Indoor partition wall installation system for prefabricated buildings

An installation system and a technology for inner partition walls, which are applied in construction, building components, building structures, etc., can solve the problems of increasing production costs, difficult to reuse, and damage to the overall structure of composite partition walls, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings.

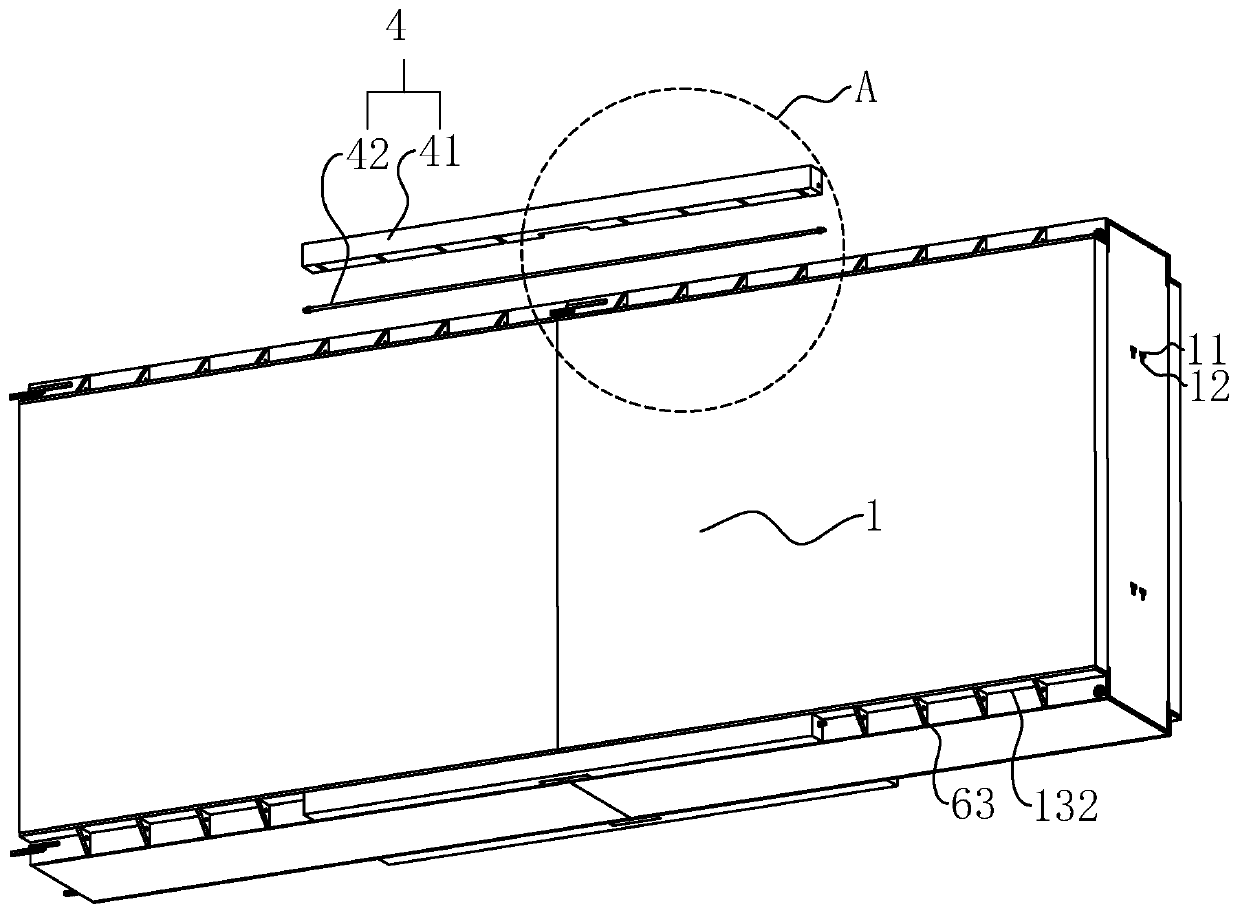

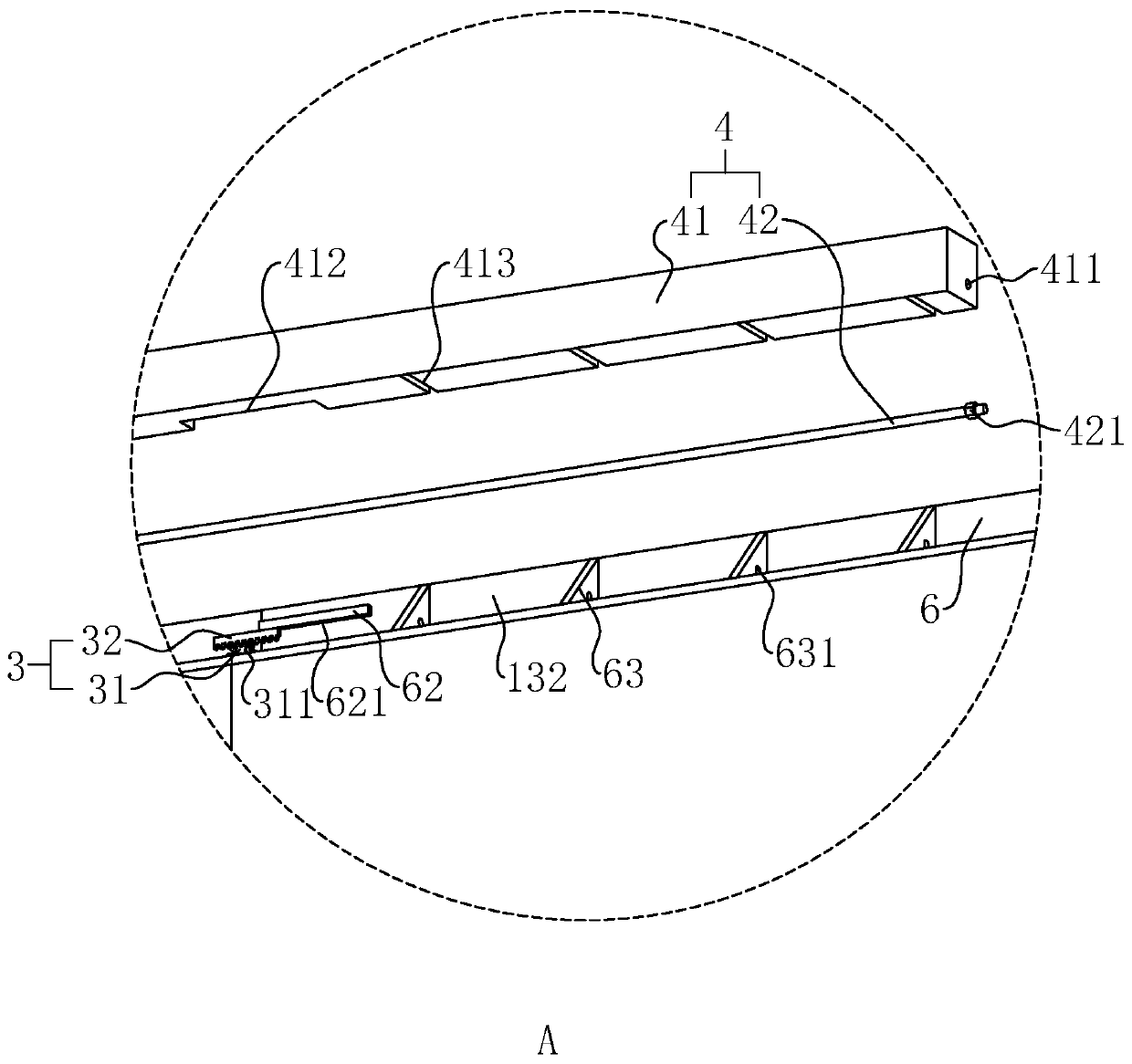

