Patents

Literature

140 results about "Far ultraviolet" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Extreme ultraviolet, with a wavelength of 121nm-10nm. Near ultraviolet (NUV) is the one closest to visible or optical light, while extreme ultraviolet is the farthest from visible light and closest to x-rays. Extreme ultraviolet (EUV) also contains more energy per photon than near or far ultraviolet light.

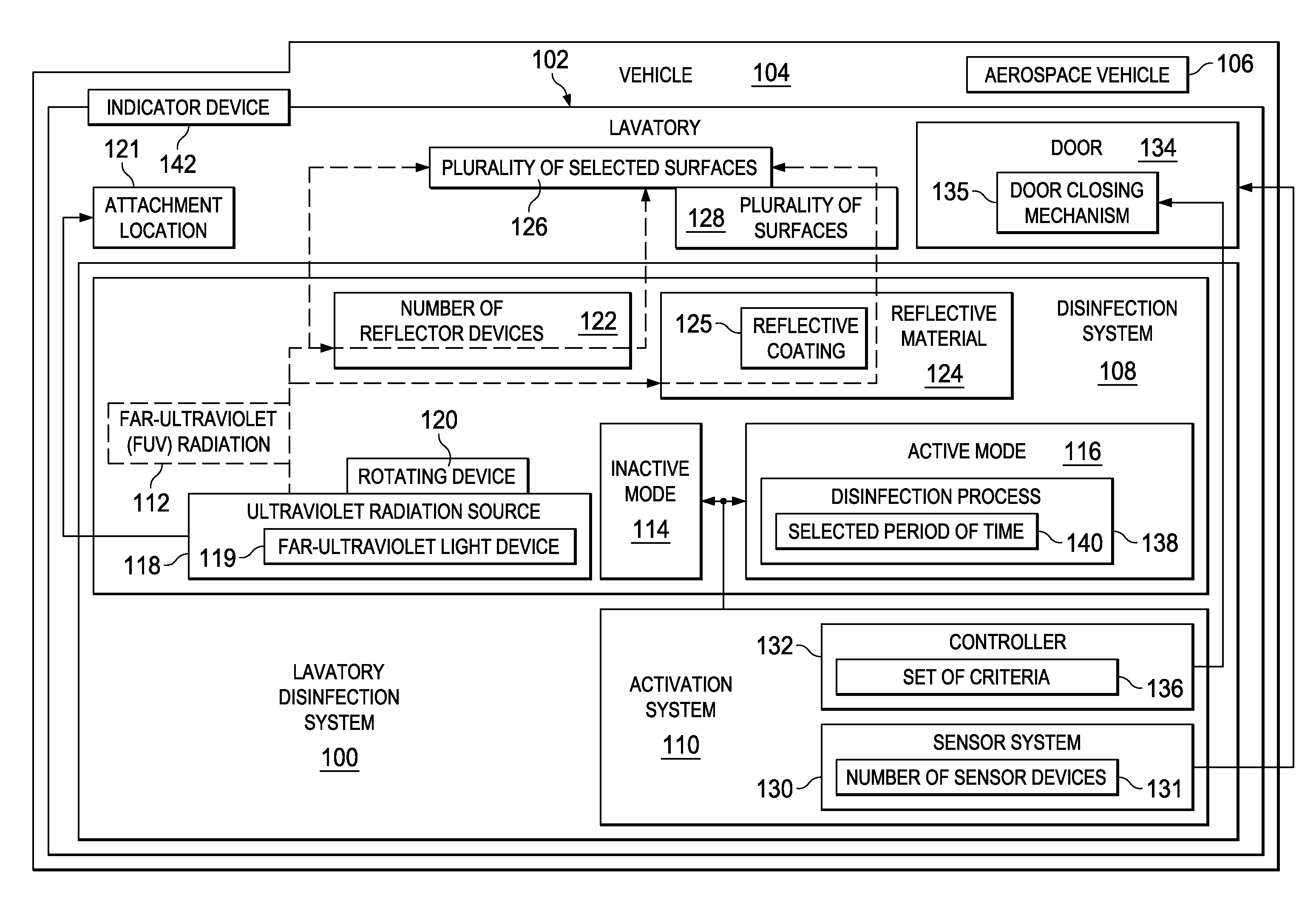

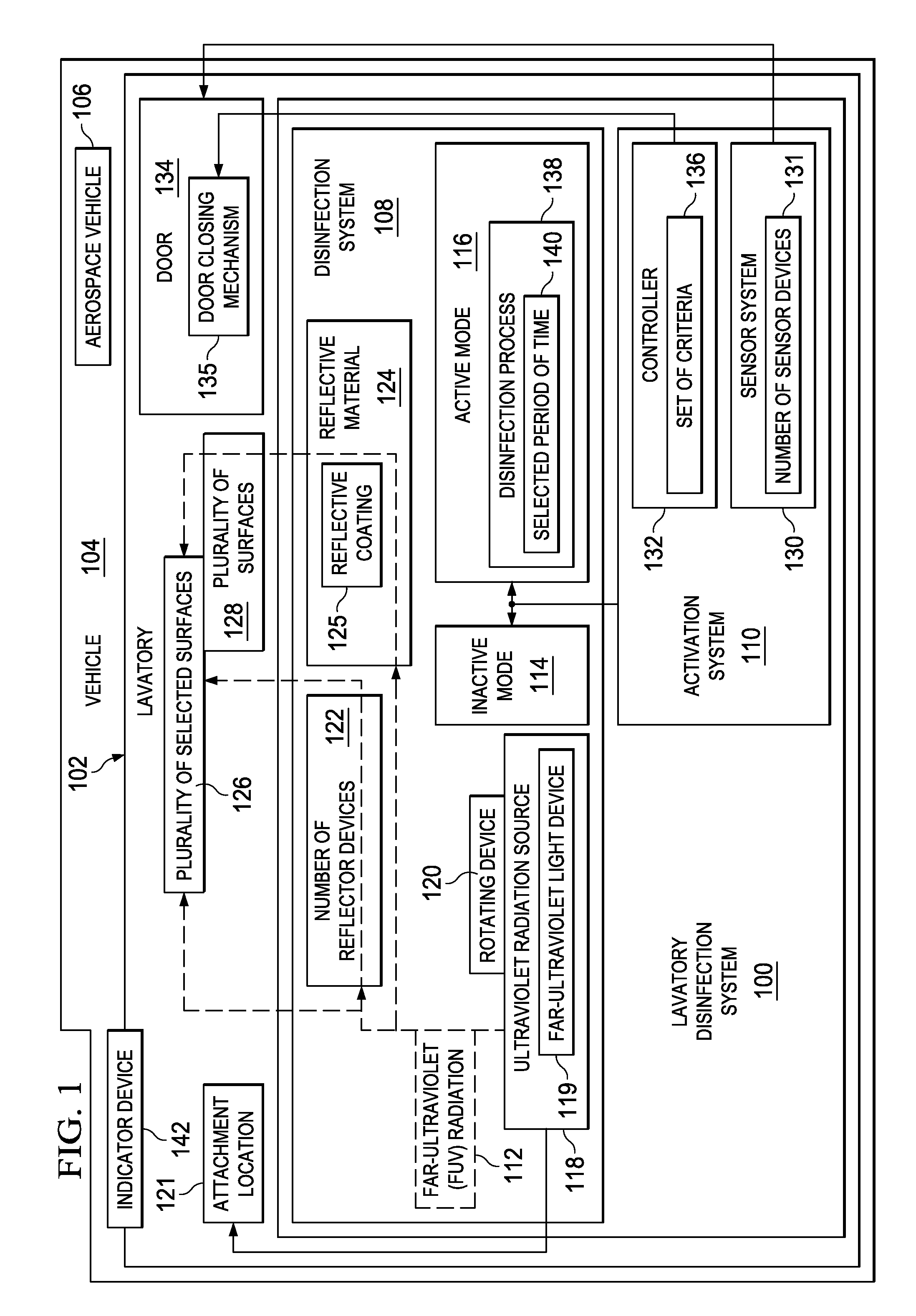

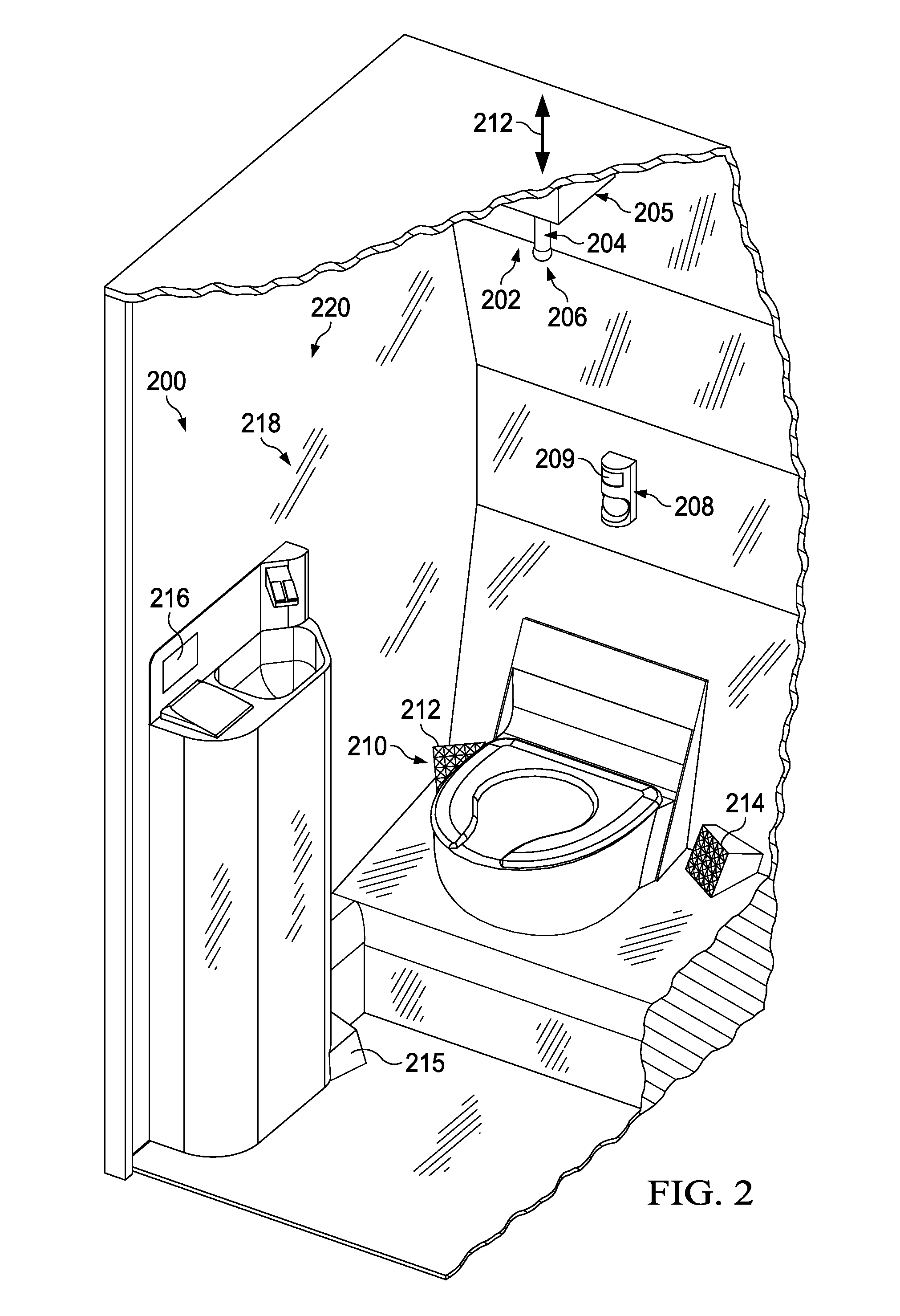

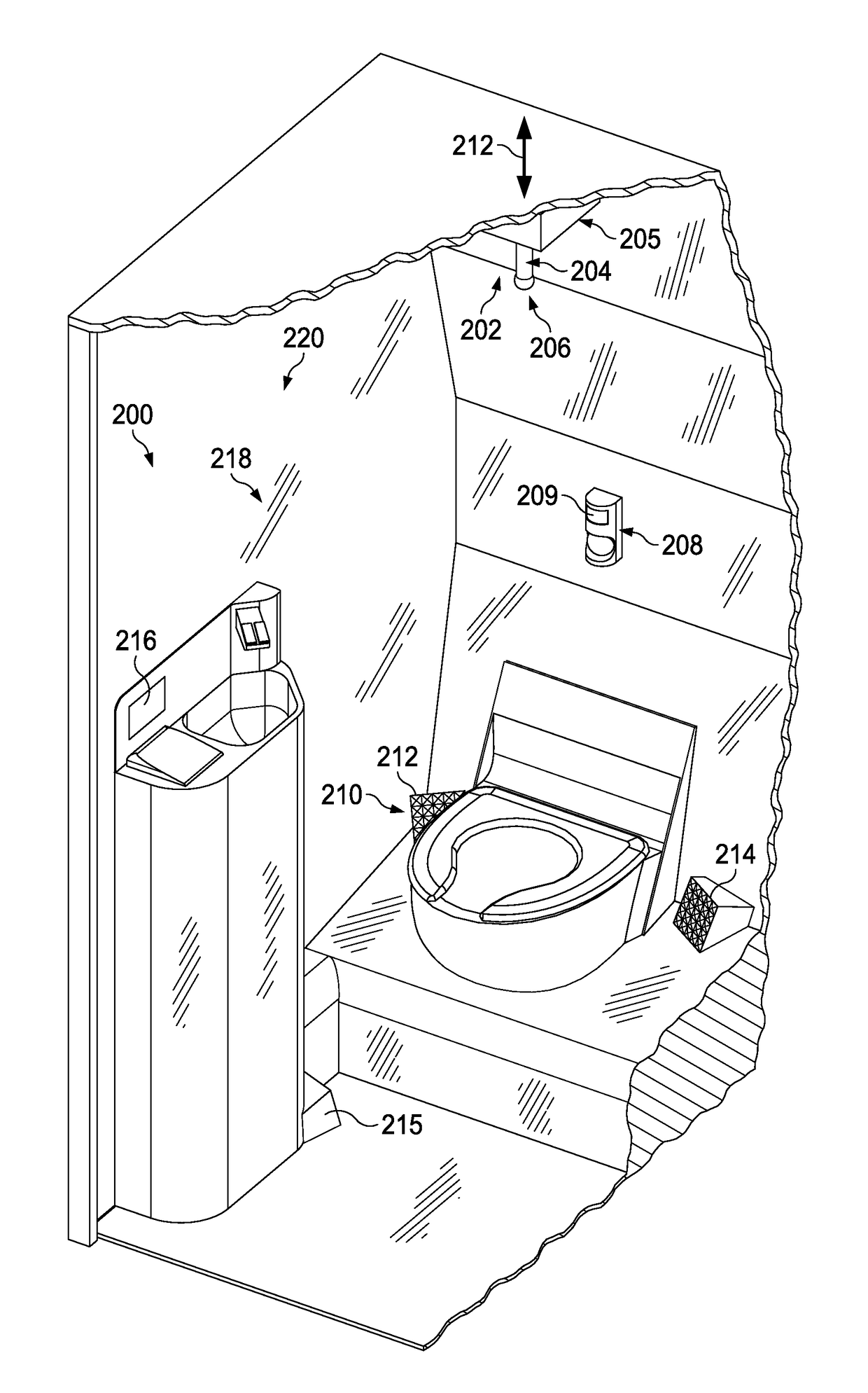

