Patents

Literature

50results about How to "Improve line width uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

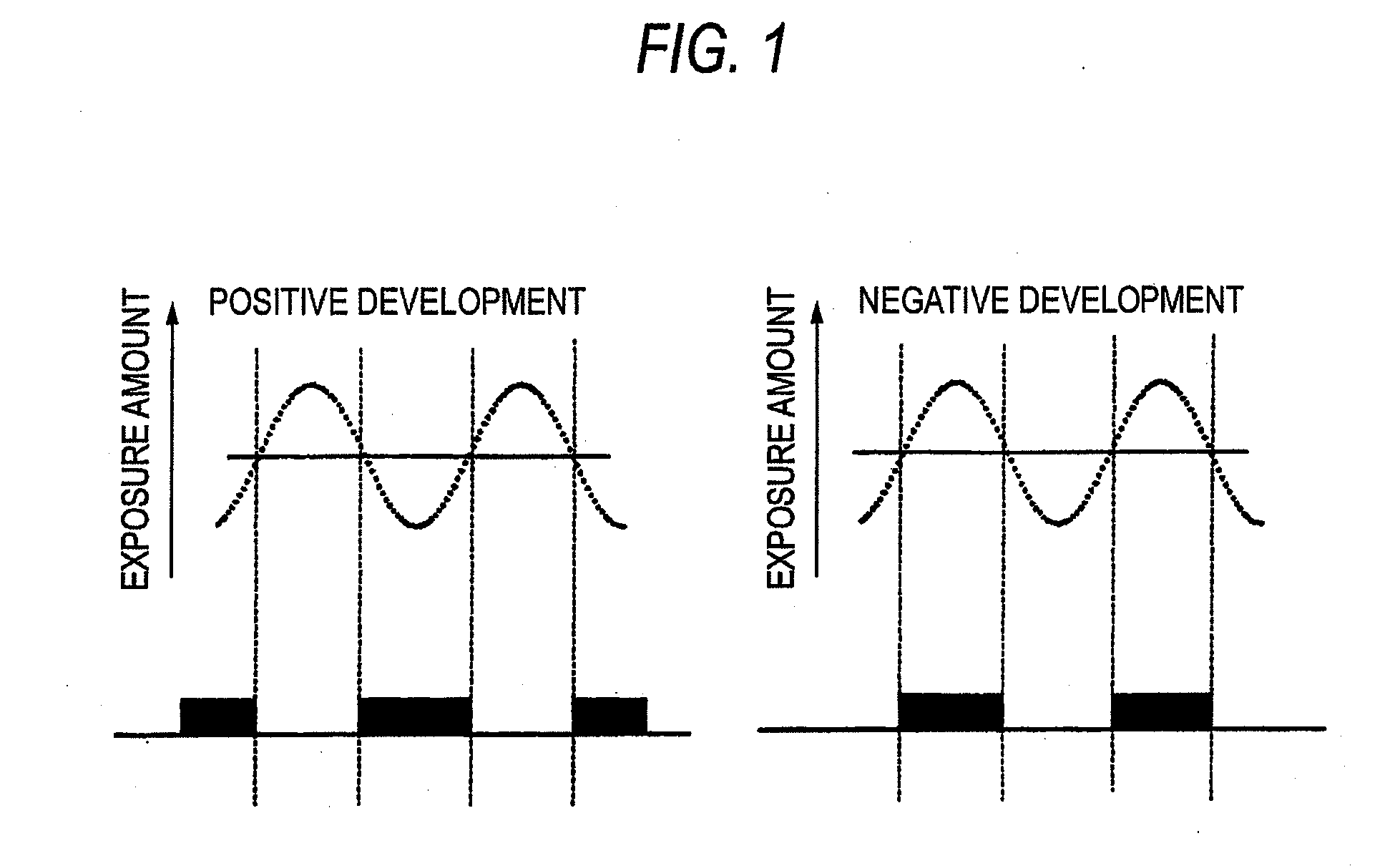

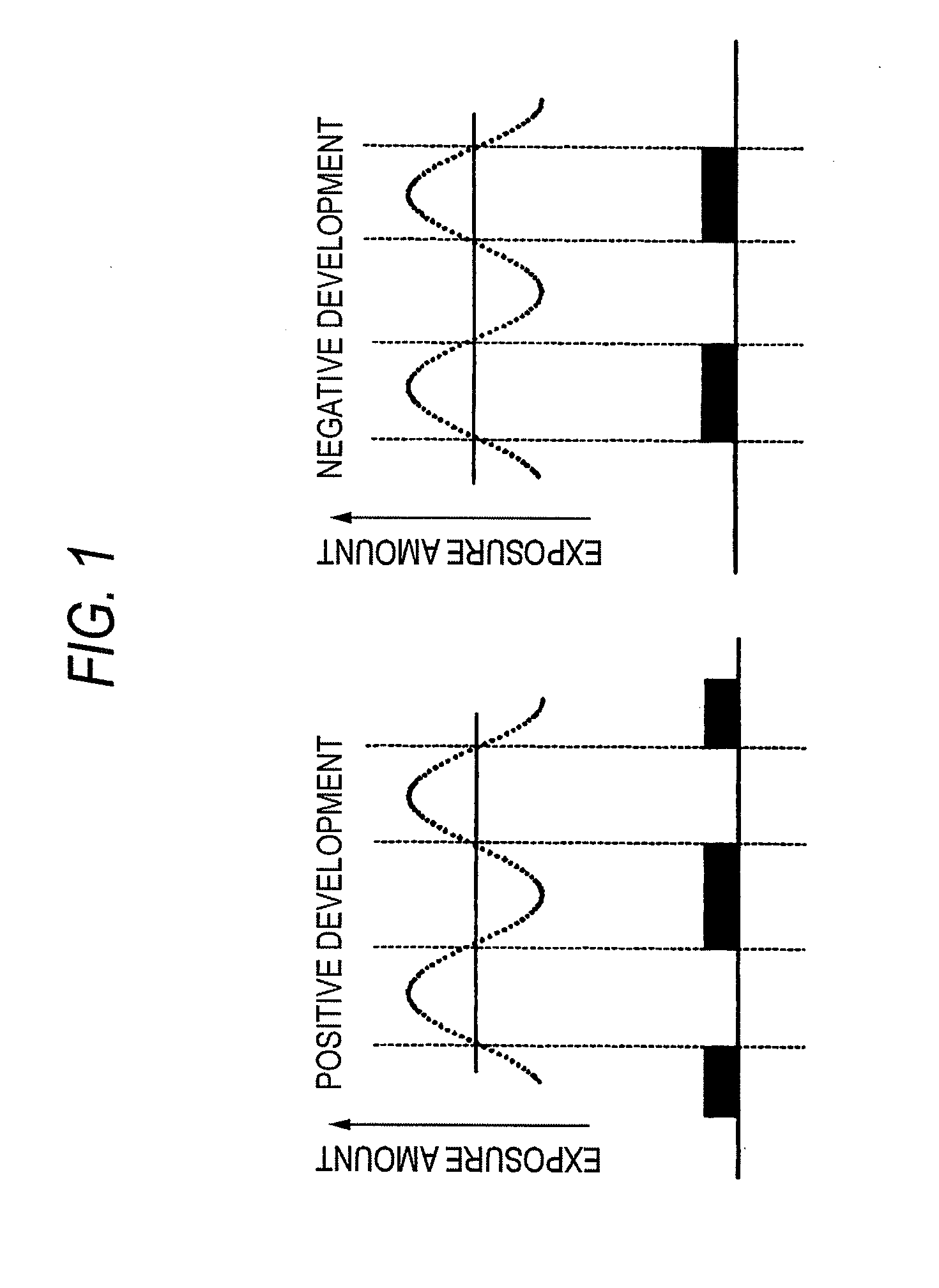

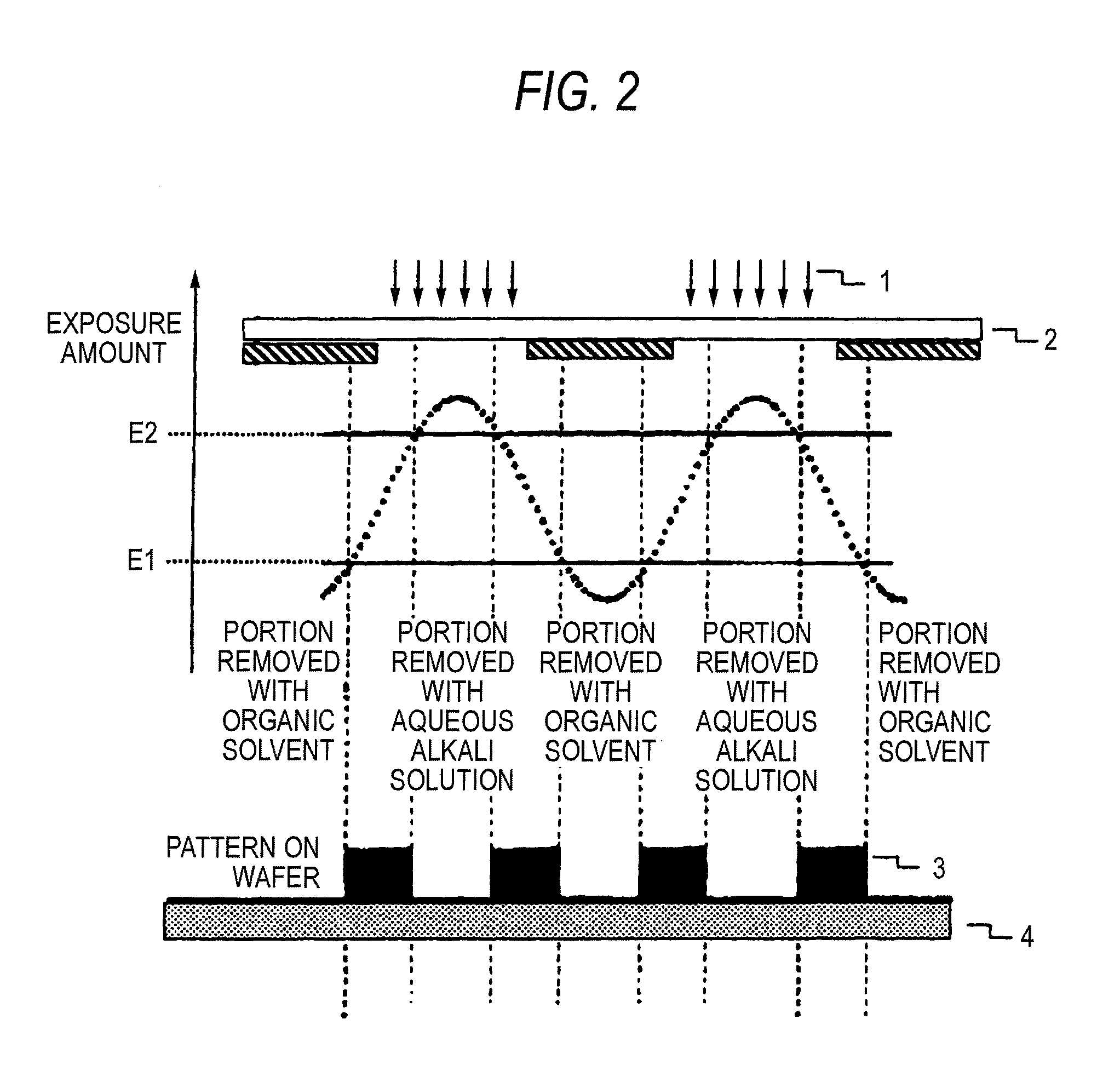

Method of forming patterns

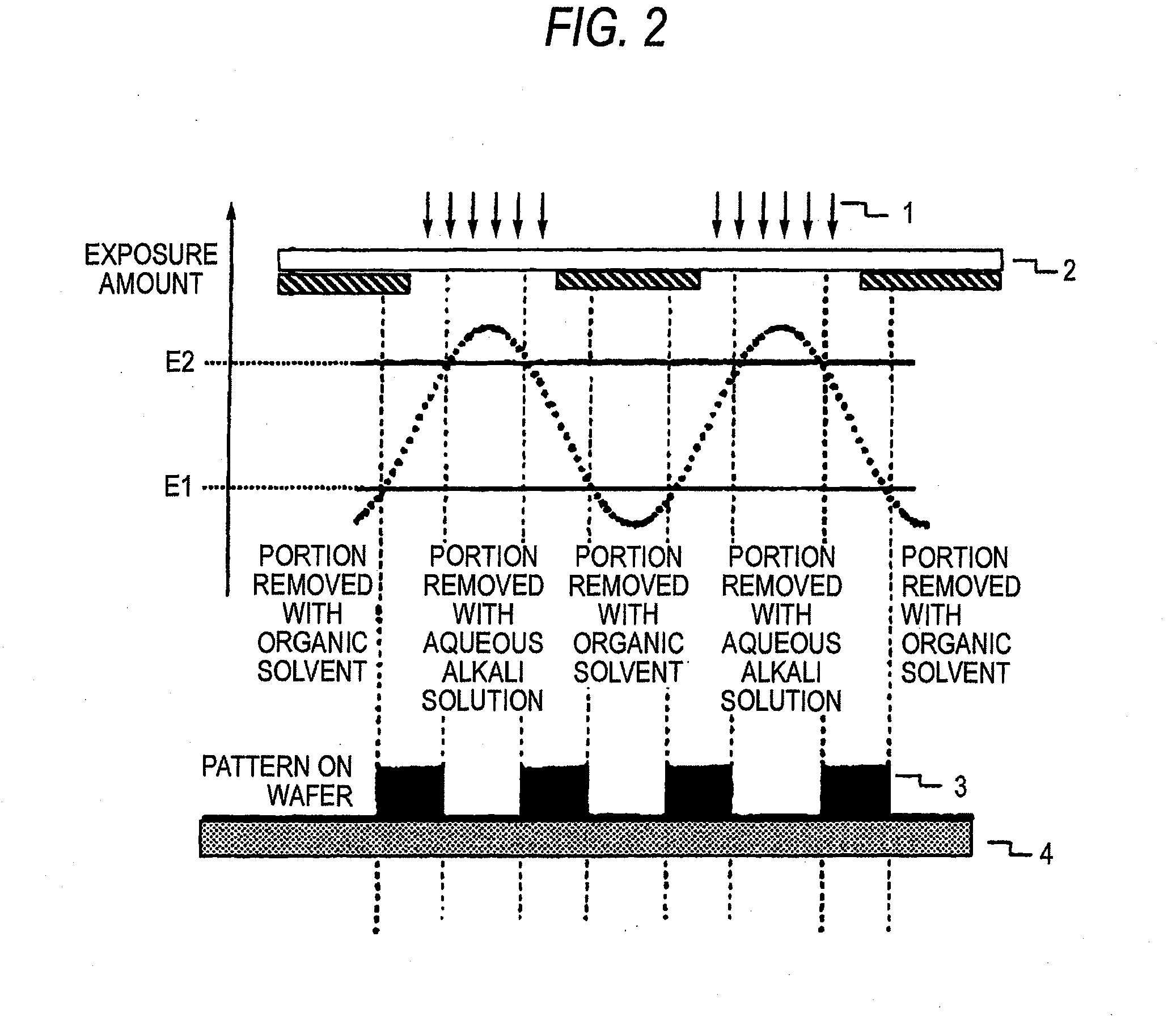

ActiveUS20080318171A1Enhanced in-plane uniformity of line widthReduced line edge roughnessPhotosensitive materialsPhoto-taking processesActinic RaysRadiation exposure

