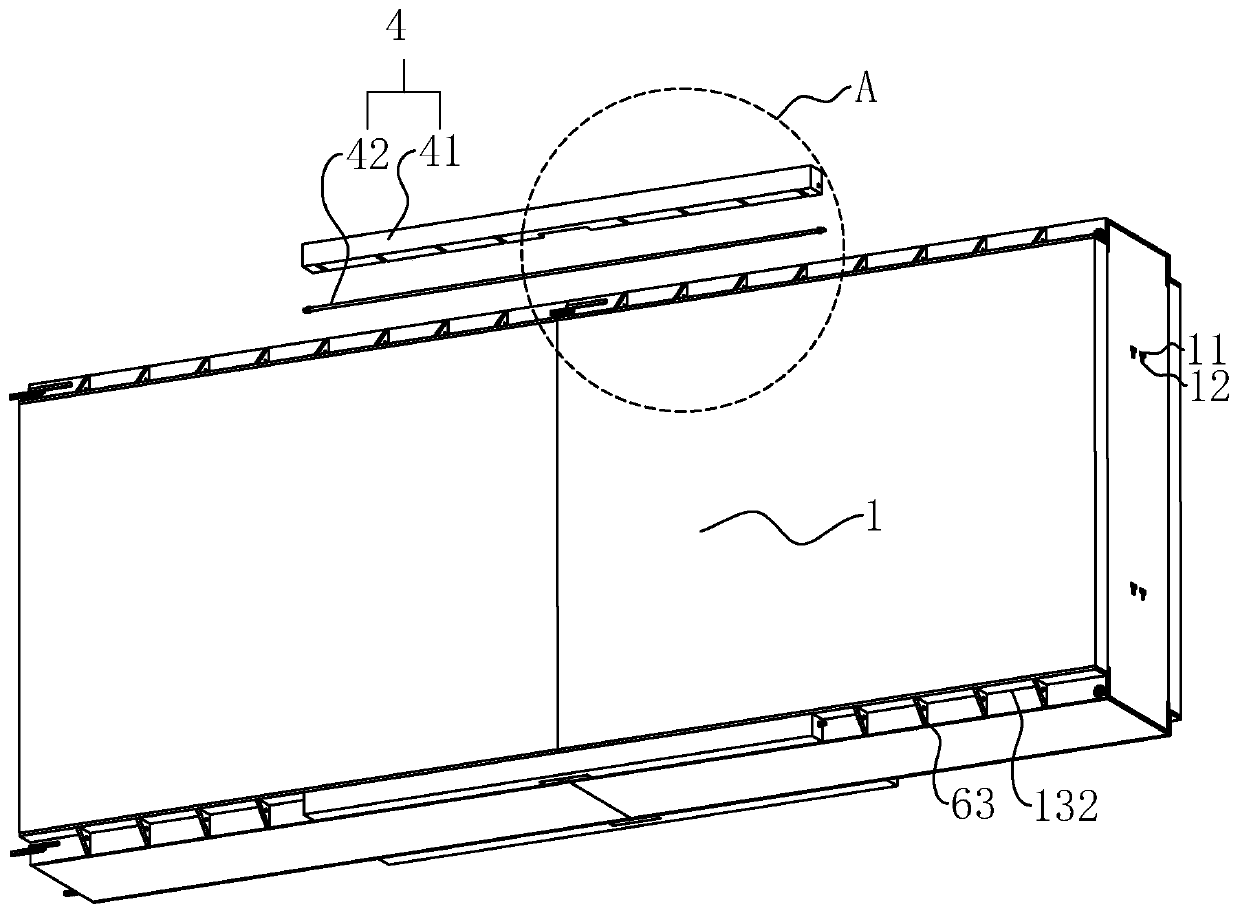

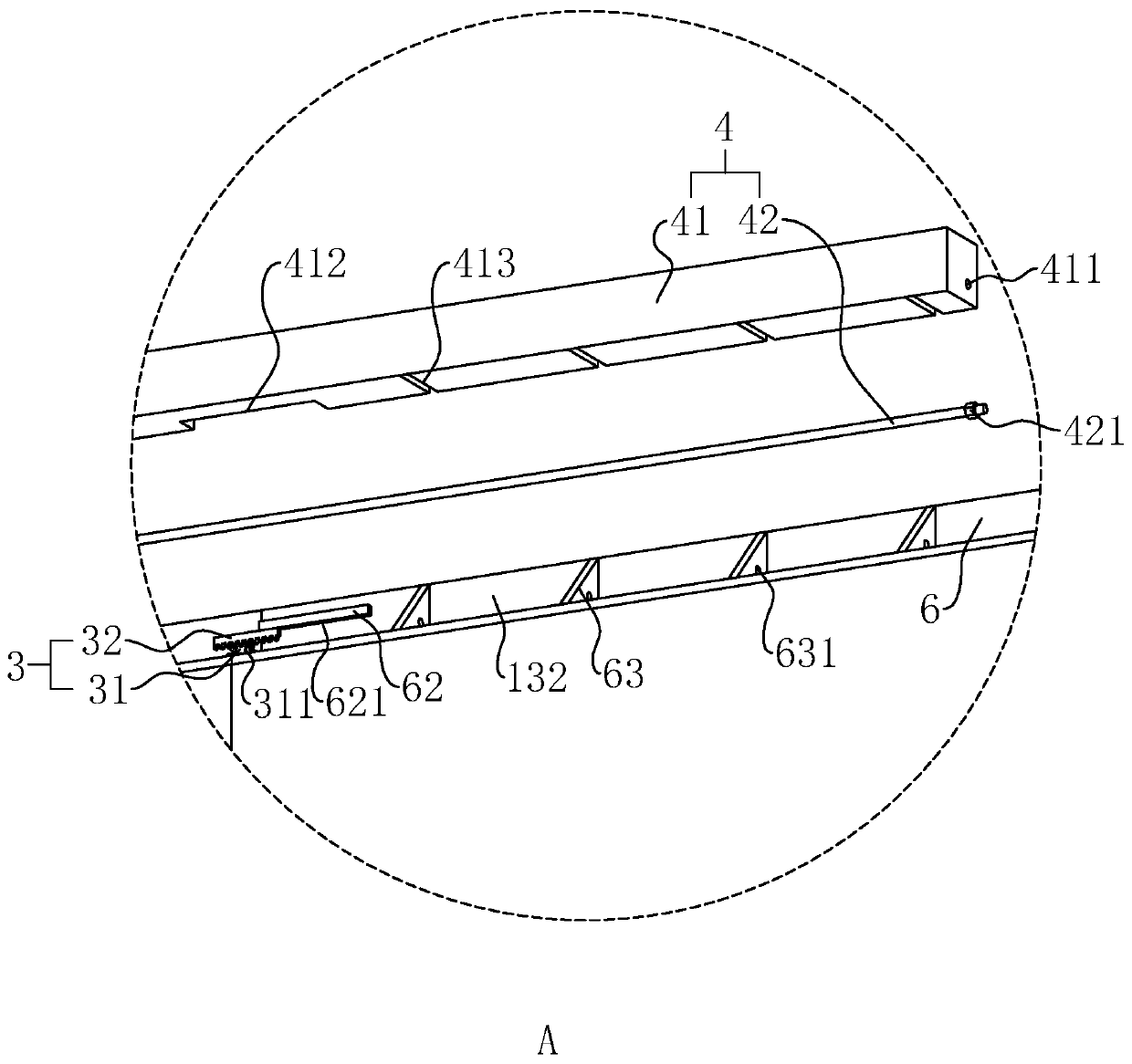

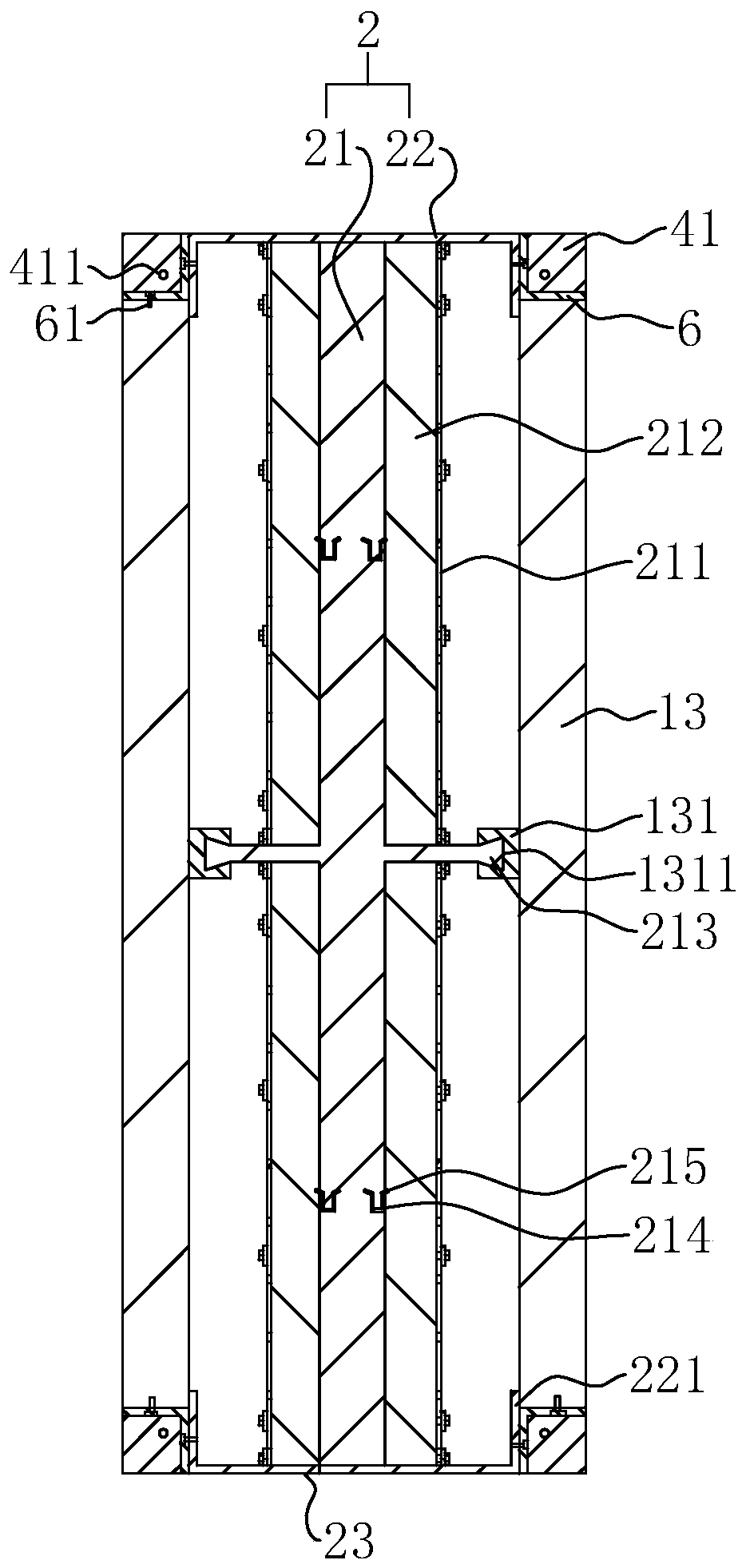

Indoor partition wall installation system for prefabricated buildings

The invention relates to an indoor partition wall installation system for prefabricated buildings. The indoor partition wall installation system comprises a plurality of partition wall templates whichare spliced to one another. The multiple partition wall templates are fixed to one another through a fixing mechanism. Each partition wall template is provided with a tensioning mechanism used for pulling together the two adjacent partition wall templates. Each partition wall template comprises a keel frame and gypsum boards arranged on the two sides of the keel frame. The keel frame is providedwith a positioning and fixing mechanism which is used for positioning installation positions of the two adjacent partition wall templates. During installation, the installation positions of the two partition wall templates are pre-positioned through the positioning mechanism, then the two partition wall templates are pulled together through the tensioning mechanism, the gap between the two partition wall templates is narrowed, and finally the two partition wall templates are fixed through the fixing mechanism. Compared with the traditional mode that fixing is achieved through cement mortar, the partition wall template connecting structure is convenient to disassemble, the integrity of the partition wall templates is not damaged, secondary utilization can be achieved, and the production cost is reduced.

