Steel fiber for ultrahigh-performance concrete

An ultra-high-performance, steel fiber technology, applied in the field of ultra-high-performance concrete, can solve the problems of concrete structure safety, adverse effects on durability, poor bonding performance, and few anchor points, so as to improve the interface bonding strength and end-to-end Effects of anchoring ability, improvement of interface bond strength, and uniform increase of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a steel fiber for ultra-high performance concrete;

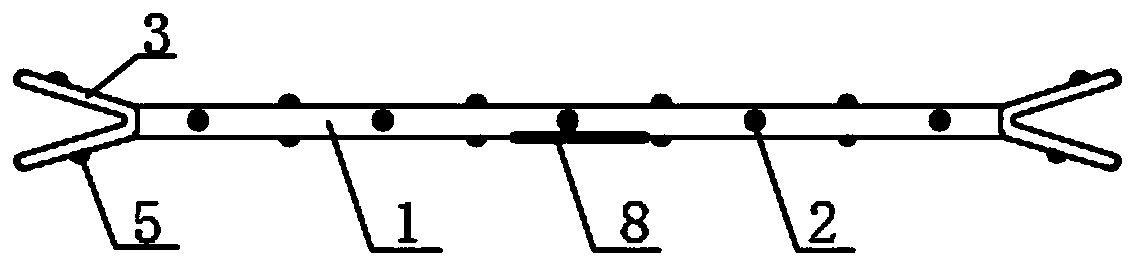

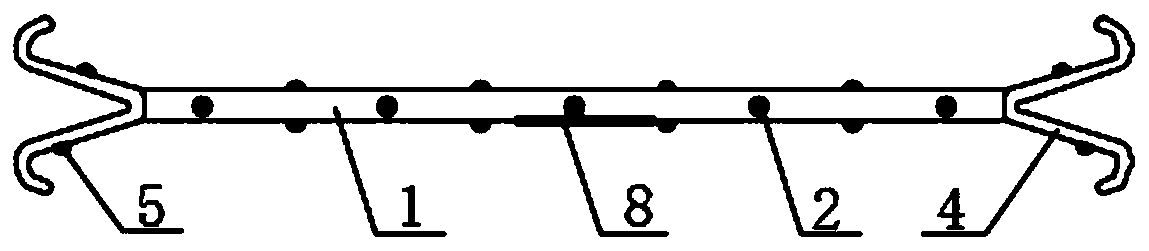

[0033] Such as Figure 1-3 and Figure 7 As shown, the steel fiber used for ultra-high performance concrete in this embodiment includes a steel fiber body with a circular cross section. The steel fiber body is a straight steel fiber body 1, and a raised structure 2 is provided on its surface. Three raised structures are evenly distributed along the cross-section of the steel fiber body, and the projections of the two rings of raised structures adjacent to each other along the longitudinal direction of the steel fiber body are evenly staggered in the cross-section, and special-shaped end hooks are arranged at both ends of the steel fiber body .

[0034] The present invention increases the number of anchor points on the surface of the steel fiber by providing a raised structure on the surface of the steel fiber body, and also increases the interface bonding area between the steel fiber and the c...

Embodiment 2

[0043] The invention provides a steel fiber for ultra-high performance concrete;

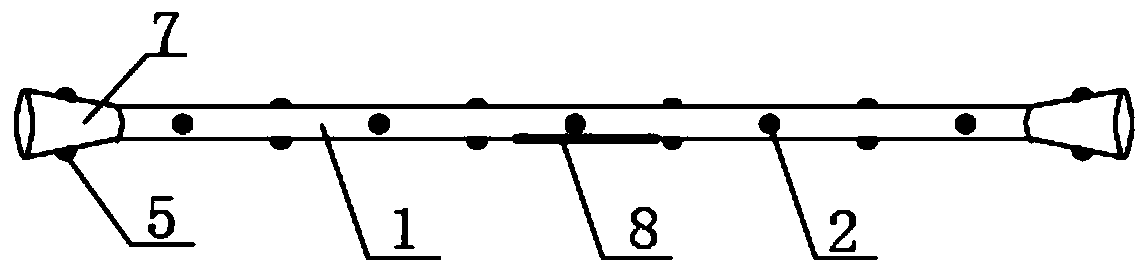

[0044] Such as Figure 4-6 and Figure 7 As shown, the steel fiber used for ultra-high performance concrete in this embodiment includes a steel fiber body with a circular cross section. The steel fiber body is a corrugated steel fiber body 6, and a raised structure 2 is provided on its surface. Three protruding structures are evenly distributed along the cross-section of the steel fiber body, and the projections of two rings of protruding structures adjacent to each other along the longitudinal direction of the steel fiber body are evenly staggered in the cross-section, and special-shaped end hooks are provided at both ends of the steel fiber body.

[0045] The present invention increases the number of anchor points on the surface of the steel fiber by providing a raised structure on the surface of the steel fiber body, and also increases the interface bonding area between the steel fiber and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com