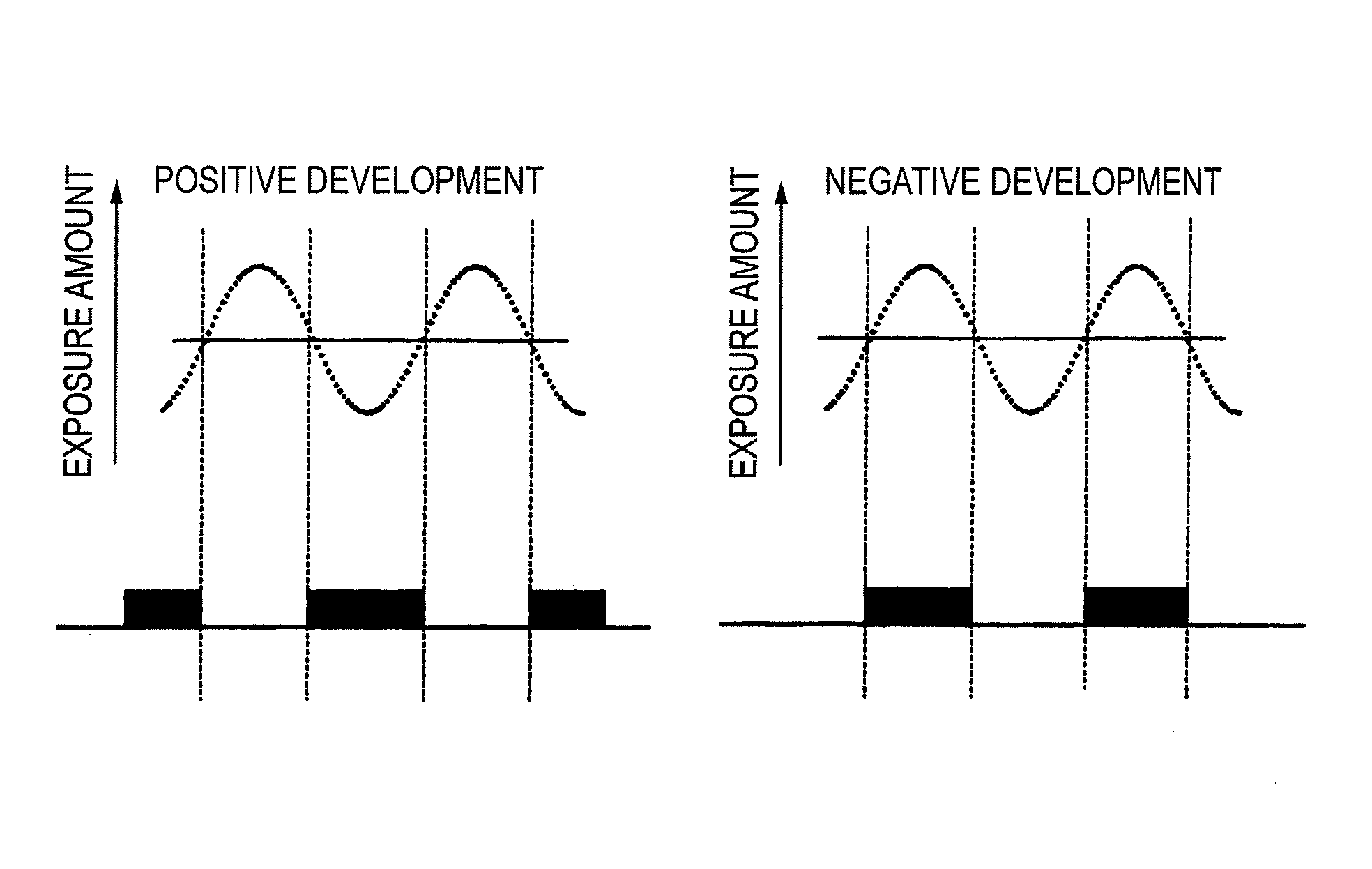

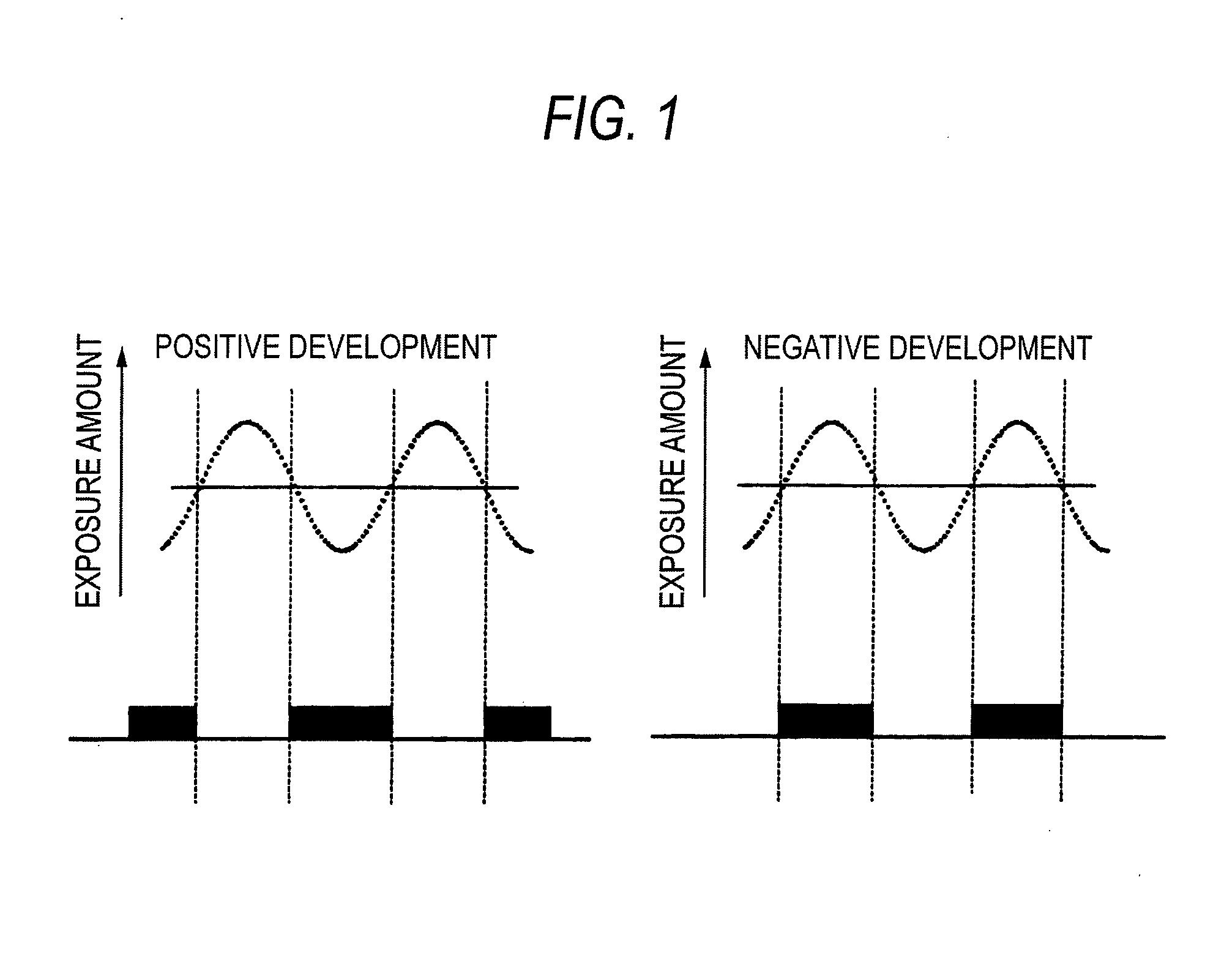

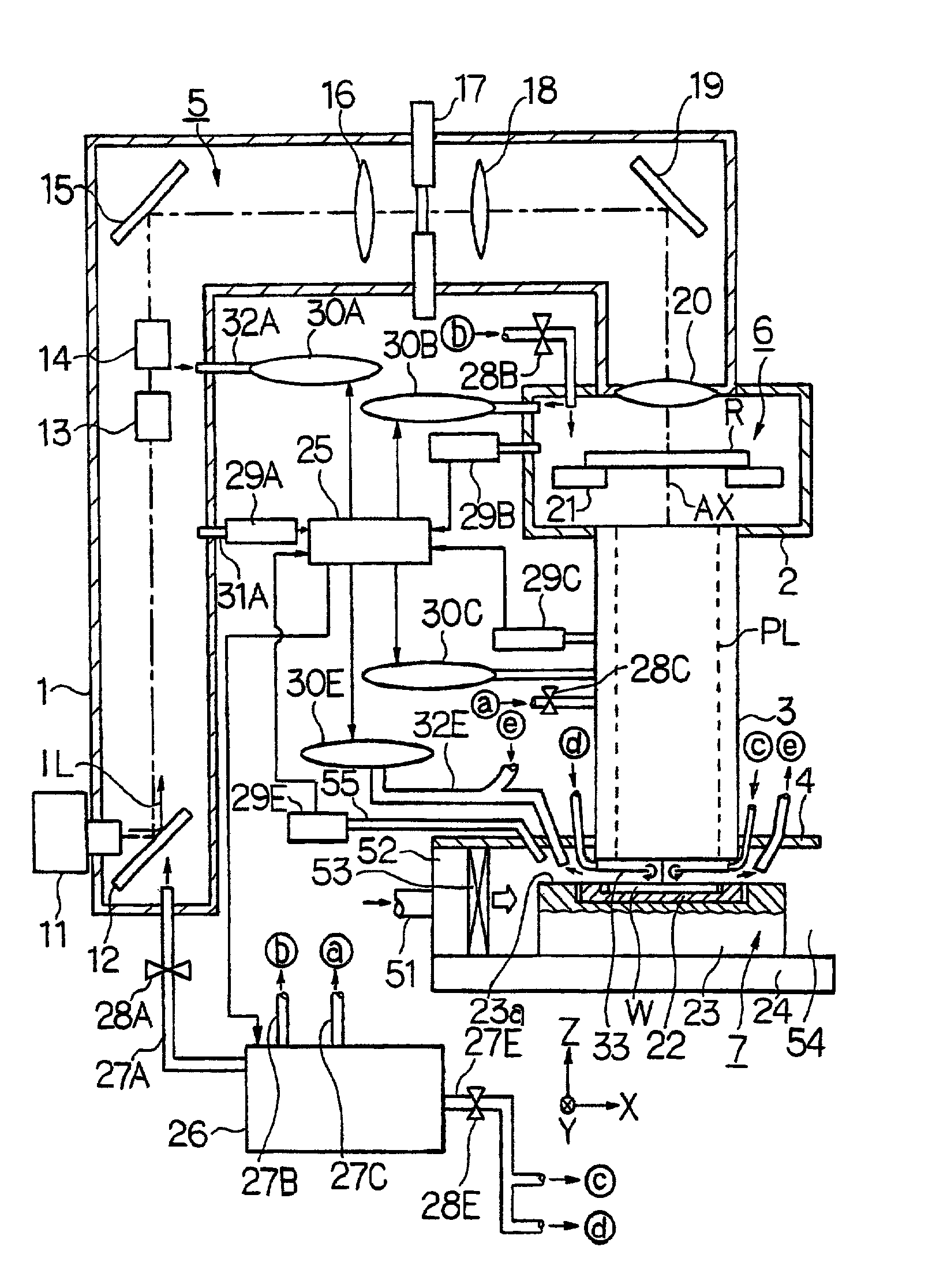

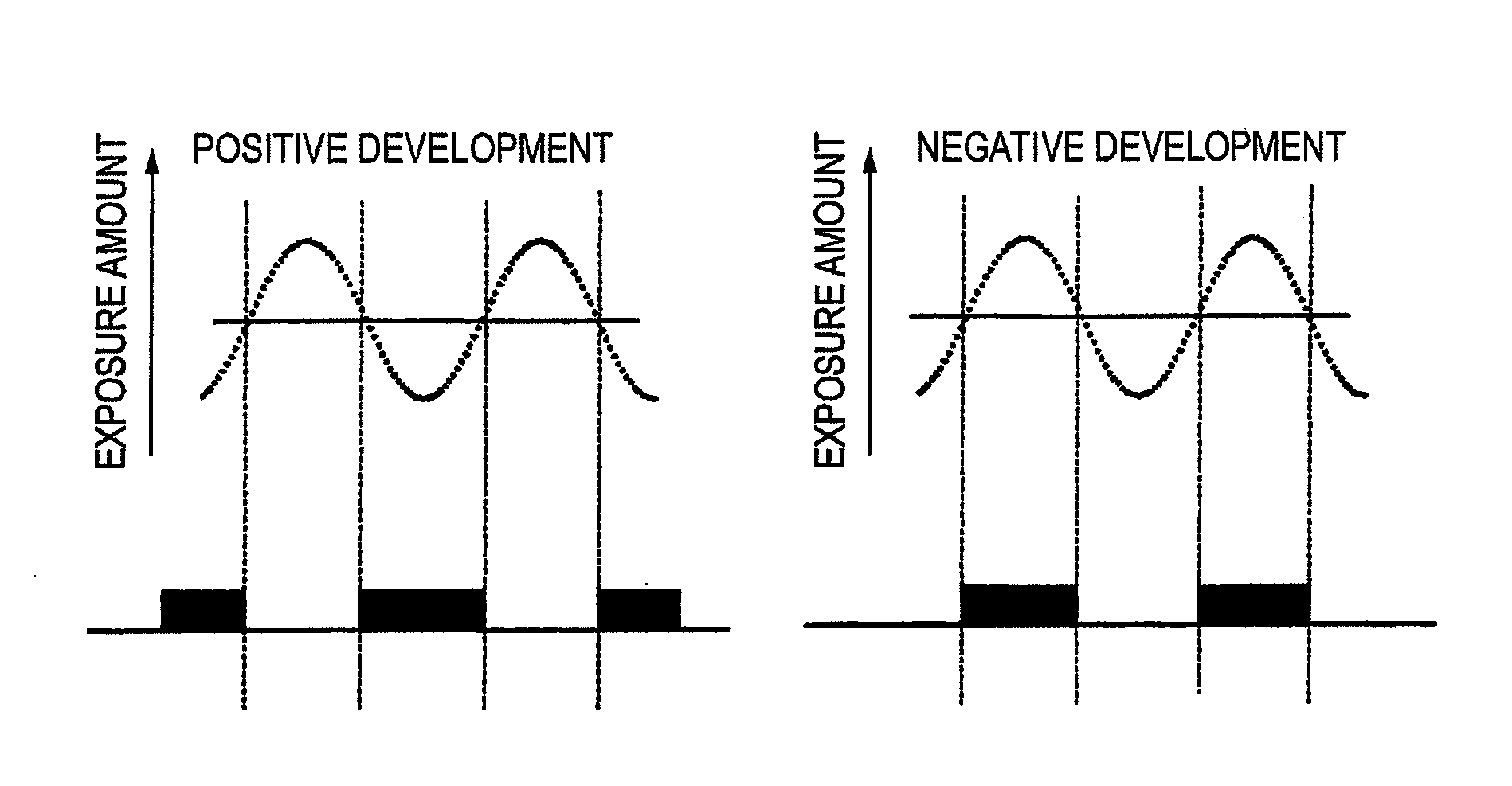

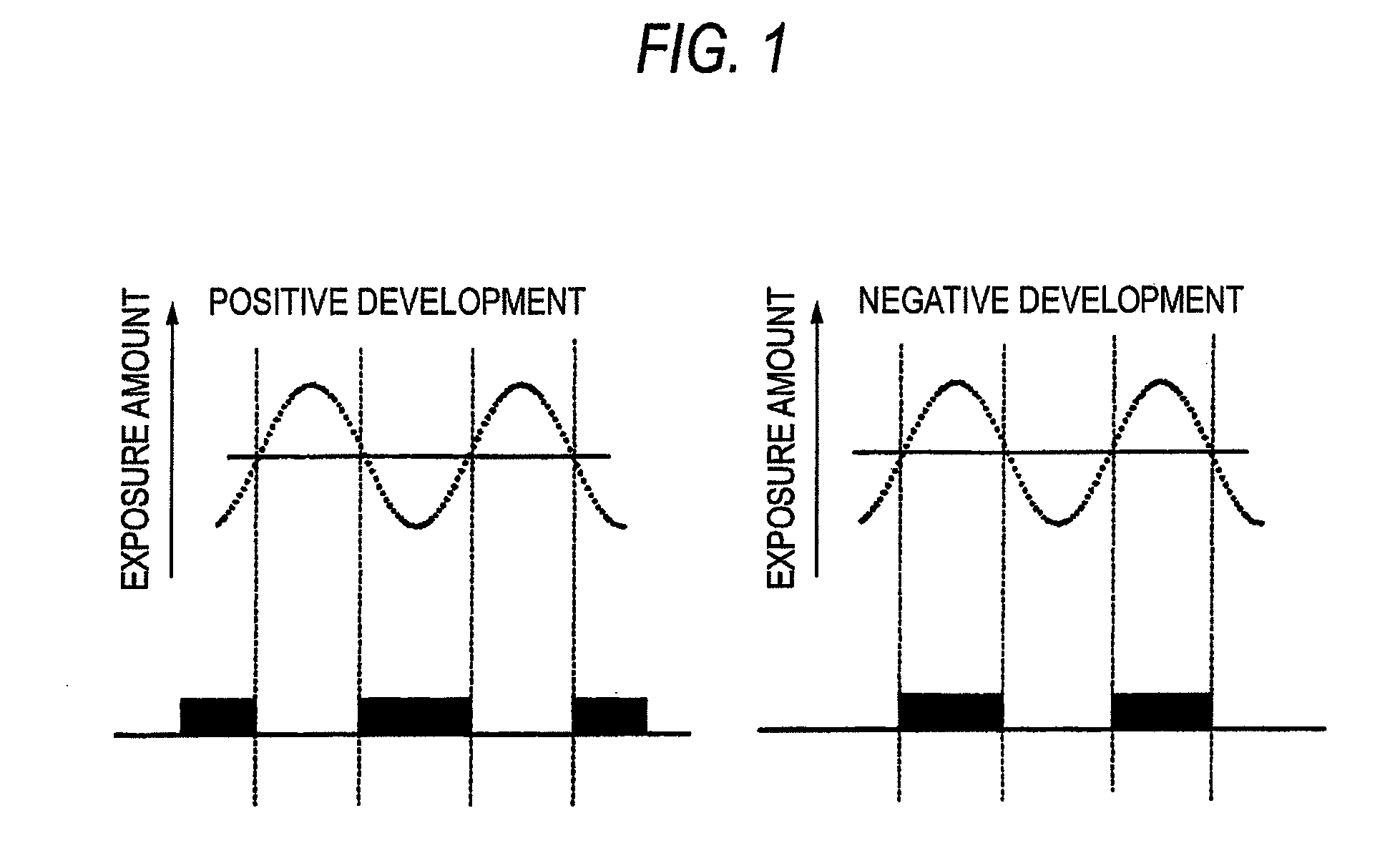

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

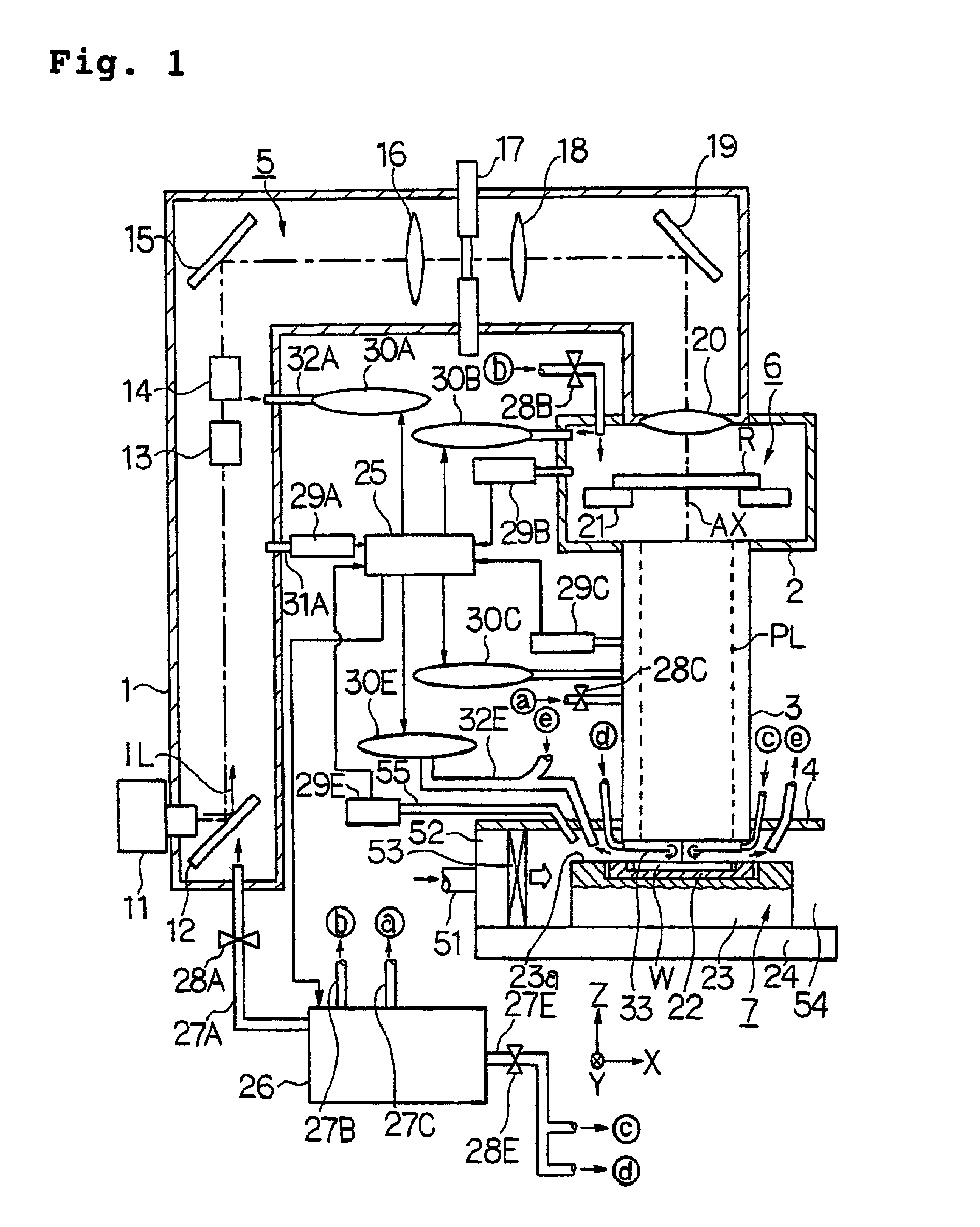

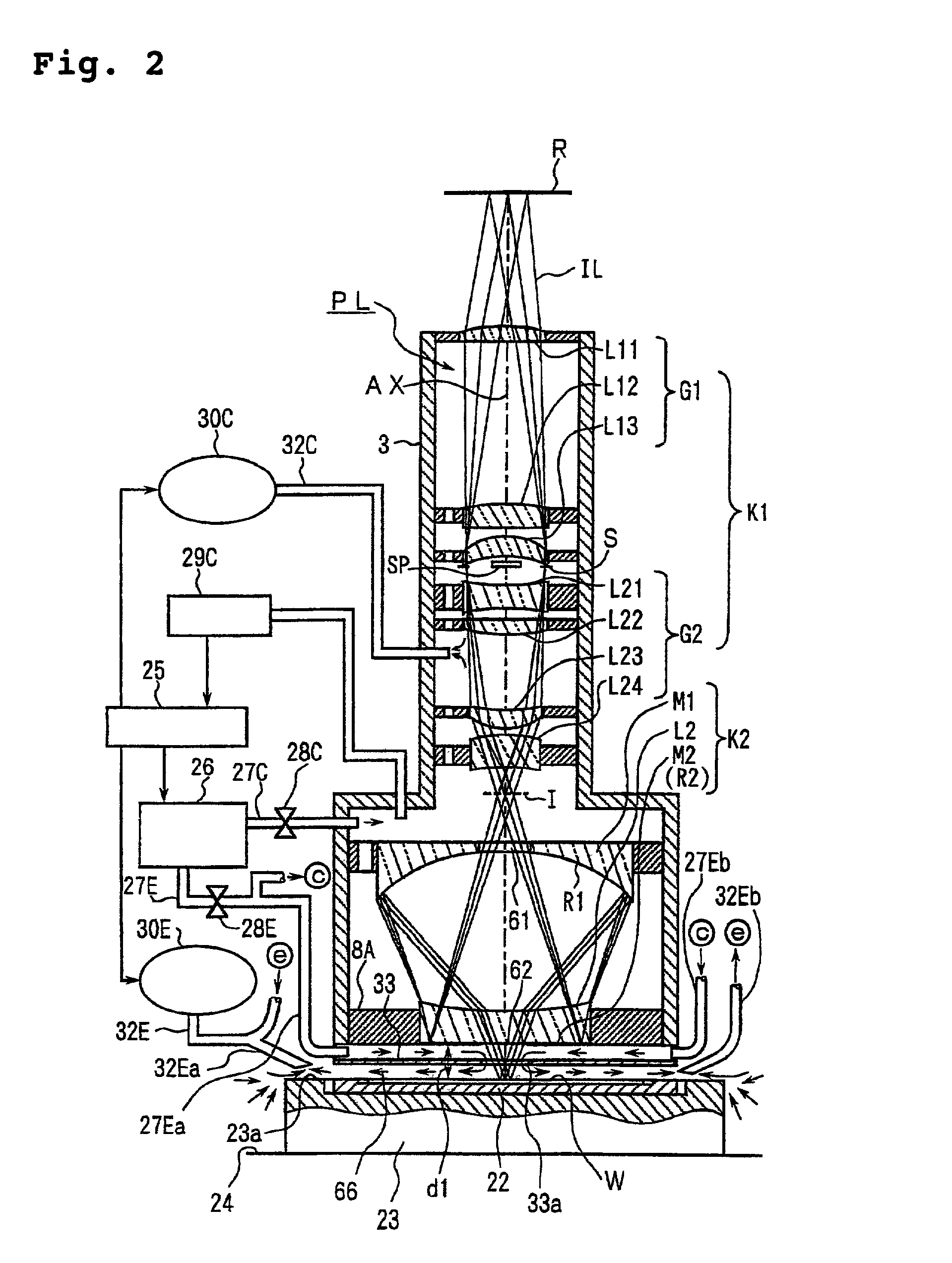

Exposure method and system

InactiveUS6970228B1Improve uniformityHigh strengthPhotomechanical exposure apparatusMicrolithography exposure apparatusLight beamOptoelectronics

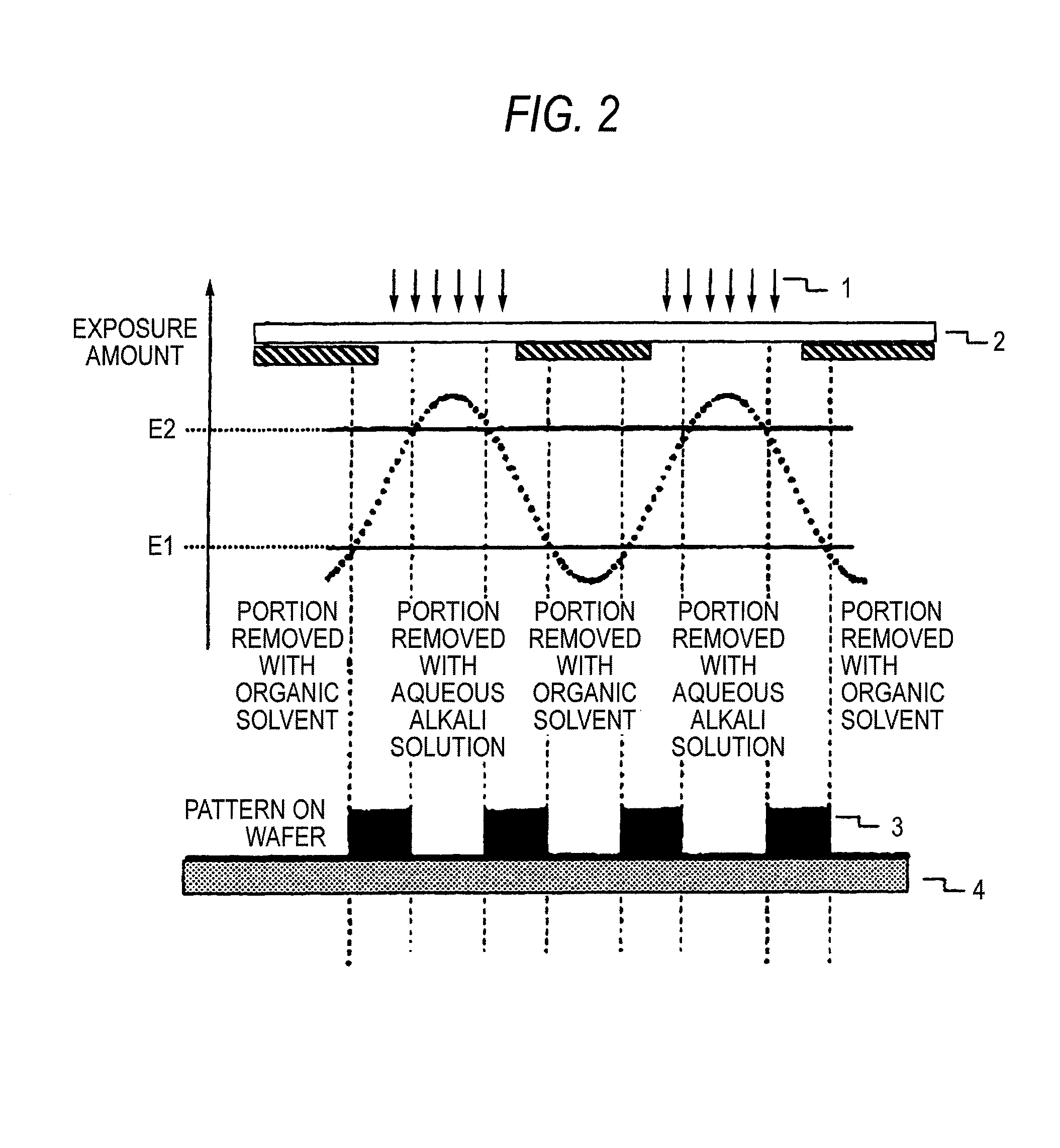

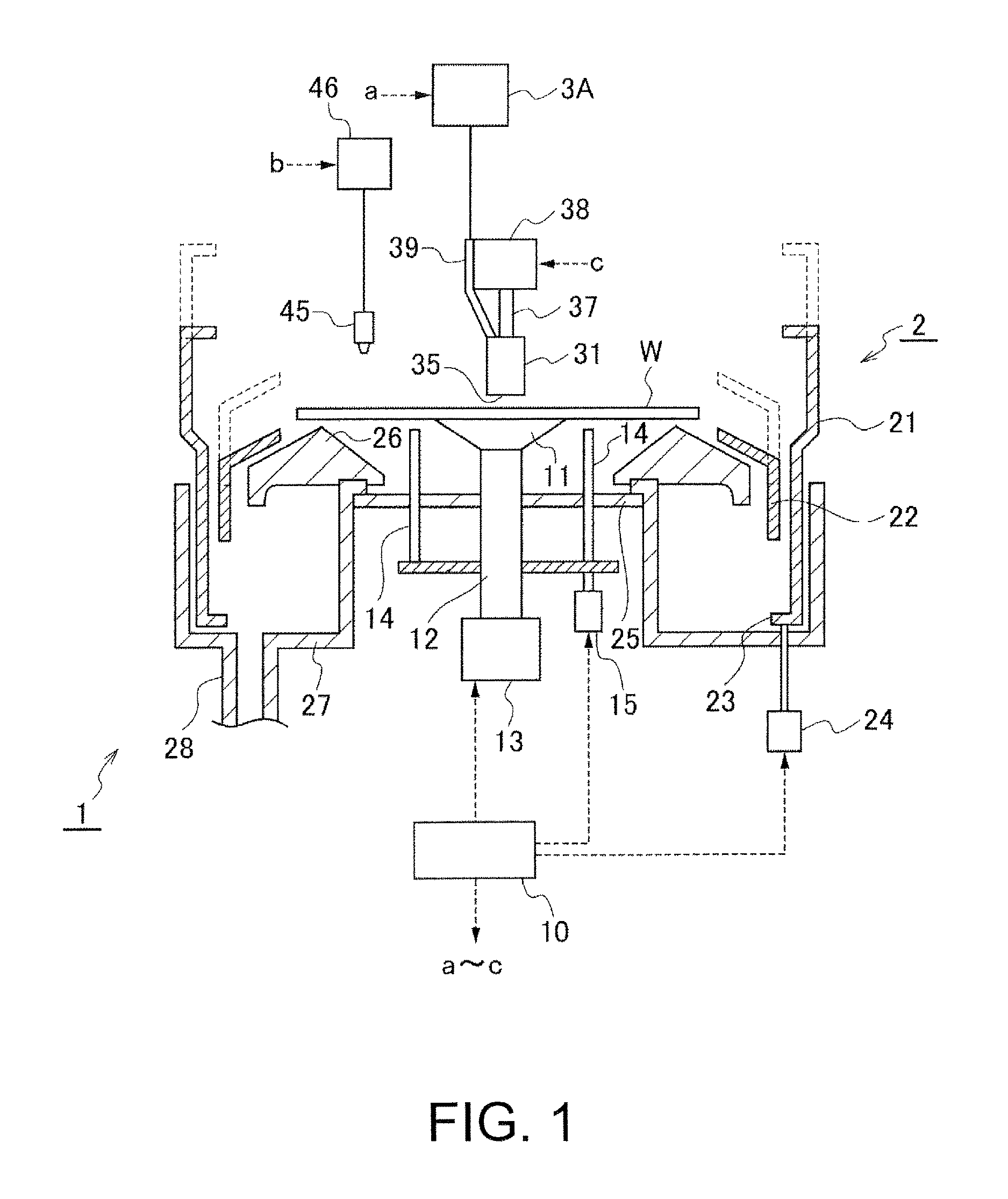

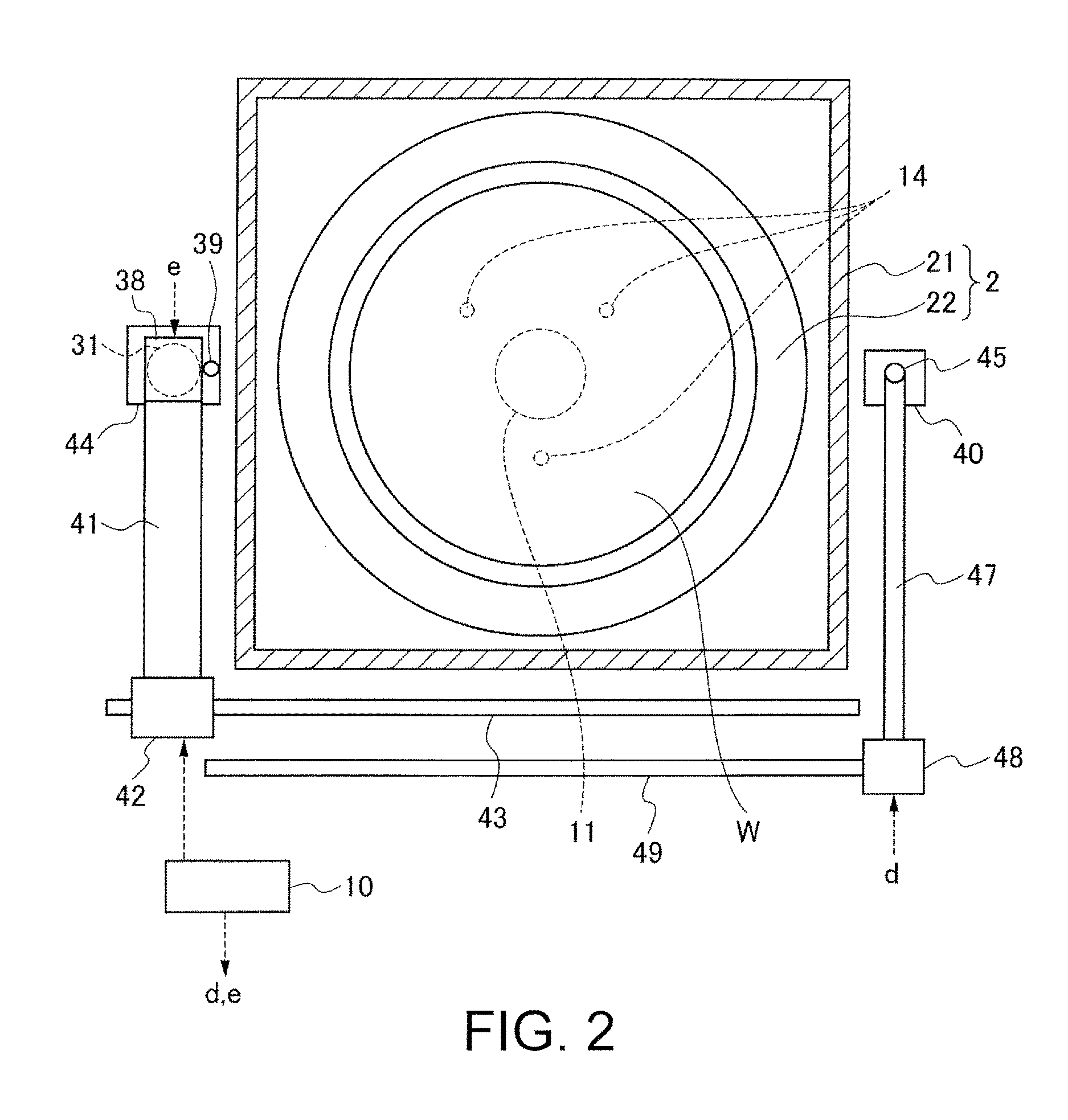

An exposure method and an exposure apparatus make it possible to easily supply a gas through which an exposure light beam is transmitted, to a space between a projection optical system and a substrate. A wafer is exposed with an image of a pattern on a reticle by radiating the exposure light beam having passed through the pattern on the reticle, onto the wafer via a projection optical system. A purge guide plate, which has a guide hole, is installed between the wafer and an optical member disposed at the tip of the projection optical system. A purge gas, through which the exposure light beam is transmitted, is supplied to the space between the wafer and the optical member. The purge gas flows through the guide hole toward the wafer, and then flows in directions toward the outer circumference.

Owner:NIKON CORP

Method of forming patterns

ActiveUS20120135355A1Enhanced in-plane uniformity of line widthReduced line edge roughnessSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusActinic RaysFluence

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

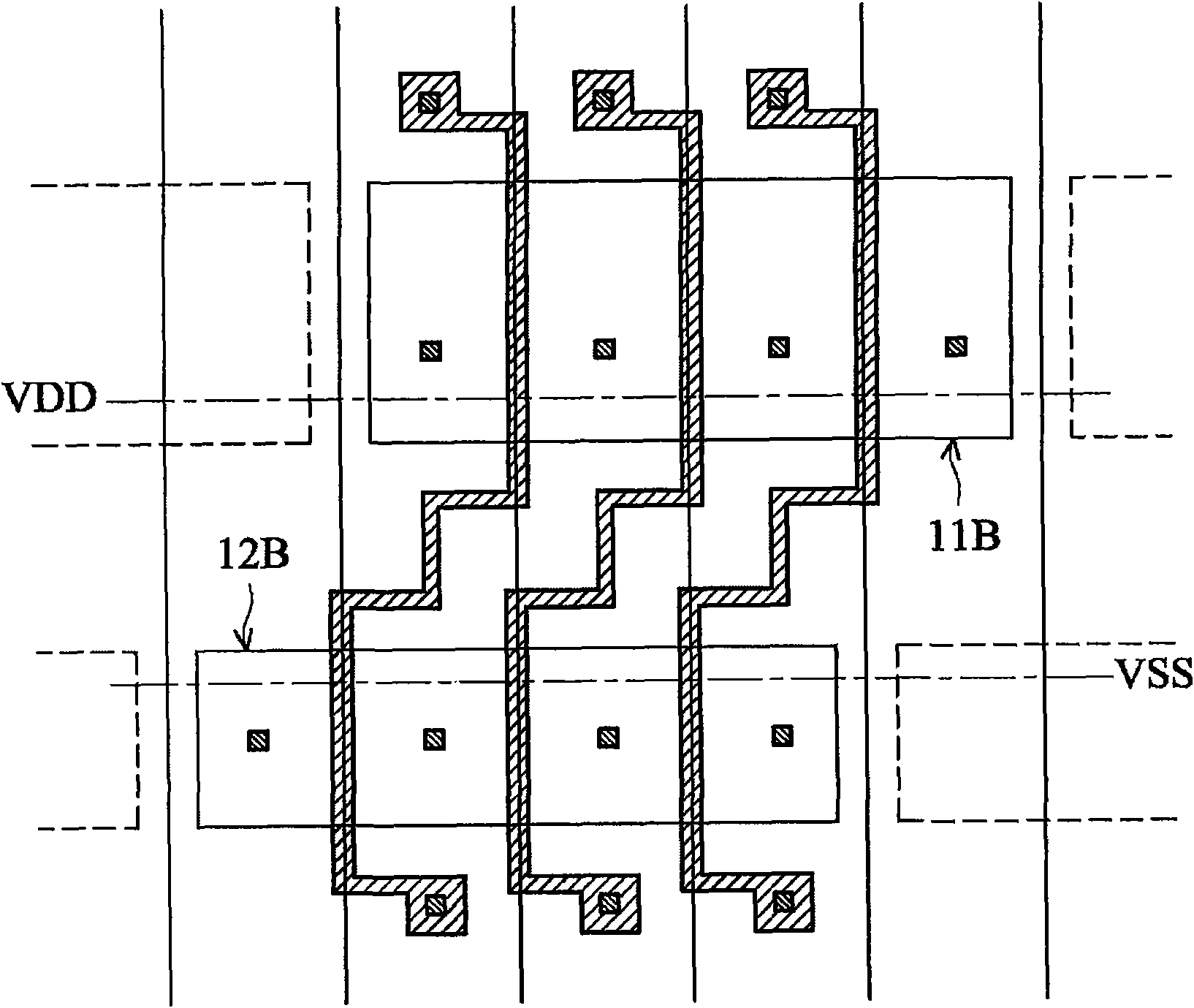

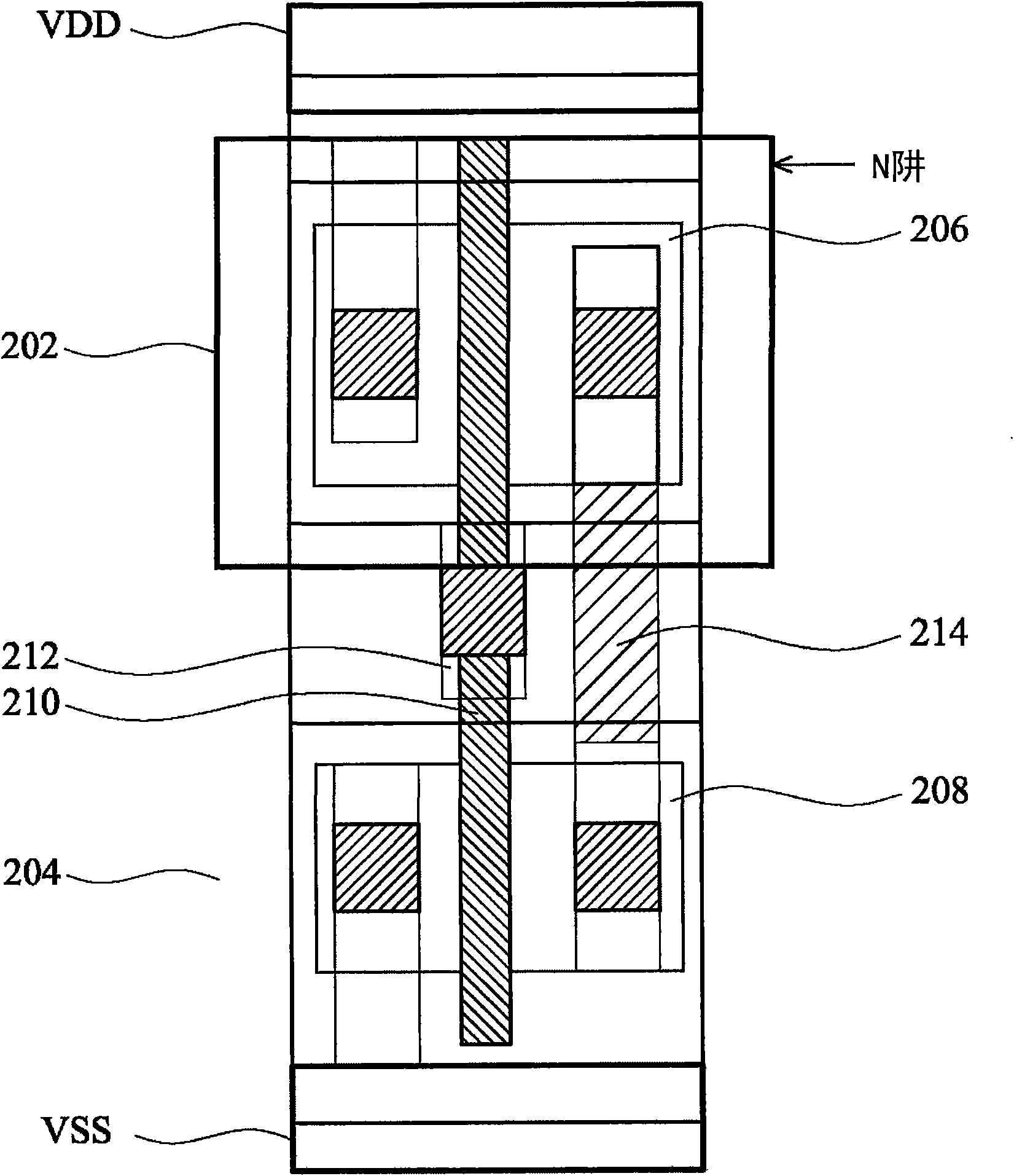

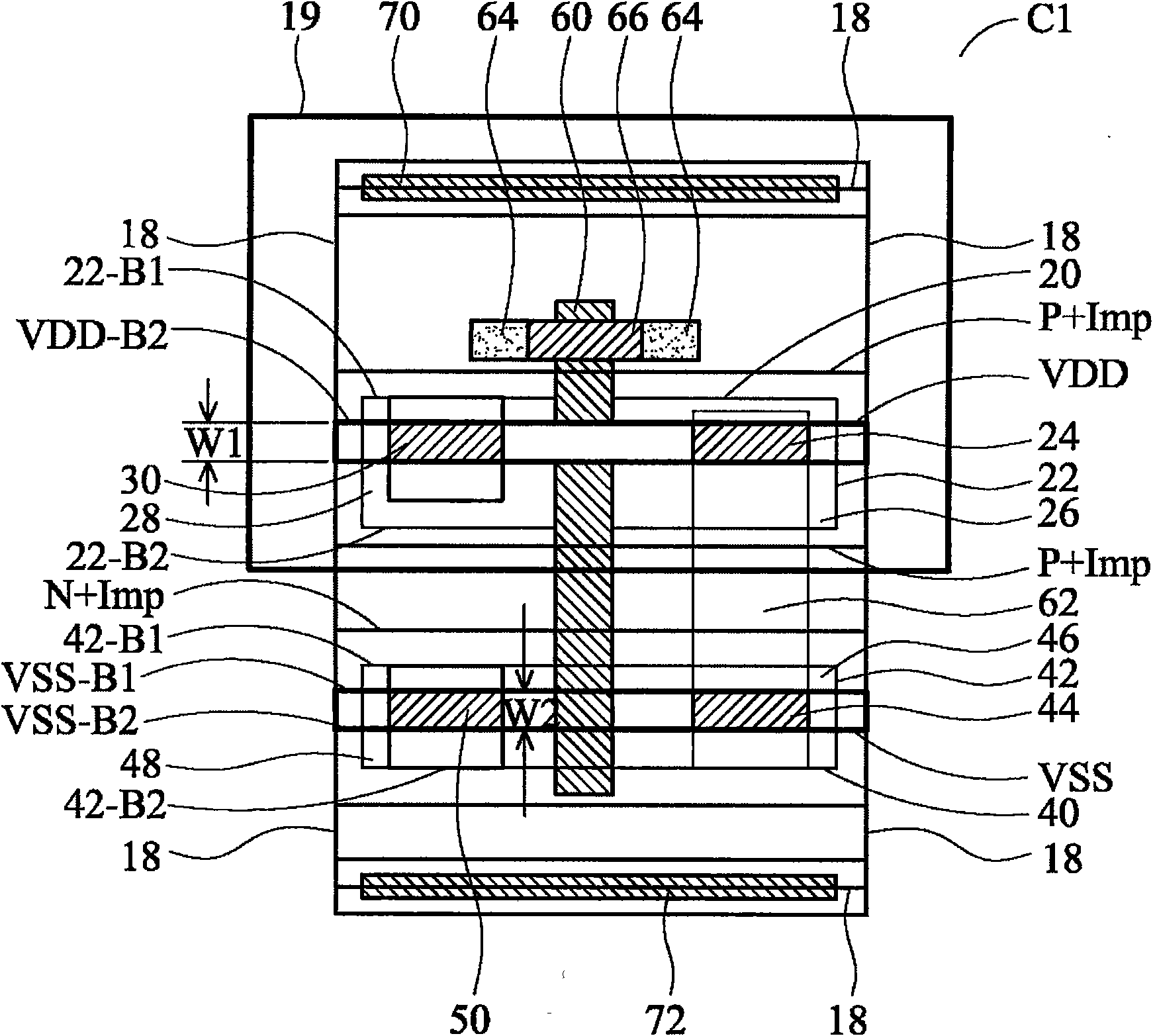

Integrated circuit structure

ActiveCN101615614AImprove line width uniformityReduce usageTransistorSemiconductor/solid-state device detailsLine widthSemiconductor

The invention discloses an integrated circuit structure, comprising a p-type metal oxide semiconductor transistor having a first gate electrode, a first source electrode and a first drain electrode; and an n-type metal oxide semiconductor transistor having a second source electrode, a second drain electrode and a second gate electrode, wherein the second gate electrode and the first gate electrode are a part of a grate electrode lead. Other transistors are not arranged between the p-type metal oxide semiconductor transistor and the n-type metal oxide semiconductor transistor. The integrated circuit structure further comprises a power lead connected with the first source electrode; a grounding lead connected with the second source electrode; and an inside connection point electrically connected with the grate electrode lead. The inside connection point is located outside a region of metal oxide semiconductor comprising the region of a PMOS transistor, an NMOS transistor and between the two ones, wherein the grate electrode lead is located at the region straightly in general. The invention can improve the line width uniformity of the grate electrode lead.