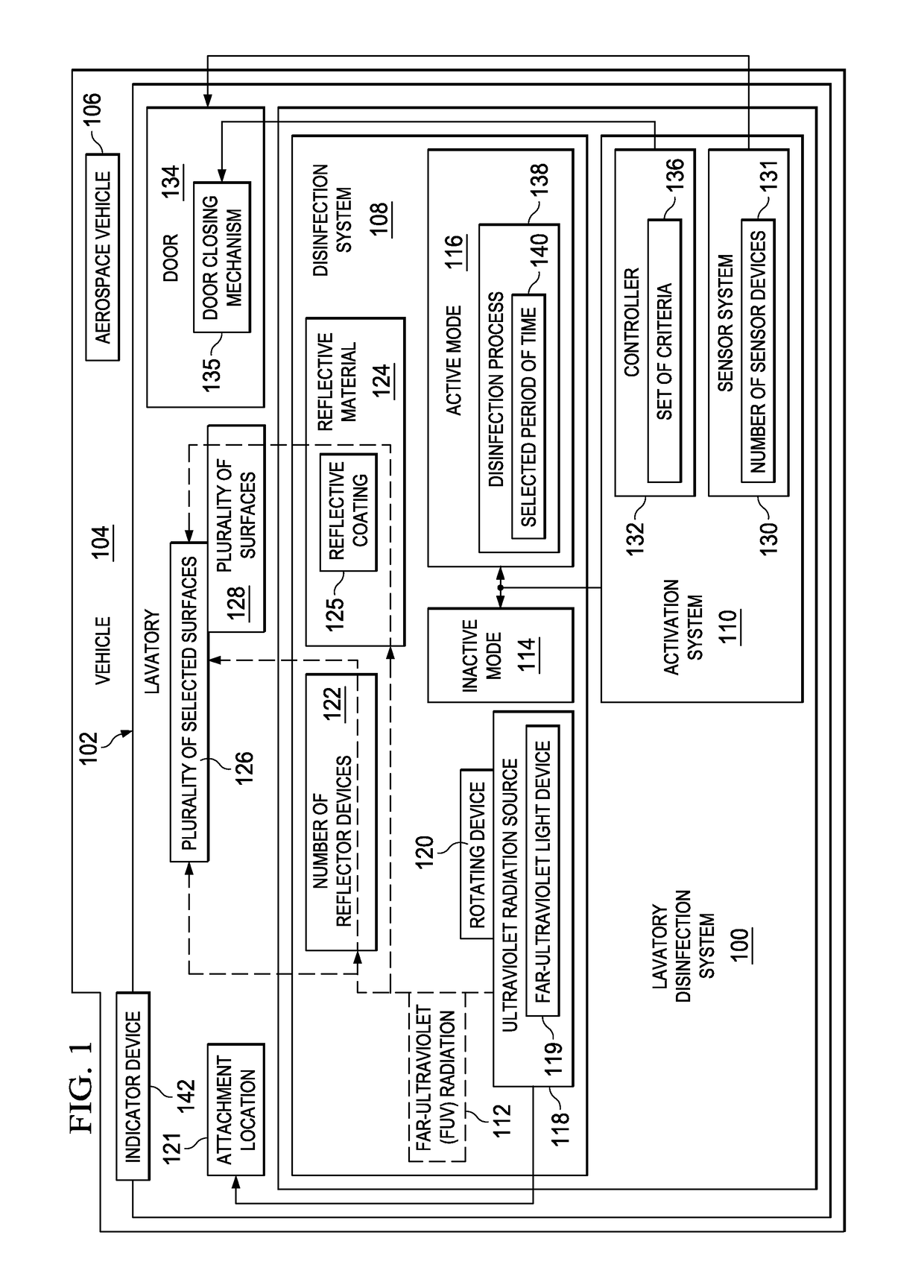

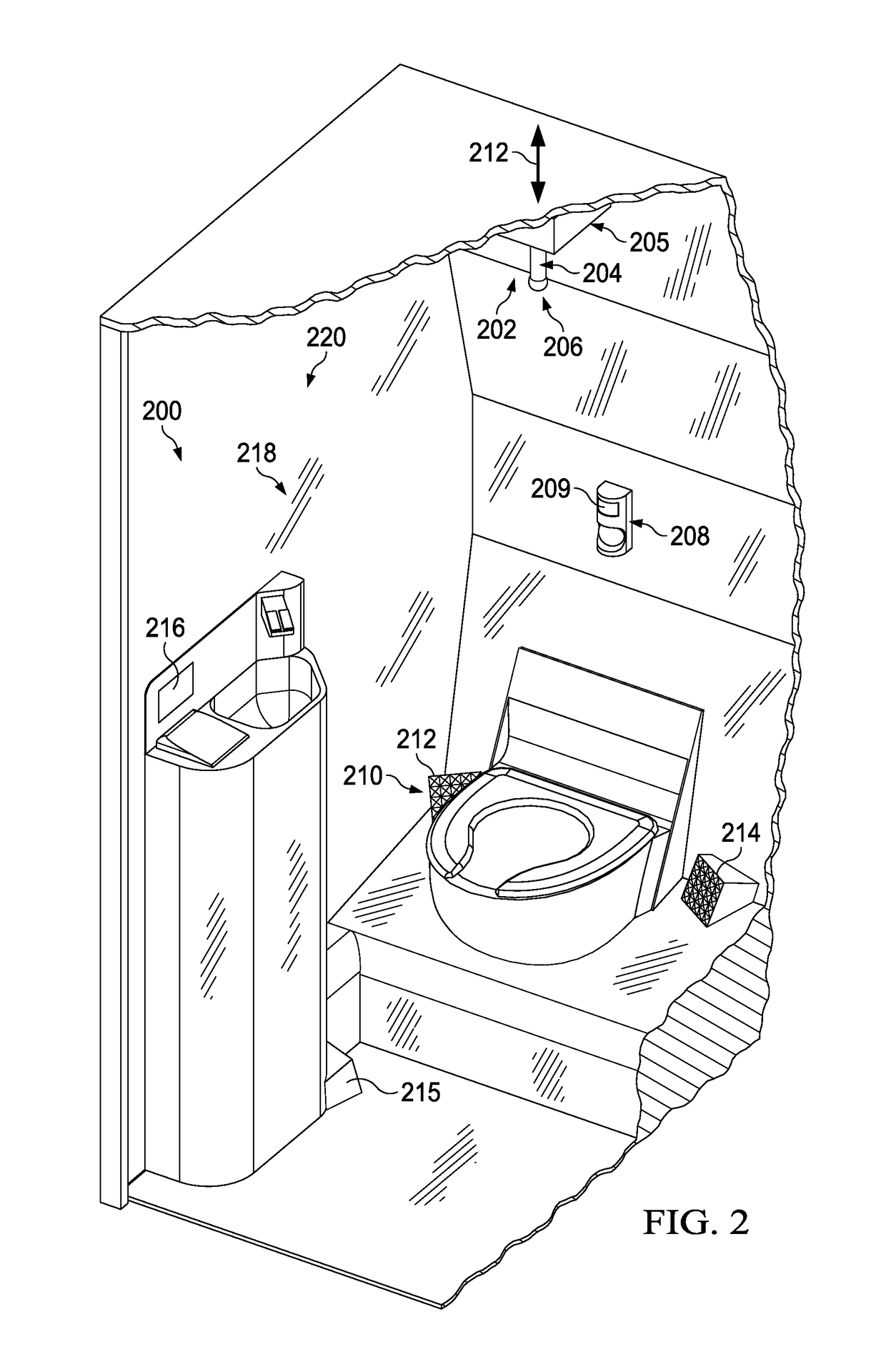

Lavatory Disinfection System

A method and apparatus for disinfecting a lavatory inside a vehicle in response to a set of criteria being met. A determination is made as to whether a set of criteria for activation of a disinfection system that emits far-ultraviolet radiation to perform a disinfection process inside a lavatory has been met. In response to a determination that the set of criteria has been met, the disinfection system is activated to perform the disinfection process inside the lavatory using the far-ultraviolet radiation.