Owner:GUANGDONG KANGJUN IND DEV CO LTD

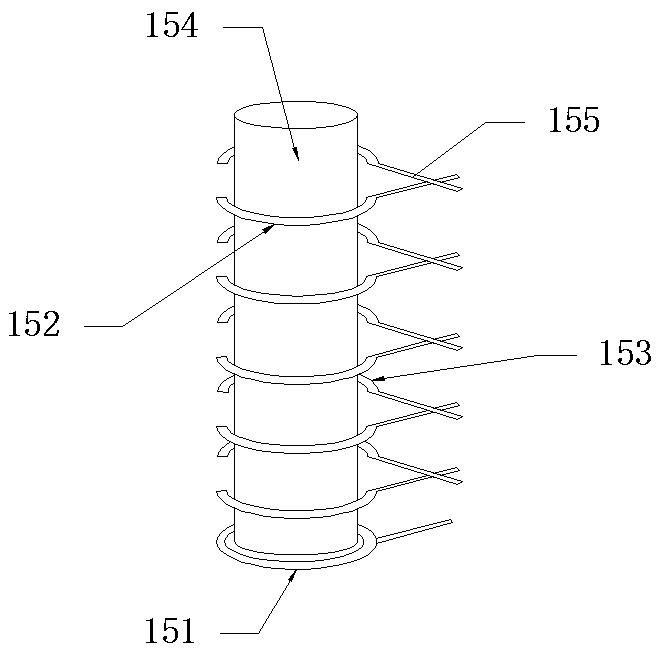

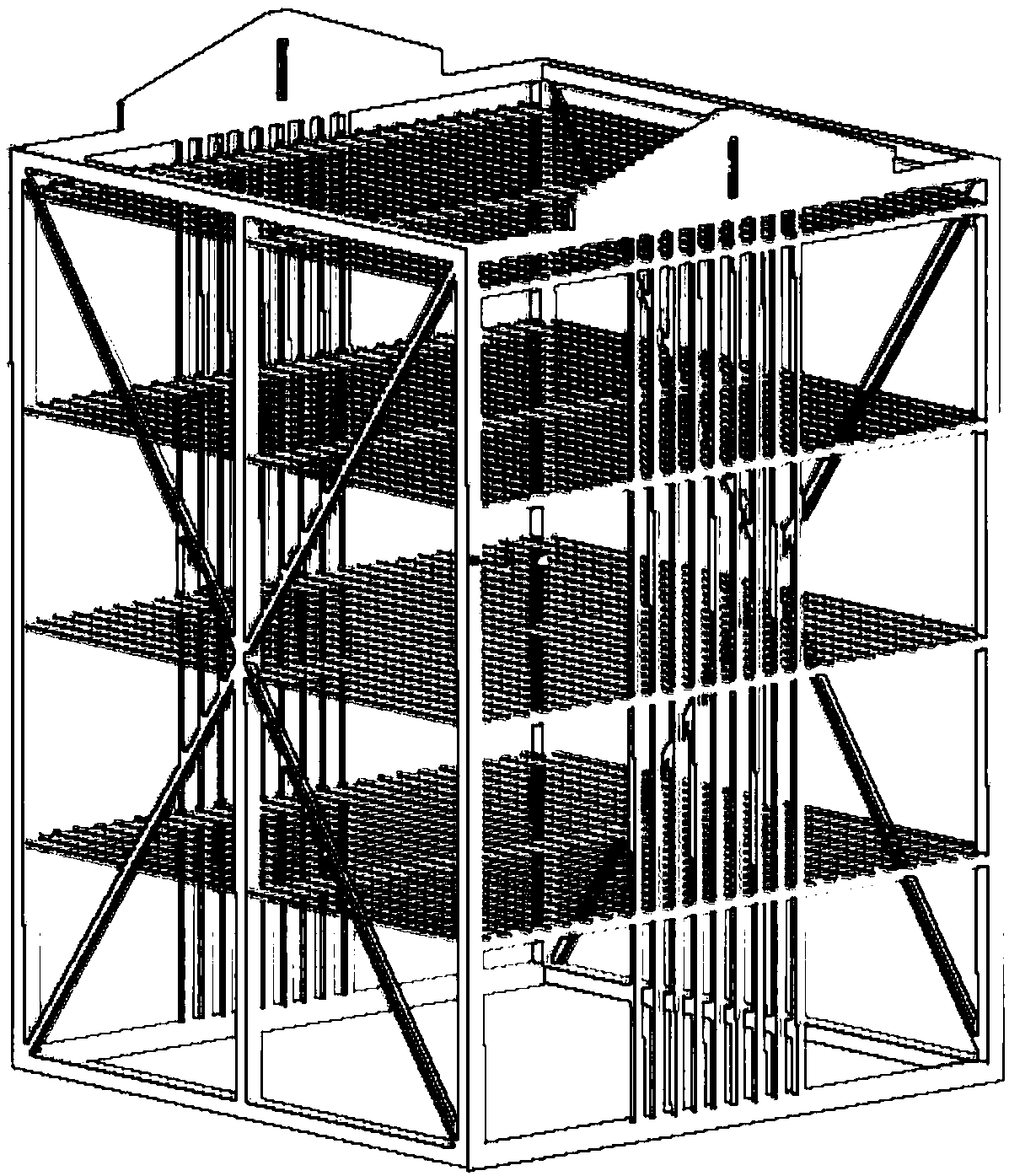

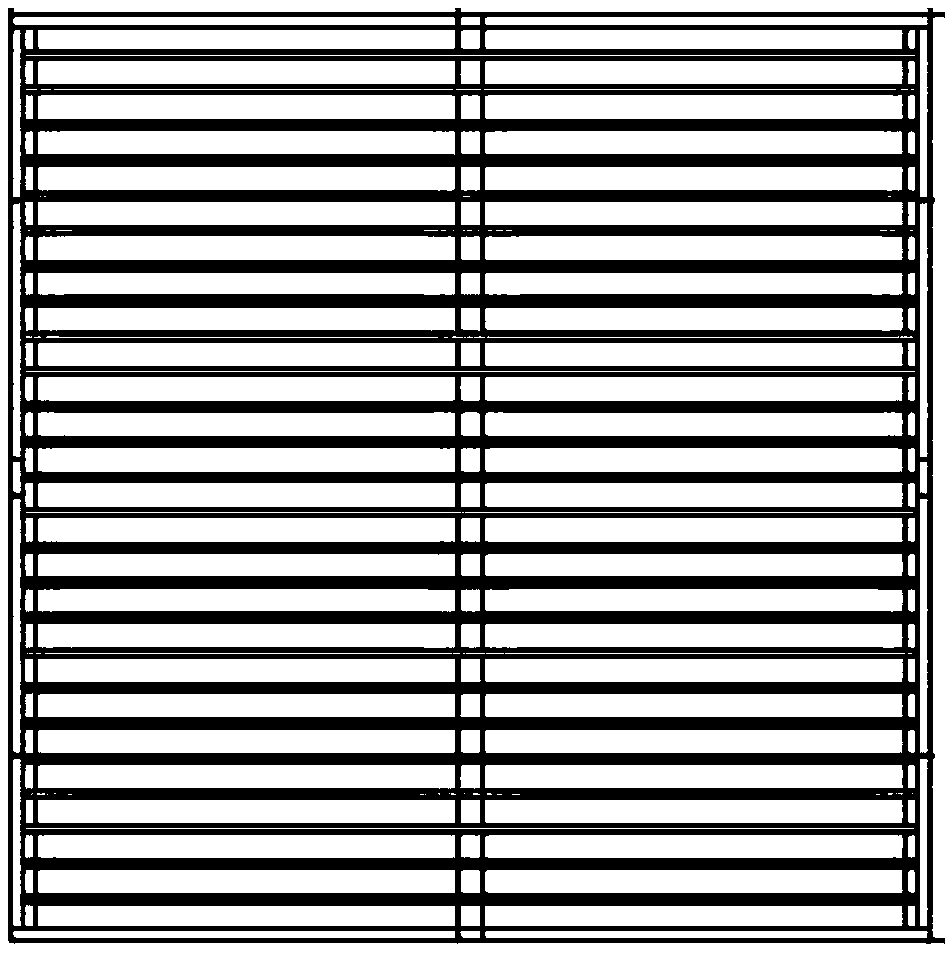

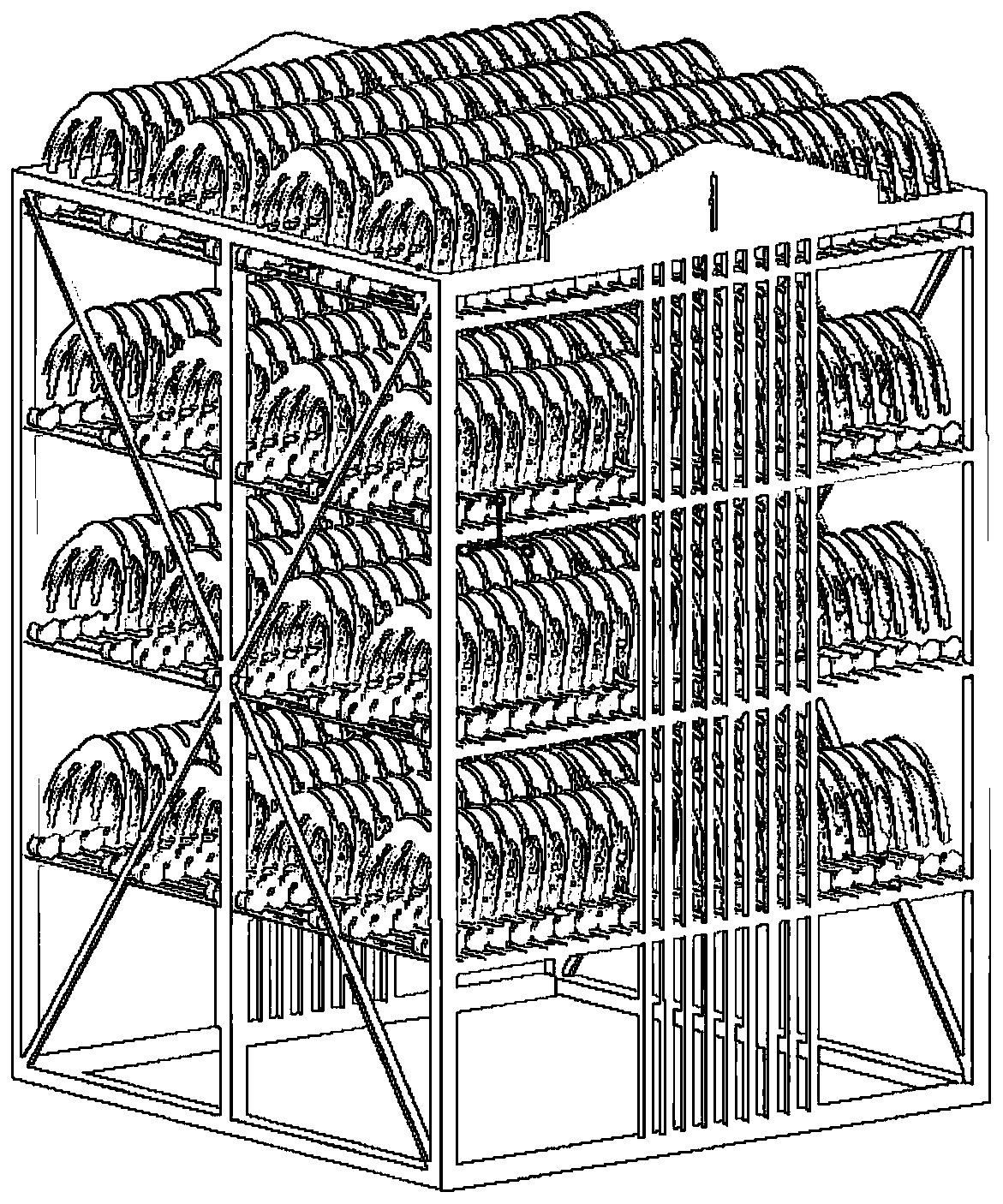

Heat treatment process for parts for automobile shock absorption system and heat treatment support frame

InactiveCN108929936AReasonable structureArrange neatlyFurnace typesHeat treatment furnacesHardnessEngineering

The invention discloses a heat treatment process for parts for an automobile shock absorption system and a heat treatment support frame, the heat treatment process comprises normalizing treatment, quenching treatment and tempering treatment; and the parts are placed in a heat treatment furnace for heat treatment by the heat treatment support frame. The heat treatment support frame comprises a frame body, the frame body is composed of a top square frame, intermediate layer square frames, a bottom square frame and a plurality of side frame pillars, the plurality of side frame pillars are vertically welded to the top corners of the top square frame and the bottom square frame, the intermediate layer square frames are sequentially in parallel ate intervals welded to the side frame pillars connecting the top square and the bottom square frame, and strip-like grilling are welded on the intermediate layer square frames. The heat treatment support frame is more reasonable in structure comparedwith that in the prior art, the parts can be placed neatly, the accommodation space is large without damaging the integrity of the parts, the heat conduction is more uniform, the heat treatment efficiency is improved; and the heat treatment process improves the mechanical strength and hardness of the parts, and improves metallographic structures.