Owner:TAIWAN SEMICON MFG CO LTD

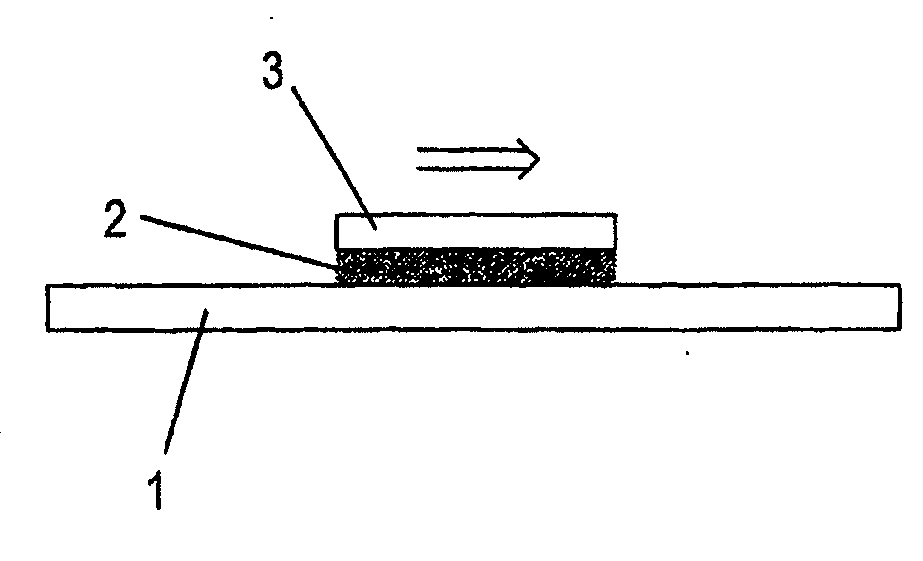

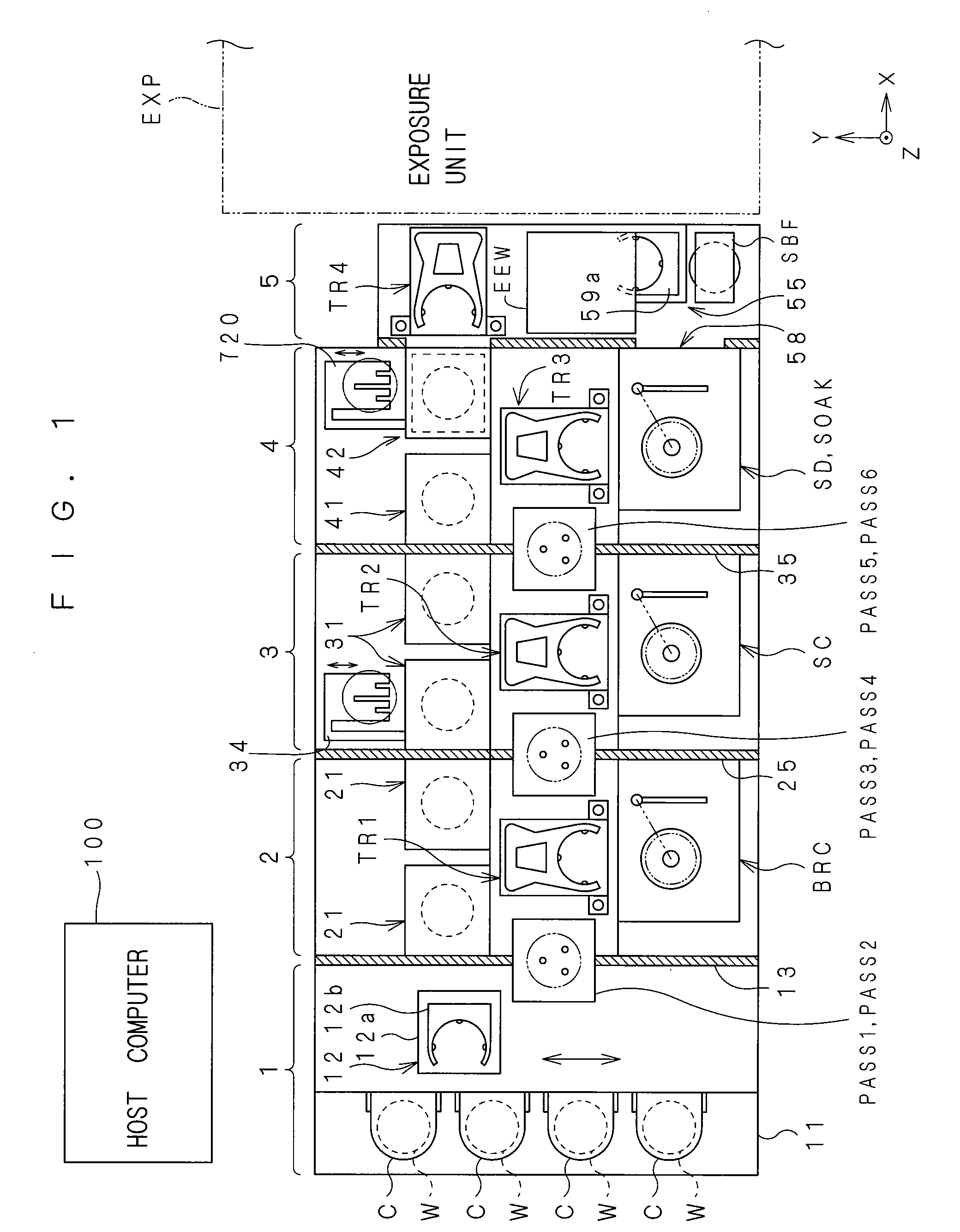

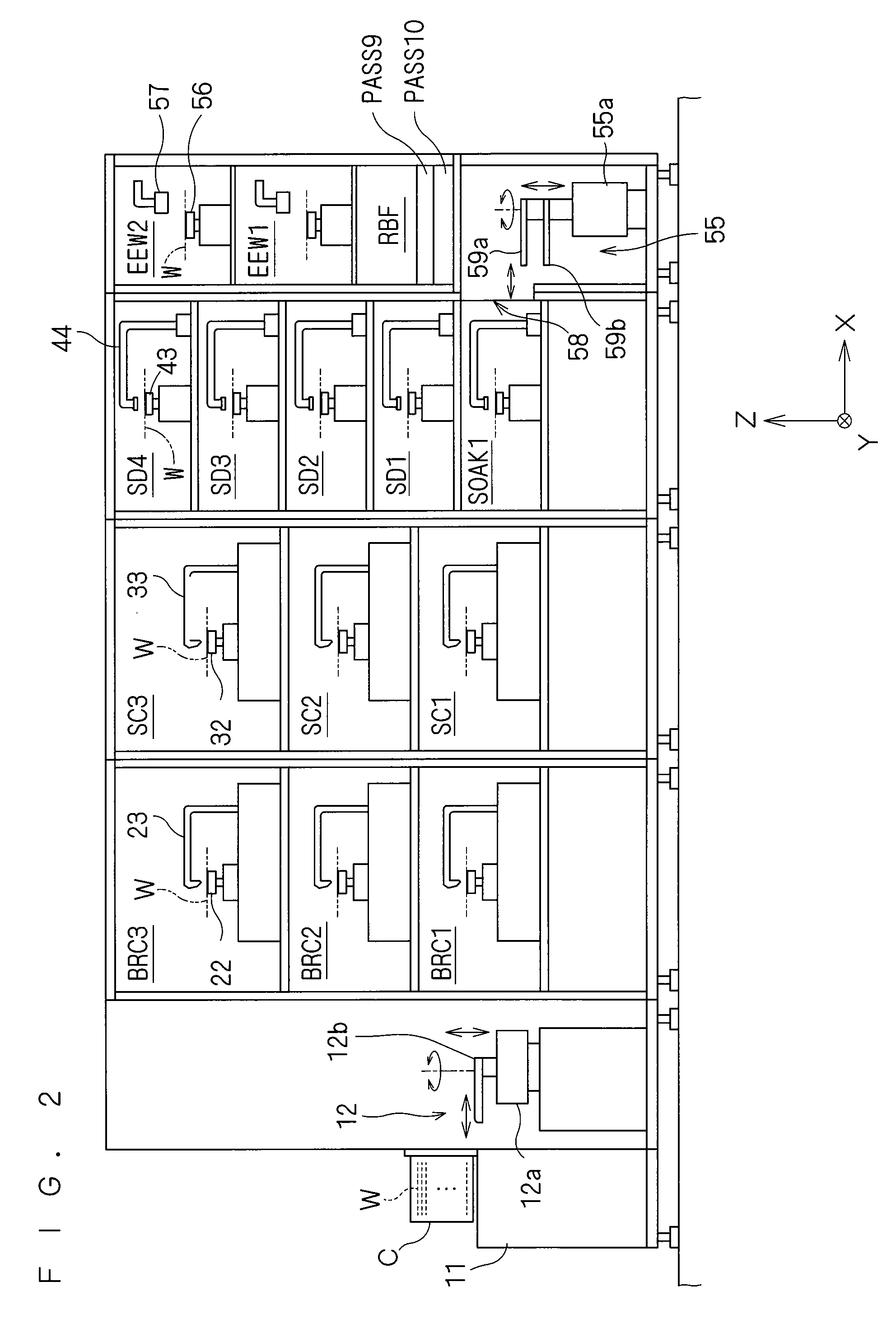

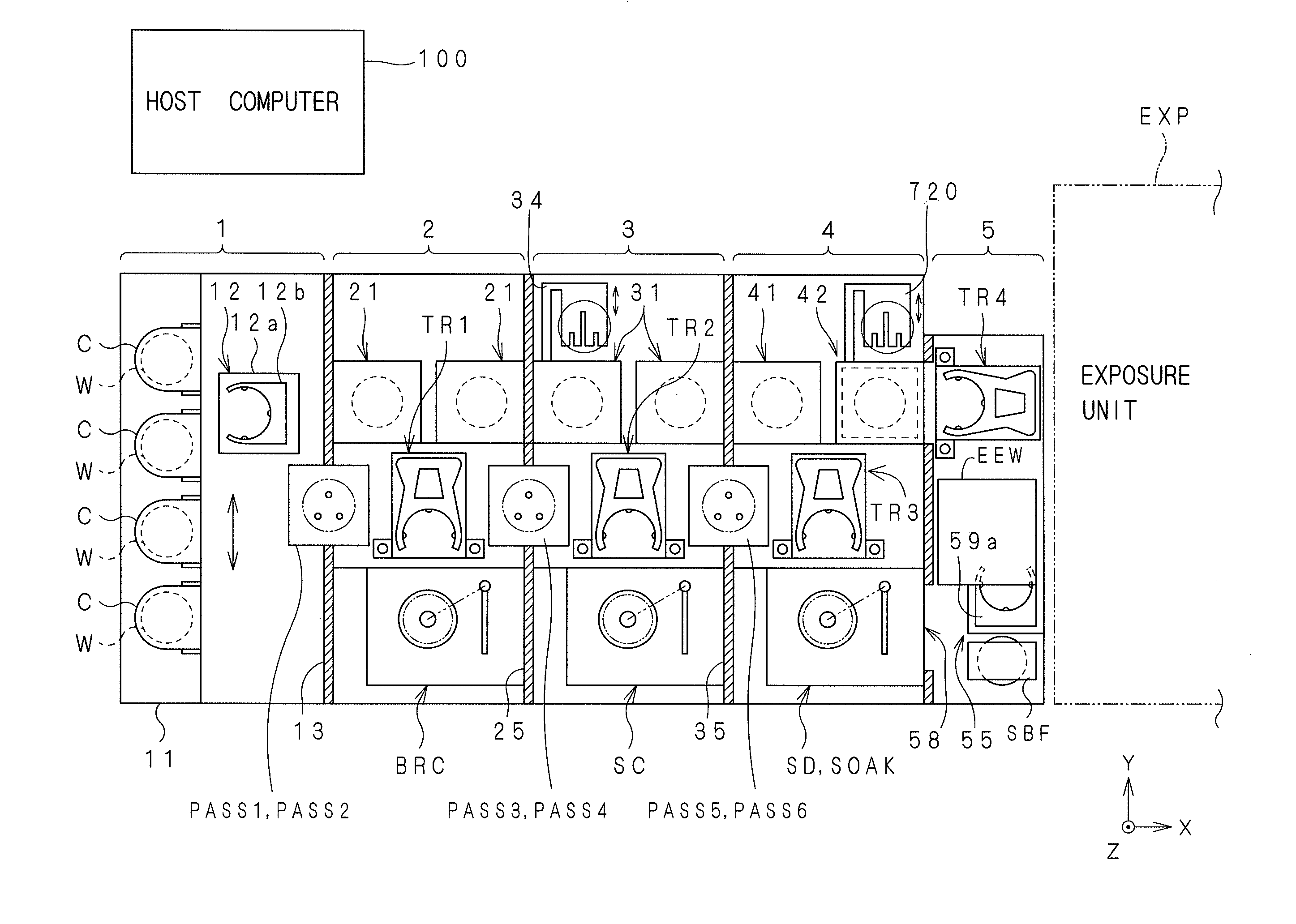

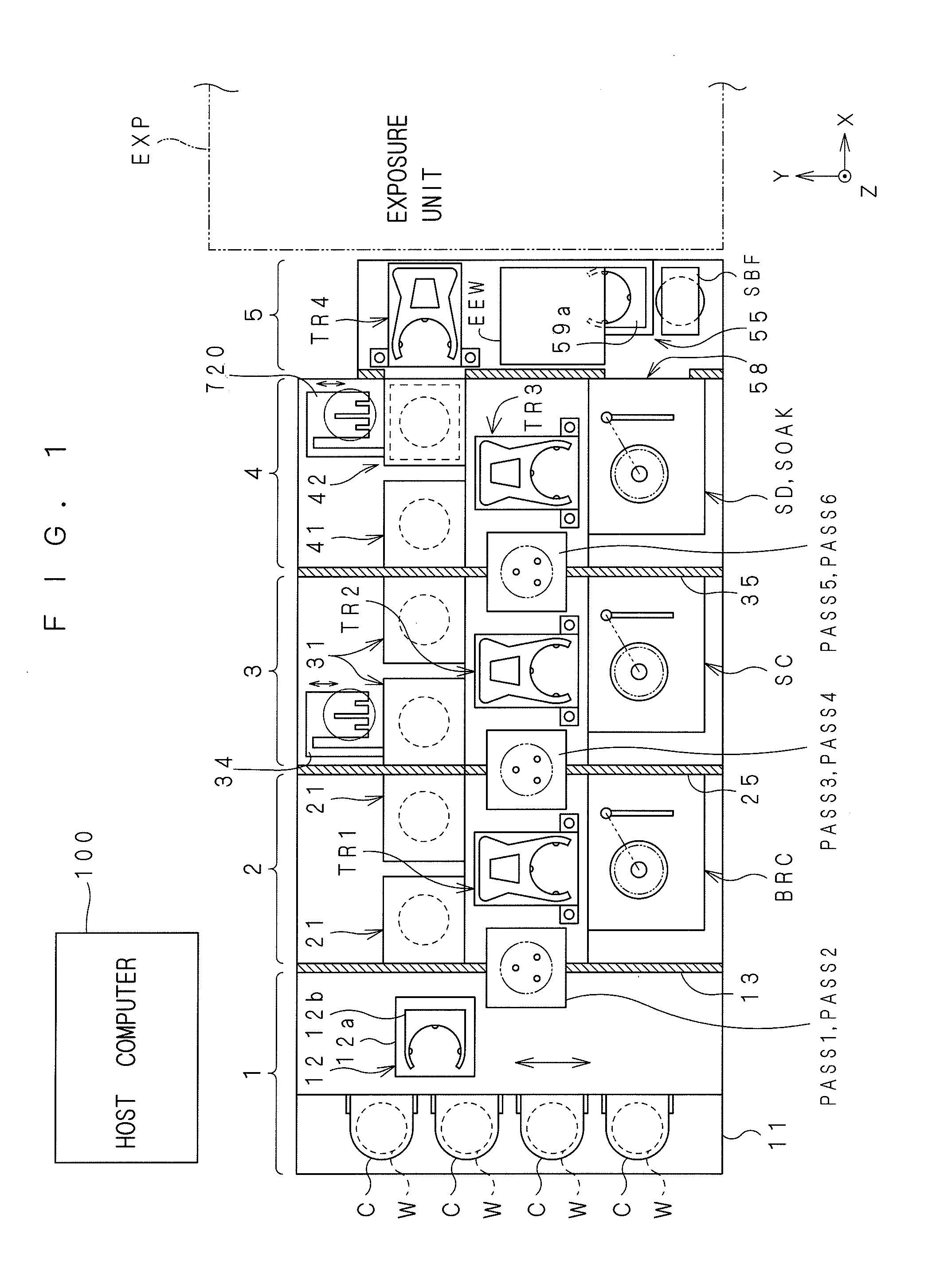

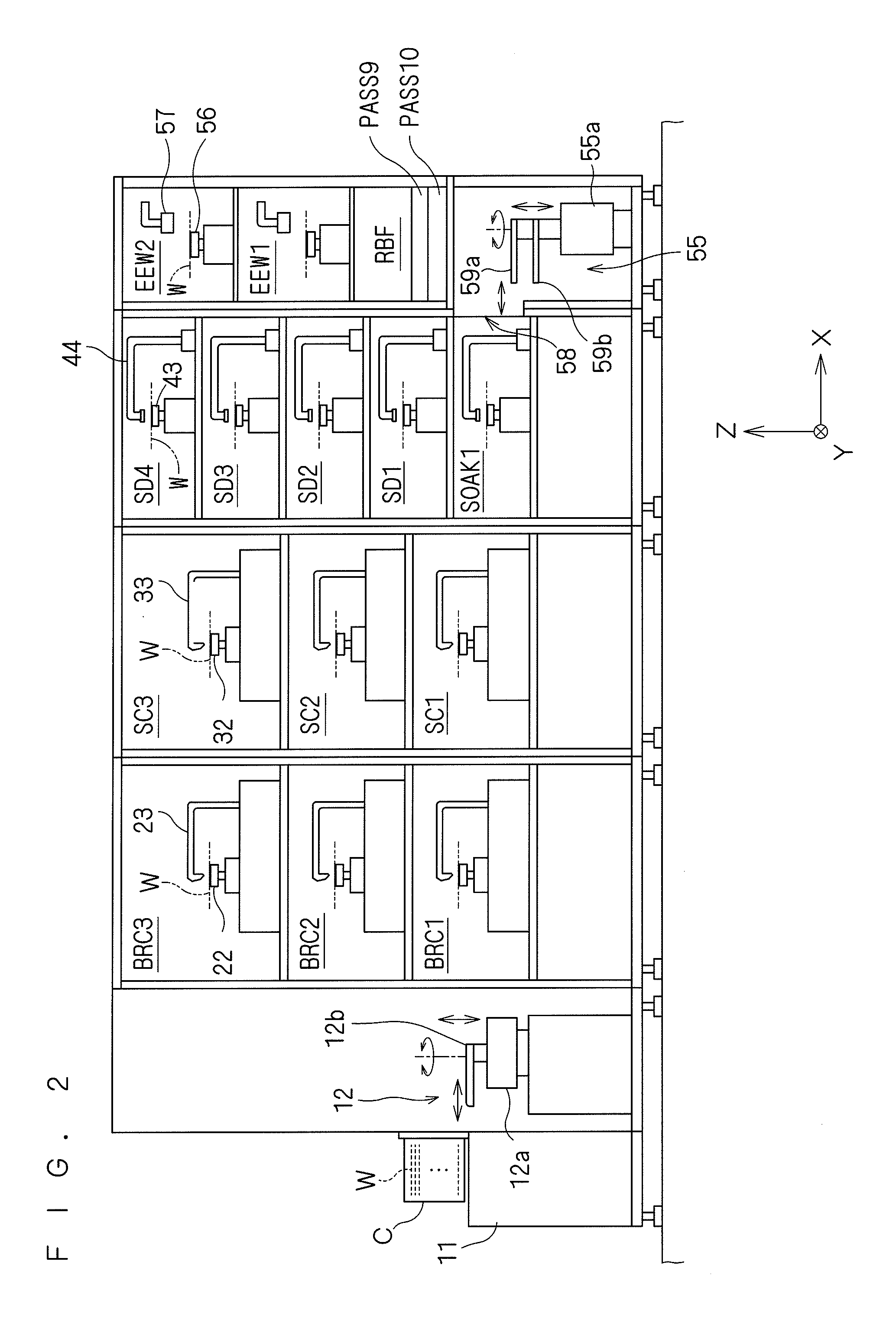

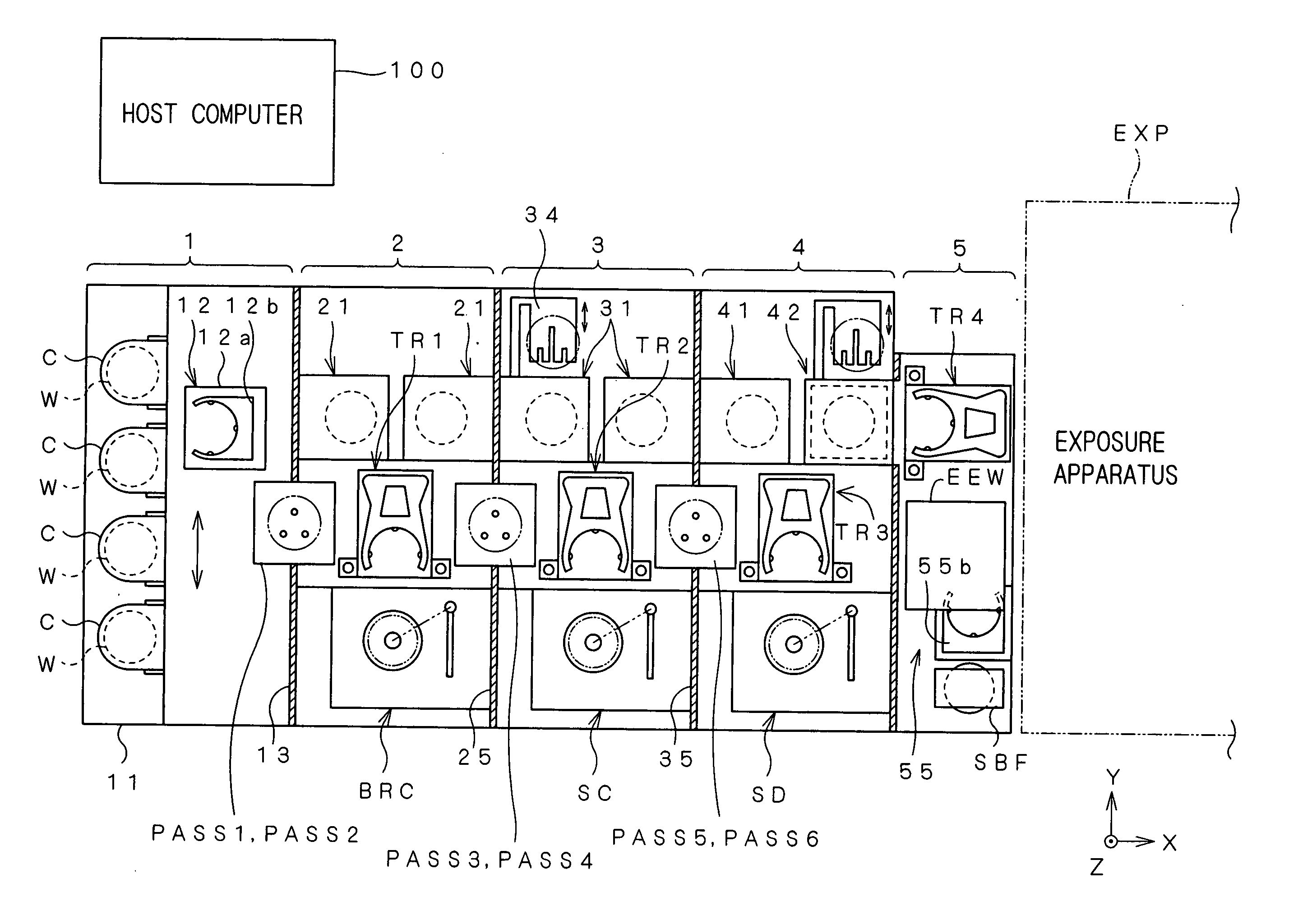

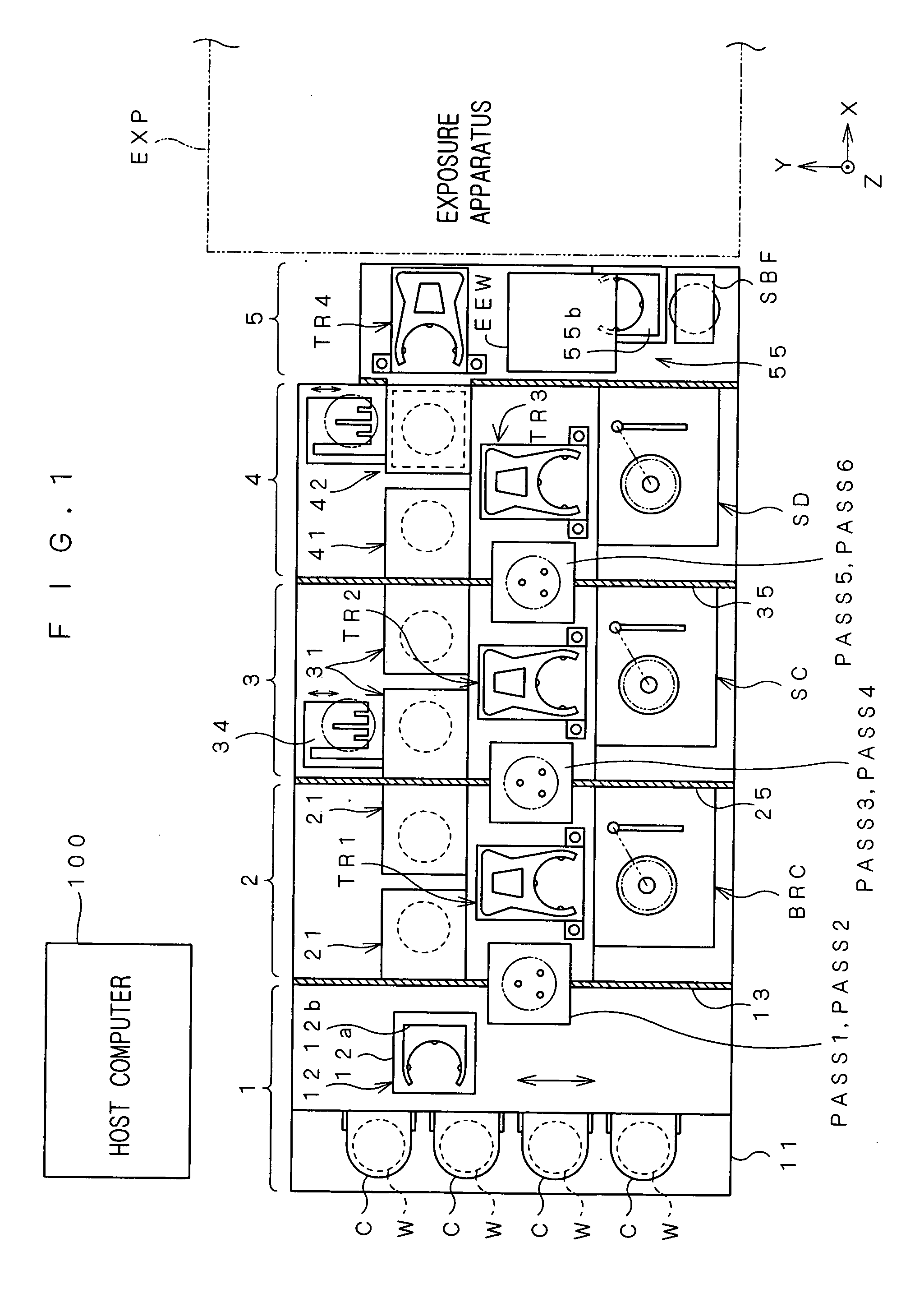

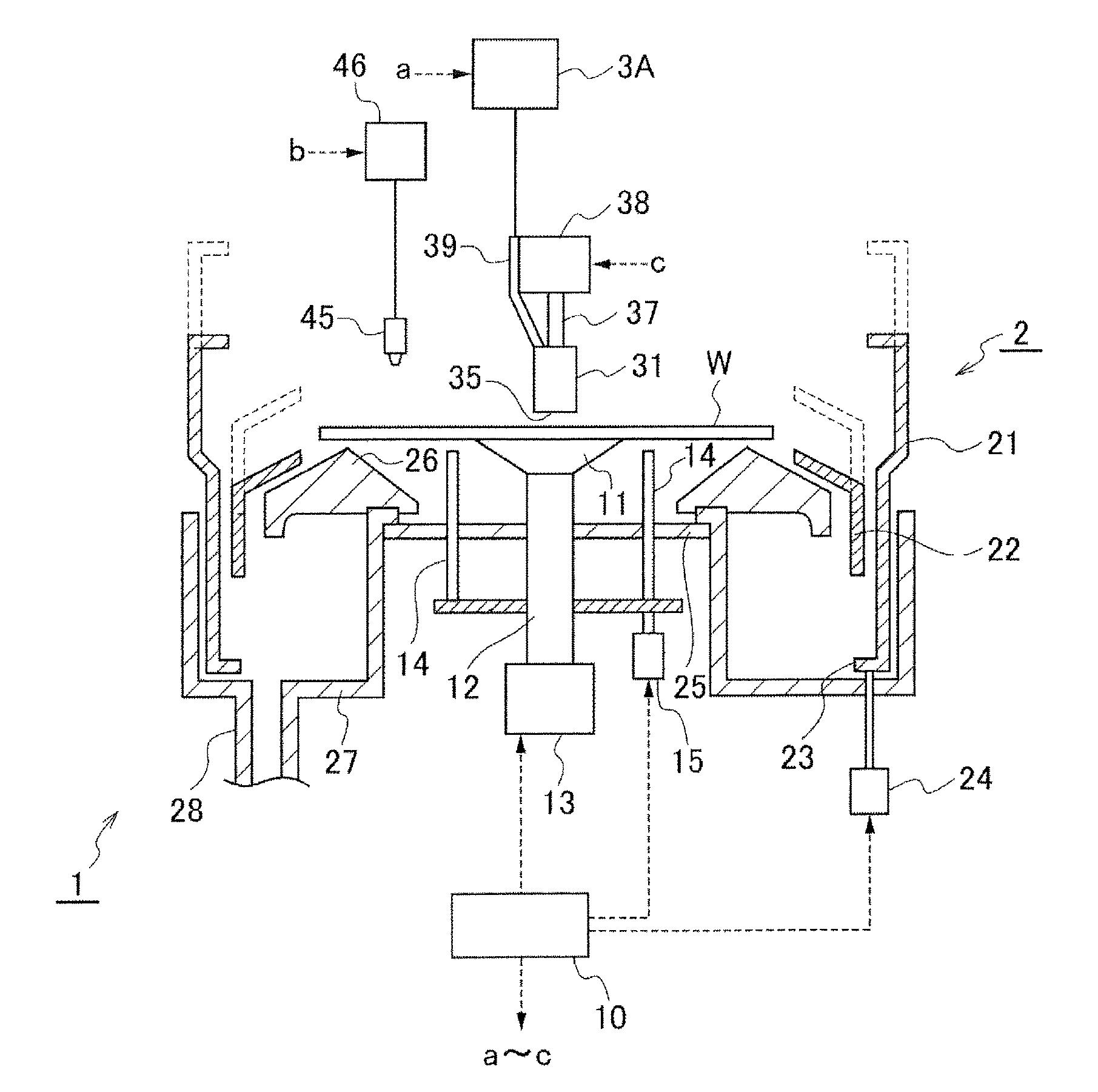

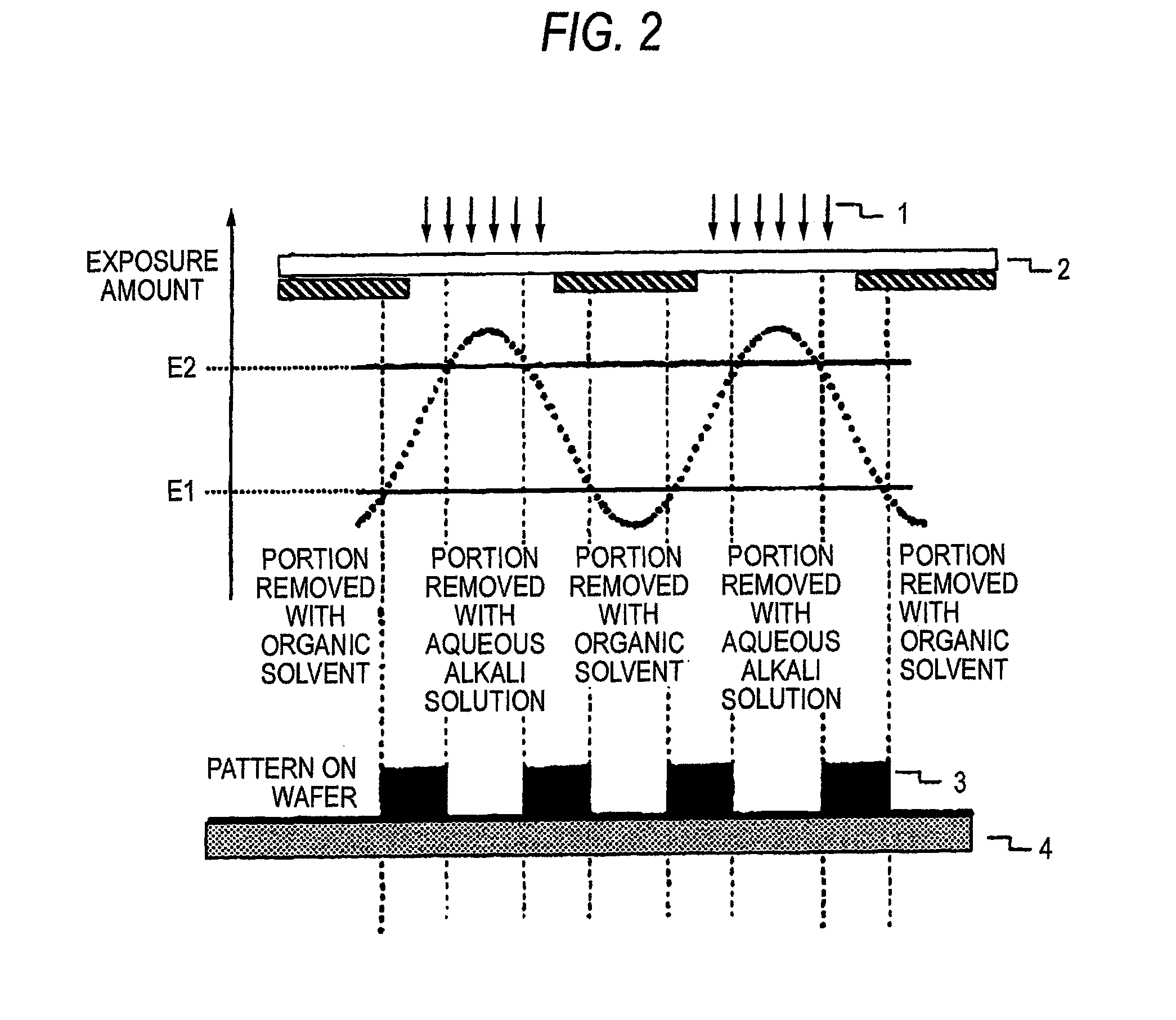

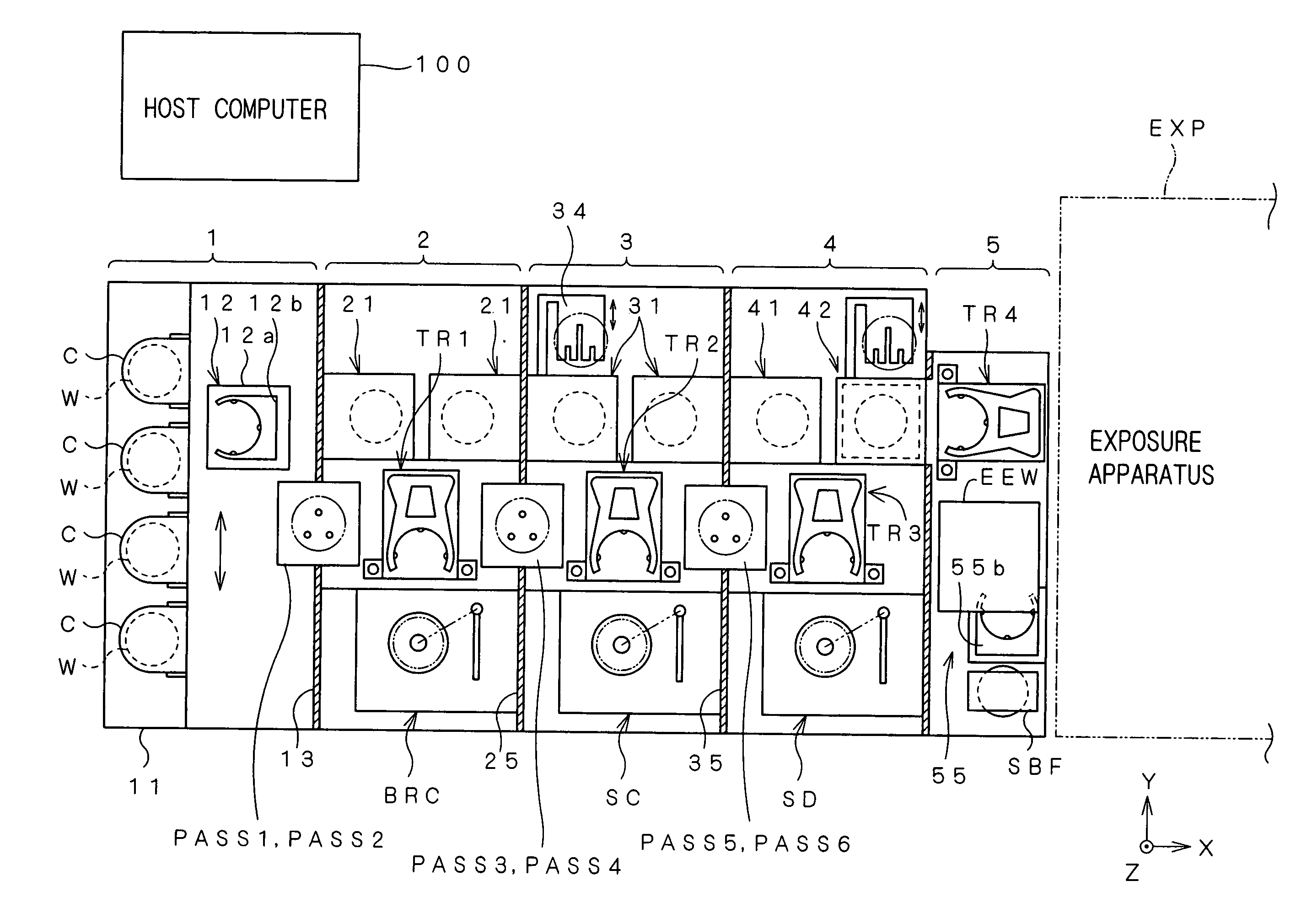

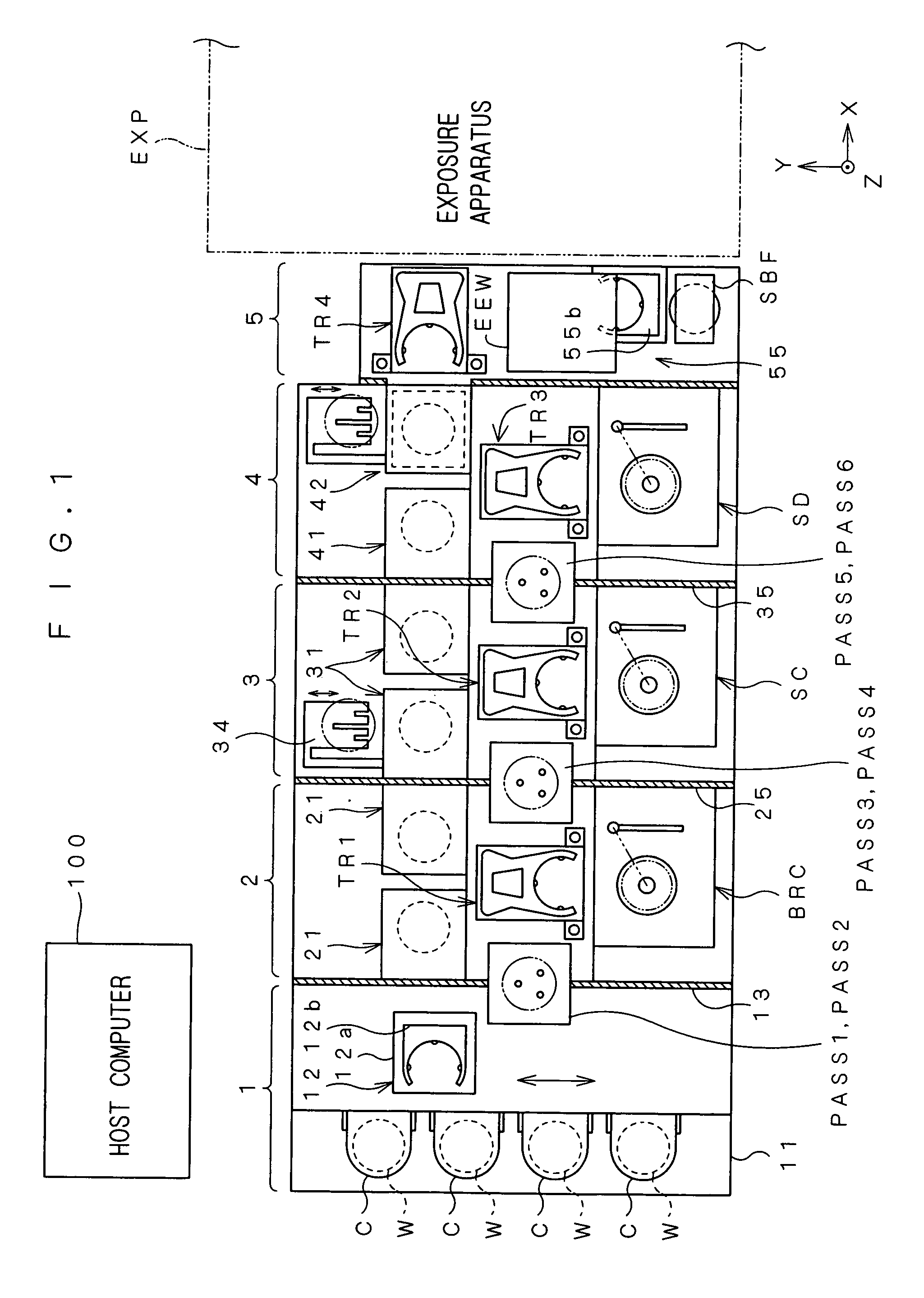

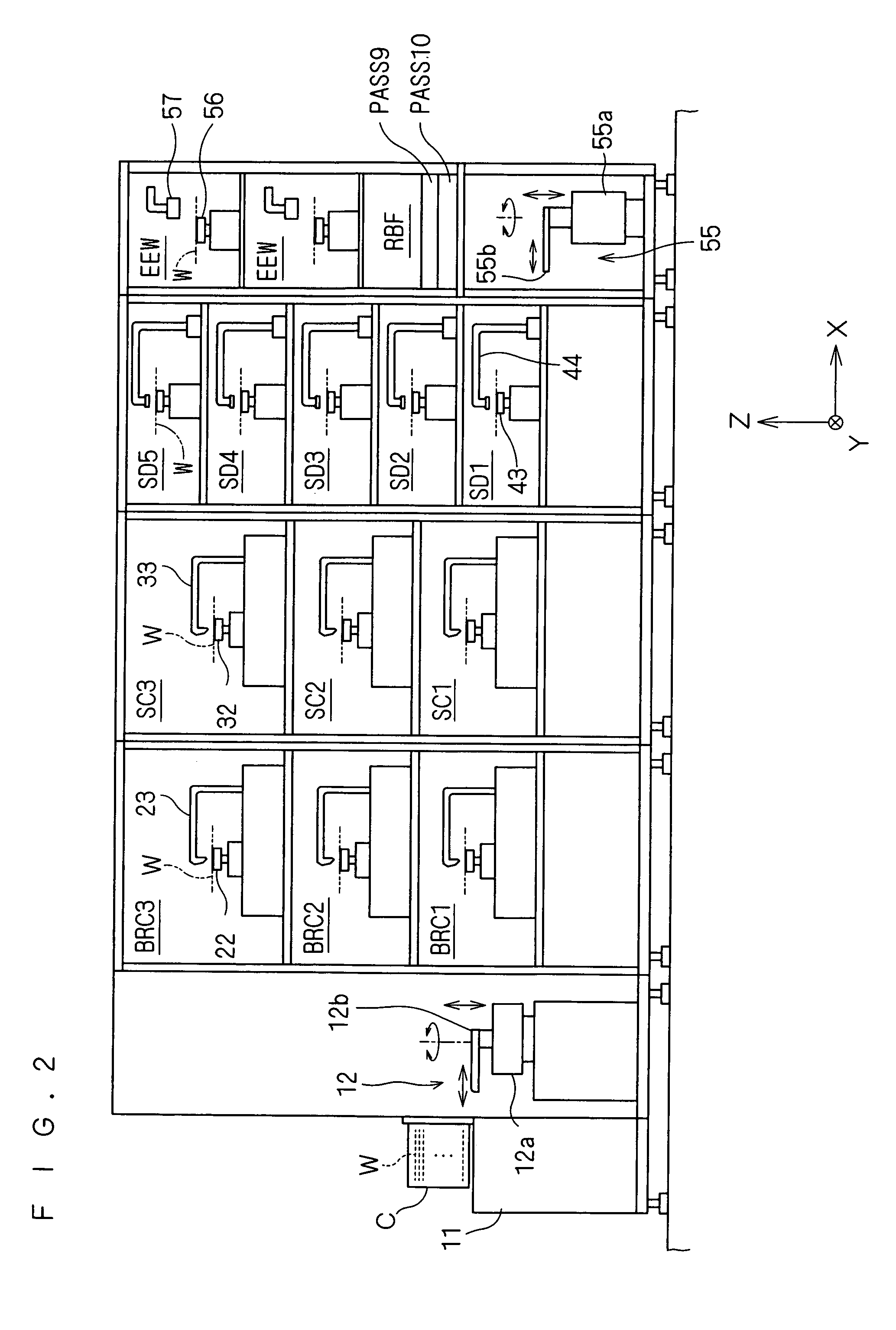

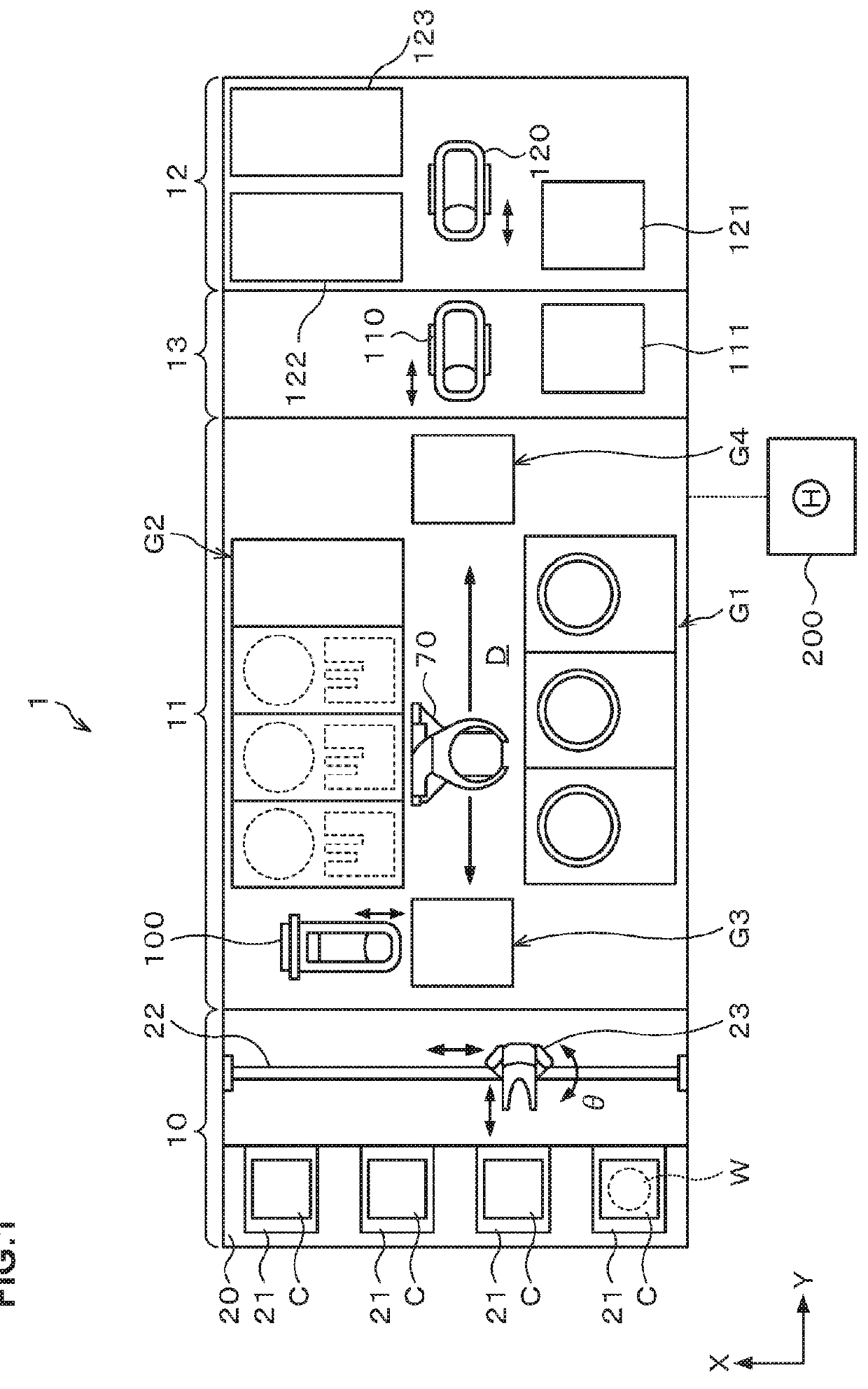

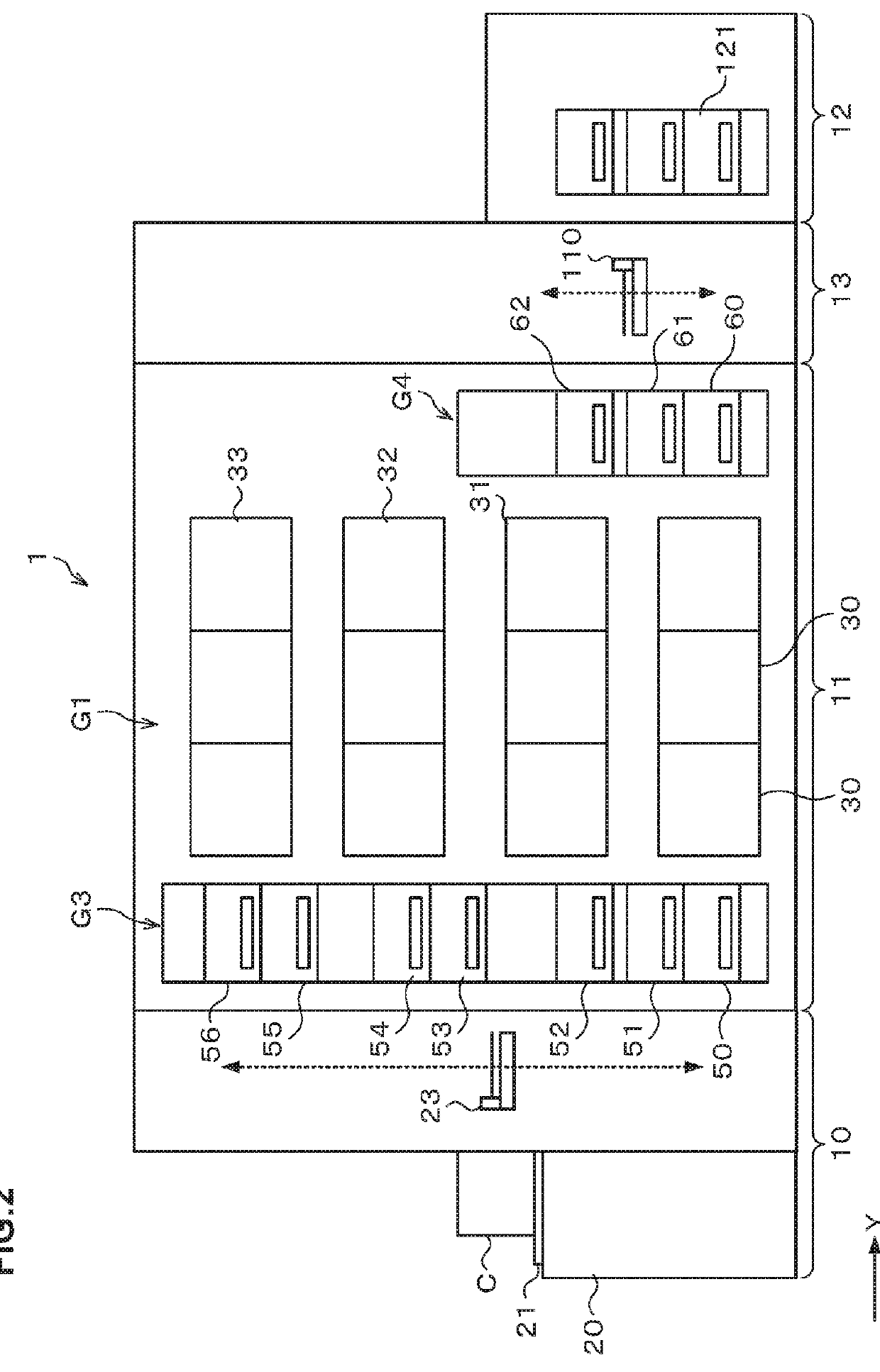

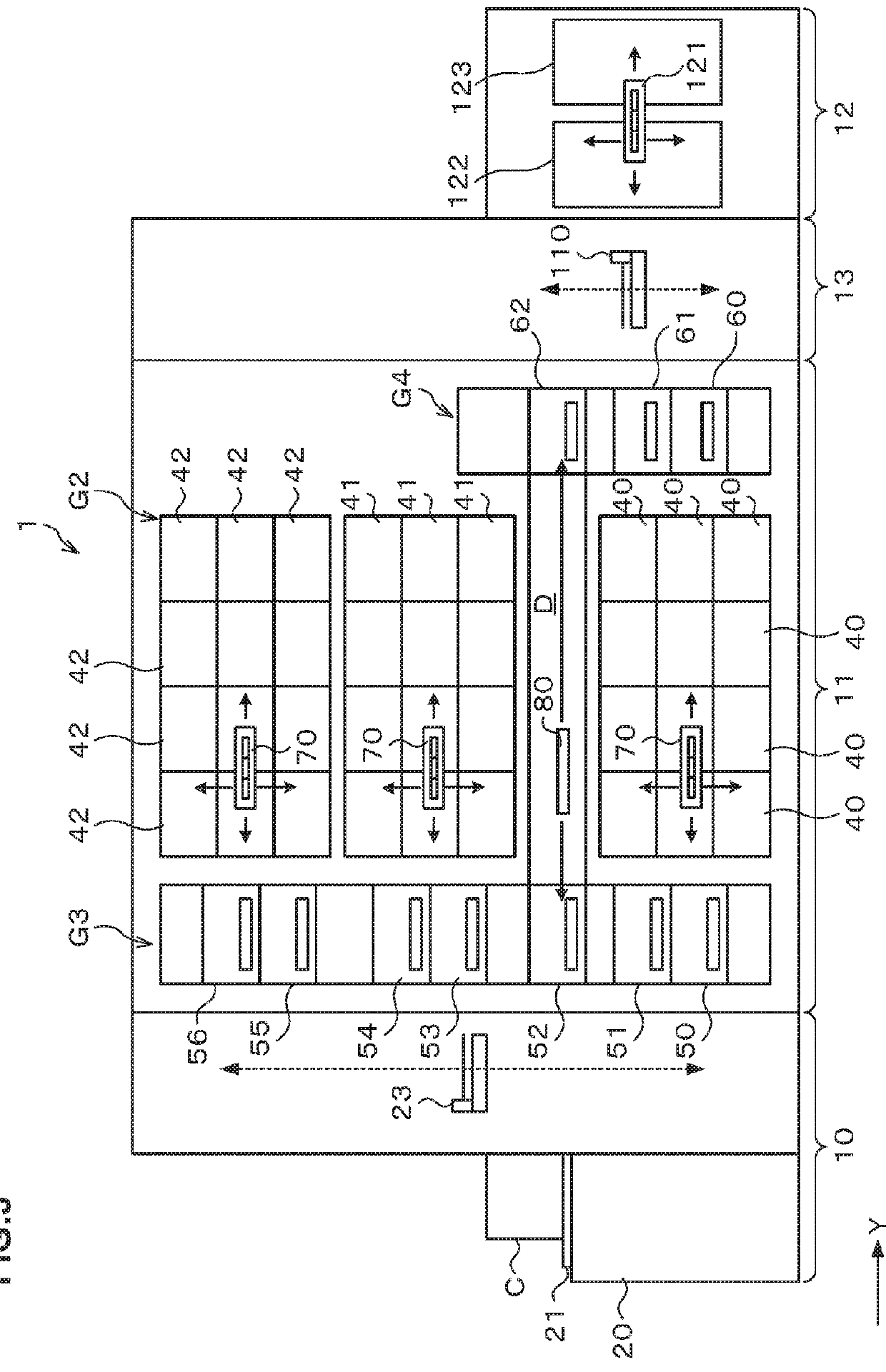

Apparatus for and method of processing substrate subjected to exposure process

InactiveUS20070058147A1Improve line width uniformityUniform processingSemiconductor/solid-state device manufacturingPhotosensitive material processingResistLine width

A substrate subjected to an exposure process by an exposure unit is transported into a cleaning processing unit in a substrate processing apparatus. An adjustment is made to the presence time (more specifically, the waiting time or the cleaning time) of the exposed substrate in the cleaning processing unit to adjust the instant of the end of a cleaning process so as to provide a constant time interval between the instant of the completion of the exposure process and the instant of the end of the cleaning process. Such adjustments provide a constant time interval between the instant of the completion of the exposure process and the instant of the start of a post-exposure bake process, and also provide a constant time interval between the, instant of the completion of the cleaning process and the instant of the start of the post-exposure bake process. This achieves further improvements in the line width uniformity of a pattern formed when a chemically amplified resist is used.

Owner:SOKUDO CO LTD

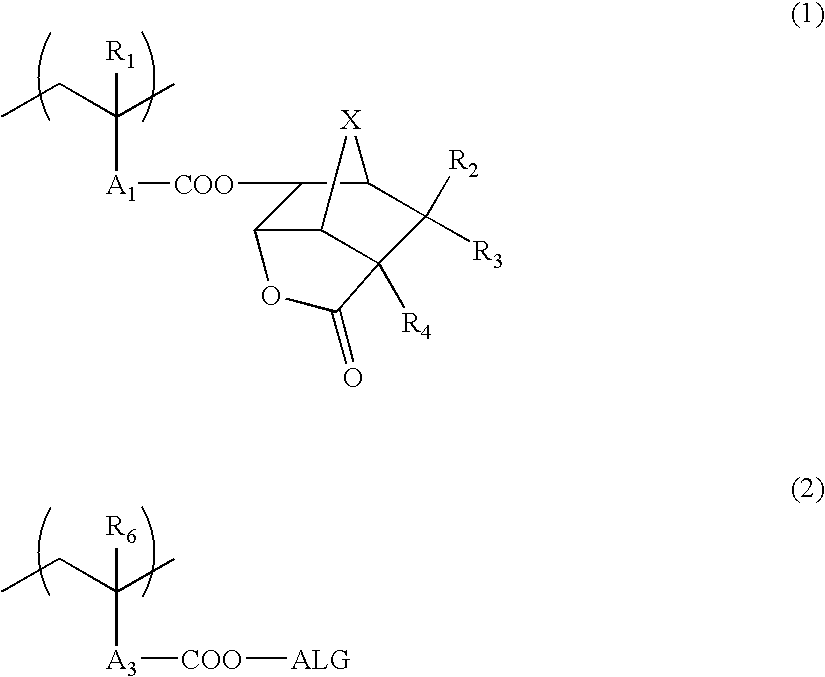

Positive resist composition and pattern forming method utilizing the same

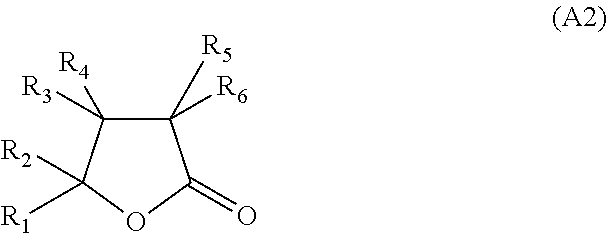