Owner:THE BOEING CO

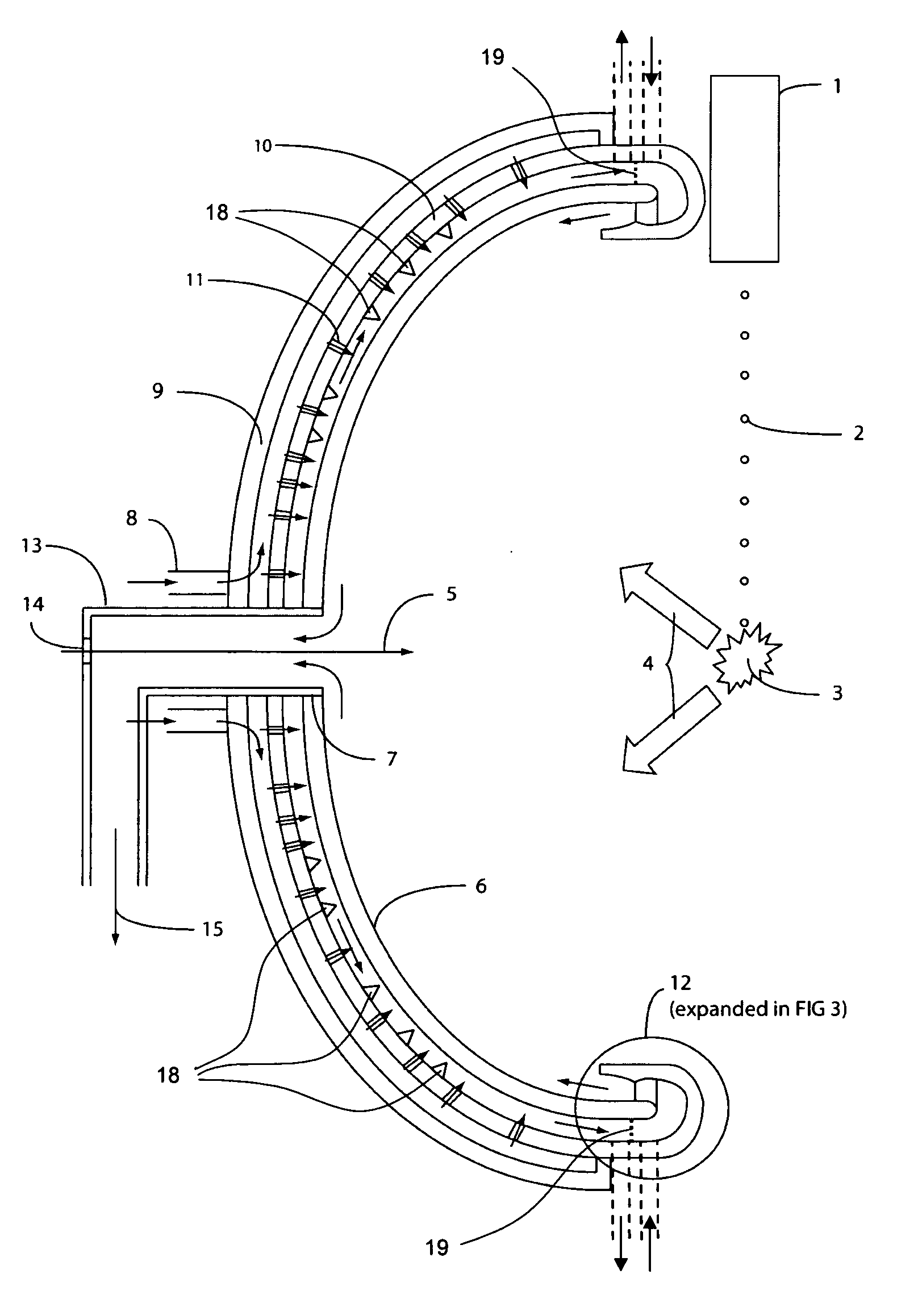

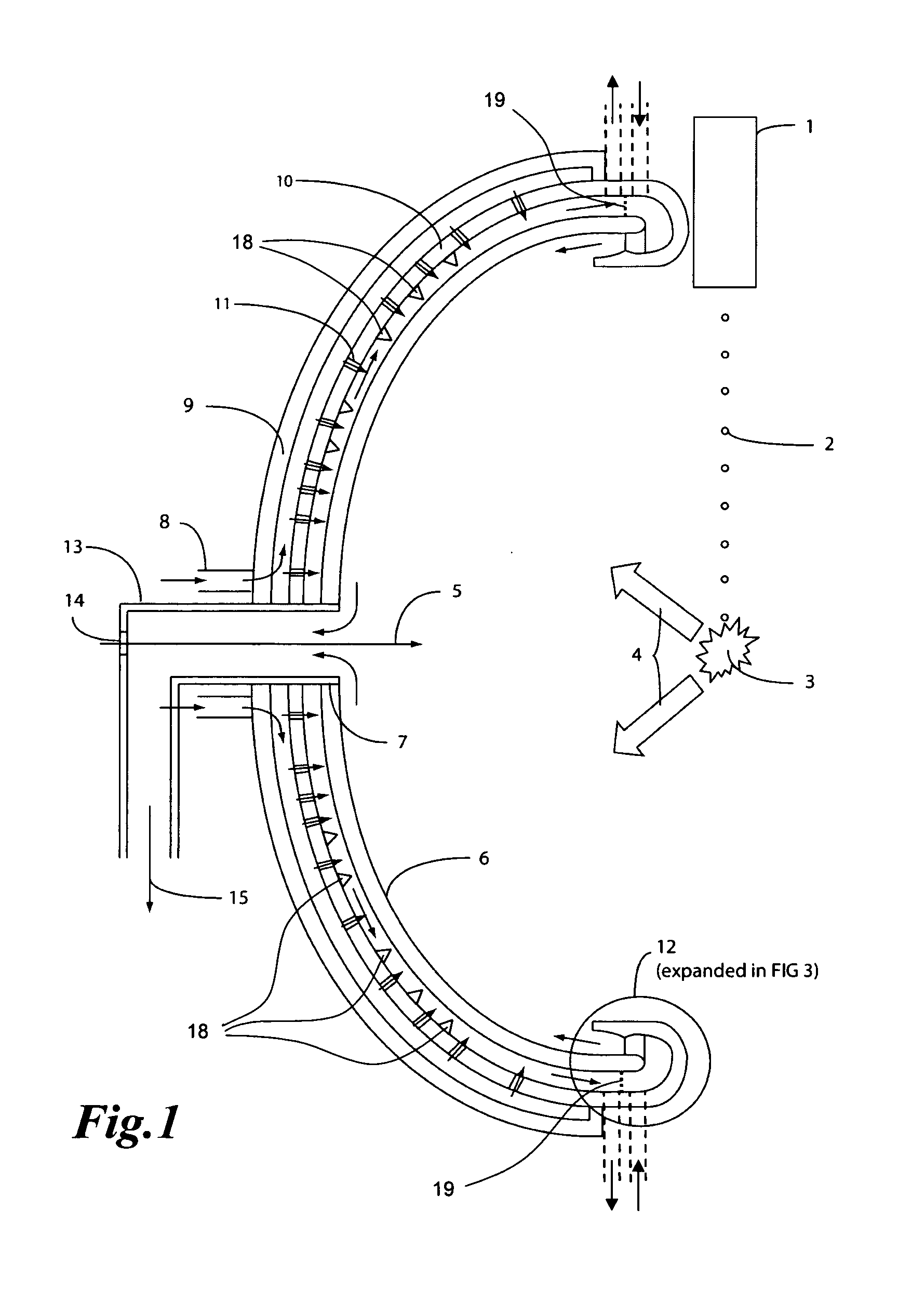

