Substrate processing method and substrate processing apparatus

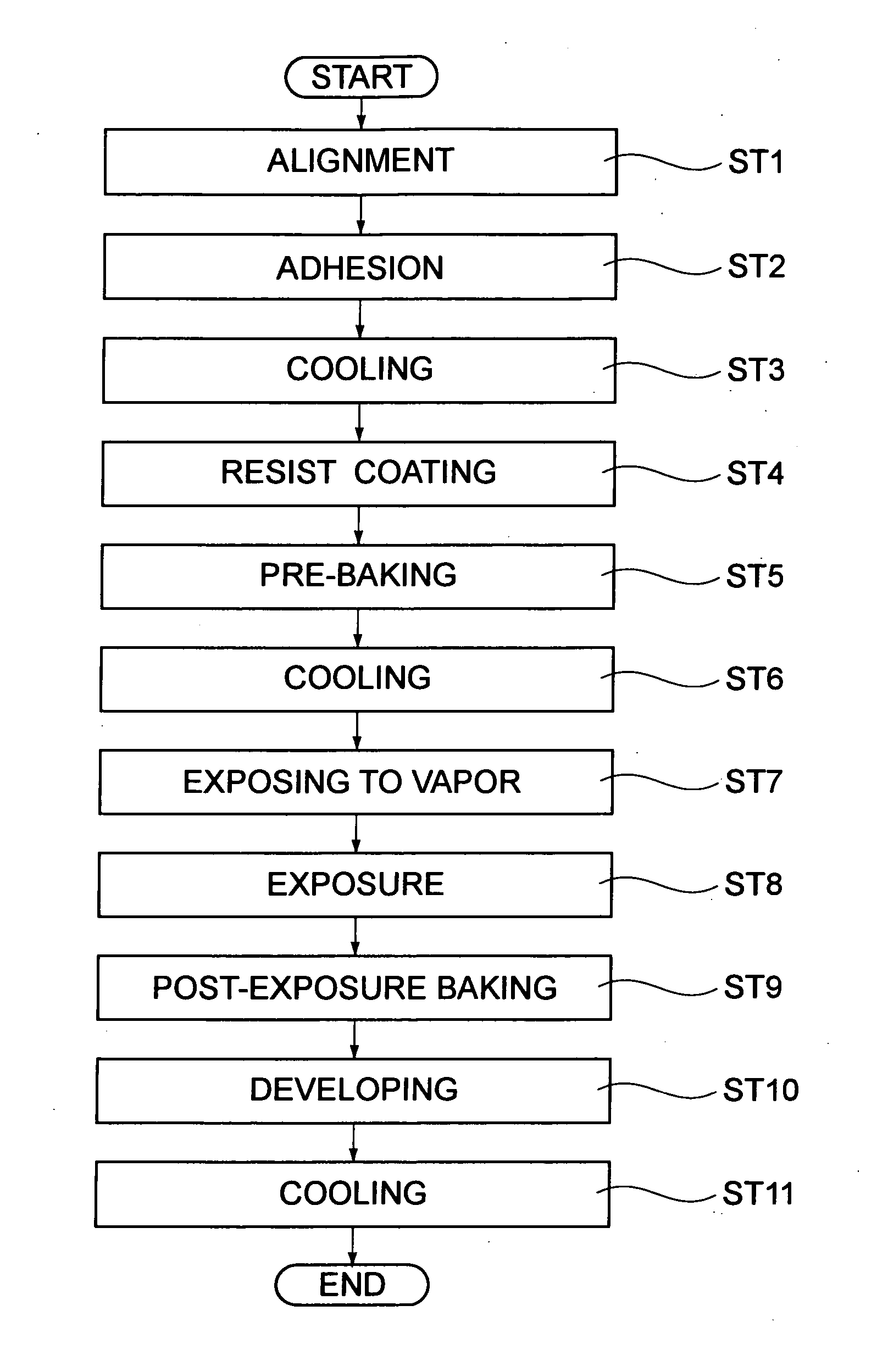

a substrate processing and substrate technology, applied in the direction of photosensitive material processing, transportation and packaging, coatings, etc., can solve the problem that the air down flow described above is not able to remove the impurities of molecule level, and achieve the effect of improving the uniformity of line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