ActiveUS7291441B2Improve the problemImprove line width uniformityPhotosensitive materialsRadiation applicationsActinic RaysAlicyclic Hydrocarbons

A positive resist composition comprising: a resin that comprises a repeating unit including a specific norbornane lactone structure and a repeating unit including a specific alicyclic hydrocarbon structure, and that increases a solubility of the resin in an alkaline developer by an action of an acid; and a compound that generates an acid upon treatment with one of an actinic ray and radiation, and a pattern forming method utilizing the same.

Owner:FUJIFILM HLDG CORP +1

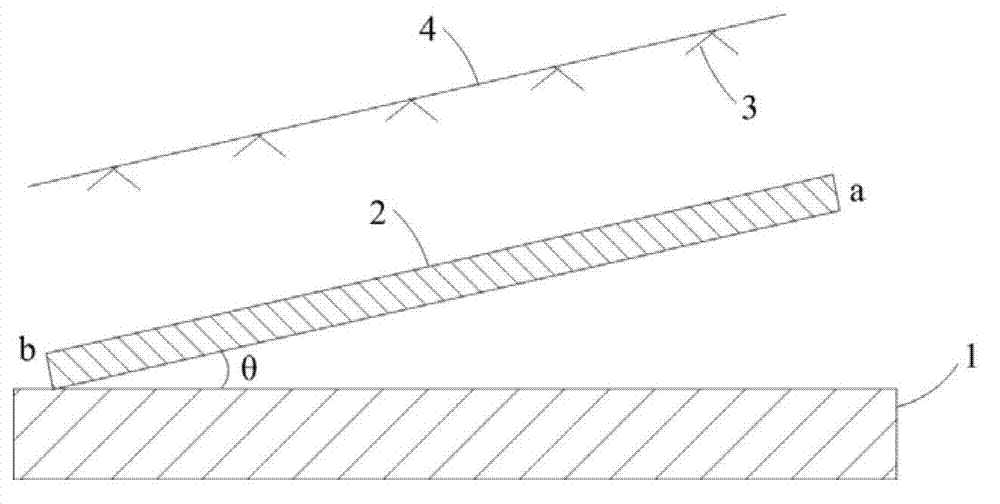

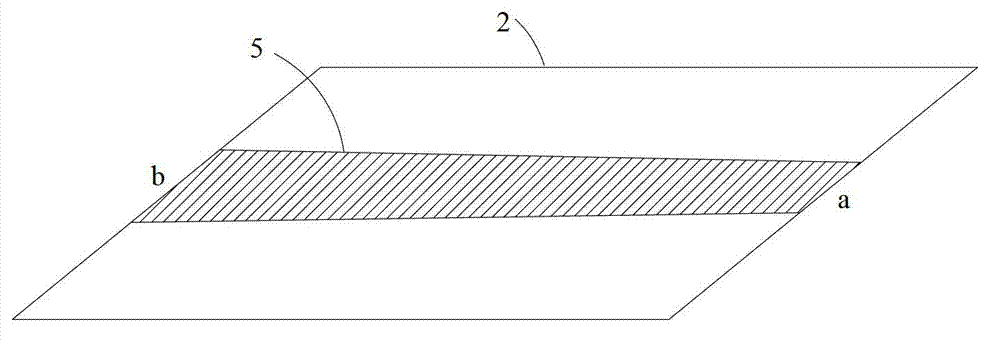

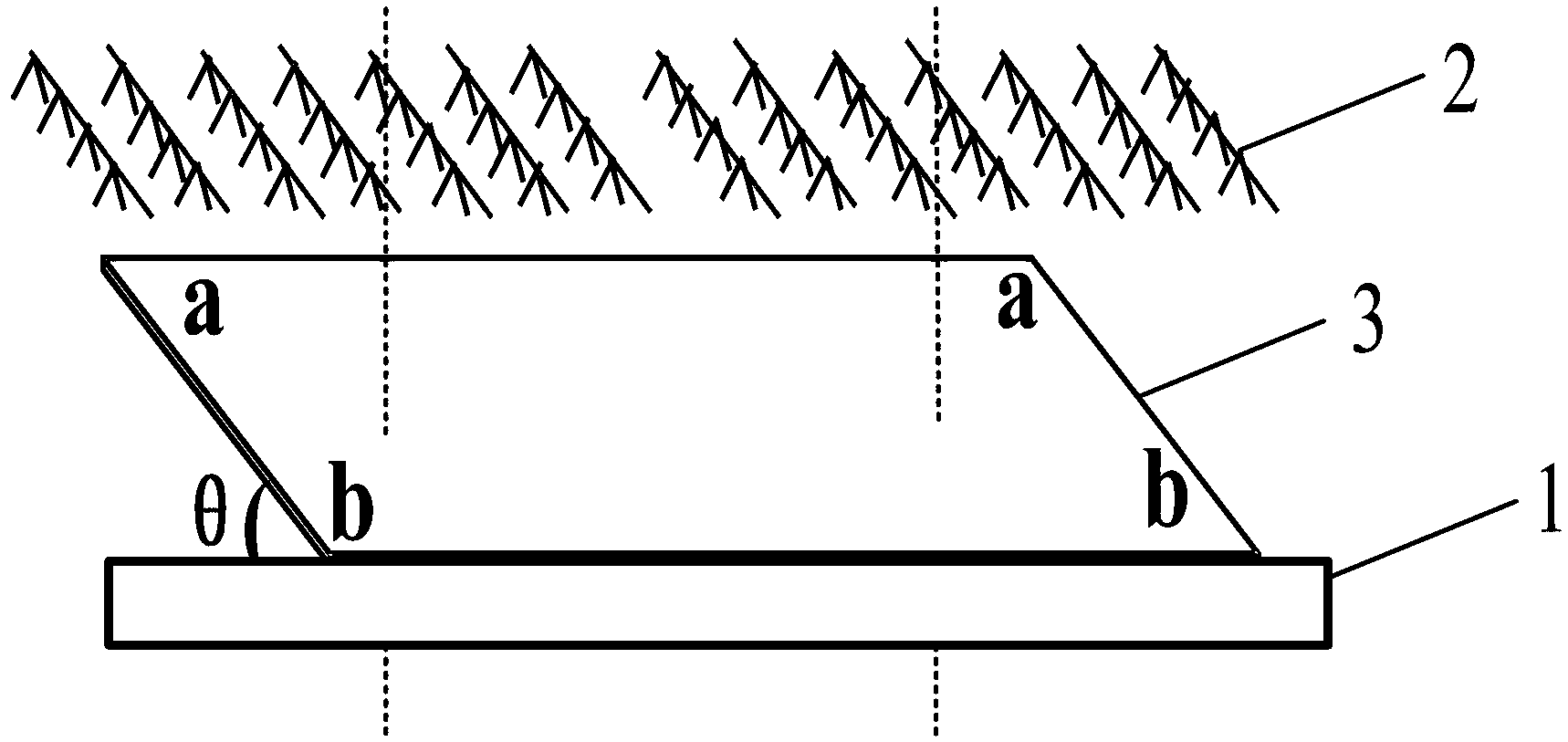

Developing method

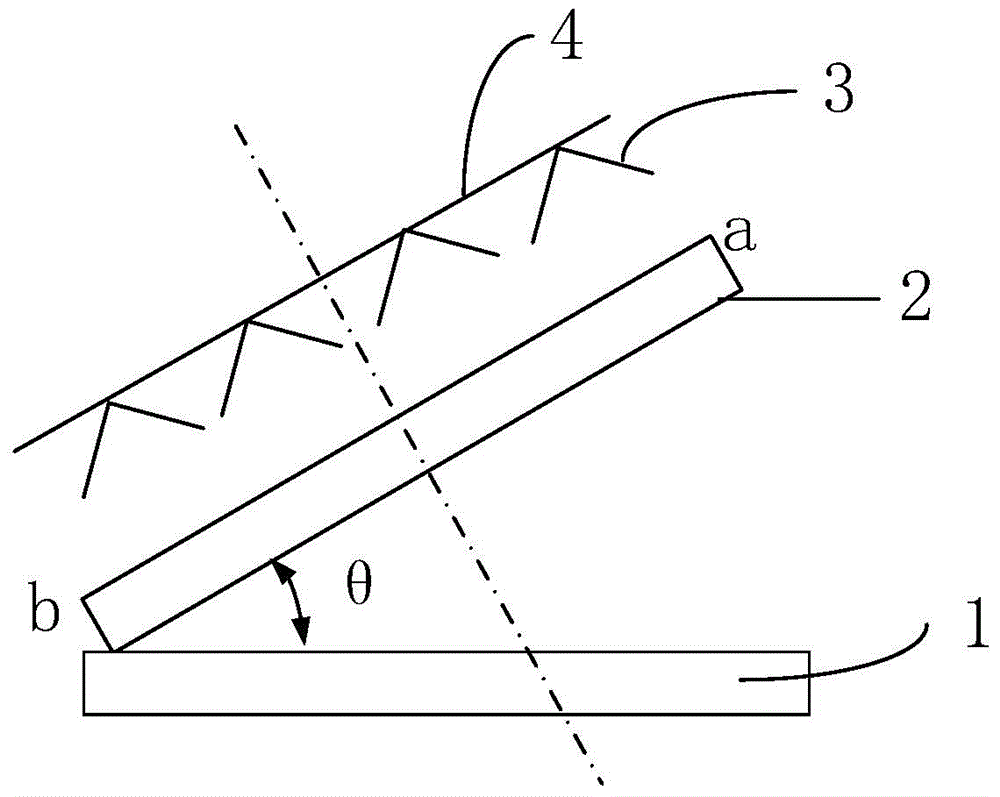

InactiveCN103207543AWill not cause chippingImprove uniformityPhotosensitive material processingEngineeringLithography

The invention provides a developing method which comprises the following steps of: inclining a substrate relative to a developing machine table, wherein a first side edge of the substrate is upward, and a second side edge, which is opposite to the first side edge, of the substrate is downward; and an inclination angle between the substrate and the developing machine table is theta1 which is more than 0 degree and less than 90 degrees; uniformly spraying a developing solution to the substrate through a nozzle arranged above the substrate, wherein the developing time is t1; then inclining the substrate relative to the developing machine table, wherein the second side edge of the substrate is upward, and the first side edge of the substrate is downward; and an inclination angle between the substrate and the developing machine table is theta2 which is more than 0 degree and less than 90 degrees; uniformly spraying a developing solution to the substrate through the nozzle arranged above the substrate, wherein the developing time is t2. By the developing method, the uniformity of a linear width of a photoetched graph obtained by development can be improved.