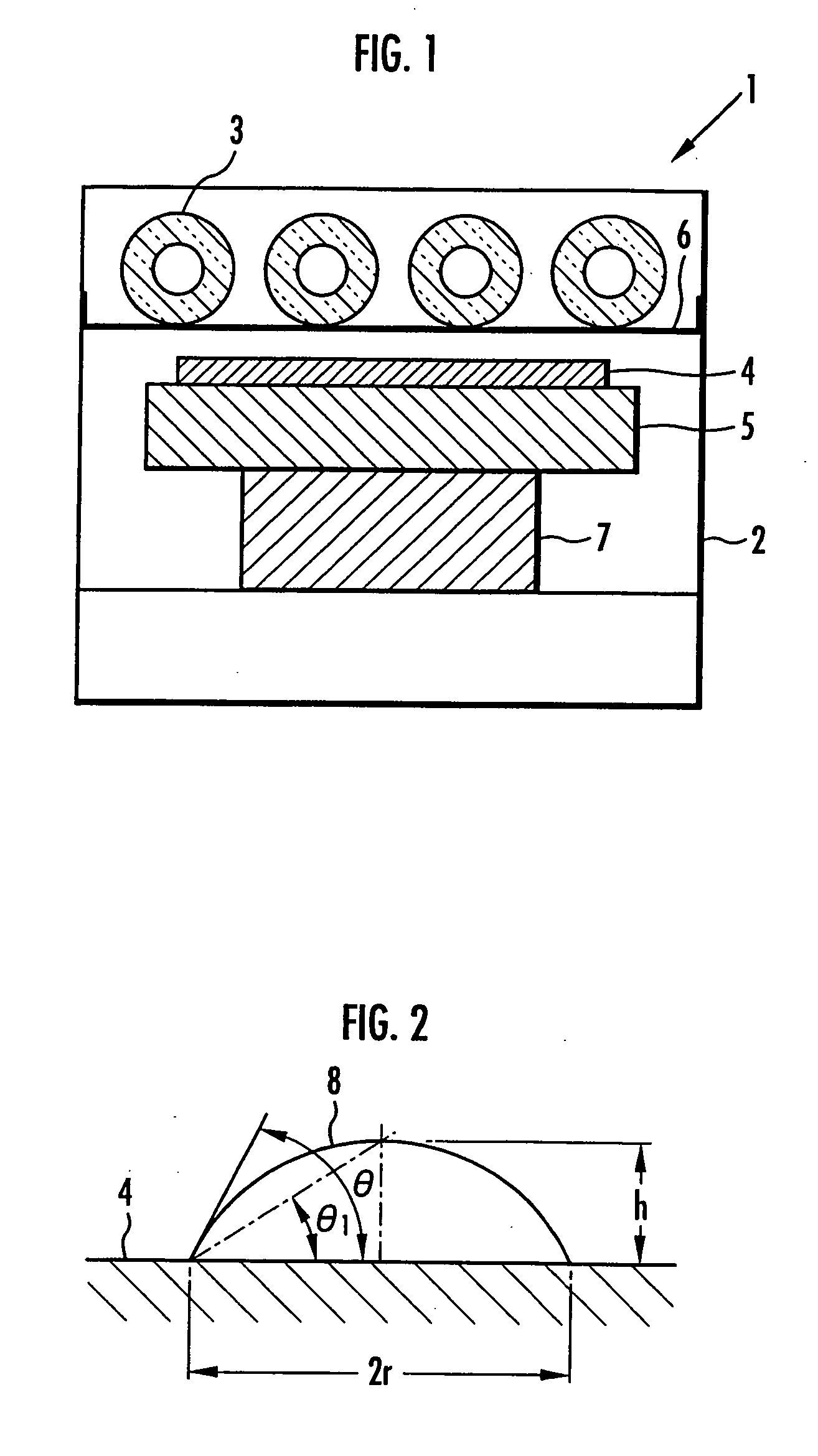

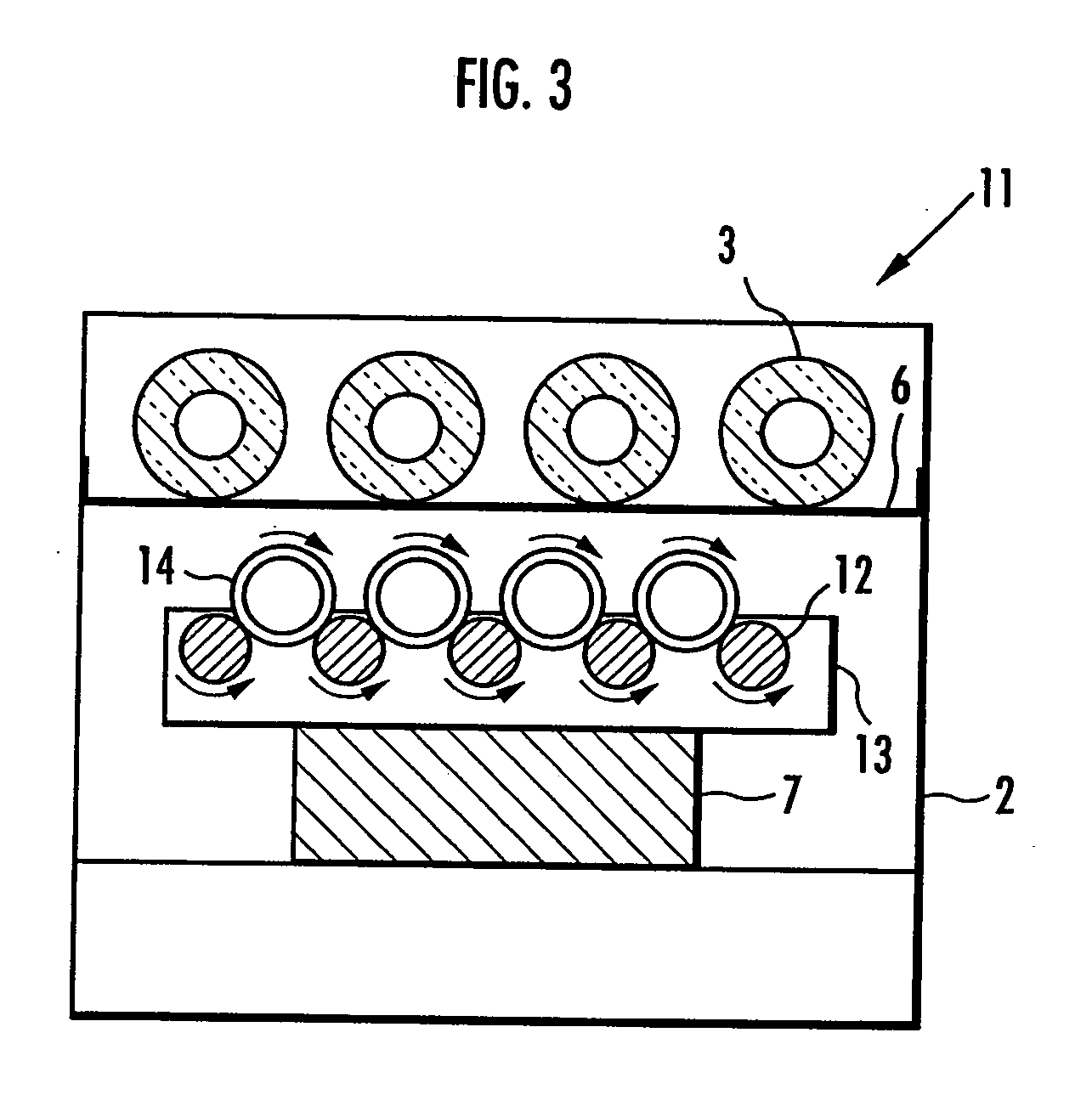

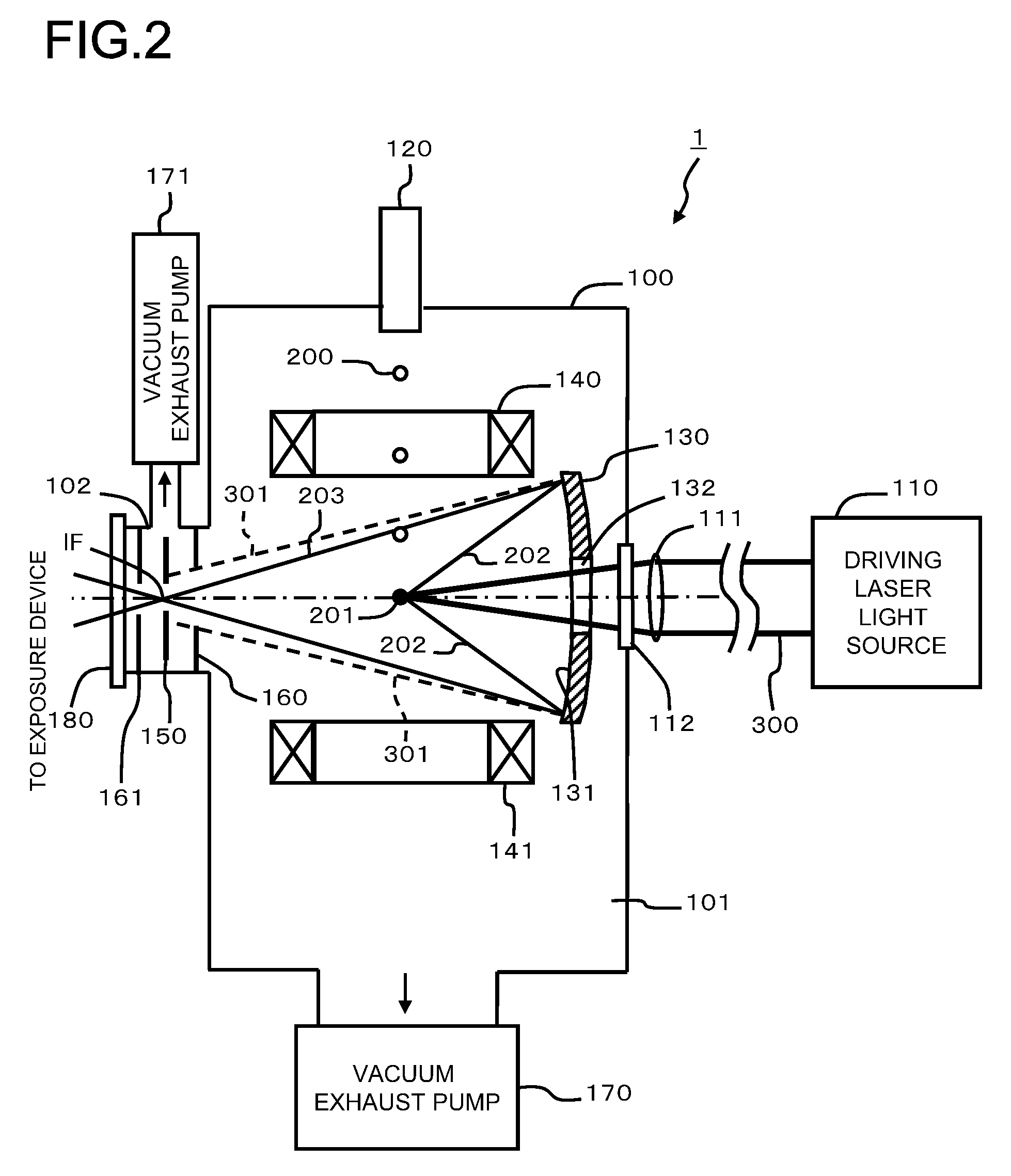