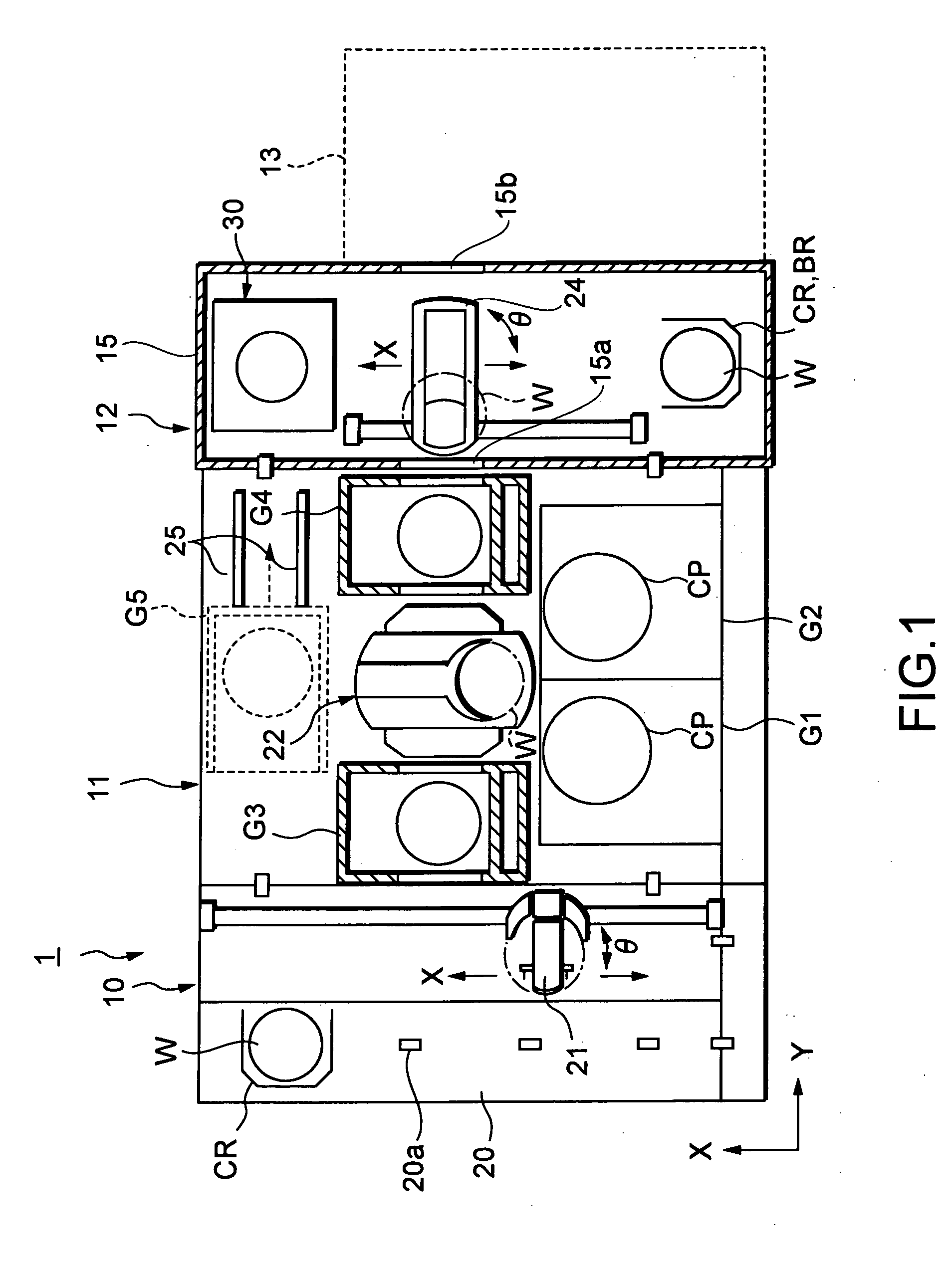

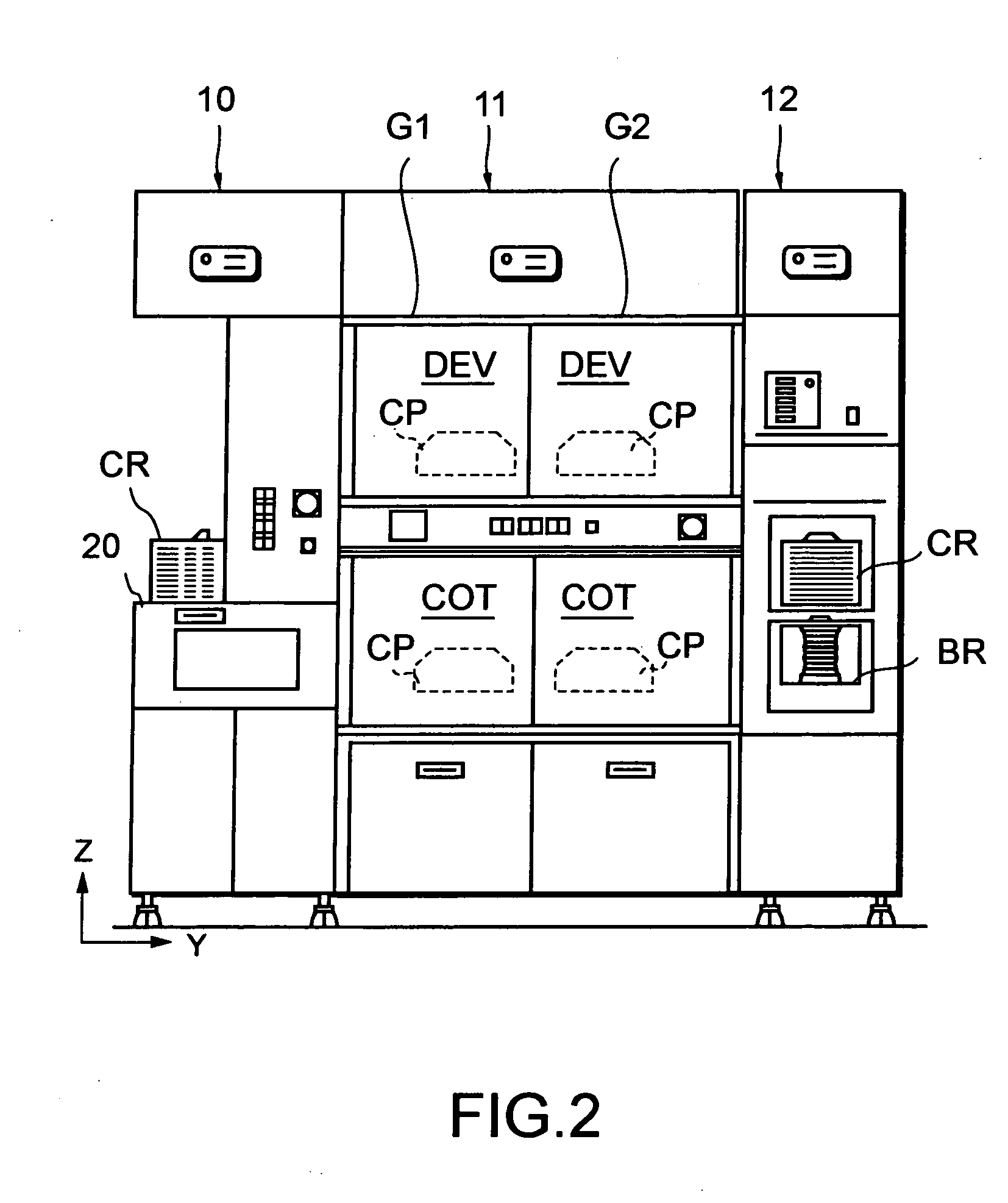

first embodiment

[0039]FIG. 4 is a sectional view of the vapor processing unit 30 relating to the above-mentioned In this vapor processing unit 30, for example, on an upper portion of cylindrically shaped holding table 34, provided for holding the wafer W, for example, a cylindrically shaped lid 32 is disposed. A lifting mechanism 26 configured of an air cylinder enables the lid 32 to be lifted and lowered. An O-ring for seal is attached to the lower end of the lid 32. When the lid 32 is lowered by the lifting mechanism 26, a processing chamber R is formed as the lower end portion thereof touches the holding table 34.

[0040] A plurality of holes 34a, for example three, pierces through the holding table 34. Three Support pins 29 supporting the wafer W from the back side are provided and a lifting cylinder 36 enables the support pins 29 to protrude and sink to the surface of the holding table 34 through the holes 34a. Thereby, the wafer W can be delivered to and received from the wafer transfer mechan...

second embodiment

[0048]FIG. 6 is a sectional view showing a vapor processing unit according to the present invention. Incidentally in FIG. 6, the same numerals and symbols will be used to designate the same components as those in FIG. 4, and the explanation thereof will be omitted. A heating plate 43 heating the wafer W by placing the wafer W thereon is disposed on the holding table 41 in the vapor processing unit 40. The heating plate 43 has, for example, a heater 45 and the wafer W is heated thereby. On the heating