Owner:BOE TECH GRP CO LTD +1

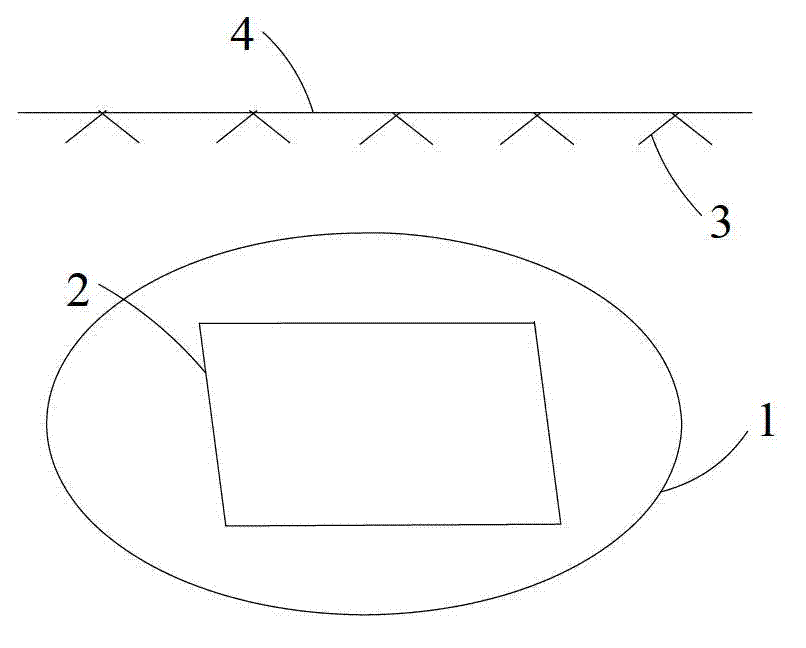

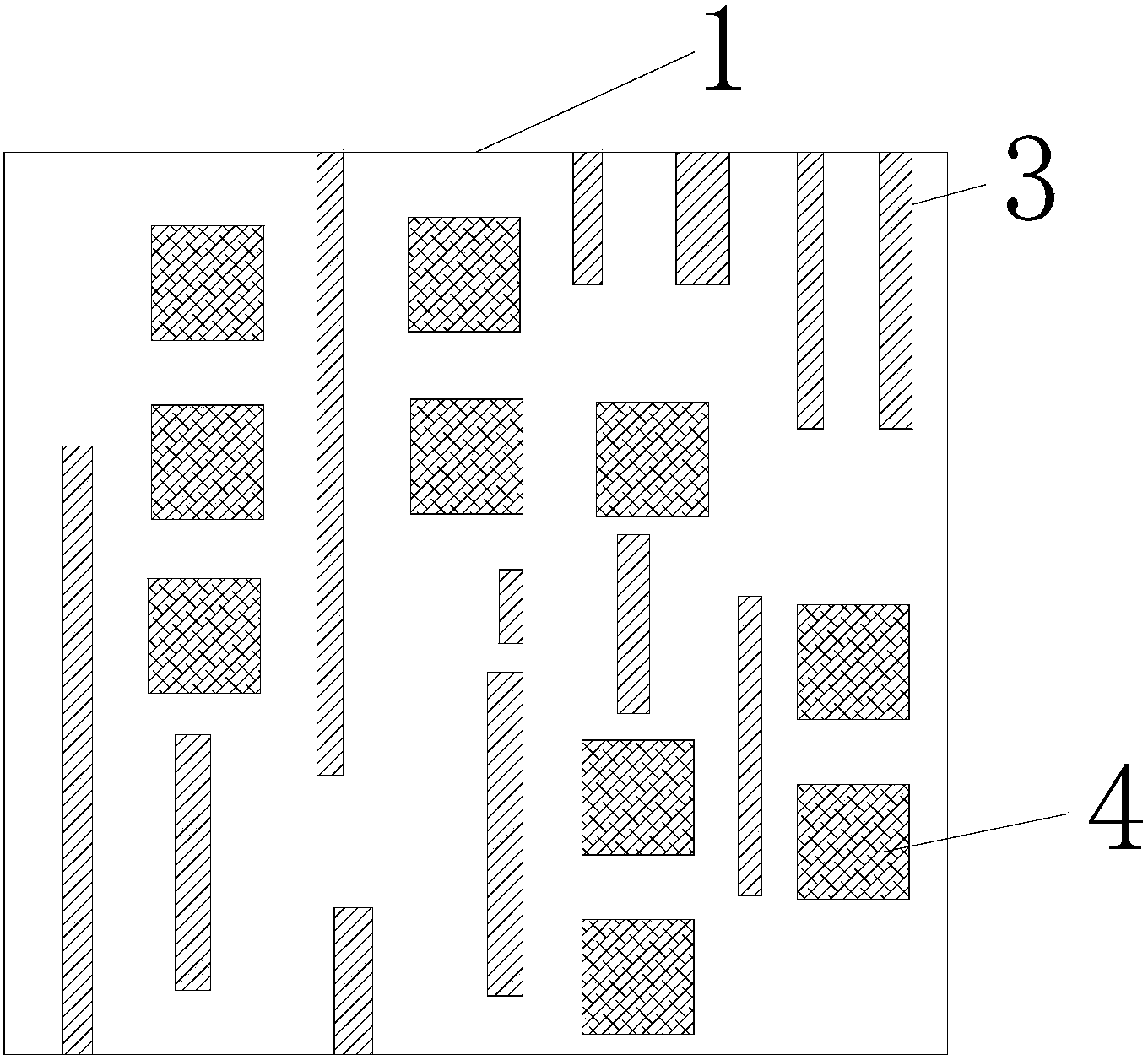

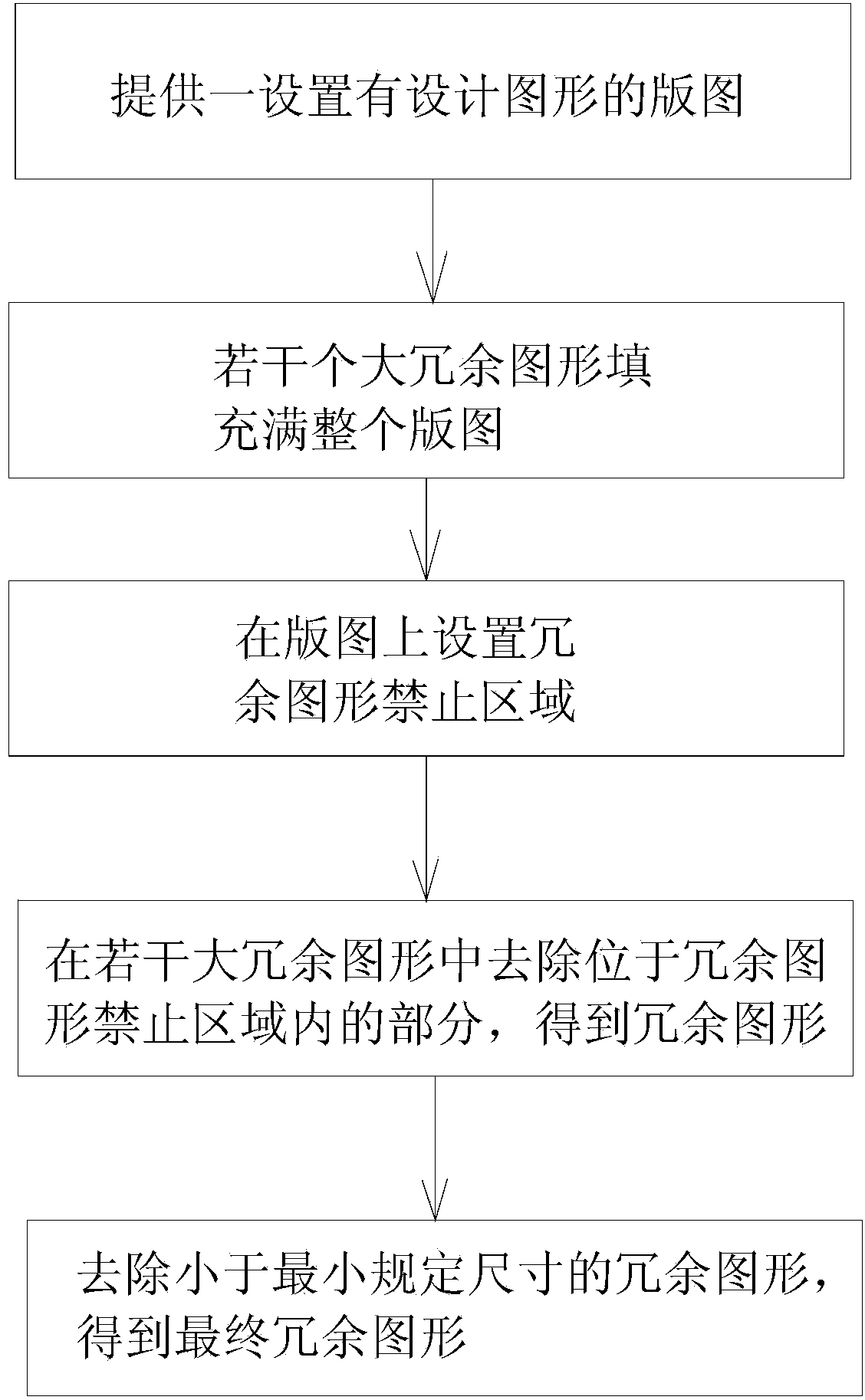

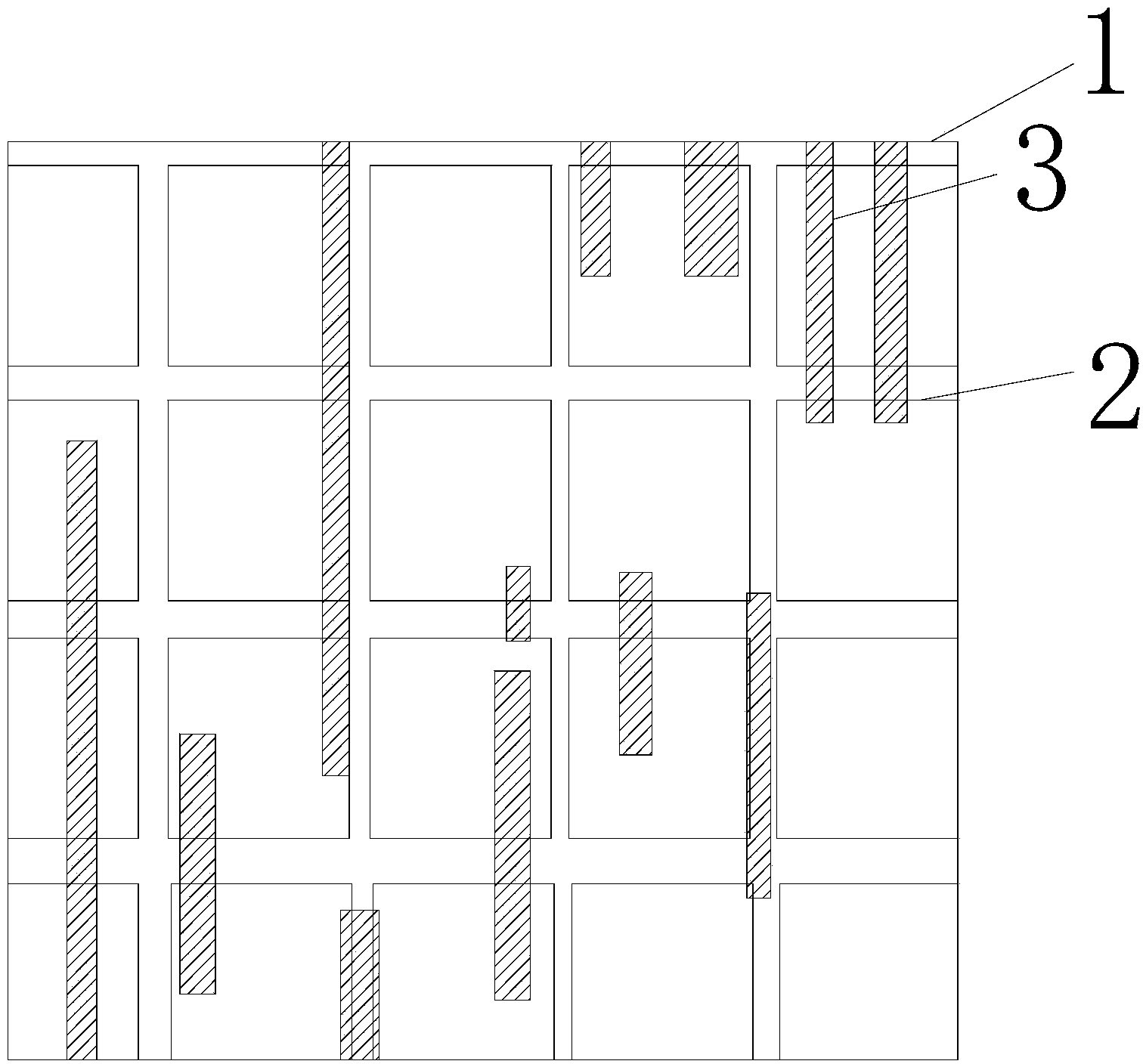

Filling method for redundancy graph

InactiveCN103886150APadding achievedIncrease graphics densitySpecial data processing applicationsGraphicsA domain

The invention provides a filling method for a redundancy graph. Through software for filling the redundancy graph, firstly, the whole area of a domain is filled with the redundancy graph; secondly, a prohibited area of the redundancy graph is selected; thirdly, the redundancy graph located in the prohibited area is removed through the Boolean operation. By means of the method, filling of the redundancy graph with the larger area can be achieved, the graph density of the whole domain is improved, and therefore line width uniformity of a wafer after the wafer is etched and flatness of the wafer after chemical machinery grinding are improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