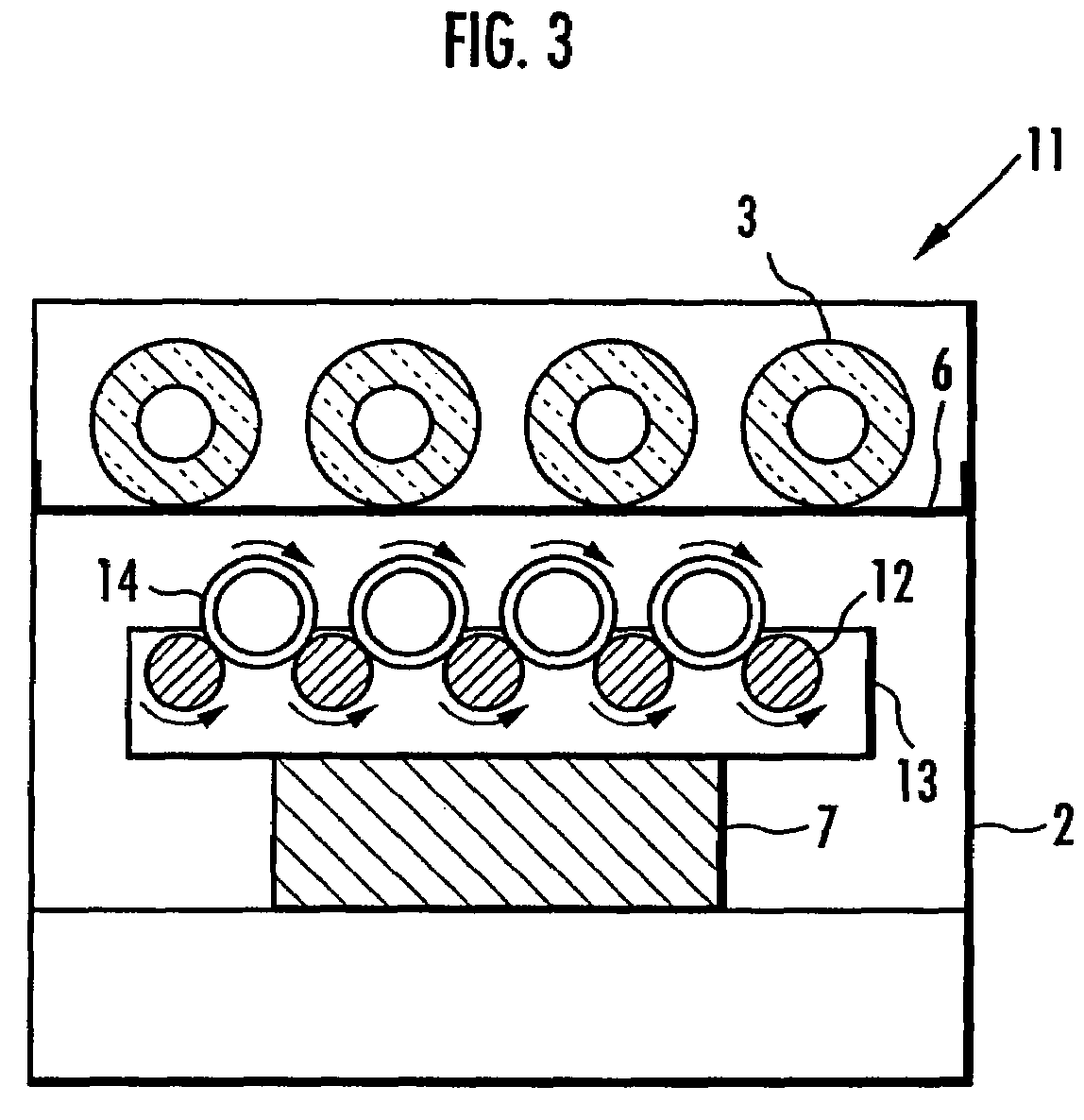

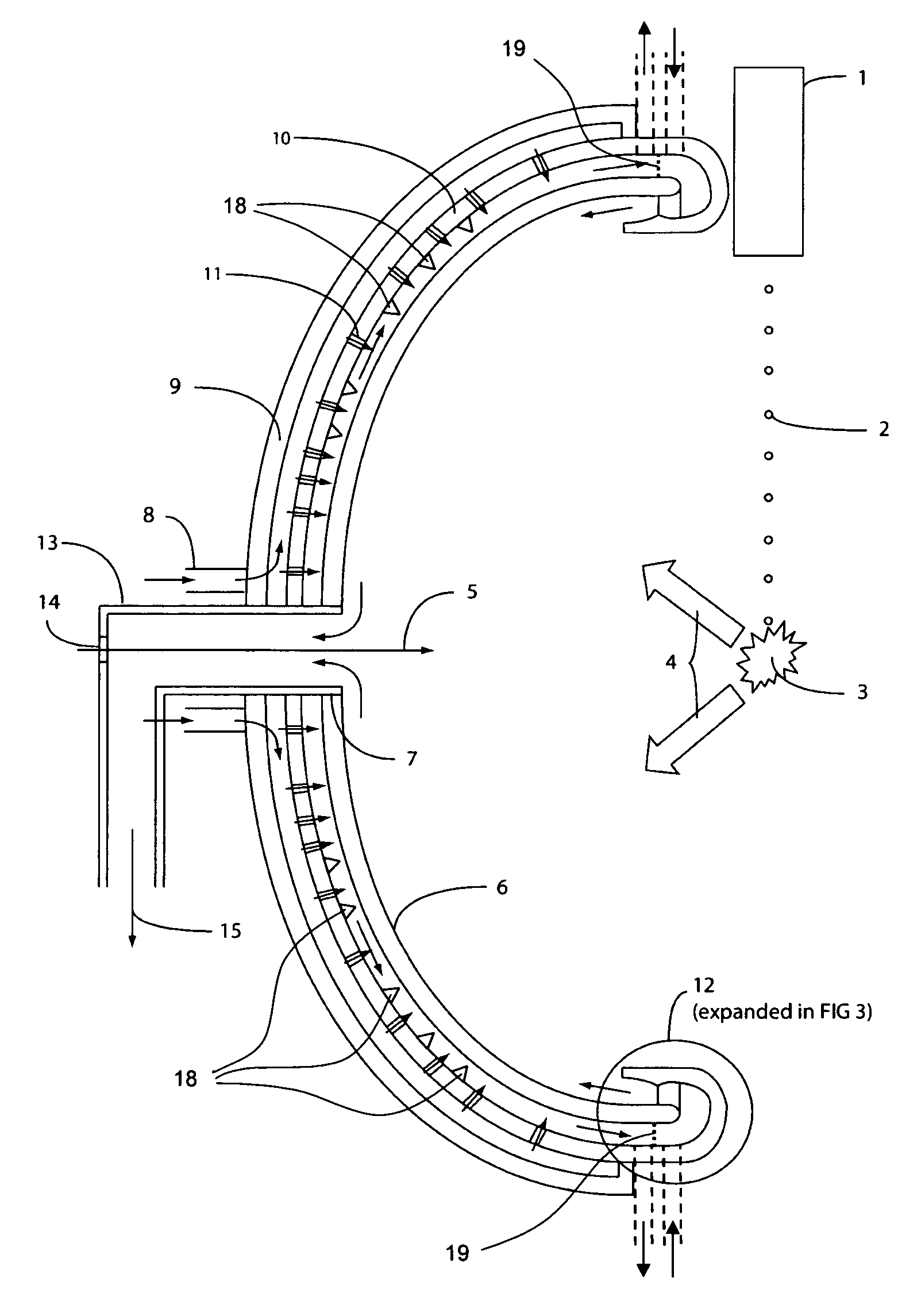

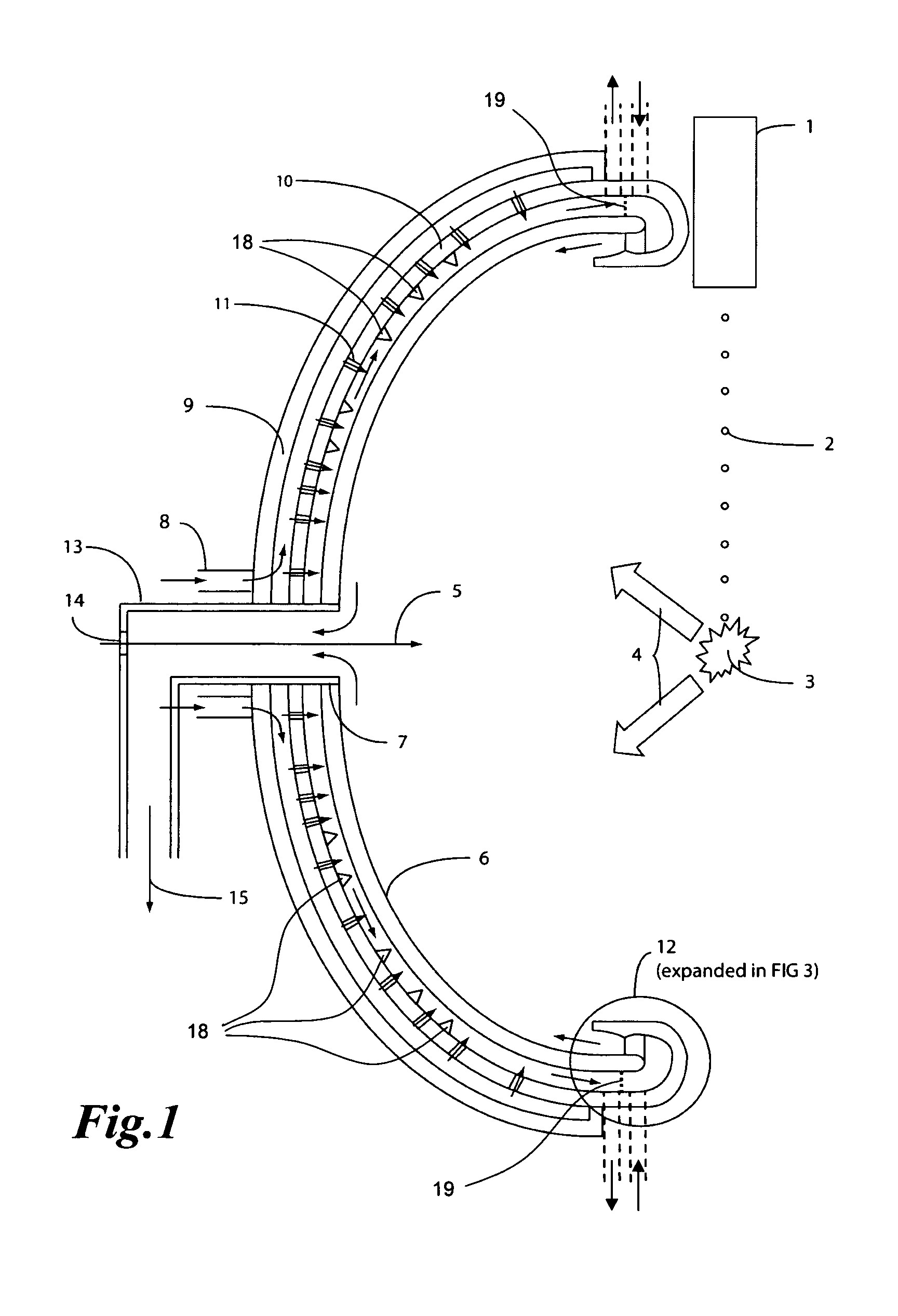