Owner:ANHUI LUOSHI SHENGTAI AUTO PARTS

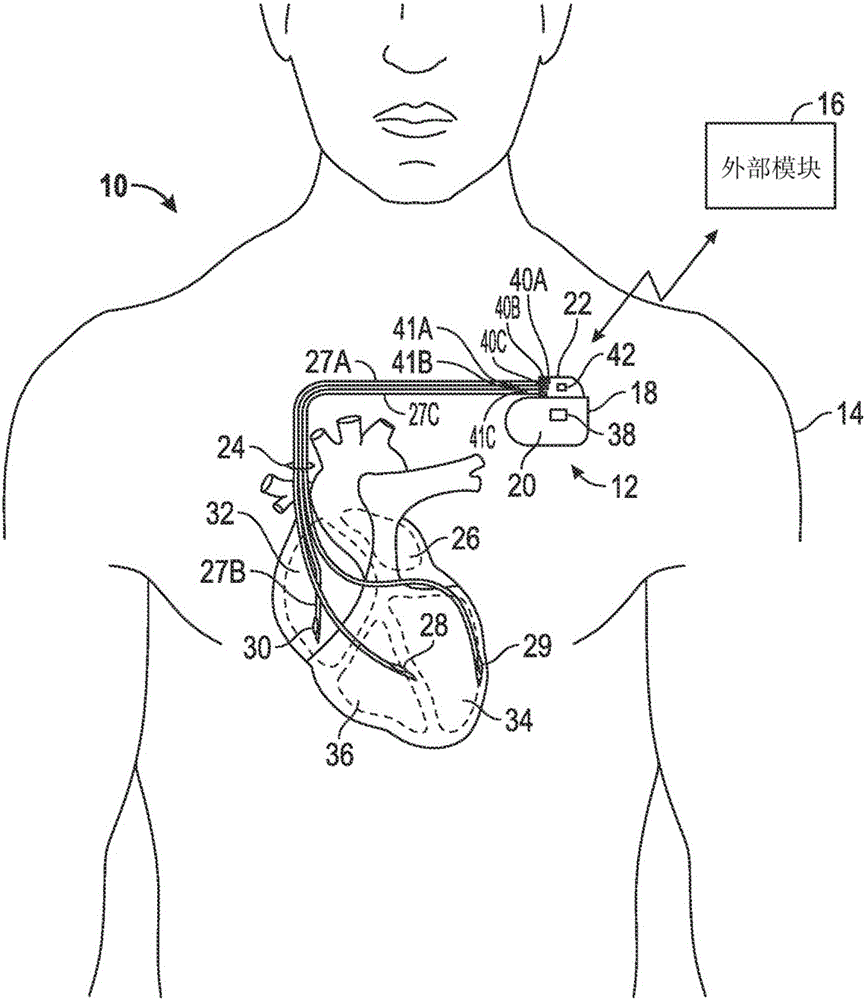

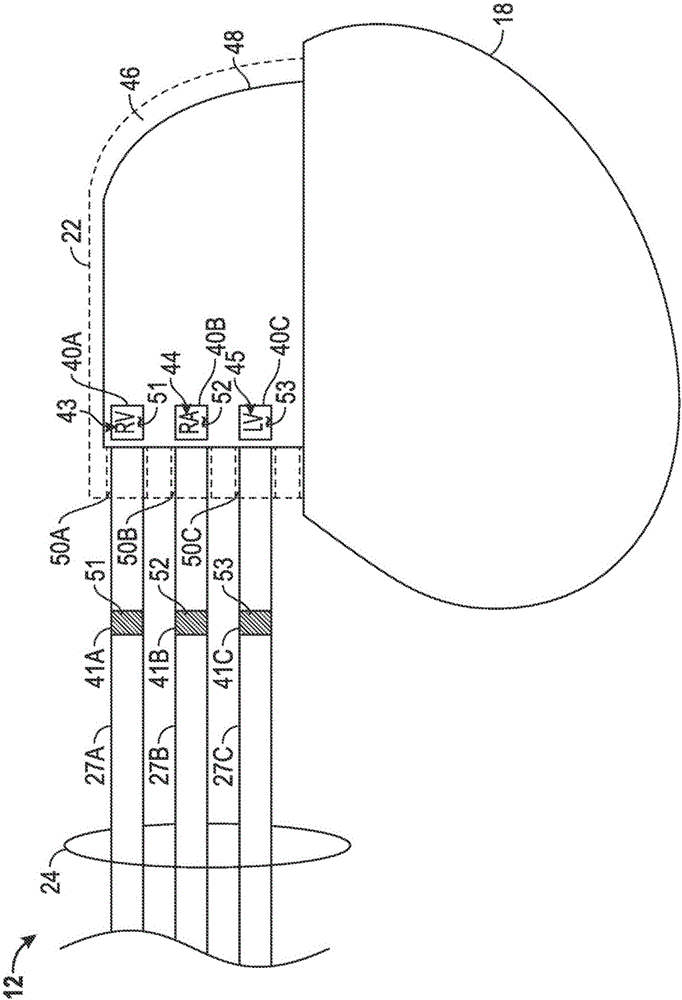

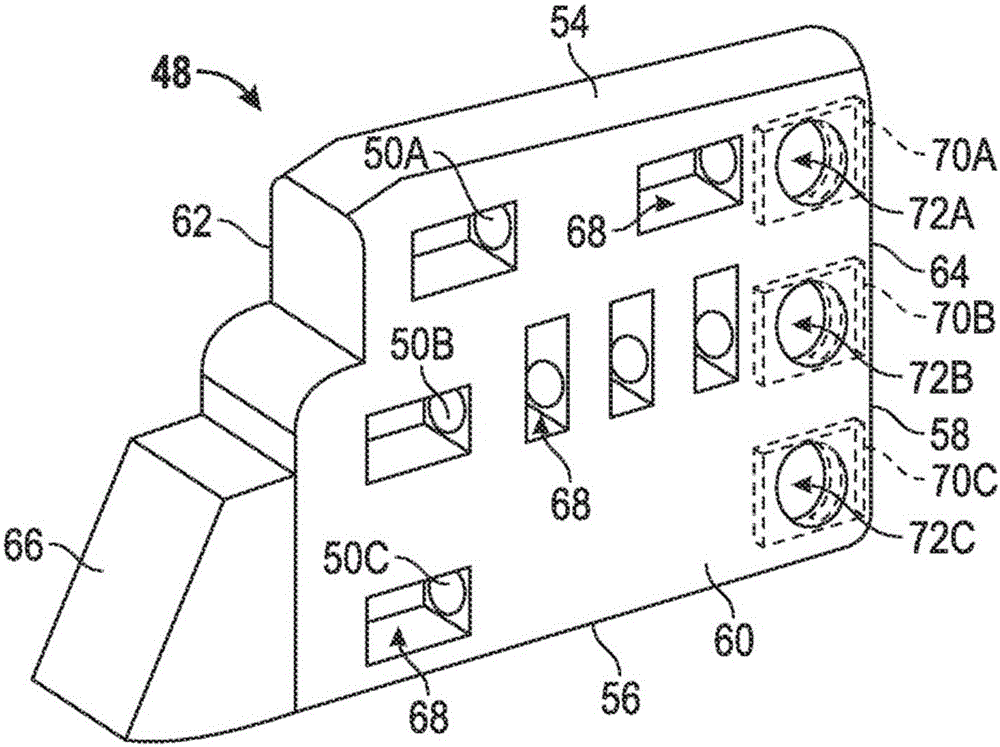

Labeled implantable medical devices

InactiveCN105764566AWithout compromising integrityWithout compromising propertiesIncorrect coupling preventionInternal electrodesMedical deviceBiomedical engineering

In general, techniques are described for labeling an implantable medical device (IMD). In one example, an IMD can include a housing including electronic circuitry. The IMD can include a header coupled to the housing and includes a core. The core can define a bore and include a first metal label positioned adjacent to the at least one bore. The IMD includes a lead assembly including at least one lead having a distal end and a proximal end, the at least one lead including a second metal label, the distal end including at least one electrode and the proximal end received within the bore.

Owner:CARDIAC PACEMAKERS INC

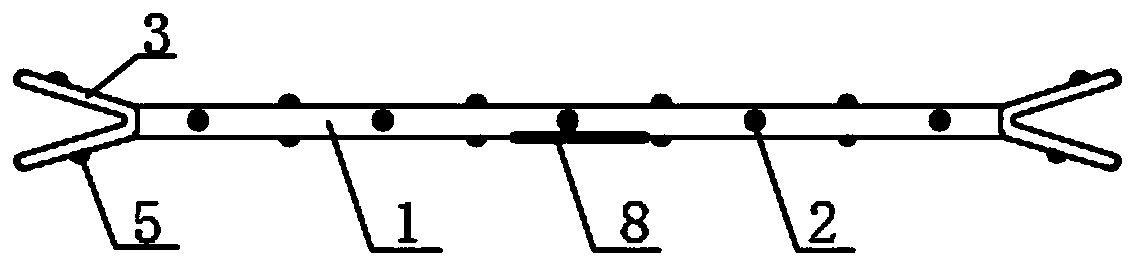

Steel fiber for ultrahigh-performance concrete

PendingCN109956692AIncrease the interface bonding areaImprove interfacial bond strengthConvex structureWave shape

The invention discloses a steel fiber for ultrahigh-performance concrete. The steel fiber comprises a steel fiber body with a circular cross section, the steel fiber body is straight or wave-shaped, the surface of the steel fiber body is provided with a plurality of convex structures, the plurality of convex structures are uniformly distributed along the cross section of the steel fiber body, theprojections of the two annular convex structures, which are adjacent to each other longitudinally along the steel fiber body, on the cross section are uniformly staggered, and special-shaped end hooksare arranged at two ends of the steel fiber body. The arrangement of the convex structures and the special-shaped end hooks increases the number of anchoring points and the interfacial bonding area of the steel fiber, and the end hooks increase the anchorage range of the steel fiber and a cement matrix, so the interfacial bond strength and the end anchoring ability of the steel fiber are improved, the tensile strength of the ultrahigh-performance concrete is improved, and the length of the steel fiber is shortened under the premise of meeting the interfacial bonding area of the steel fiber, thereby the cost is maximally saved.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com