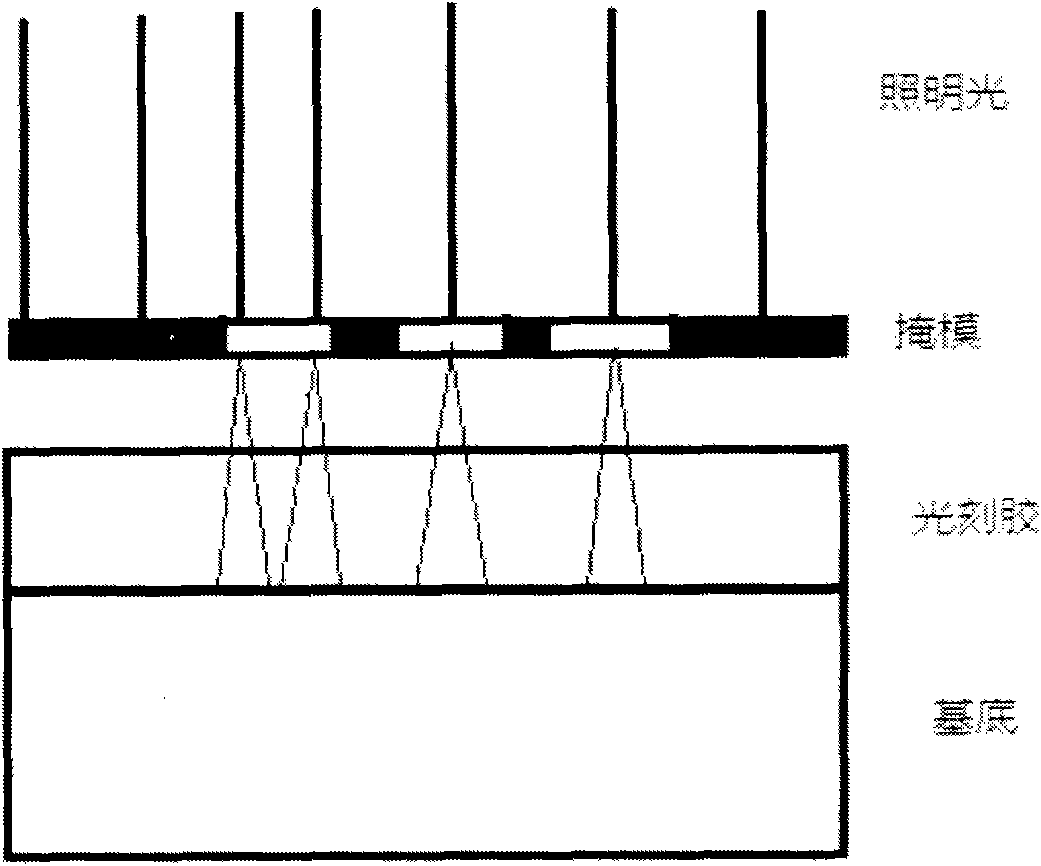

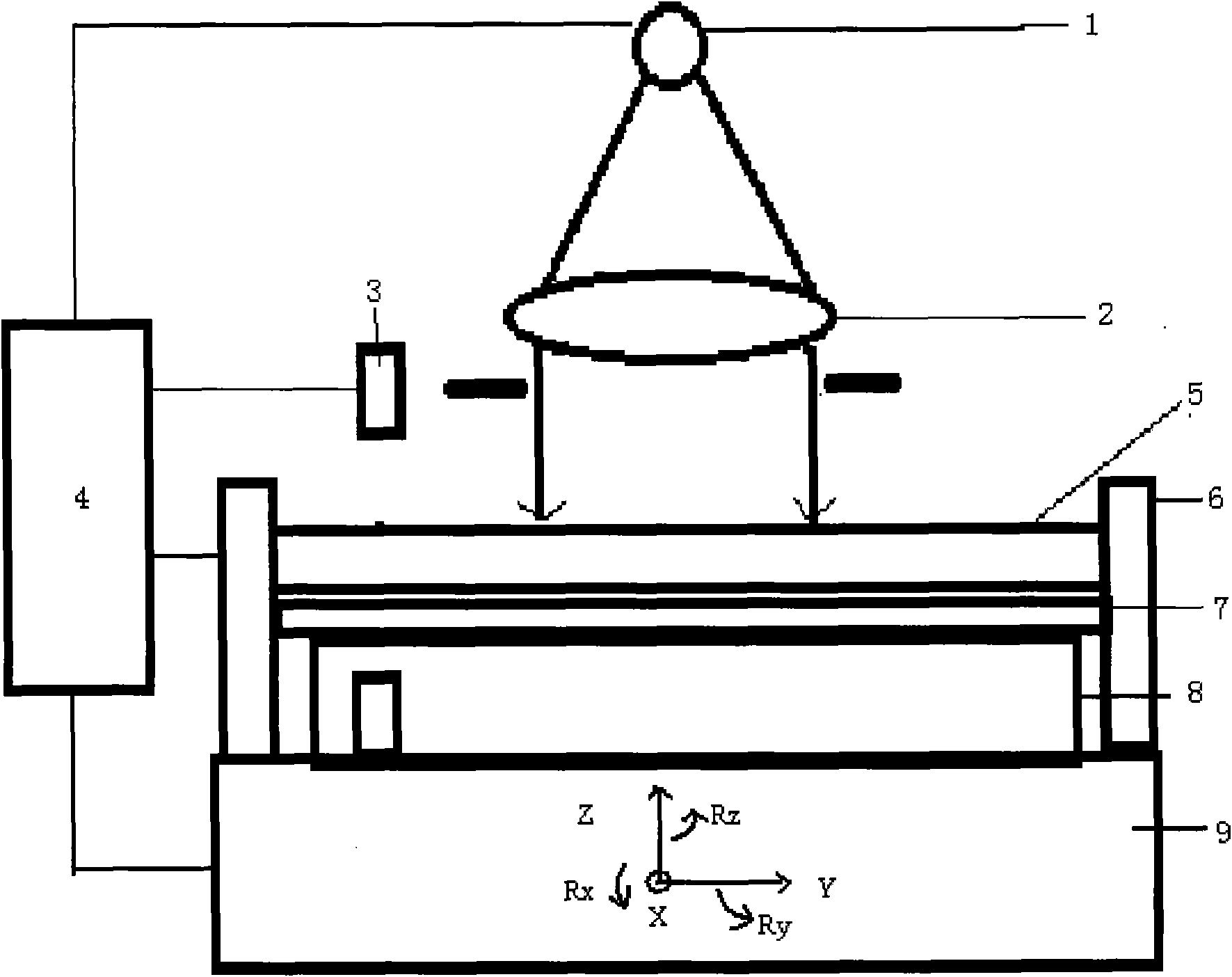

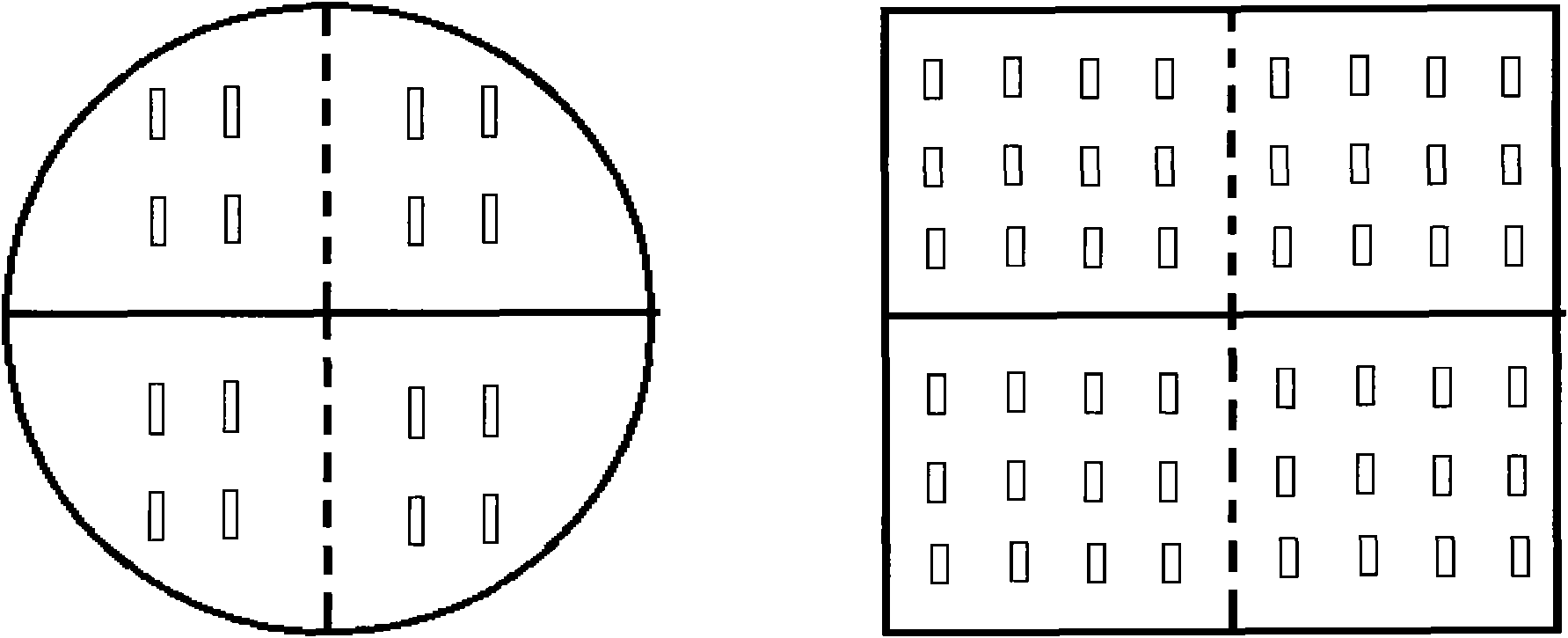

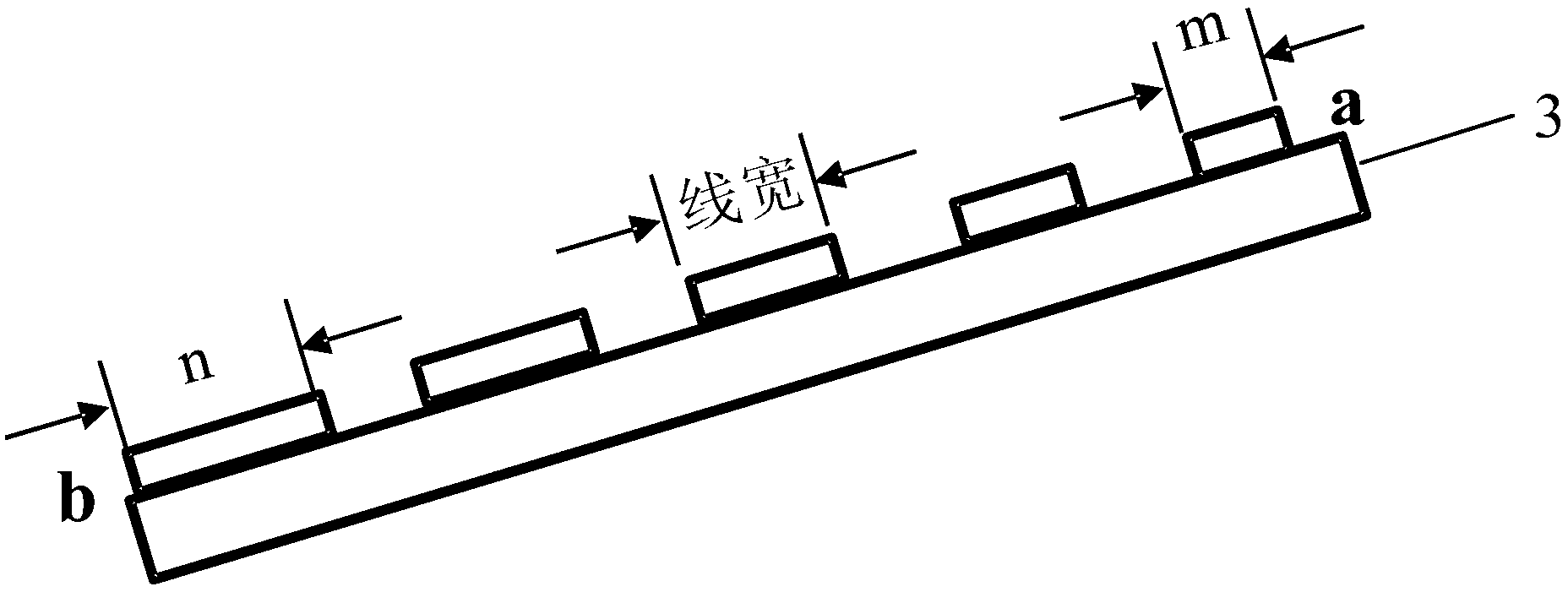

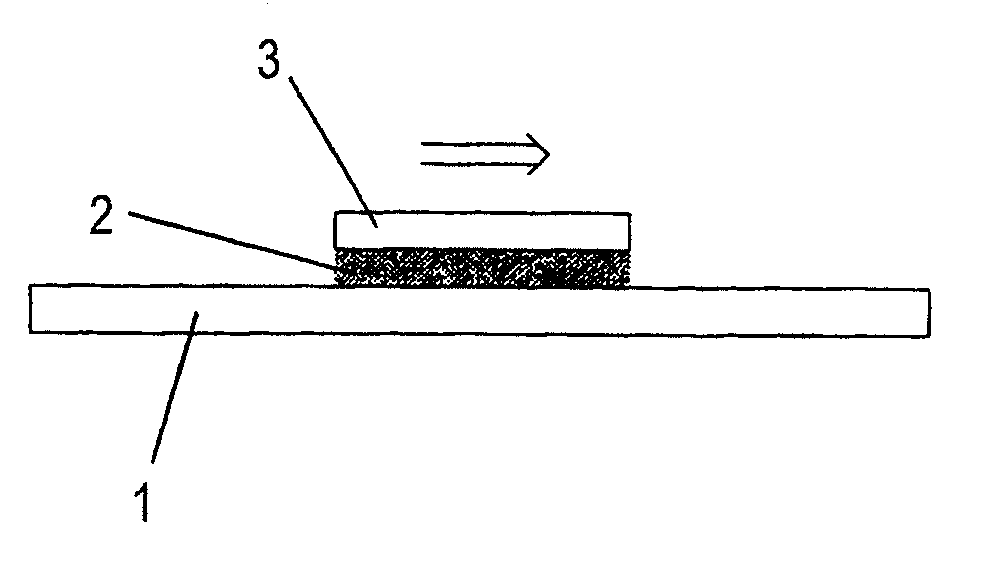

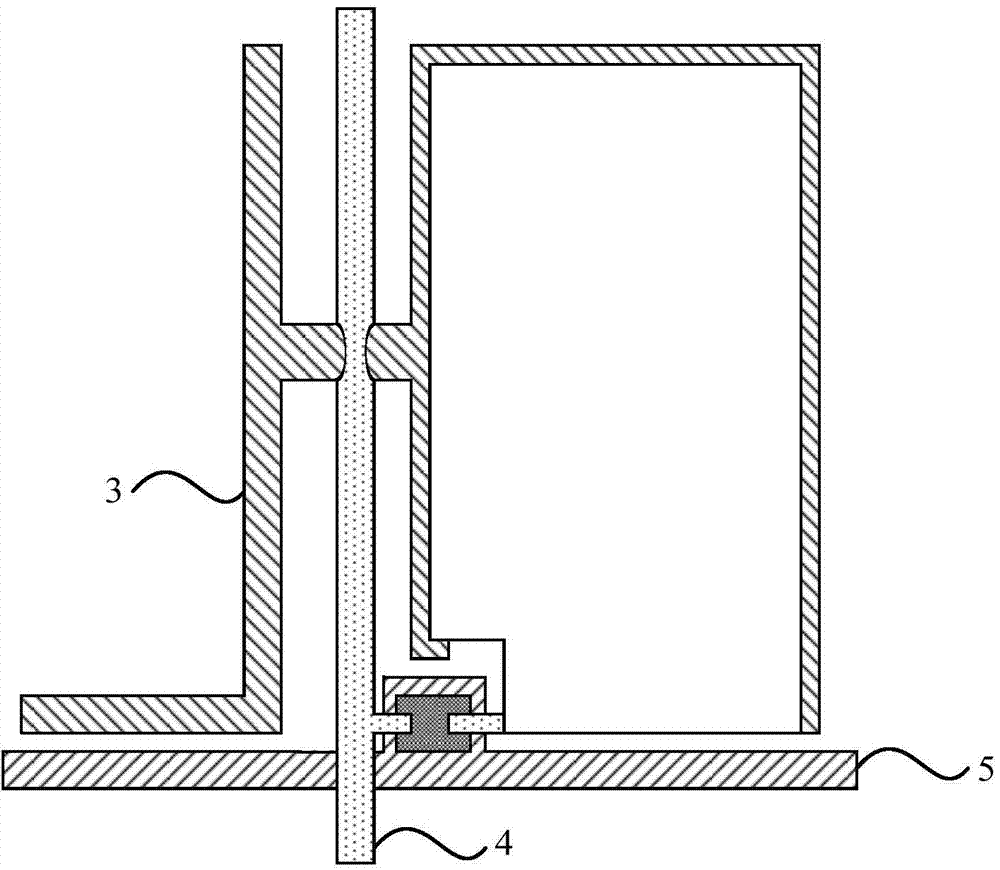

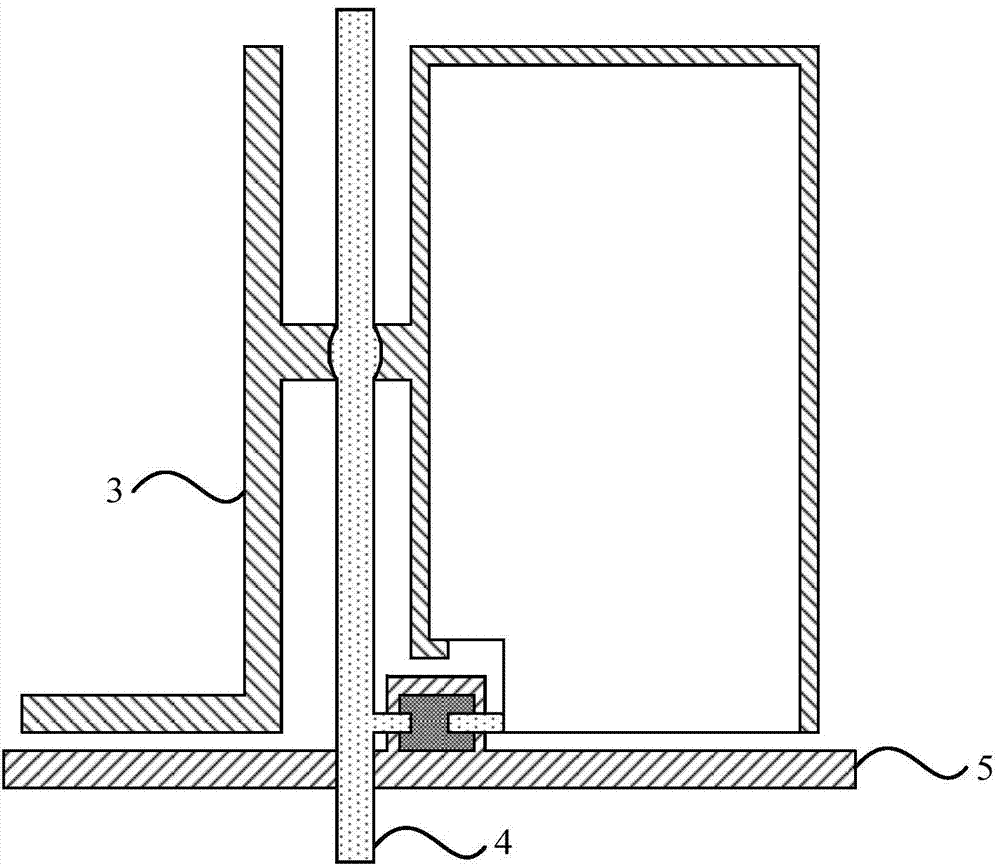

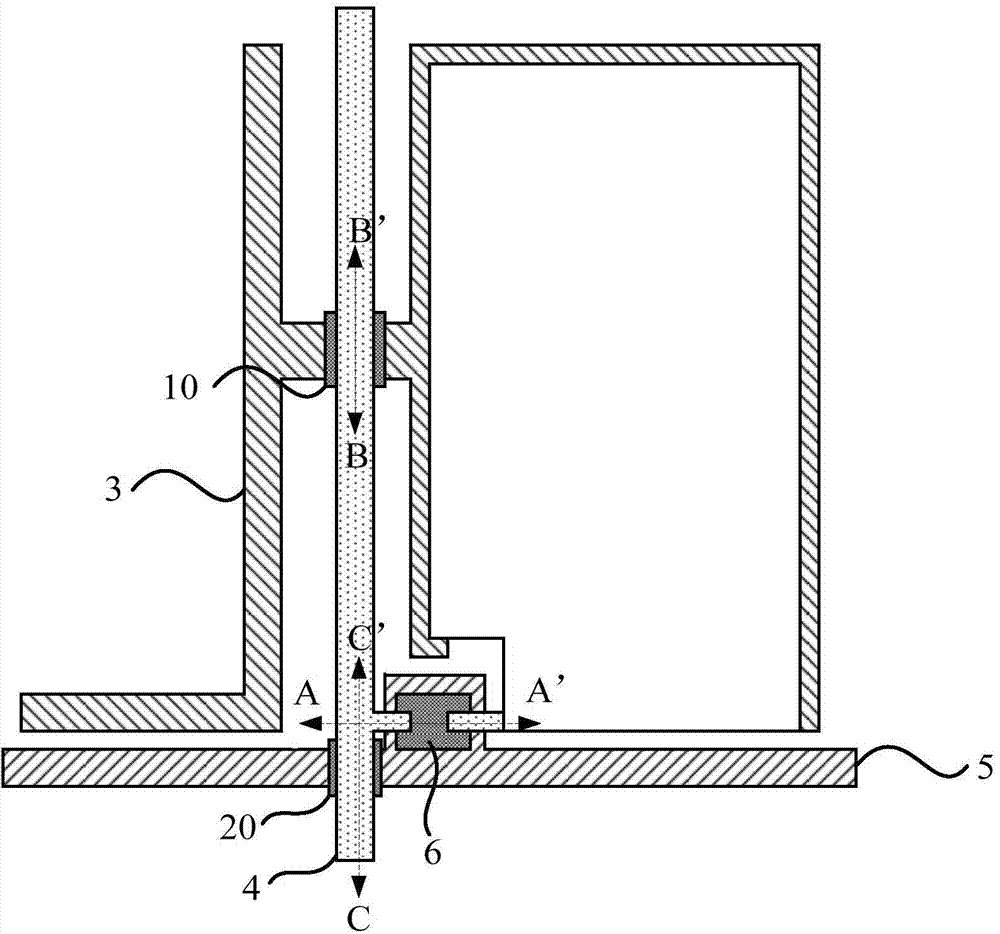

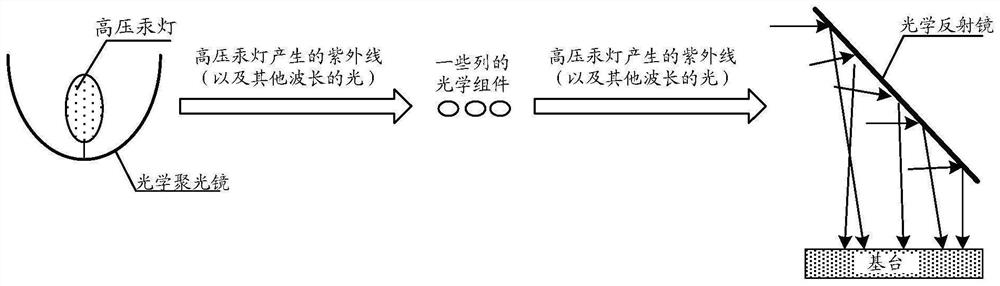

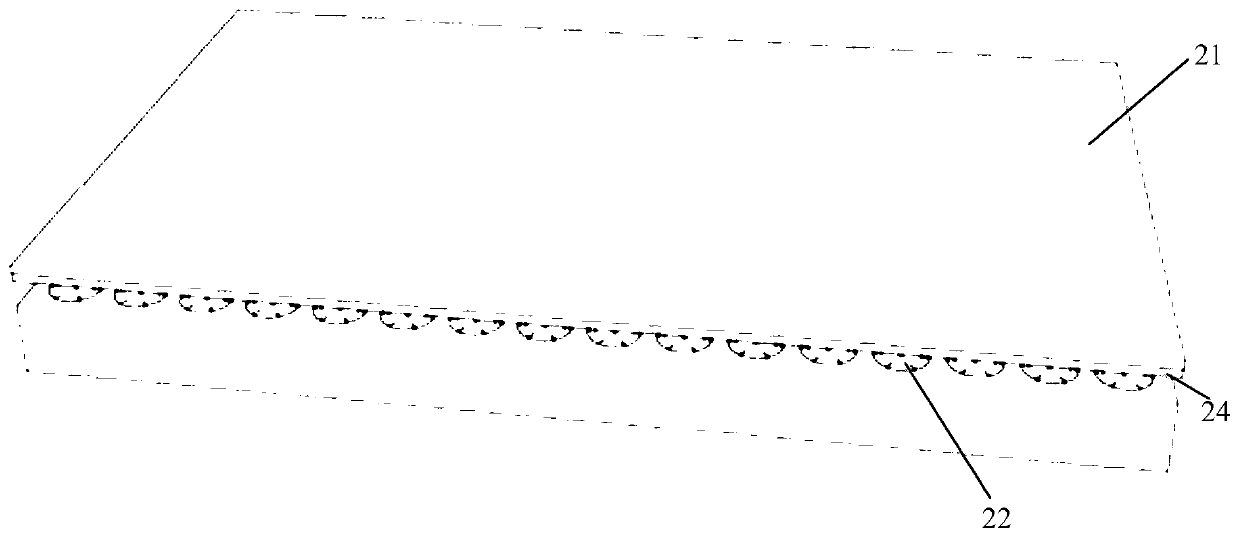

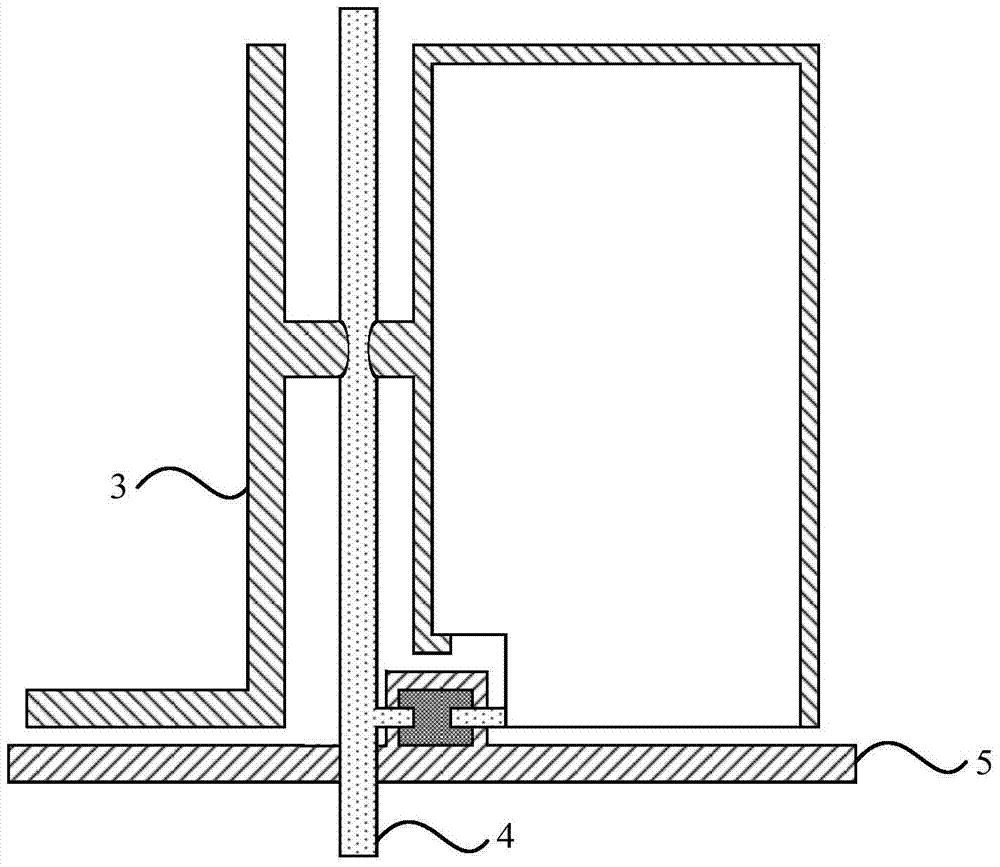

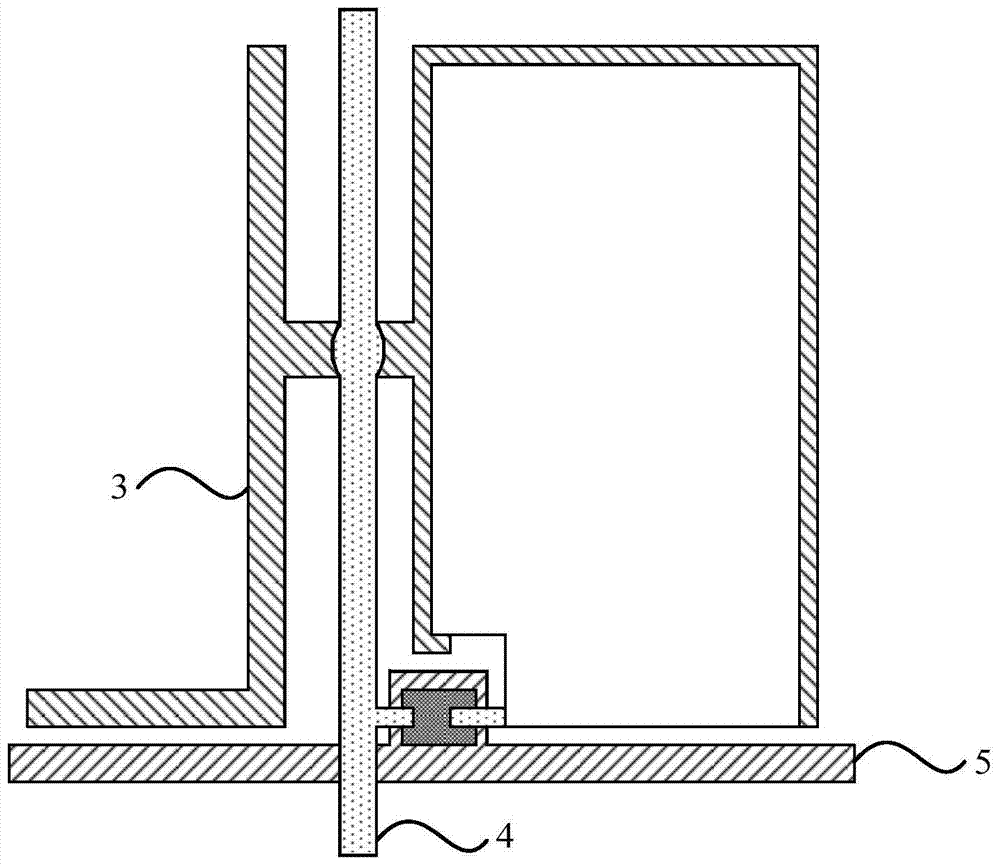

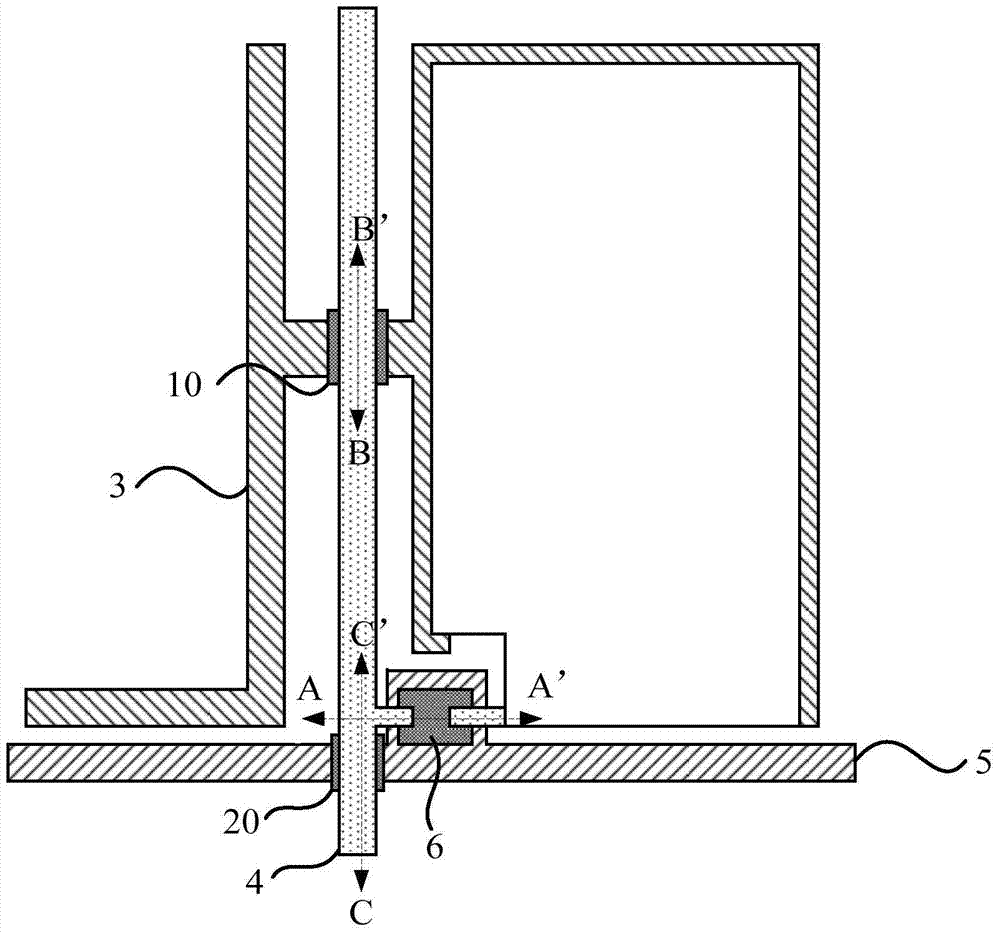

Proximity contact scan exposure device and method

ActiveCN102736421AImprove dose uniformityImprove line width uniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusOptical propagationDose uniformity

The invention discloses a proximity contact scan exposure device which successively comprises the following parts along the optical propagation direction: an illumination system which is used for outputting parallel lights; a mask which is irradiated by the parallel lights to generate emergent light output; a substrate which is positioned below the mask and is irradiated by the emergent lights emitted from the mask; and a working table which supports the mask and the substrate. When the scan exposure device is in use, the mask and the substrate synchronously move with the working table. In comparison with a traditional aligned mask aligner, although the yield of the device provided by the invention is a little lower, dose uniformity is raised such that linewidth uniformity (CDU) is improved. In comparison with a traditional projection type mask aligner, although precision of the device provided by the invention is not such high, projection lens is not required so as to reduce the cost.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

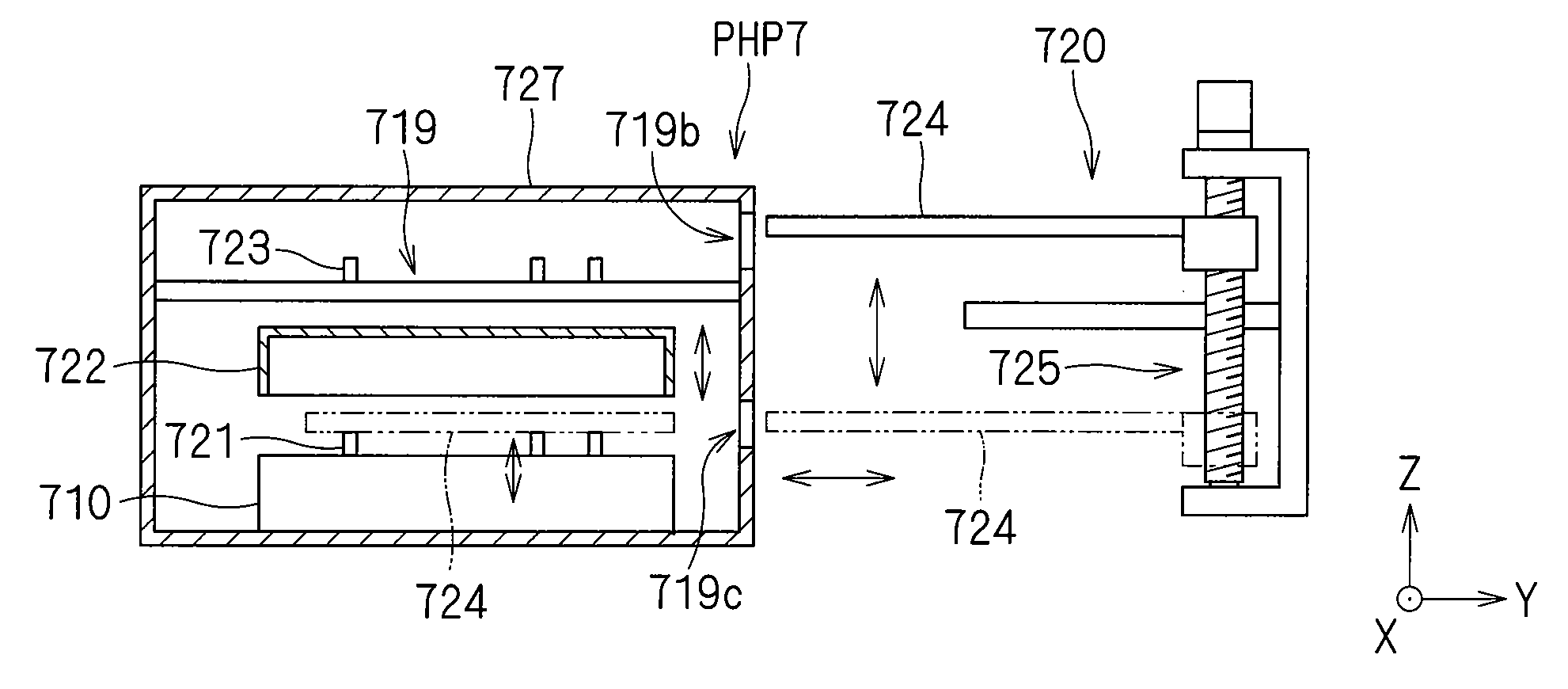

Apparatus for and method of processing substrate subjected to exposure process

ActiveUS20100126527A1Improve line width uniformityUniform processingLighting and heating apparatusSemiconductor/solid-state device manufacturingProcess engineeringThermal treatment

A method of processing a substrate subjected to an exposure process includes the steps of: transporting a substrate subjected to the exposure process to a cleaning processing part and performing a cleaning process in said cleaning processing part on said substrate subjected to the exposure process. The method also includes the steps of transporting said substrate subjected to the cleaning process from said cleaning processing part to a heating processing part and performing a heating process in said heating processing part on said substrate subjected to the cleaning process. A first interprocess time interval between the instant at which the exposure process of a substrate is completed and the instant at which the heating process of the substrate is started is made approximately constant, and a second interprocess time interval between the instant at which the cleaning process of the substrate is completed and the instant at which the heating process of the substrate is started is made approximately constant.

Owner:SCREEN SEMICON SOLUTIONS CO LTD

Positive resist composition and pattern forming method utilizing the same

ActiveUS20060046190A1Improve line width uniformityMaintain good propertiesRadiation applicationsPhotomechanical apparatusActinic RaysAlicyclic Hydrocarbons

A positive resist composition comprising: a resin that comprises a repeating unit including a specific norbornane lactone structure and a repeating unit including a specific alicyclic hydrocarbon structure, and that increases a solubility of the resin in an alkaline developer by an action of an acid; and a compound that generates an acid upon treatment with one of an actinic ray and radiation, and a pattern forming method utilizing the same.

Owner:FUJIFILM HLDG CORP +1

Substrate processing apparatus

InactiveUS20060120716A1Improve line width uniformityLiquid processingPhotomechanical apparatusResistLine width

When a first substrate transferred outwardly from an indexer cell is the last substrate prior to reticle change in an exposure apparatus, the outward transfer of a second substrate to be processed subsequently to the first substrate from the indexer cell is temporarily stopped. After a lapse of time corresponding to reticle replacement time, the outward substrate transfer is restarted, and the second substrate is transferred outwardly from the indexer cell. For the exposure apparatus, the second substrate subjected to a resist coating process is received at the instant when the reticle replacement is completed after the completion of the exposure process of the first substrate. This provides a constant time interval between the completion of the resist coating process of substrates and the execution of the exposure process thereof without the decrease in processing efficiency. As a result, a uniform processing history for the substrates is achieved to further improve the line width uniformity of a pattern.

Owner:DAINIPPON SCREEN MTG CO LTD

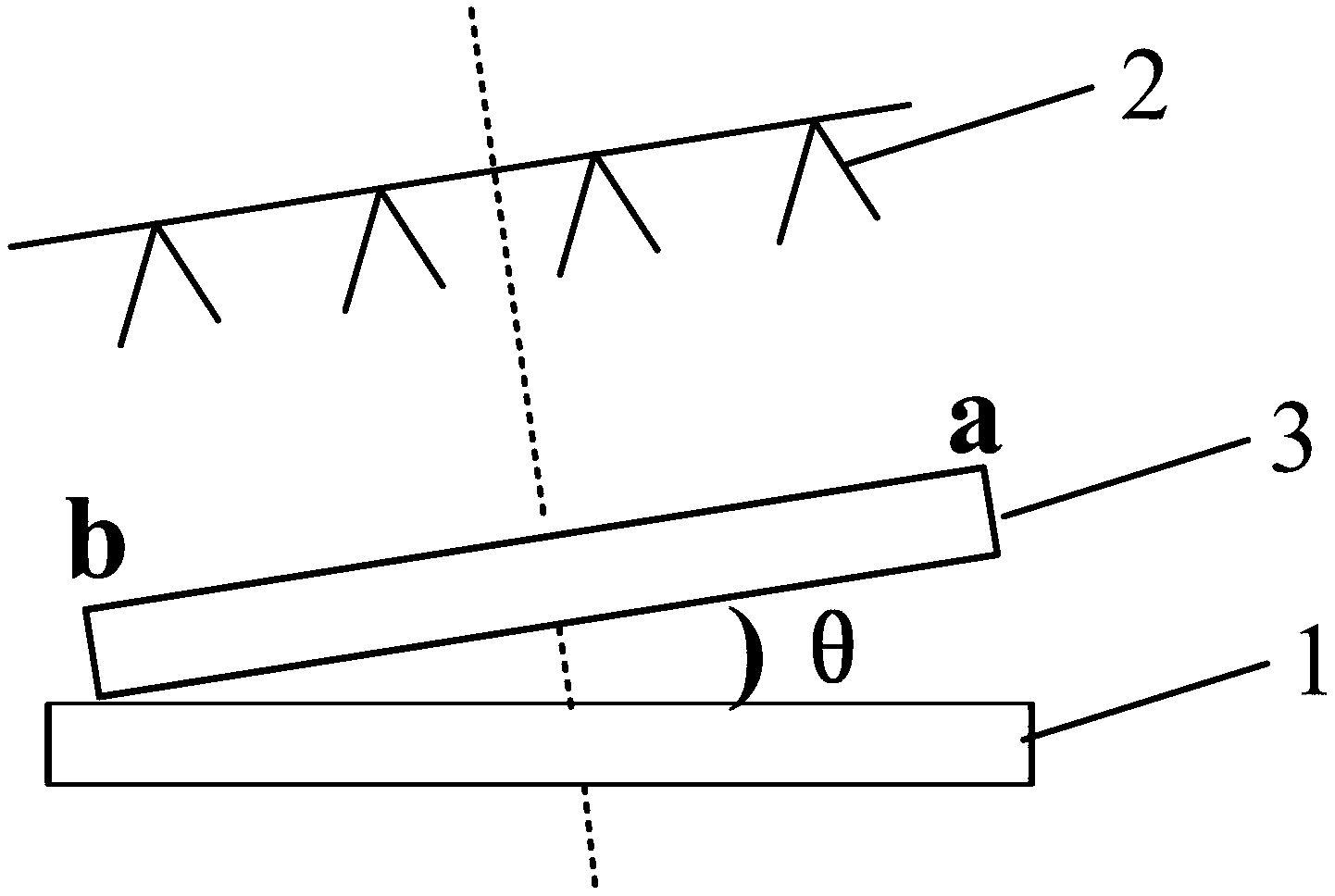

Developing method and developing device

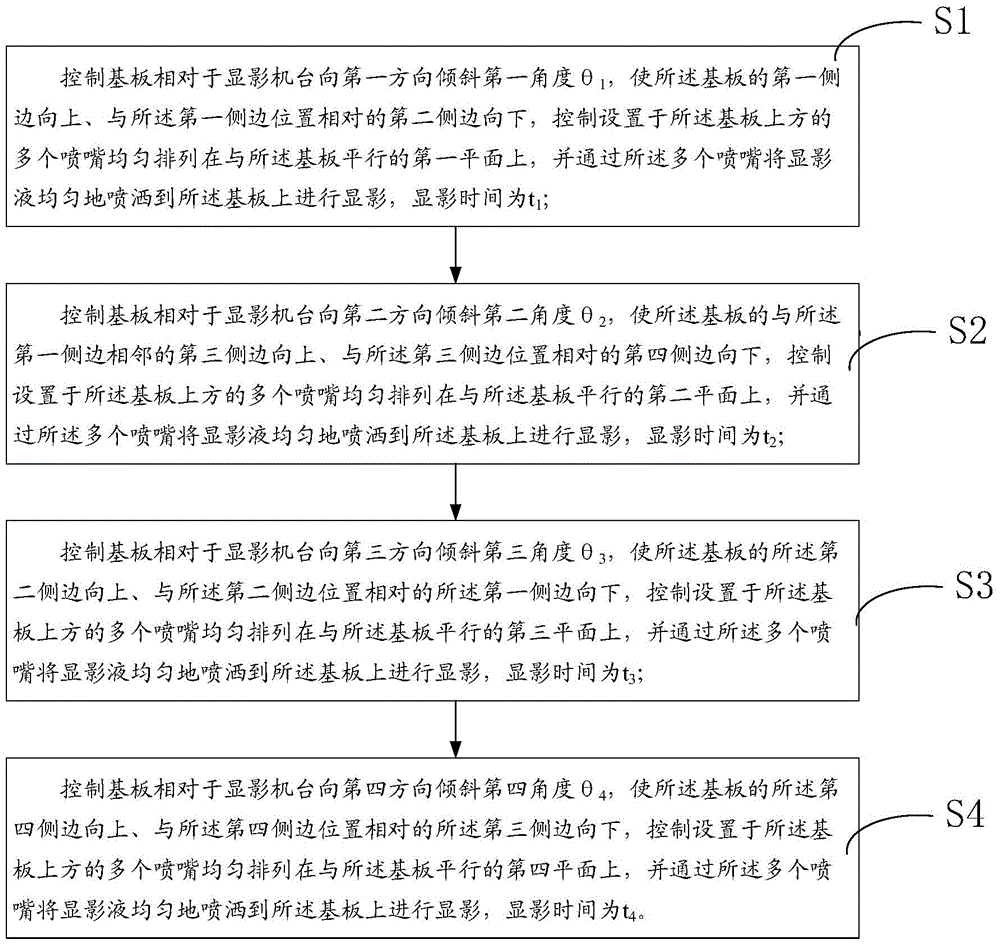

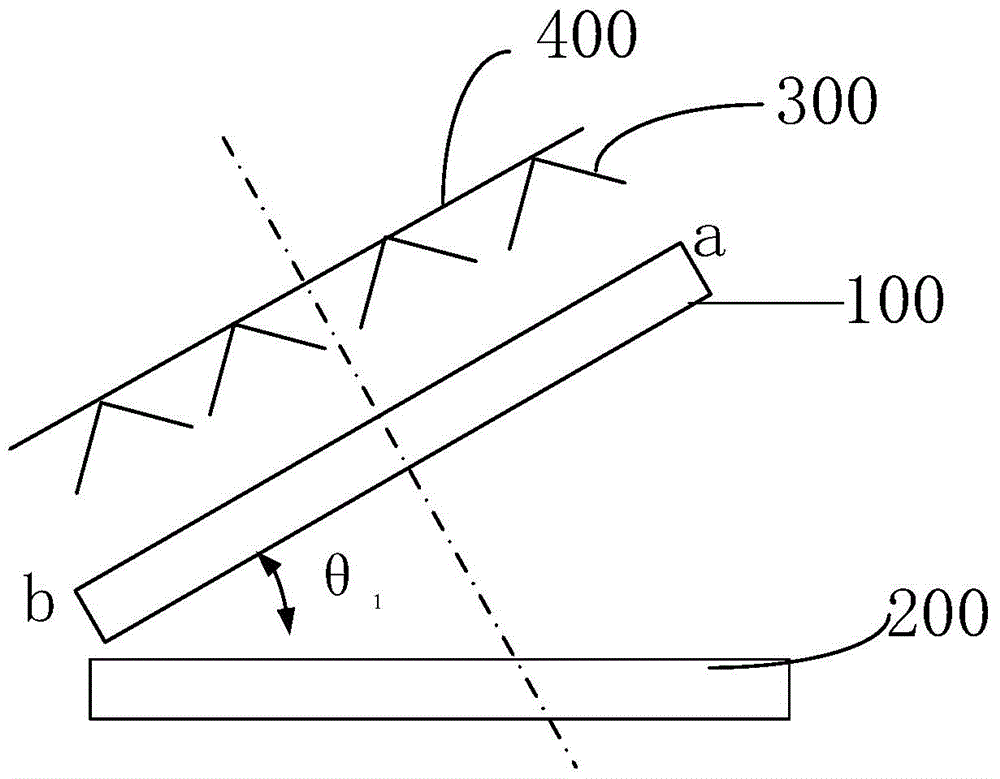

InactiveCN104062857AImprove uniformityRealize all-round oblique developmentPhotosensitive material processingSpray nozzleEngineering

The invention provides a developing method and a developing device. The method comprises the following steps of controlling a base plate to incline for a first angle theta 1 towards a first direction relative to a developing machine table, controlling a plurality of spray nozzles to be on the first plane parallel to the base plate, uniformly spraying developing liquid on the base plate for developing; controlling the base plate to incline for a second angle theta 2 towards a second direction relative to the developing machine table, controlling the plurality of the spray nozzles to be on a second plane parallel to the base plate, and uniformly spraying the developing liquid on the base plate for developing; controlling the base plate to incline for a third angle theta 3 towards a third direction relative to the developing machine table, controlling the plurality of the spray nozzles to be on the third plane parallel to the base plate, uniformly spraying the developing liquid on the base plate for developing; and controlling the base plate to incline for a fourth angle theta 4 towards a fourth direction relative to the developing machine table, controlling the plurality of the spray nozzles to be on a fourth plane parallel to the base plate, and uniformly spraying the developing liquid on the base plate for developing. According to the scheme, the linear width uniformity of a developed photoetching pattern can be improved.