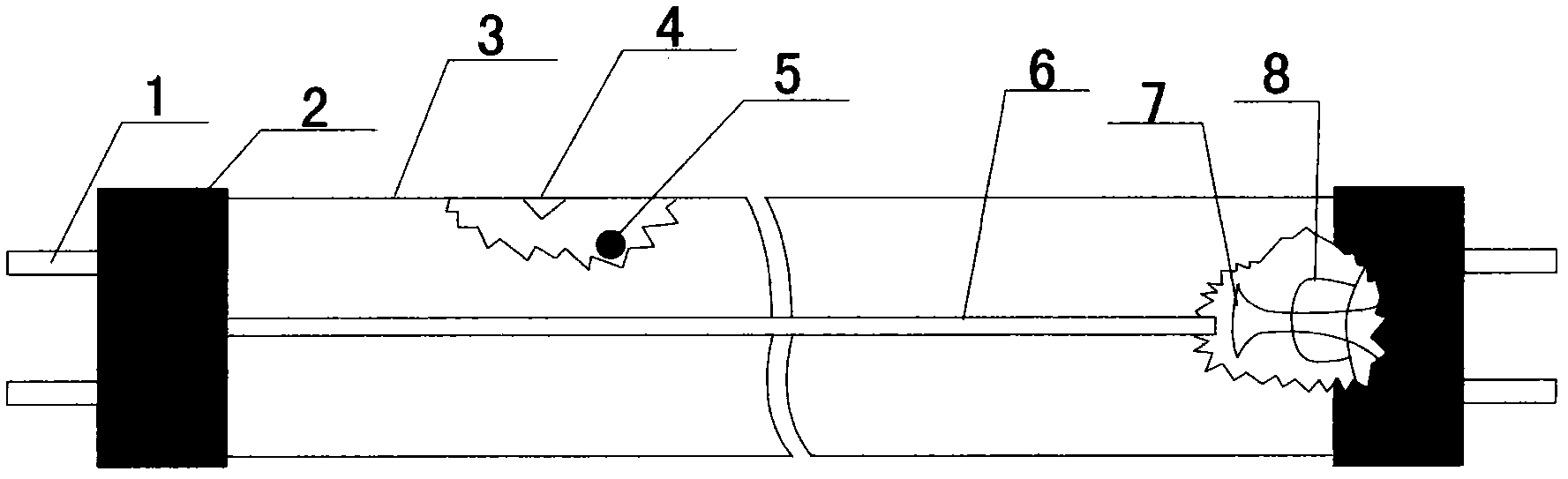

Extreme ultraviolet light source with a debris-mitigated and cooled collector optics