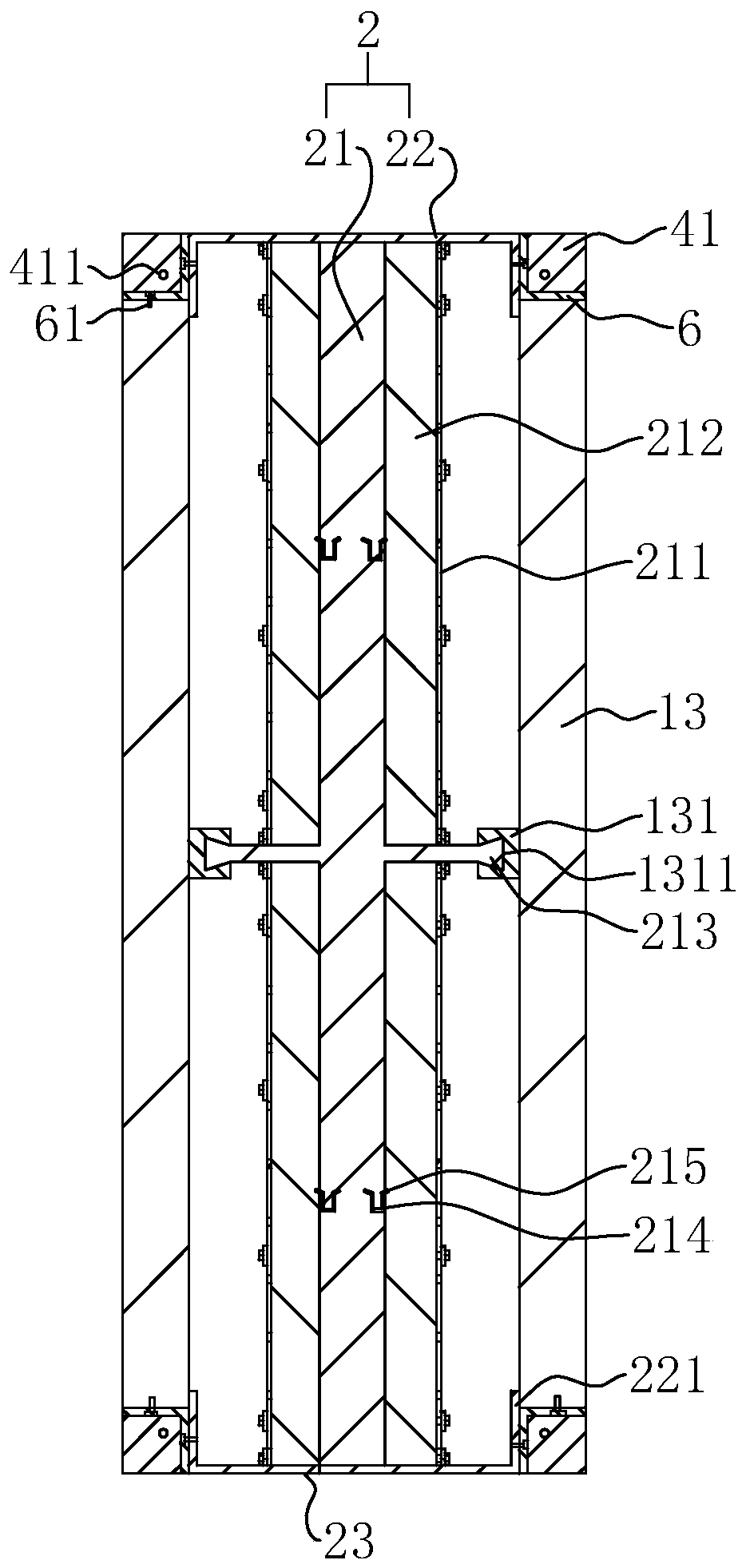

[0038] refer to figure 1 with image 3 , is an indoor partition wall installation system for a prefabricated building disclosed in the present invention, which includes a plurality of partition wall templates 1 formed by splicing each other from left to right, and a plurality of partition wall templates 1 pass through a tensioning mechanism 3 (refer to figure 2 ) and fixing mechanism 4 for connection and fixation, each partition wall template 1 includes keel frame 2 and gypsum board 13, keel frame 2 includes sky keel 22, ground keel 23, and vertical and horizontal keels 21 interlaced to form a grid, sky keel 22 is fixed on the top of the vertical and horizontal keel 21, the ground keel 23 is fixed on the bottom of the vertical and horizontal keel 21, and the plasterboard 13 is covered and installed on both sides of the keel 2.

[0039] The side of the gyps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com