Owner:BOE TECH GRP CO LTD +1

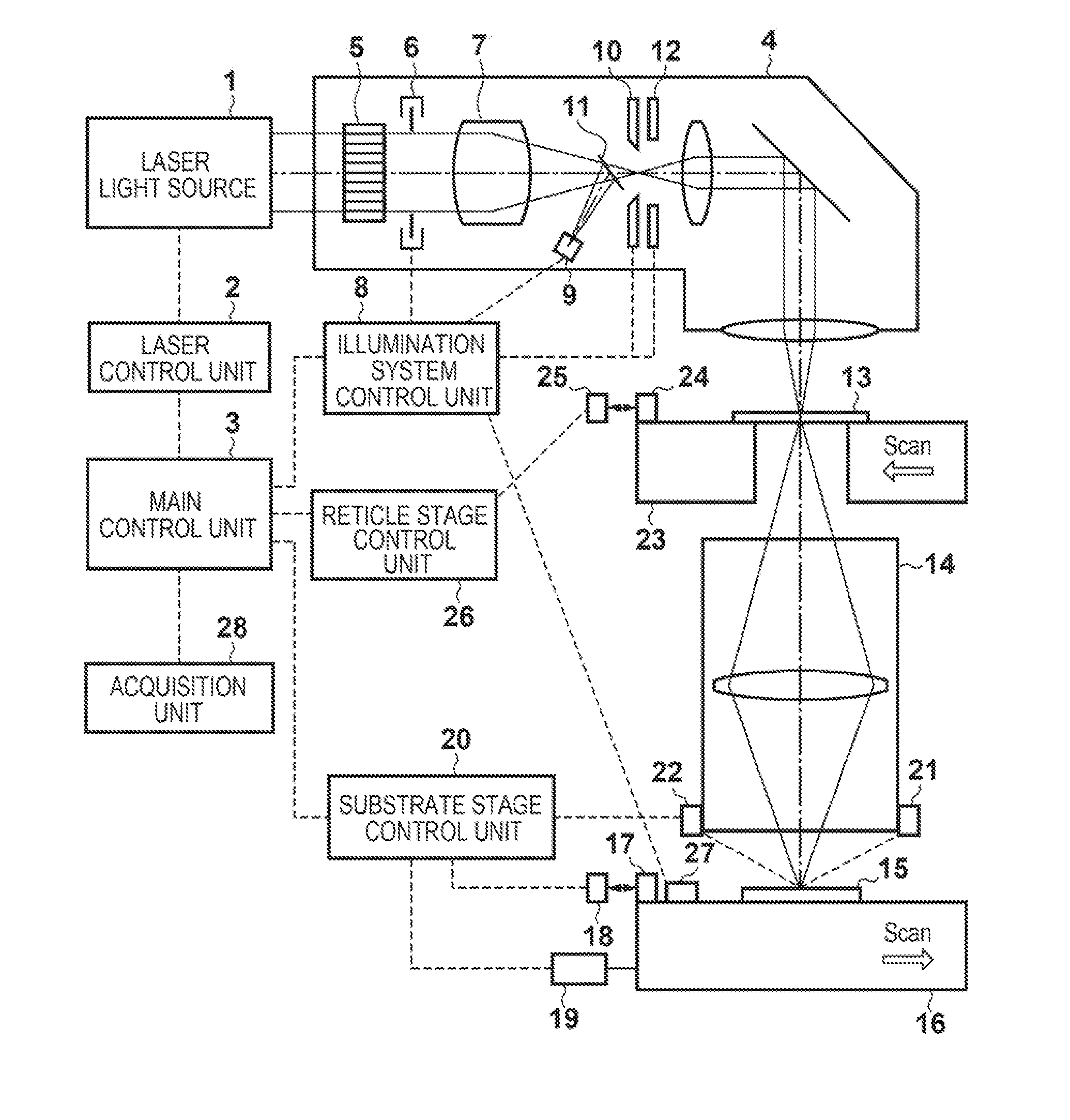

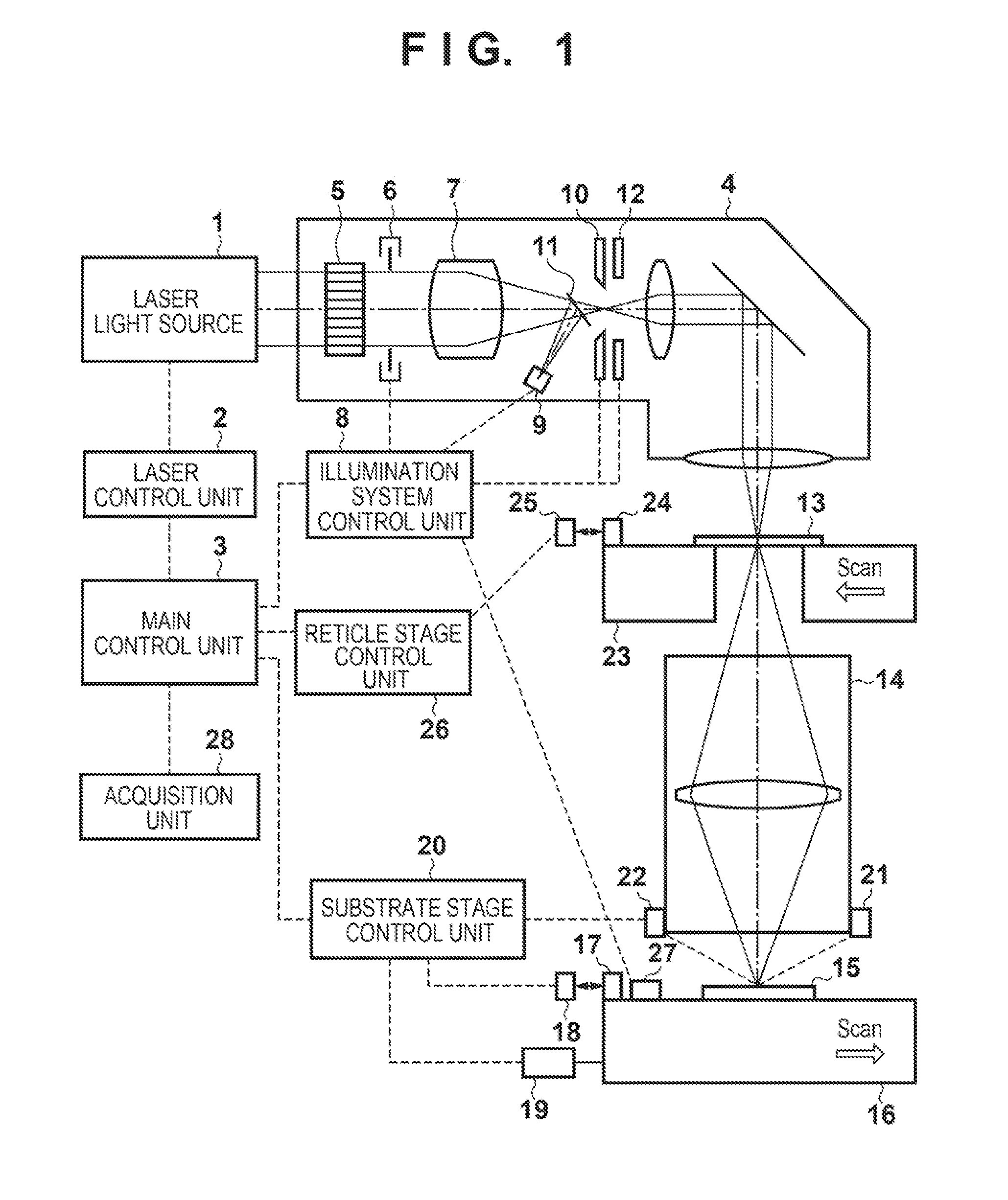

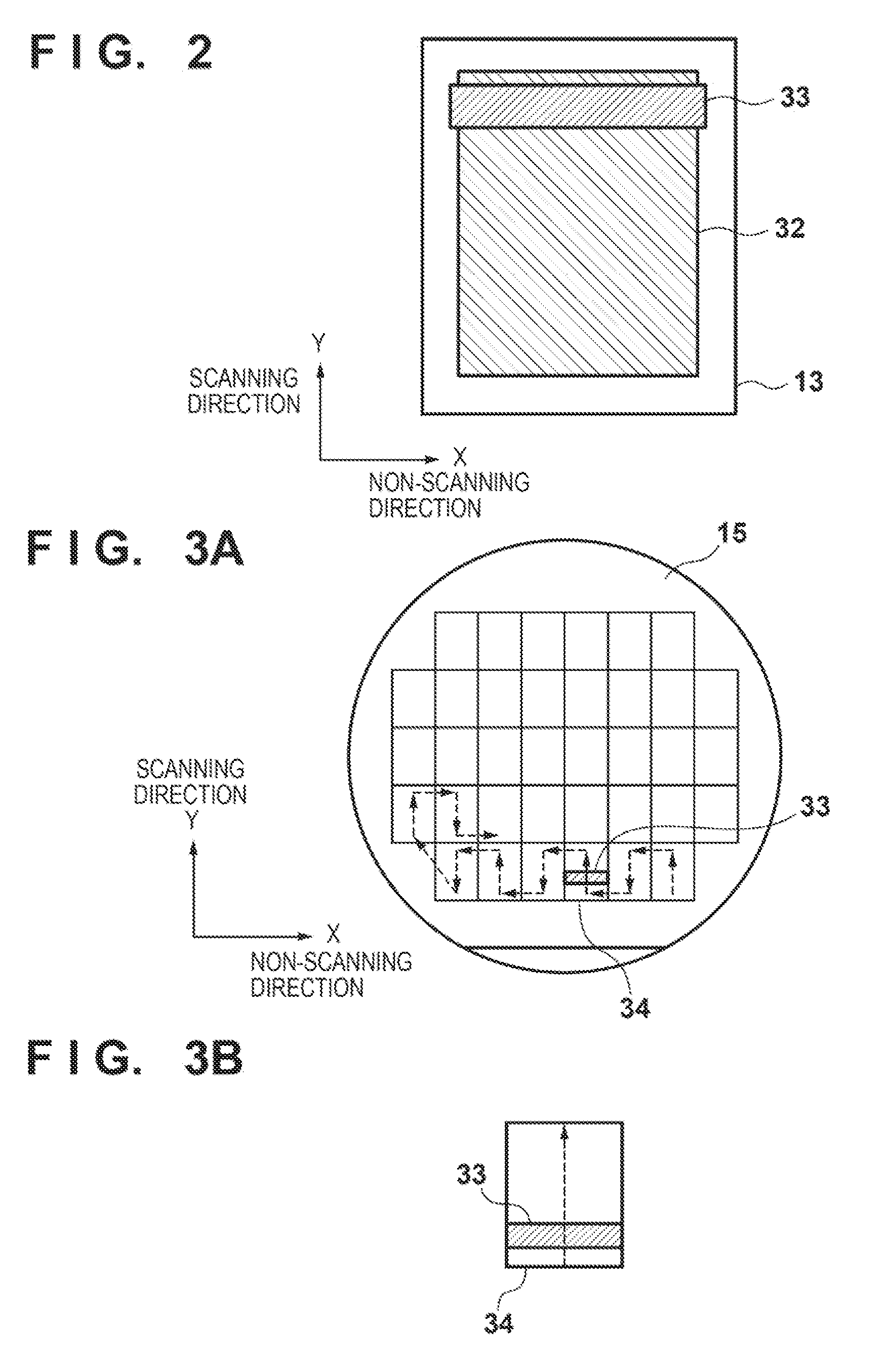

Exposure apparatus and device manufacturing method

ActiveUS20130314682A1Improve line width uniformityPhotomechanical apparatusElectrographic process apparatusCamera lensControl unit

An exposure apparatus includes a control unit configured to calculate a target exposure amount distribution in a scanning direction within the target shot region using a target exposure amount at a position in the target shot region and a target exposure amount at a position in an adjacent shot region adjacent to the target shot region in the scanning direction and configured to perform a scan exposure for the target shot region while controlling an exposure amount according to scanning of the substrate so as to obtain the calculated target exposure amount distribution as an exposure amount distribution in a scanning direction within the target shot region.

Owner:CANON KK

Developing device and developing method

InactiveCN103324038AConsistent concentrationImprove line width uniformitySolid-state devicesElectrographic process apparatusSpray nozzleEngineering

The invention provides a developing device and a developing method. According to the developing device and the developing method, the consistent concentration of a developing liquid contacted by glass in each direction can be ensured by arranging a spray nozzle used for spraying the developing liquid, a machine table used for bearing a glass substrate, and an inclination controller used for controlling the spray nozzle and the machine table to incline an angle towards a direction, and keeping the angle in a preset time, controlling the machine table and the spray nozzle to slant a preset angle towards the first direction of the machine table by the inclination controller during an inclination cycle period, and keeping the angle in a preset time, controlling the machine table and the spray nozzle to sequentially slant the preset angle towards the other directions of the machine table by the inclination controller according to a preset inclination direction sequence, and keeping the inclination angle in a preset time; consequently, the line width uniformity after developing can be improved.

Owner:BOE TECH GRP CO LTD +1

Method of forming patterns

ActiveUS20110076625A1Reduce scumReduce roughnessRadiation applicationsSemiconductor/solid-state device manufacturingActinic RaysRay

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

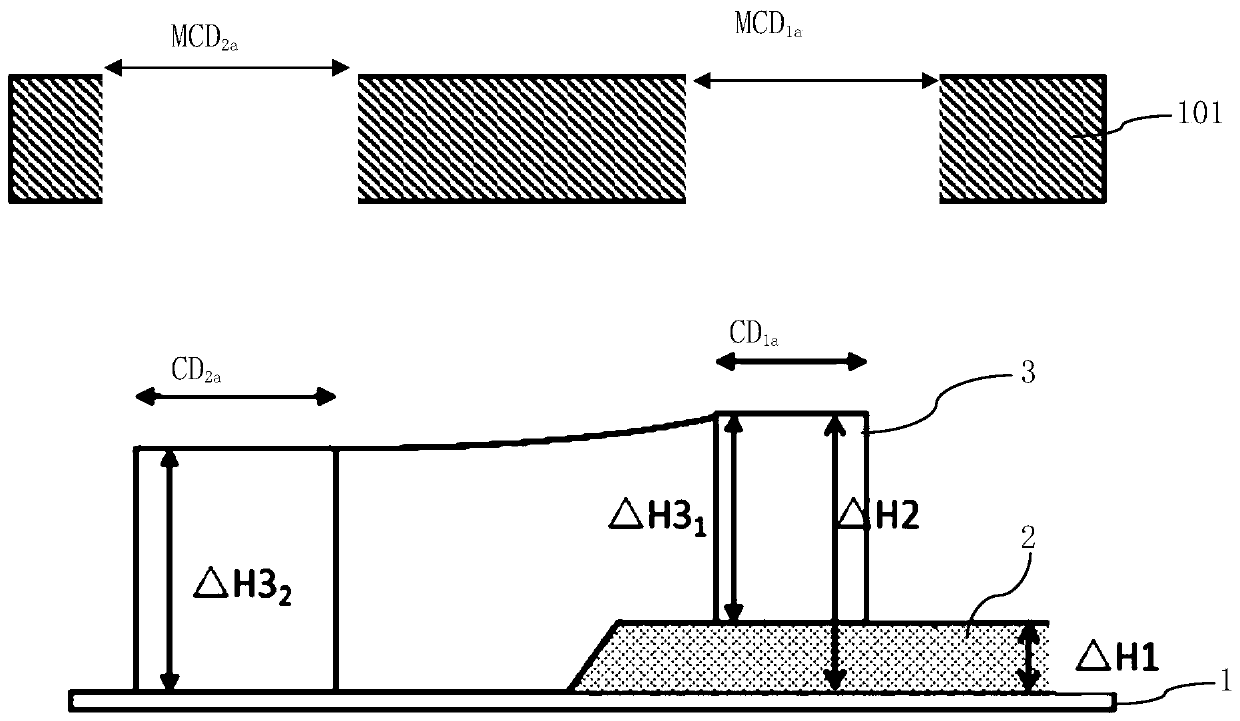

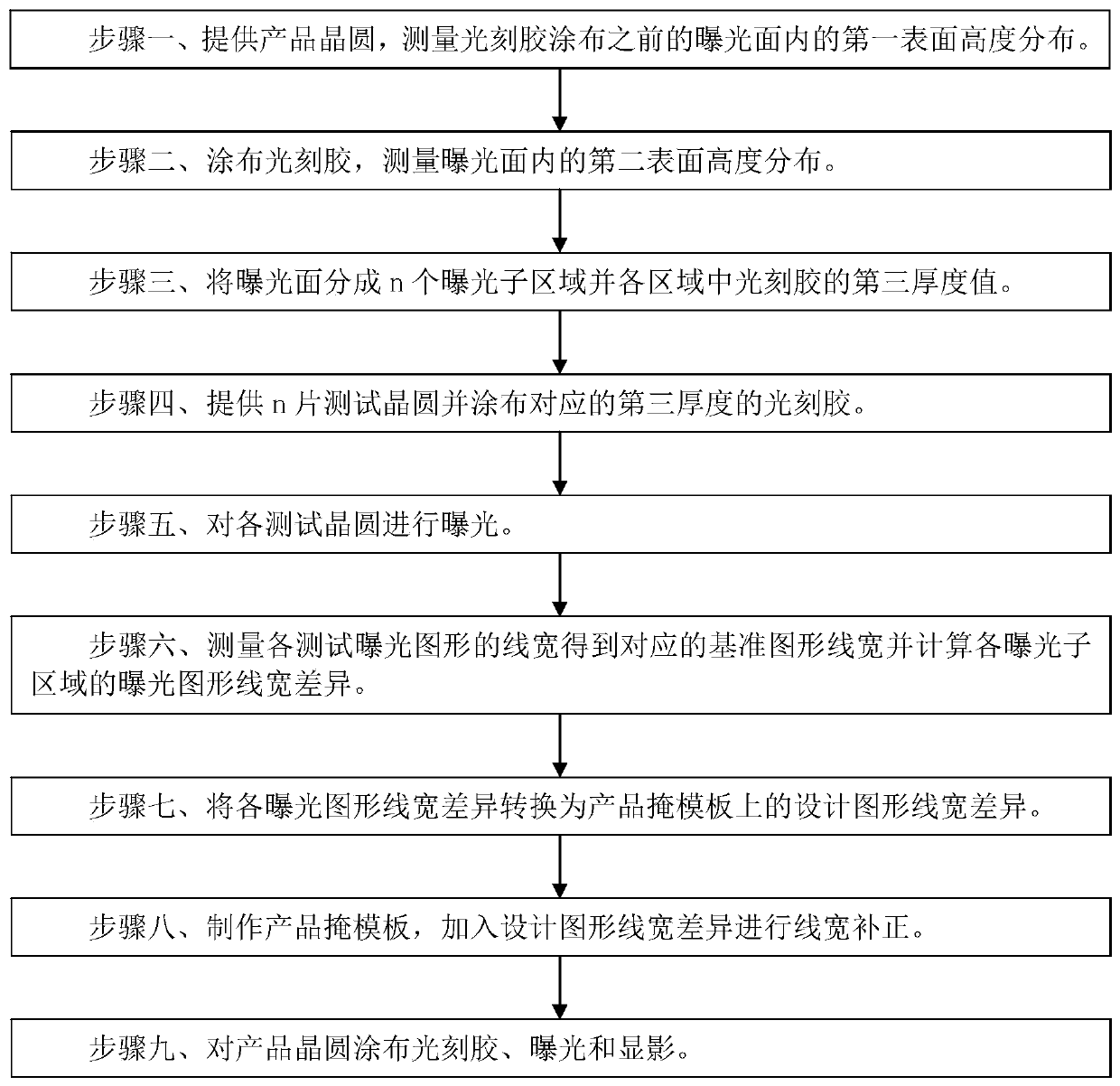

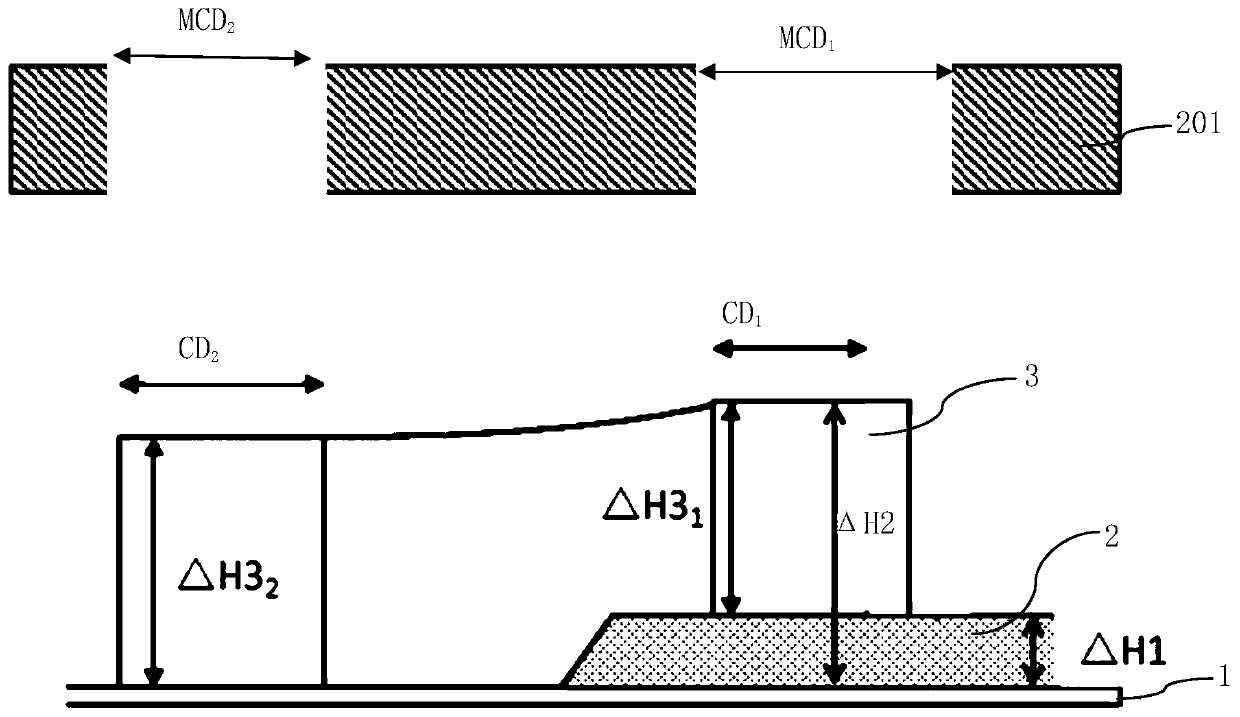

Photoetching process method

ActiveCN110767540AEliminate line width differences in exposed graphicsImprove line width uniformitySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingPhotoresistExposure

The invention discloses a photoetching process method, which comprises the following steps: providing a product wafer, and measuring a first surface height distribution in an exposure plane before photoresist applying; applying photoresist, and measuring a second surface height distribution in the exposure plane; dividing the exposure plane into n exposure subareas and calculating a third thickness value of the photoresist in each exposure subarea; providing n test wafers and coating the n test wafers with photoresist with a third thickness; exposing the test wafers; measuring the line width of each test exposure pattern to obtain a corresponding reference pattern line width and calculating the exposure pattern line width difference of each exposure subarea; converting each exposure pattern line width difference into a design pattern line width difference on a product mask; manufacturing a product mask, and adding the design pattern line width difference to perform line width correction; and coating the product wafer with photoresist, and carrying out exposing and developing. According to the invention, exposure pattern line width difference caused by uneven surface morphology in the wafer exposure plane can be reduced or eliminated, and the line width uniformity of the product can be improved.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Developing apparatus, developing method and storage medium

ActiveUS20170045821A1Improve line width uniformityImprove uniformityLiquid surface applicatorsSemiconductor/solid-state device manufacturingPuddleNozzle

A developing apparatus includes: a substrate holder that hold a substrate horizontally; a developer nozzle that supplies a developer onto the substrate to form a liquid puddle; a turning flow generation mechanism including a rotary member that rotates about an axis perpendicular to the substrate while the rotary member is being in contact with the liquid puddle thereby to generate a turning flow in the liquid puddle of the developer formed on the substrate; and a moving mechanism for moving the turning flow generation mechanism along a surface of the substrate. The line-width uniformity of a pattern can be improved by forming turning flows in a desired region of the substrate and stirring the developer.

Owner:TOKYO ELECTRON LTD

Method of forming patterns

ActiveUS8632942B2Reduce scumReduce roughnessPhotosensitive materialsPhotoprinting processesActinic RaysFluence

A method of forming patterns includes (a) coating a substrate with a resist composition for negative development to form a resist film having a receding contact angle of 70 degrees or above with respect to water, wherein the resist composition for negative development contains a resin capable of increasing the polarity by the action of an acid and becomes more soluble in a positive developer and less soluble in a negative developer upon irradiation with an actinic ray or radiation, (b) exposing the resist film via an immersion medium, and (c) performing development with a negative developer.

Owner:FUJIFILM CORP

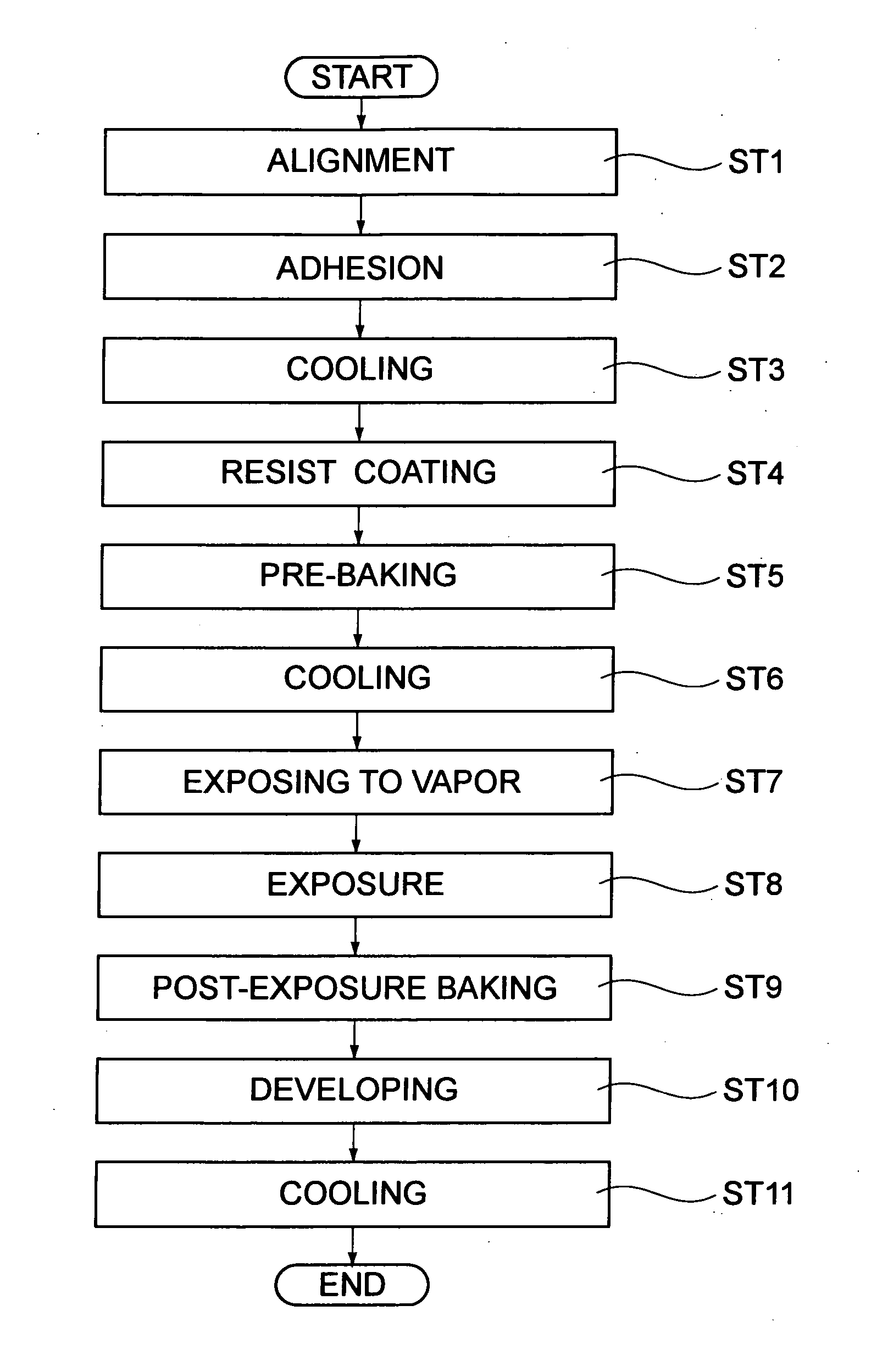

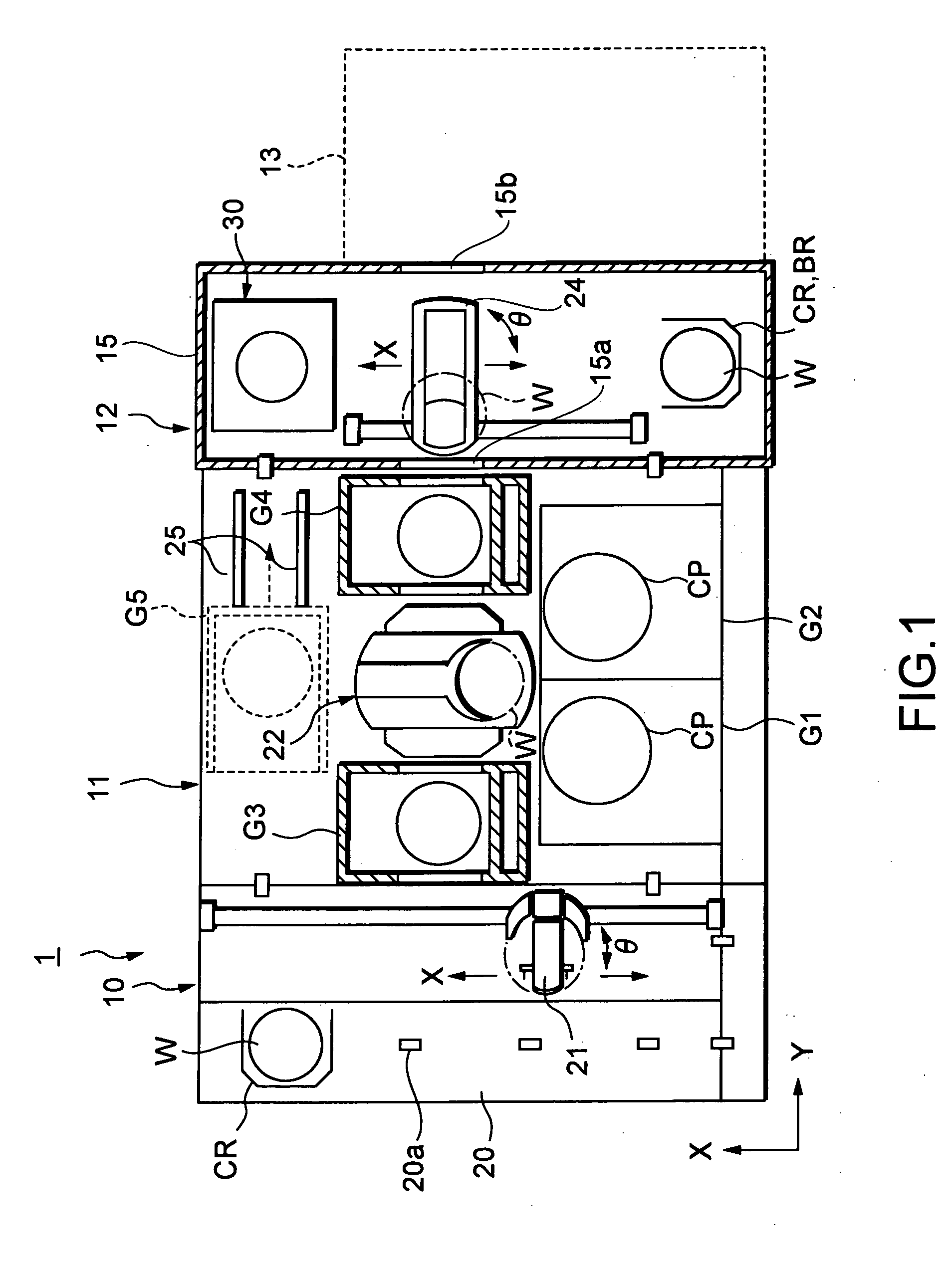

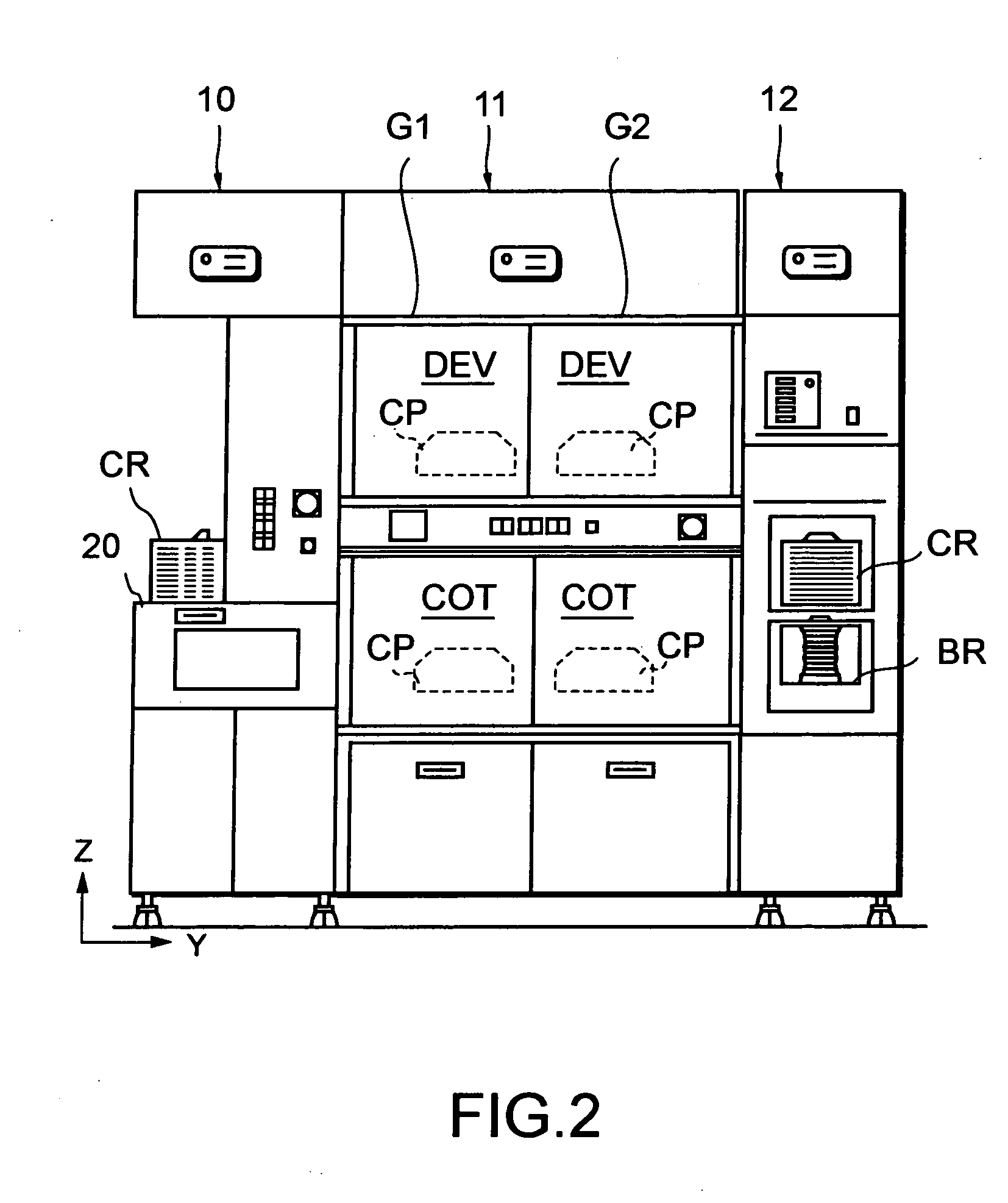

Substrate processing method and substrate processing apparatus

InactiveUS20050130445A1Improve line width uniformityImprove uniformitySemiconductor/solid-state device manufacturingPhotosensitive material processingResistWafering

The wafer coated with the resist is deliberately placed in the vapor before being transferred to an aligner that exposes the resist on the wafer, the vapor, for example, the moisture, uniformly adheres onto the resist on the wafer. As a result, the substrate can uniformly be exposed in the following exposing process, and the uniformity of the line width and the like can be improved.

