Anti-corrosion agent composition

A technology of composition and resist, which is applied in the direction of optics, optomechanical equipment, instruments, etc., can solve the problem of residual film rate, line width uniformity, decreased adhesion of resist film, insufficient, resist formation characteristics and Insufficient properties such as solubility, etc., achieve the effect of reducing the amount of residual solvents, improving stability, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10、 comparative example 1~5

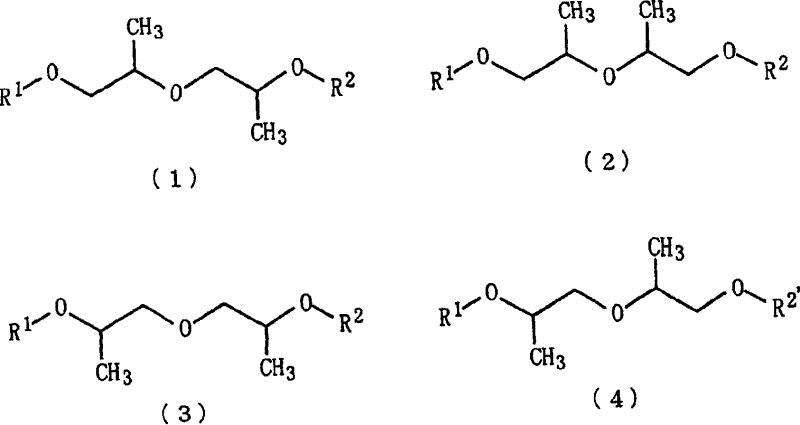

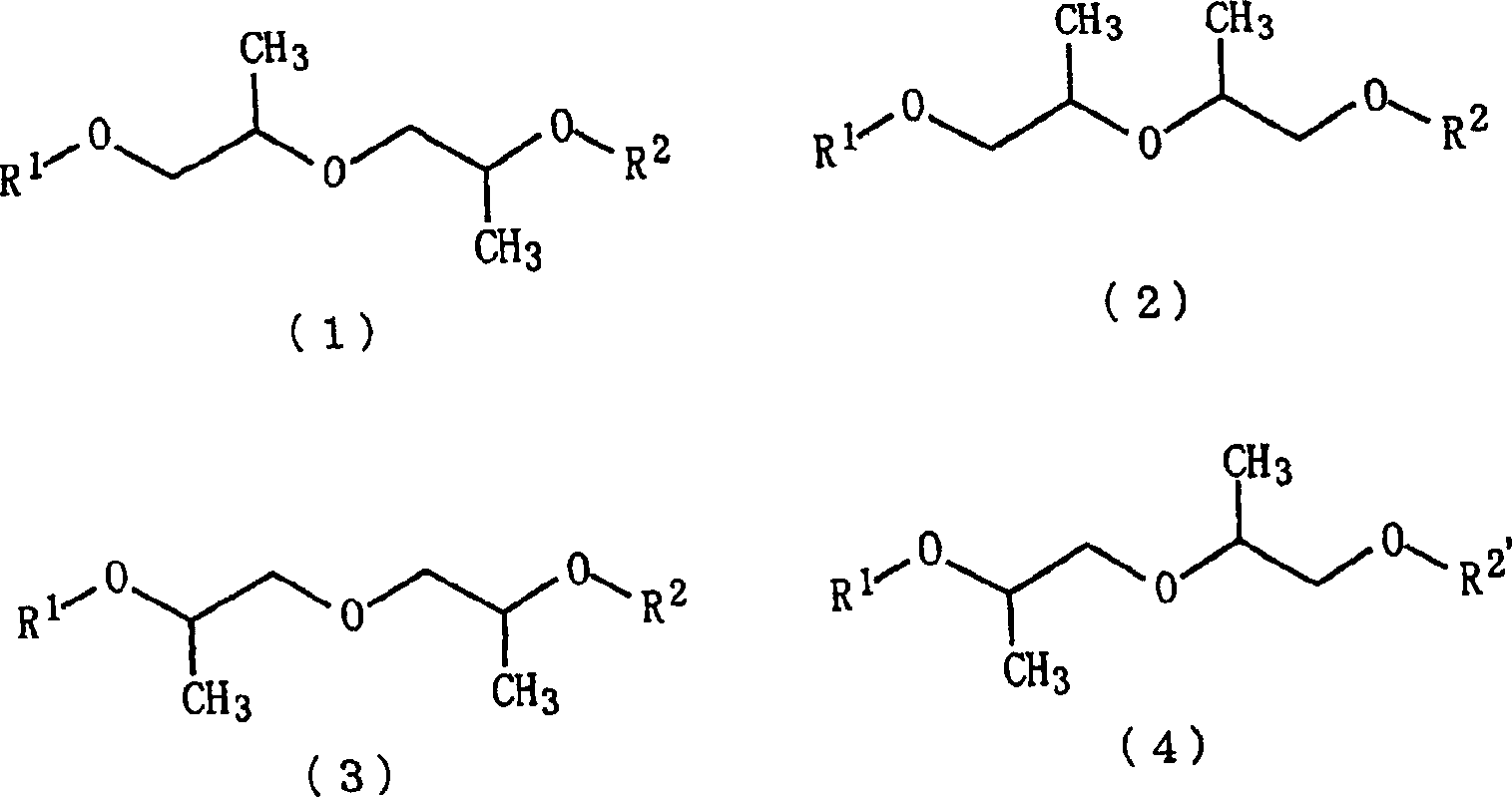

[0073] 2 g of the esterification reaction product of 1 mole of 2,4,4,4'-tetrahydroxybenzophenone and 3 moles of naphthoquinone-1,2-diazido-5-sulfonyl chloride and cresol novolak resin 8 g was dissolved in 40 g of solvents (numbers are weight ratios) of the composition shown in Table 1 to prepare a coating liquid of a positive photoresist composition. Table 1 shows the results of the following evaluation tests (1) to (3) performed on the coating liquid thus obtained.

[0074] (1) Whether there are precipitates

[0075] The prepared coating solution was filtered with a 0.2 μm membrane filter, and left to stand at 40° C., and the presence or absence of precipitates in the coating solution after 1 month and 2 months was investigated.

[0076] (2) Sensitivity change

[0077] Whether or not the sensitivity of the photoresist composition changed after 3 months was investigated. That is, when the coating liquid immediately after preparation is applied to the base material and dried...

Embodiment 11~14、 comparative example 6~7

[0099] Copolymerization of monohydroxyadamantyl acrylate and tetrahydropyranyl methacrylate to obtain 70 mol% of monohydroxyadamantyl acrylate units and 30 mol% of tetrahydropyranyl methacrylate units. Copolymerization of weight average molecular weight 8000 things. To the obtained resin, a solvent having a composition described in Table 2 was added to make the solid content 25% by weight, and heated at 50° C. for 10 minutes to examine the dissolution rate (solubility) of the resin. The results are shown in Table 2. The abbreviations in the table are the same as above.

[0100] ○: Becomes a homogeneous transparent solution

[0101] ×: Granular insoluble resin remains on the wall of the vessel

[0102] Solvent (mixing weight ratio)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com