Array baseplate, manufacturing method thereof and display device

A technology of an array substrate and a manufacturing method, applied in the field of array substrate manufacturing, can solve the problem of increasing the coupling capacitance between a data line and a common electrode line or a data line and a scanning line, increasing the coupling capacitance between a data line 4 and a common electrode line, adverse effects, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

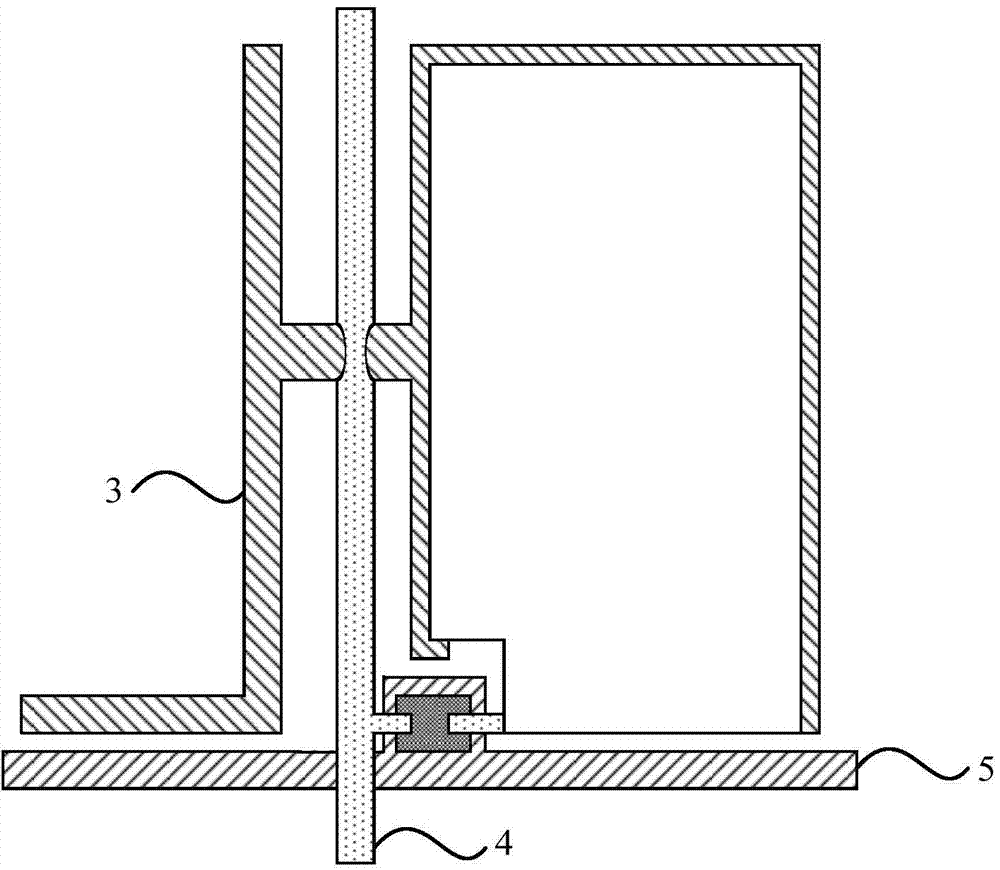

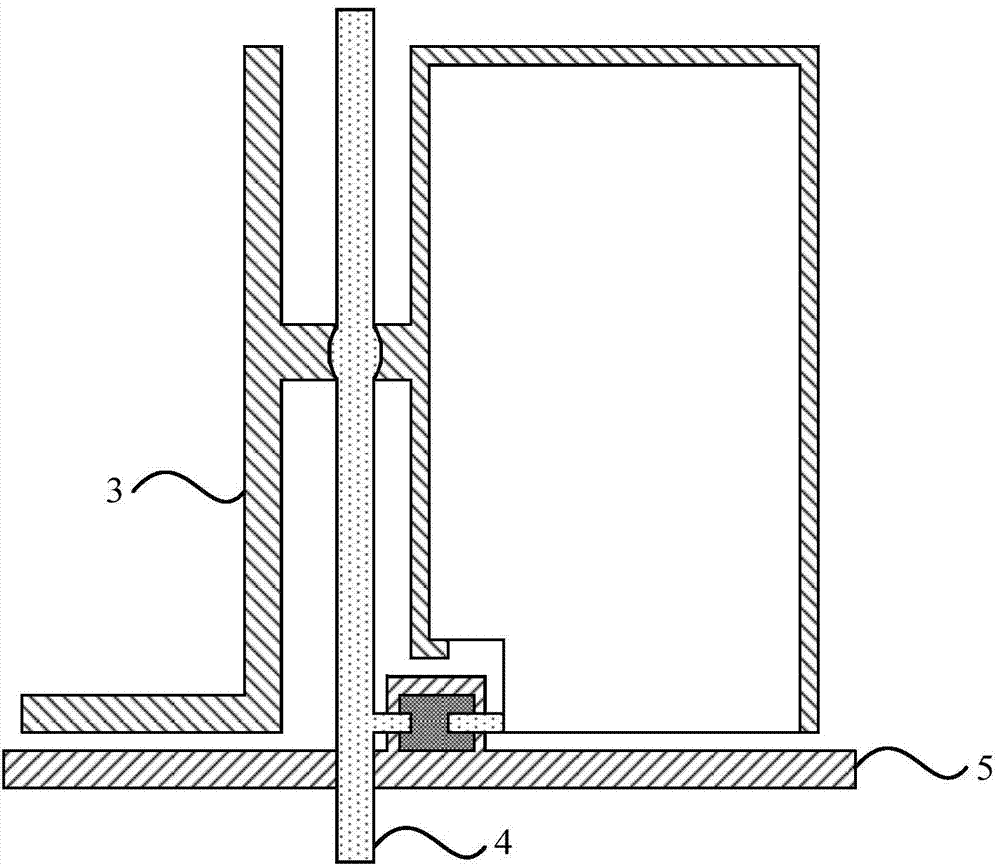

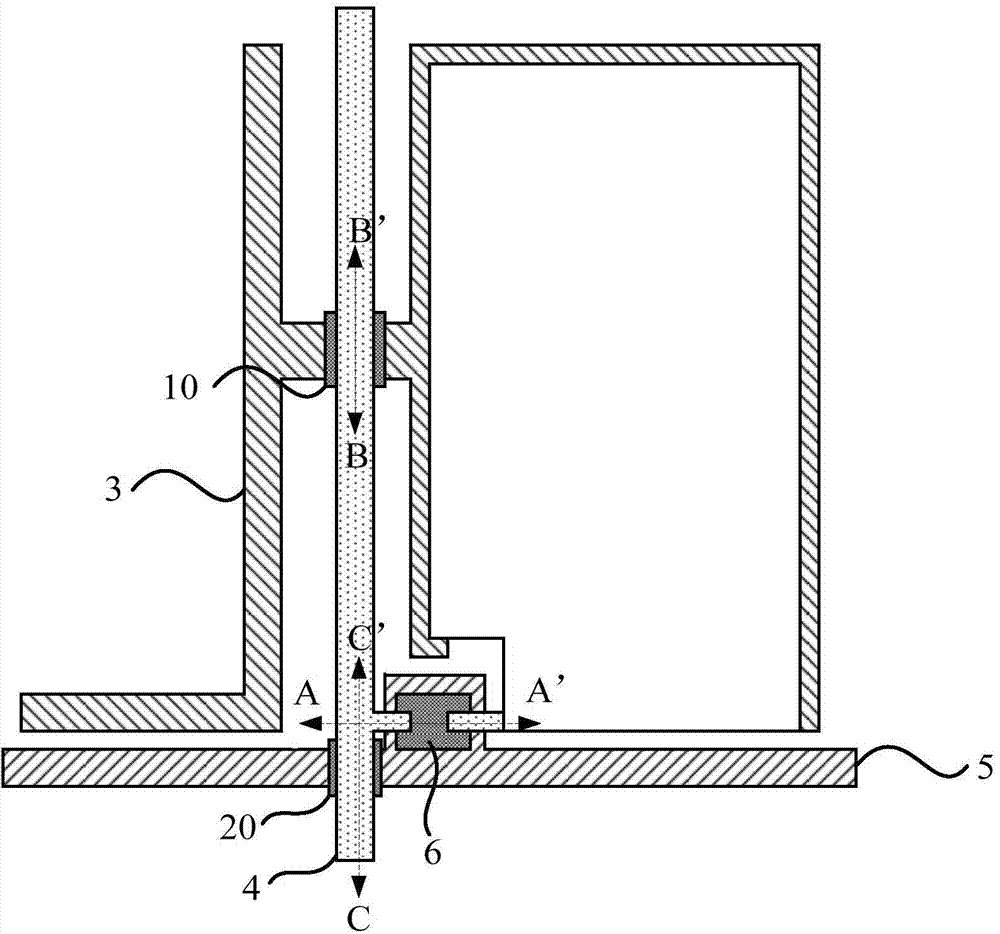

[0073] Such as image 3 As shown, the array substrate according to one embodiment of the present invention includes:

[0074] base1;

[0075] Gate lines 5, common electrode lines 3 and data lines 4 arranged on the substrate;

[0076] The first spacer layer 10 disposed in the first overlapping area of the common electrode line 3 and the data line 4 and located between the common electrode line 3 and the data line 4, the first spacer layer 10 extends at least in the width direction of the data line 4 One side is extended to a preset length;

[0077] and / or

[0078] The second spacer layer 20 arranged in the second overlapping area of the gate line 5 and the data line 4, and between the gate line and the data line 4, the second spacer layer 20 in the second overlapping area is in the width direction of the data line 4 The top extends to at least one side for a preset length.

[0079] The first spacer layer 10 can increase the distance between the common electrode line ...

Embodiment 2

[0091] Such as Figure 7 As shown, preferably, according to yet another embodiment of the present invention, the array substrate further includes:

[0092] a gate 2 disposed on the substrate 1,

[0093] The second spacer layer 20 is also arranged in the third overlapping area between the gate 2 and the data line 4, and is located between the gate 2 and the data line 4,

[0094] The second spacer layer 20 in the third overlapping region extends to at least one side in the width direction of the data line 4 by a predetermined length.

[0095] Compare Figure 7 and image 3 It can be seen that there is an overlapping area between the gate 2 and the data line 4 in the second embodiment, which is intuitively expressed as Figure 7 The gate 2 in the ratio image 3 The gate 2 is large, not only located under the active layer 6, but also located under the data line 4, the specific cross-sectional view is as follows Figure 9 shown.

[0096] Since multiple pixel areas in the arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com