Owner:TOKYO ELECTRON LTD

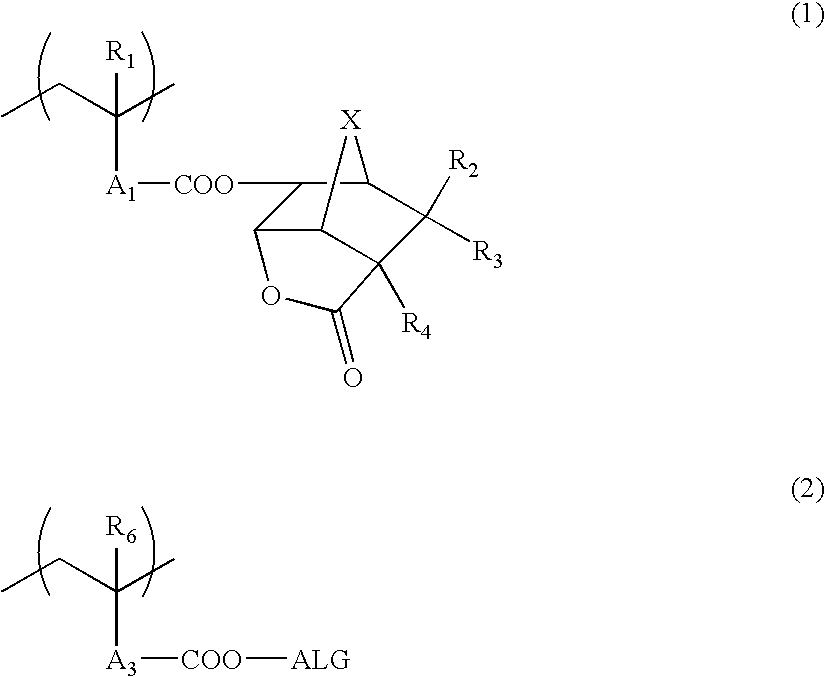

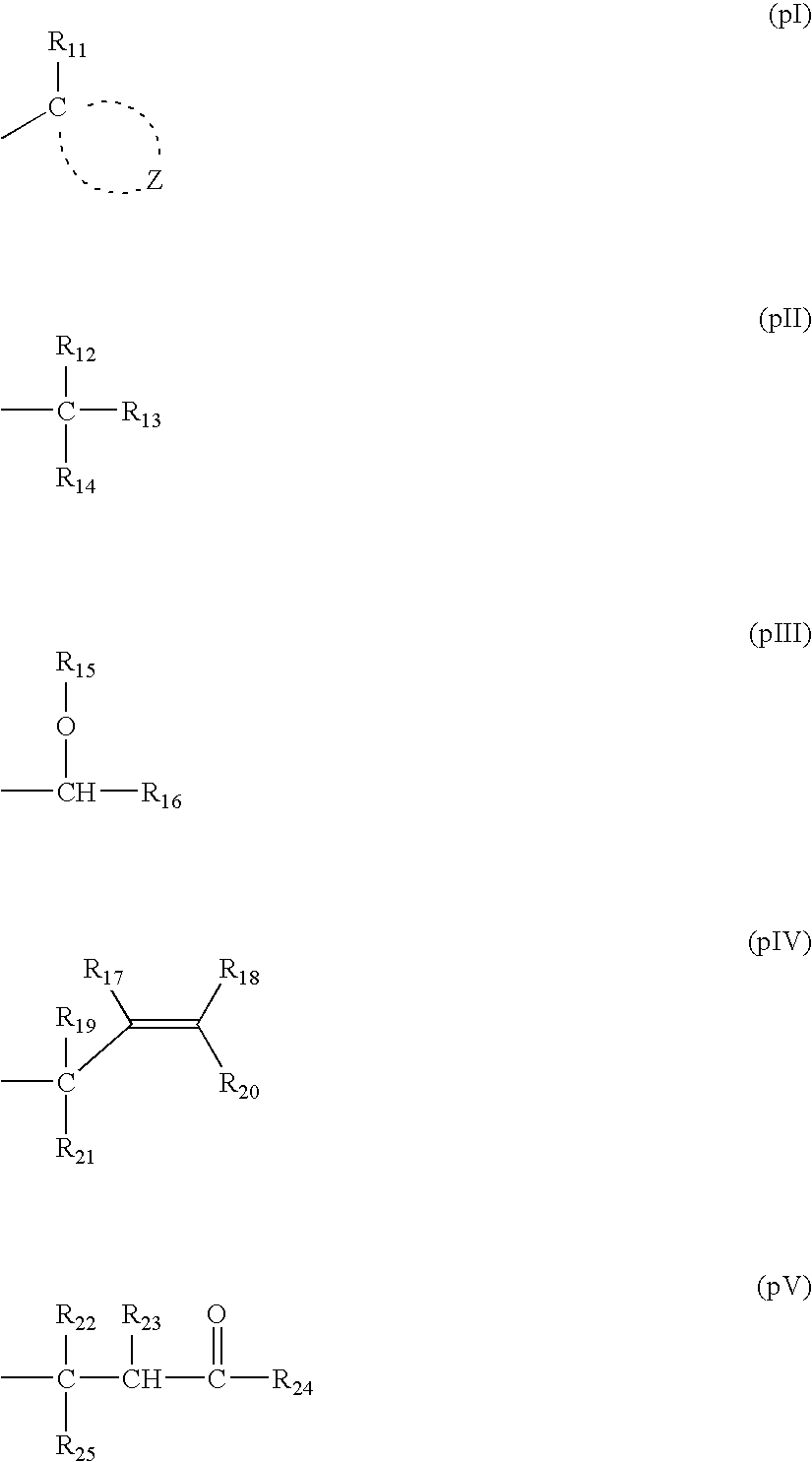

Positive resist composition and pattern forming method using the same

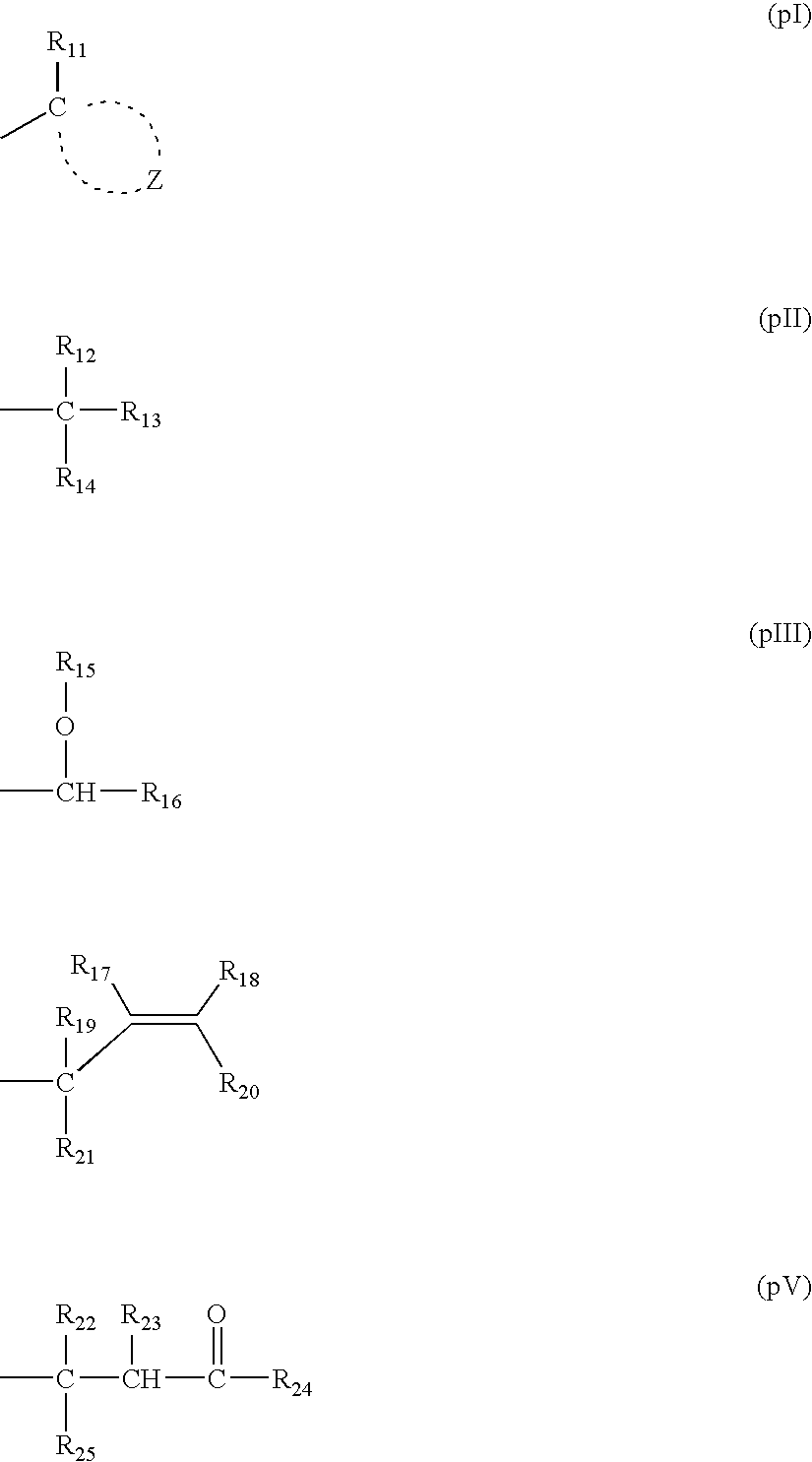

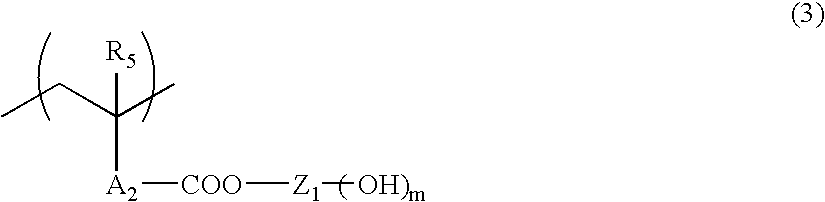

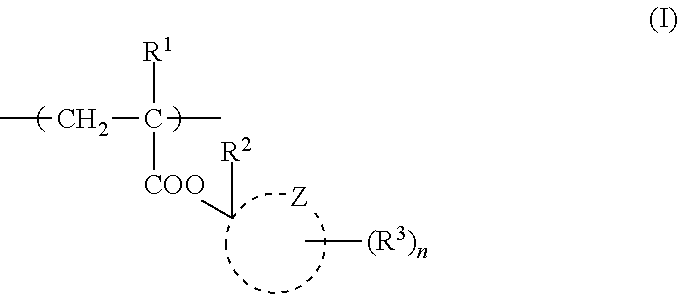

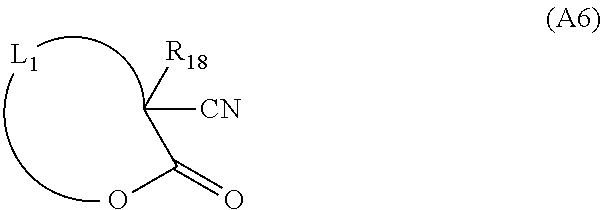

InactiveUS20110014571A1Improve filtering effectImprove line width uniformityPhotosensitive materialsRadiation applicationsResistSolubility

A positive resist composition and a pattern forming method using the resist composition are provided, the resist composition including: (A) a resin containing a repeating structural unit represented by formula (I) as defined in the specification and being capable of decomposing by an action of an acid to increase the solubility in an alkali developer; (B) an acid generator; and (C) a mixed solvent containing at least one solvent selected from the group consisting of the following Group (a) and at least one solvent selected from the group consisting of the following Groups (b) to (d):Group (a): an alkylene glycol monoalkyl ether,Group (b): an alkylene glycol monoalkyl ether carboxylate,Group (c): a linear ketone, a branched chain ketone, a cyclic ketone, a lactone and an alkylene carbonate, andGroup (d): a lactic acid ester, an acetic acid ester and an alkoxypropionic acid ester.

Owner:FUJIFILM CORP

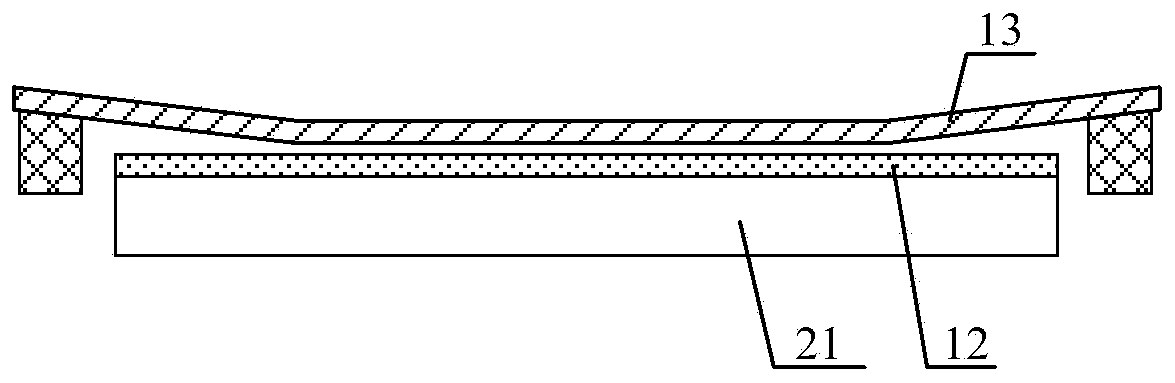

Array baseplate, manufacturing method thereof and display device

ActiveCN104849930AReduce line widthImprove line width uniformitySolid-state devicesNon-linear opticsLine widthDisplay device

The invention relates to an array baseplate, a manufacturing method thereof and a display device. The array baseplate comprises grid lines, common electrode lines, data lines, a first spacing layer and / or a second spacing layer, the grid lines, the common electrode lines and the data lines are arranged on a substrate, the first spacing layer is arranged in an overlapped area of the common electrode lines and the data lines and positioned between the common electrode lines and the data lines and extends to at least one side by preset length in the width direction of the data lines, and the second spacing layer is arranged in an overlapped area of the grid lines and the data lines and positioned between the grid lines and the data lines and extends to at least one side by preset length in the width direction of the data lines. By arranging the first spacing layer and / or the second spacing layer, when a data line metal layer is exposed, width difference of the data lines caused by difference in light reflectivity of common electrode layer metal and / or grid line layer metal and data line layer metal is reduced, so that width uniformity of the data lines is improved, risk of breaking of the data lines is lowered, and product yield is increased.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Substrate processing apparatus

InactiveUS7512456B2Improve line width uniformityLiquid processingPhotomechanical apparatusResistLine width

Owner:DAINIPPON SCREEN MTG CO LTD

Auxiliary exposure apparatus and exposure amount distribution acquisition method

ActiveUS20180095370A1Improve line width uniformityReliablySemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingResistLaser light

An auxiliary exposure apparatus is for performing auxiliary exposure of applying light of a predetermined wavelength from a laser light source to a resist film on a wafer, separately from exposure processing of transferring a pattern of a mask to the resist film applied on the wafer, and includes: a first total reflection mirror configured to reflect the light from the laser light source toward the wafer; and an imaging device including a light receiving part configured to receive light after reflected by the wafer.

Owner:TOKYO ELECTRON LTD

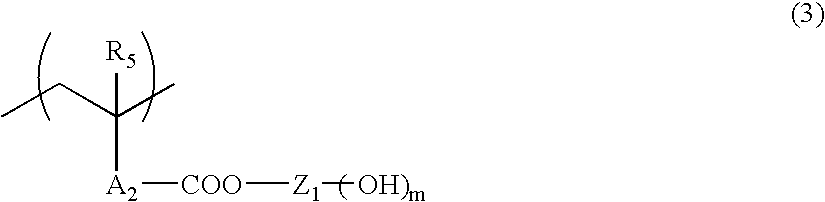

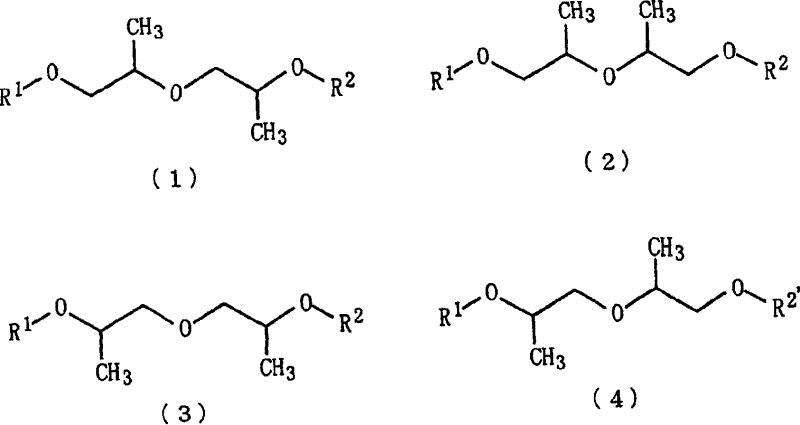

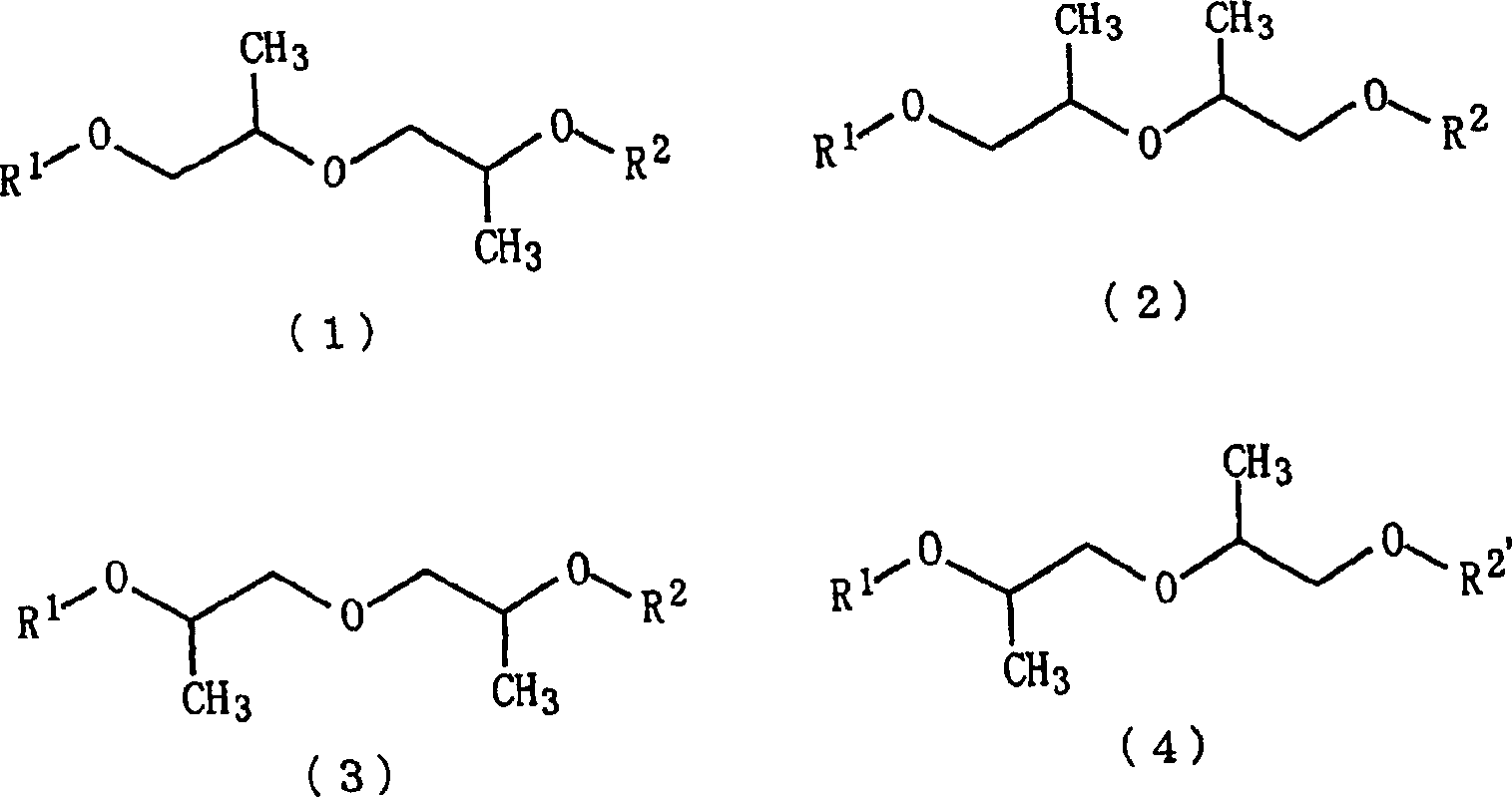

Anti-corrosion agent composition

The present invention provides a resist composition which can not only improve the solubility when preparing a resist and the adhesiveness of a resist film during development, but also have improved resist stability and excellent safety , which is a resist composition containing a resist component and an organic solvent selected from the group containing dipropylene glycol monoalkyl ether, dipropylene glycol alkyl ether acetate, etc. 1 kind of dipropylene glycol derivative, and the following formula (1)~(4) of this dipropylene glycol derivative (in the formula, R1 represents an alkyl group or an aryl group, R2 represents a hydrogen atom, an alkyl group, an aromatic group group, acetyl group or propionyl group, R2 represents acetyl group or propionyl group), the content rate of the structural isomer represented by formula (1) in the structural isomer represented by formula (1) is 30% by weight or more and less than 100% by weight % mixture of structural isomers.

Owner:DAICEL CHEM IND LTD

Novolac resin, preparation method and photoresist composition containing the resin

ActiveCN101343343AIncrease photosensitivityImproved film retentionPhotomechanical apparatusConductive material chemical/electrolytical removalWire widthHeat resistance

The invention provides phenolic varnish resin and the preparation method as well as a photoresist composition containing the phenolic varnish resin. The phenolic varnish resin is characterized in that the phenolic varnish resin is made through condensation reaction of the mixture of formaldehyde and the compound containing two aldehyde groups and one or more hydroxybenzene compounds. In the photoresist composition prepared through the phenolic varnish resin, heat resistance of the photoresist glue film is improved, and simultaneously, performances of photosensitivity, film remaining ratio and circuit wire width uniformity of the photoresist, and the like, are ameliorated, thus the photoresist composition of the invention is suitable for the LCD production.

Owner:深圳市容大感光科技股份有限公司

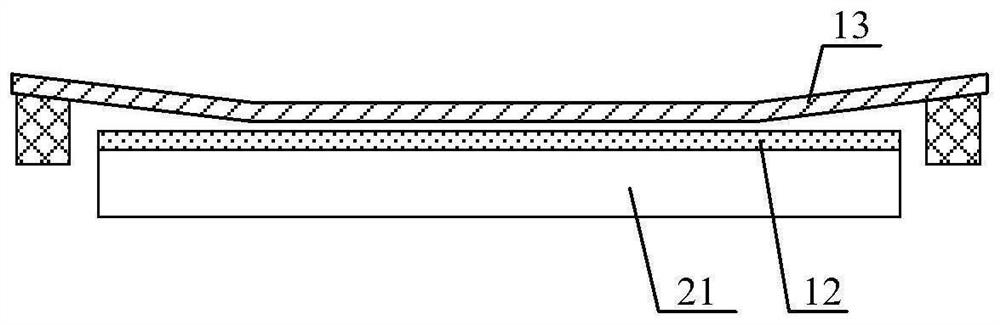

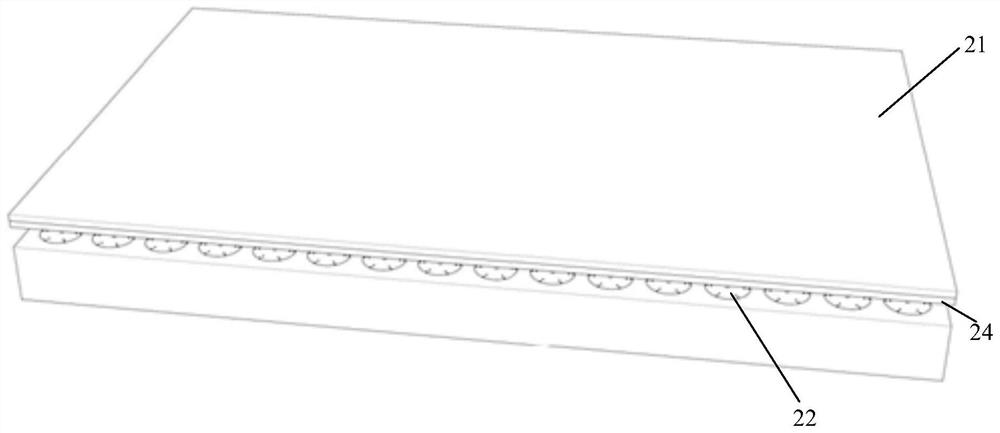

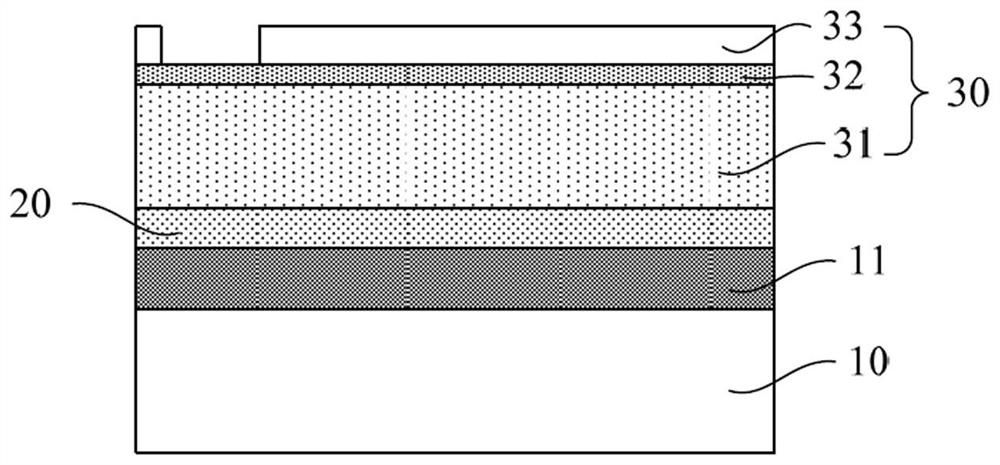

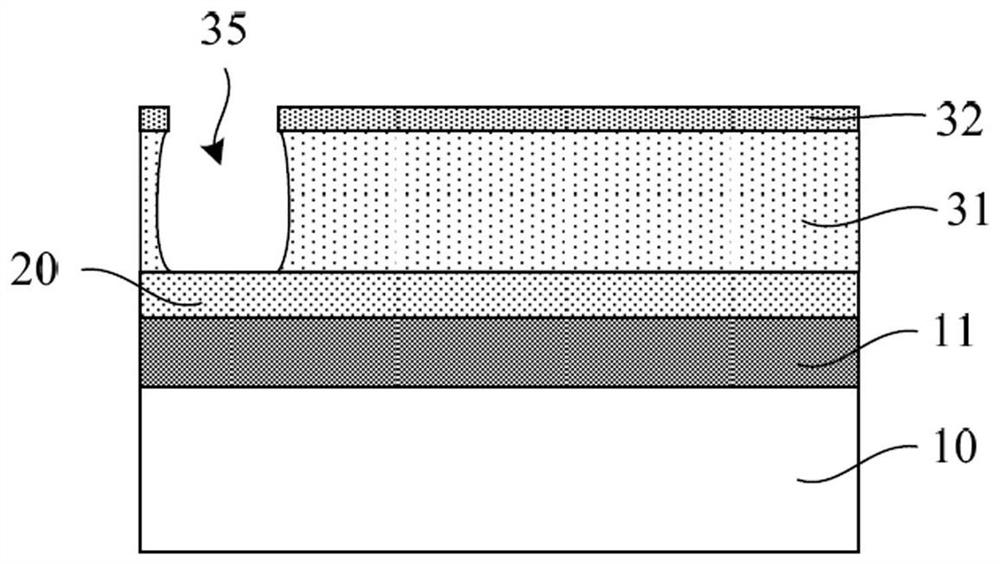

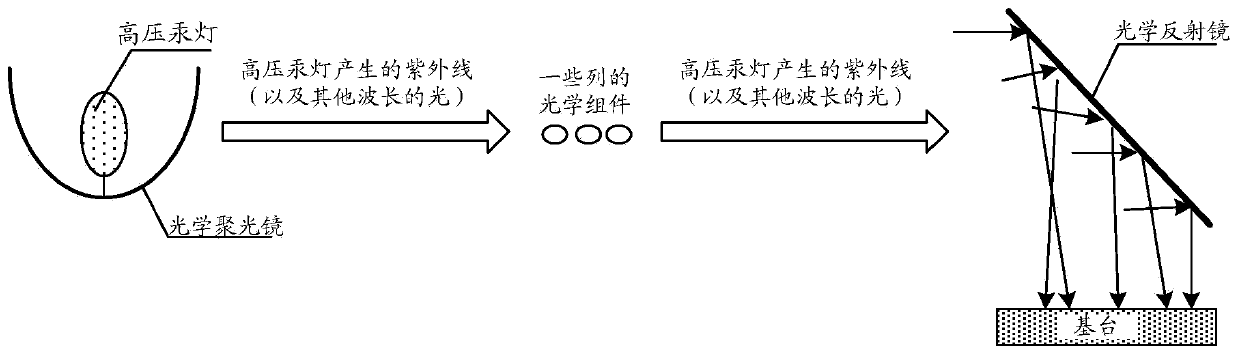

A kind of exposure equipment and exposure system

ActiveCN110320761BImprove line width uniformityConsistent temperaturePhotomechanical exposure apparatusMicrolithography exposure apparatusLine widthEngineering

The invention discloses an exposure device and an exposure system. The exposure equipment includes a pedestal and a base platform located above the base for carrying the substrate, and it is characterized in that the exposure equipment further includes a base set between the base and the base platform for adjusting the base Curvature or / and temperature adjustment of the table. In this exposure equipment, the curvature or / and temperature of the base platform can be adjusted through the adjustment device, so that the curvature of the surface of the base platform is consistent with the bending deformation of the mask plate, so that the curvature of the substrate to be exposed will also be consistent with the curvature of the mask plate The deformation phase is consistent, so that the gap between the lower surface of the mask plate at different positions and the upper surface of the substrate is consistent; or / and, the temperature at different positions of the base can be adjusted through the adjustment device, so that the temperature at different positions of the substrate remains consistent, thereby improving exposure Linewidth uniformity at different locations on the substrate.

Owner:BOE TECH GRP CO LTD +1

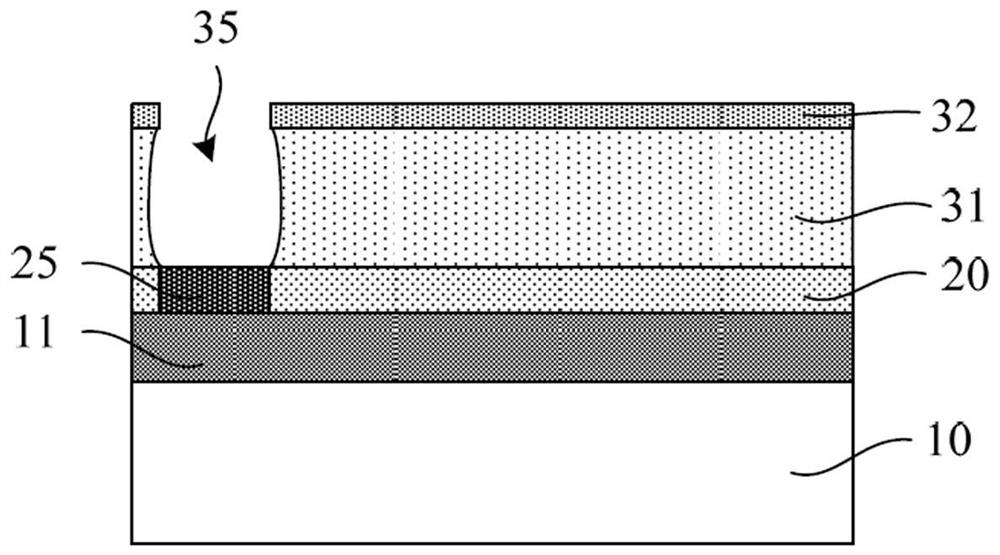

Semiconductor structure and forming method thereof

PendingCN114078693AImprove verticality of side wallsImprove flatnessSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentSemiconductor structurePhysical chemistry

The invention discloses a semiconductor structure and a forming method thereof. The forming method comprises the steps of providing a substrate; forming a to-be-doped material layer and a top hard mask layer located on the to-be-doped material layer on the substrate; performing one or more patterning processing on the top hard mask layer, the patterning processing comprising: forming a pattern structure layer on the top hard mask layer; etching the top hard mask layer by taking the graphic structure layer as a mask to form a mask opening; and removing the pattern structure layer; and after the last time of patterning processing is completed, doping ions into the to-be-doped material layer exposed out of the mask opening, and taking the to-be-doped material layer doped with ions as a target pattern layer. The etching resistance of the top hard mask layer is high, so that in the process of forming the mask opening, the influence of transverse etching on the side wall of the mask opening is small, the perpendicularity and flatness of the side wall of the mask opening are improved, the line width uniformity of the target pattern layer is correspondingly improved, and the pattern transmission precision is further improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Exposure equipment and exposure system

ActiveCN110320761AConsistent temperatureImprove line width uniformityPhotomechanical exposure apparatusMicrolithography exposure apparatusEngineeringBending of plates

The invention discloses exposure equipment and an exposure system. The exposure equipment comprises a substrate and a base, wherein the base is arranged on the substrate and is used for bearing the substrate, the exposure equipment is characterized by further comprising an adjustment device, and the adjustment device is arranged between the substrate and the base ad is used for adjusting curvatureor / and temperature. In the exposure equipment, the curvature or / and temperature of the base can be adjusted by the adjustment device, so that the curvature of a base surface is consistent with bending deformation of a mask, the curvature of a to-be-exposed substrate is also consistent with the bending deformation of the mask, and gaps in lower surfaces of the masks at different positions and an upper surface of the substrate are consistent; or / and the temperatures of the base at different positions can be adjusted by the adjustment device, so that the temperatures of the base at different positions are maintained consistent, and the linear width uniformity of the exposure substrate at different positions is improved.

Owner:BOE TECH GRP CO LTD +1

Array substrate, manufacturing method thereof, and display device

ActiveCN104849930BReduce line widthImprove line width uniformitySolid-state devicesNon-linear opticsDisplay deviceComputer science

The present invention relates to an array substrate, a manufacturing method thereof, and a display device. The array substrate includes: gate lines, common electrode lines, and data lines disposed on a substrate; The first spacer layer between the common electrode line and the data line, the first spacer layer extends to at least one side in the width direction of the data line for a predetermined length; and / or is arranged in the overlapping area of the gate line and the data line, and is located A second spacer layer between the gate line and the data line, the second spacer layer extends to at least one side in the width direction of the data line for a predetermined length. By setting the first spacer layer and / or the second spacer layer, when exposing the data line metal layer, the data caused by the difference in light reflectance between the common electrode layer metal and / or the gate line layer metal and the data line layer metal can be reduced. The difference in line width can improve the uniformity of data line width, reduce the risk of data line disconnection, and improve product yield.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com