Mulching film strip collecting device

A technology of mulching and stripping, which is applied in the direction of collectors, applications, agricultural machinery and tools, etc., can solve the problems of low tensile strength, unfavorable mechanized recycling, high impurity content of residual film, and achieve the effect of reducing the rate of residual film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

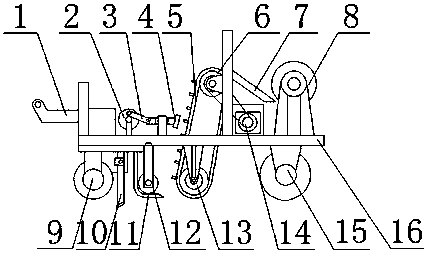

[0017] A kind of mulching strip collection device, comprises frame 16, conveying device 5, collection roller 8, and described frame 16 below is provided with guide roller 9, and guide roller 9 right side is film edge loosening plow shovel 10, film edge loosening The right side of the soil plow shovel 10 is provided with a conveying auger bottom pallet 11, and the top of the conveying auger bottom pallet 11 is provided with a horizontal miscellaneous discharge mechanism 12, and the right side of the conveying auger bottom pallet 11 is a conveying device 15, and the frame 16 is on the right. The bottom of the side is provided with a walking wheel 15, the left side above the frame 16 is provided with a traction frame 1, and the right side of the traction frame 1 is provided with a cam 2, the cam 2 is connected with the hammer head 4 through the connecting rod 3, and the right side of the hammer head 4 is the conveyor Device 5, the conveying device 5 is made up of the driven wheel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com