InactiveUS20120025109A1Effective shieldingExtended service lifeRadiation pyrometryFouling preventionFar ultravioletCarbon Dioxide / Helium

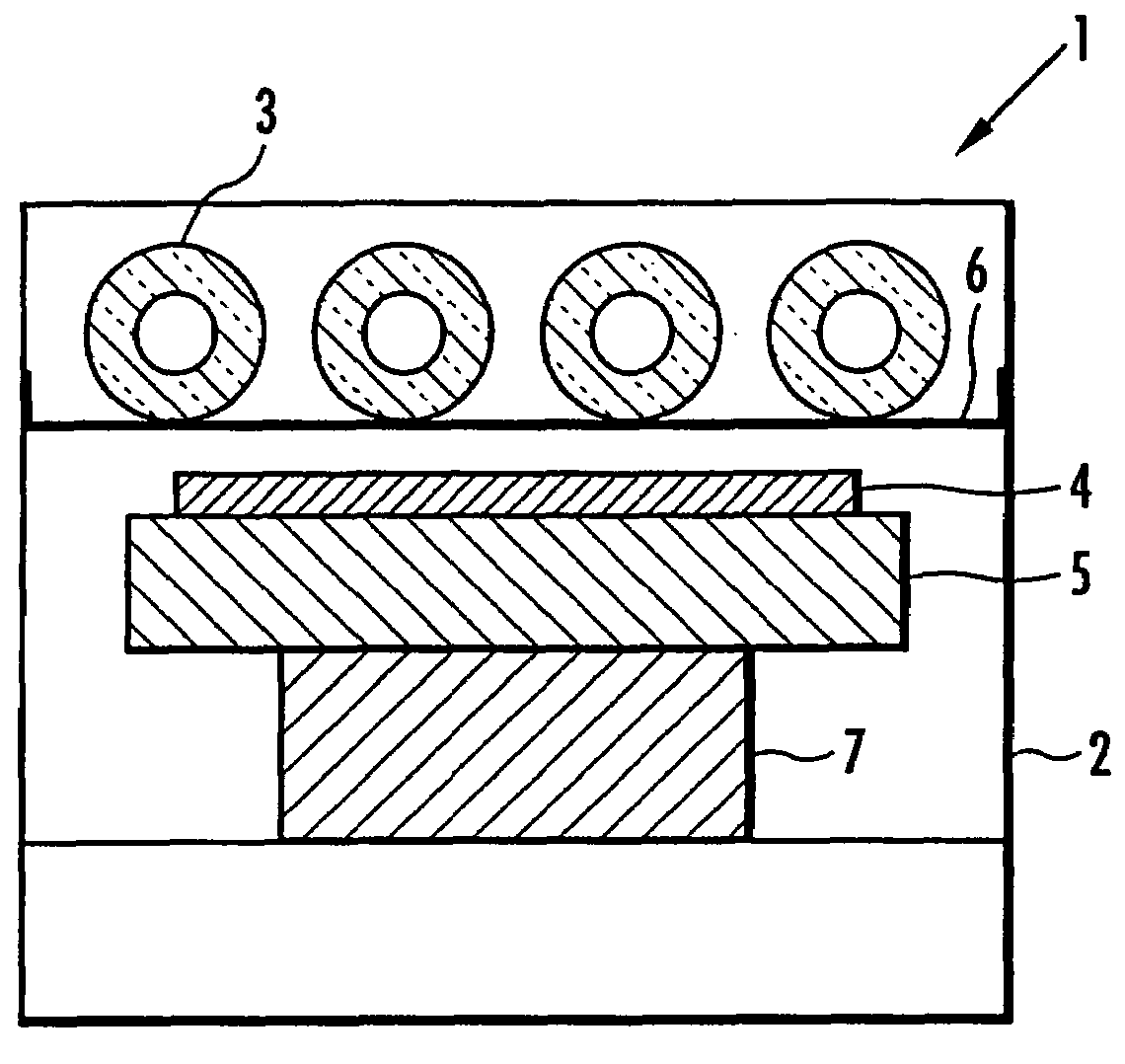

The extreme ultraviolet light source comprises a production site capable of producing extreme ultraviolet radiation in a laser-produced plasma (3), and a collector optics (6) for collimating the extreme ultraviolet radiation. A pressurized influx of gas forms a gas curtain between the production site and the collector optics (6) in order to protect the collector optics (6) from debris (4) generated at the production site. The gas influx is directed in a way that it follows the surface of the collector optics (6). By thus shielding the collector optics (6) from the debris (4) its lifetime is enhanced. The shielding gas can further be used for cooling the collector optics (6).

Owner:ETH ZZURICH

Lavatory disinfection system

ActiveUS9623133B2Material analysis using wave/particle radiationElectrical apparatusFar ultravioletUltraviolet