plate 43, three holes 43a are formed and the supporting pins 29 protrude and sink therethrough. With such configuration, the wafer W can be delivered and received from the outside. Meanwhile, a supply port 41a for supplying the vapor from the vapor generator 35 into the processing chamber R is formed on the holding table 41.

[0049] With regard to the processing steps of the vapor processing unit 40, first of all, the wafer W is placed on the heating plate 43 and the lid 32 is lowered to ...

fourth embodiment

[0054]FIG. 9 is a sectional view showing a vapor processing unit according to the present invention. Incidentally, in FIG. 9, the same numerals and symbols will be used to designate the same components as those in FIG. 4, and the explanation thereof will be omitted. In the central portion of the lid 32 in the vapor processing unit 60, an air supply port 32b is formed for supplying air into the processing chamber R from the air supply source 54 through a supply pipe 57. The air from the air supply source 54 is supplied heated, for example, with a heater 55 to a predetermined temperature, for example, 50° C. to 100° C. On the inside ceiling of the lid 32, a defusing member 56 is attached for defusing the air supplied as above uniformly inside the processing chamber R. A plurality of small holes 56a are formed on the defusing member 56. In such manner, the air spreads out as far as the edge of the wafer W.

[0055] Furthermore, although not illustrated, similar to each of the aforesaid em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| humidity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com