Owner:THE BOEING CO

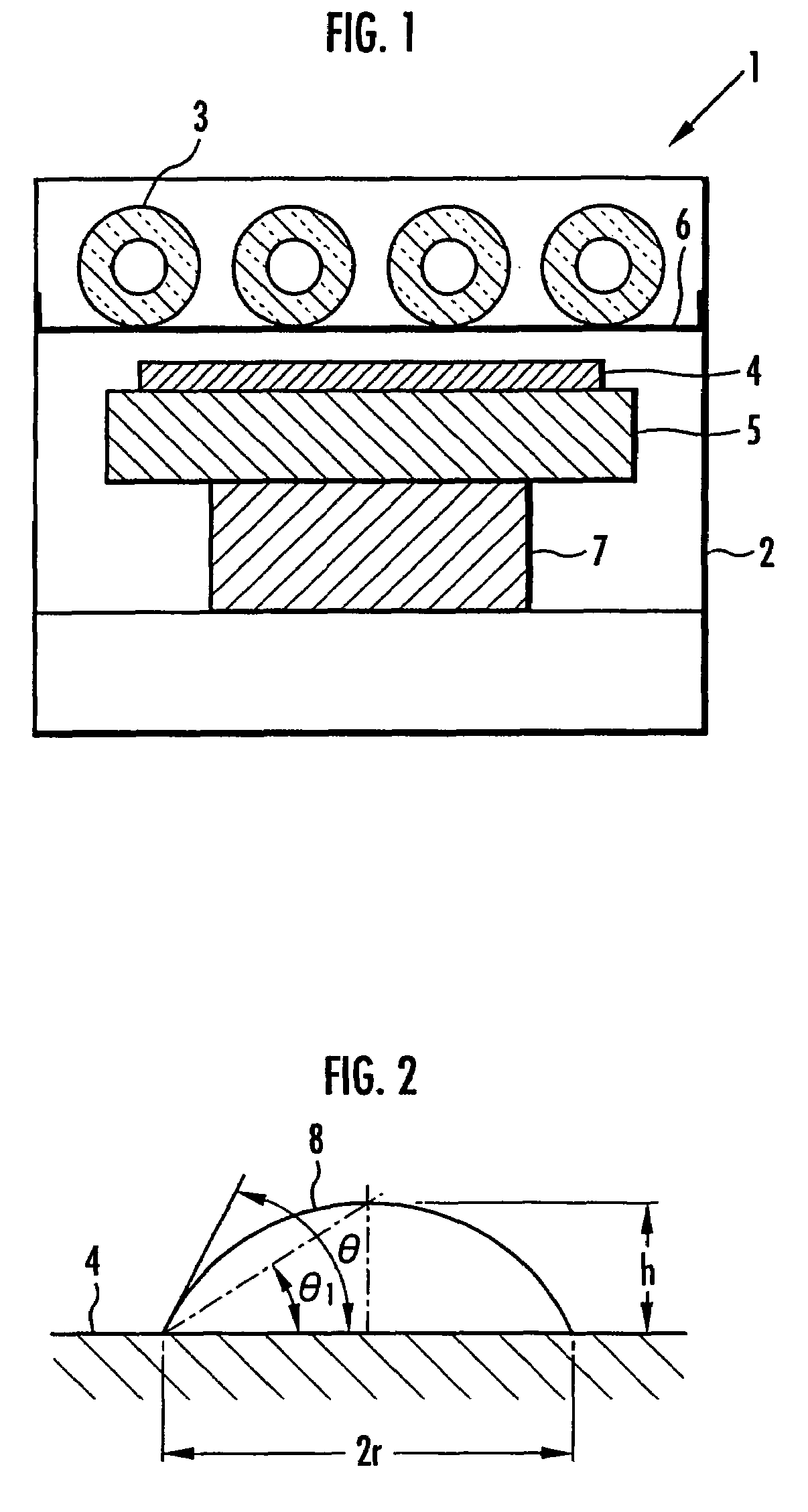

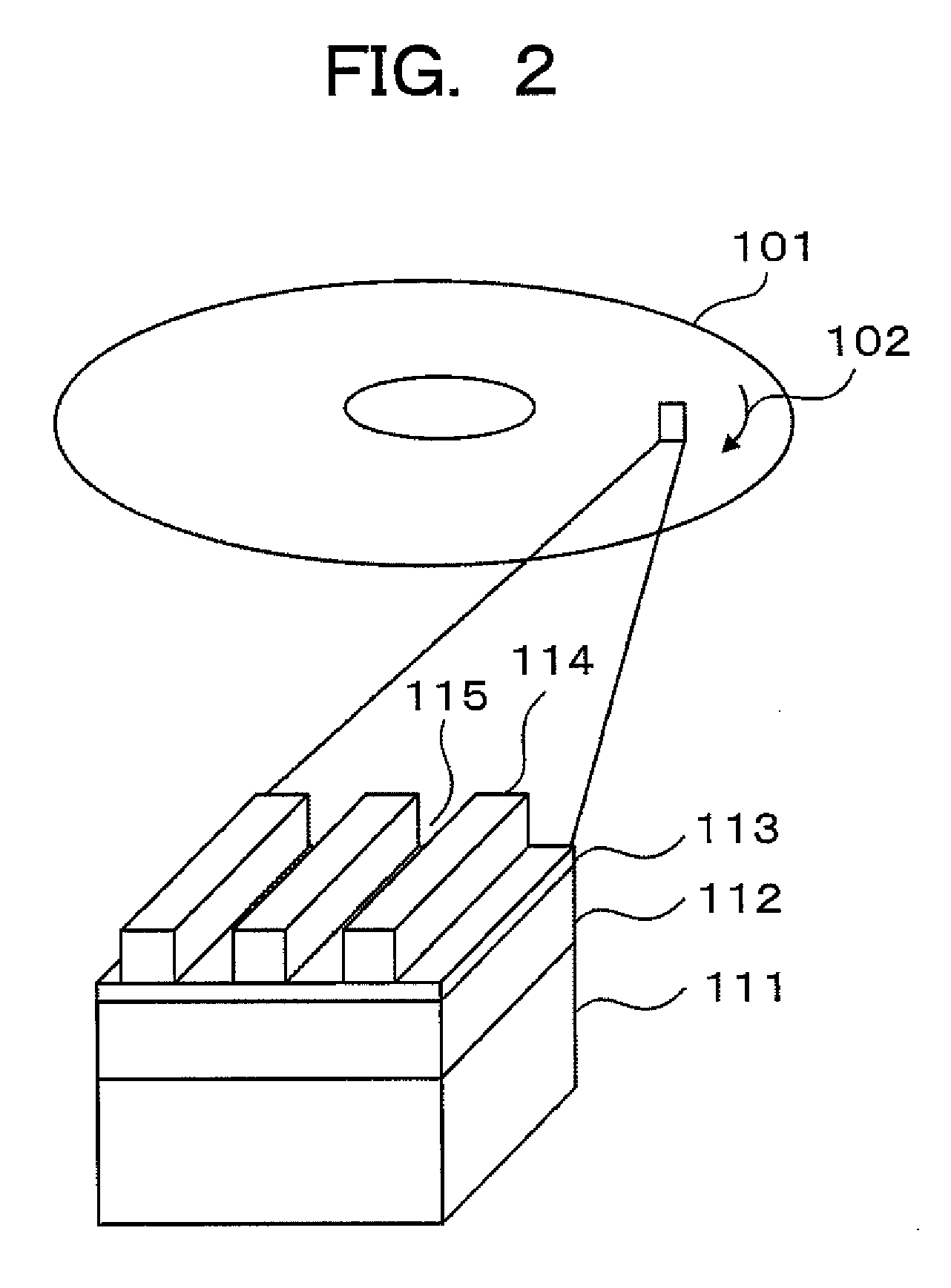

Method of manufacturing hydrophilic carbon nanotubes

InactiveUS20050214196A1Easy to introduceLarge hydrophilicityMaterial nanotechnologyMulti-walled nanotubesFar ultravioletHydrogen

There is provided a method of manufacturing hydrophilic carbon nanotubes, which is capable of imparting hydrophilicity without damaging the surface of the carbon nanotubes. By irradiating carbon nanotubes 4 with ultraviolet ray 3, hydrophilic functional group(s) are introduced into the surface of carbon nanotubes 4. Hydrophilicity is imparted to the carbon nanotubes to such an extent that a contact angle of water is in the range of less than 130°. Ultraviolet ray 3 is a far ultraviolet ray having a wavelength ranging from 1 to 190 nm. The irradiation with ultraviolet ray 3 is conducted in the presence of oxygen and hydrogen or in the presence of ozone and hydrogen. The end part(s) of carbon nanotubes 4 is opened by the irradiation with ultraviolet ray 3.

Owner:HONDA MOTOR CO LTD +1

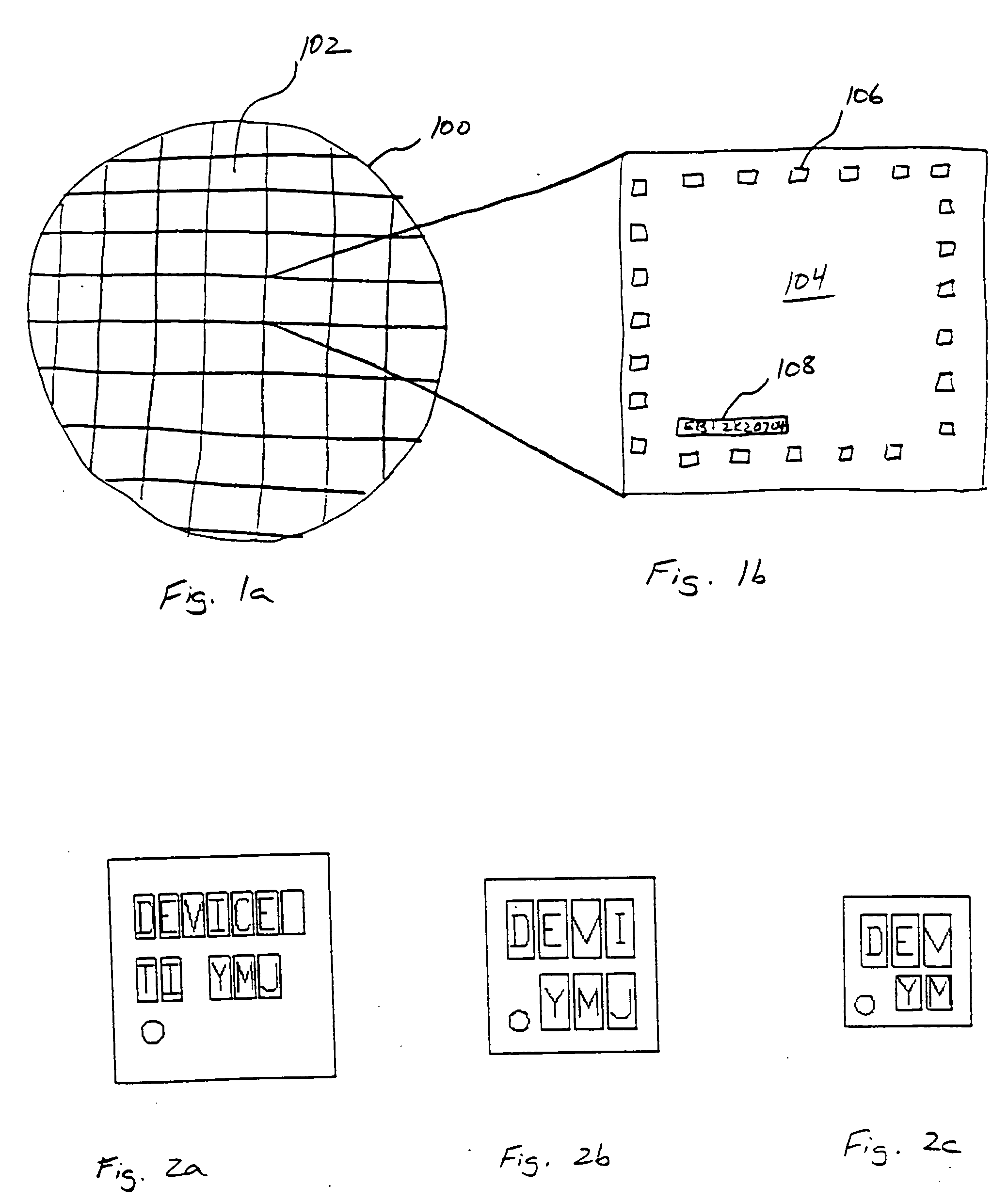

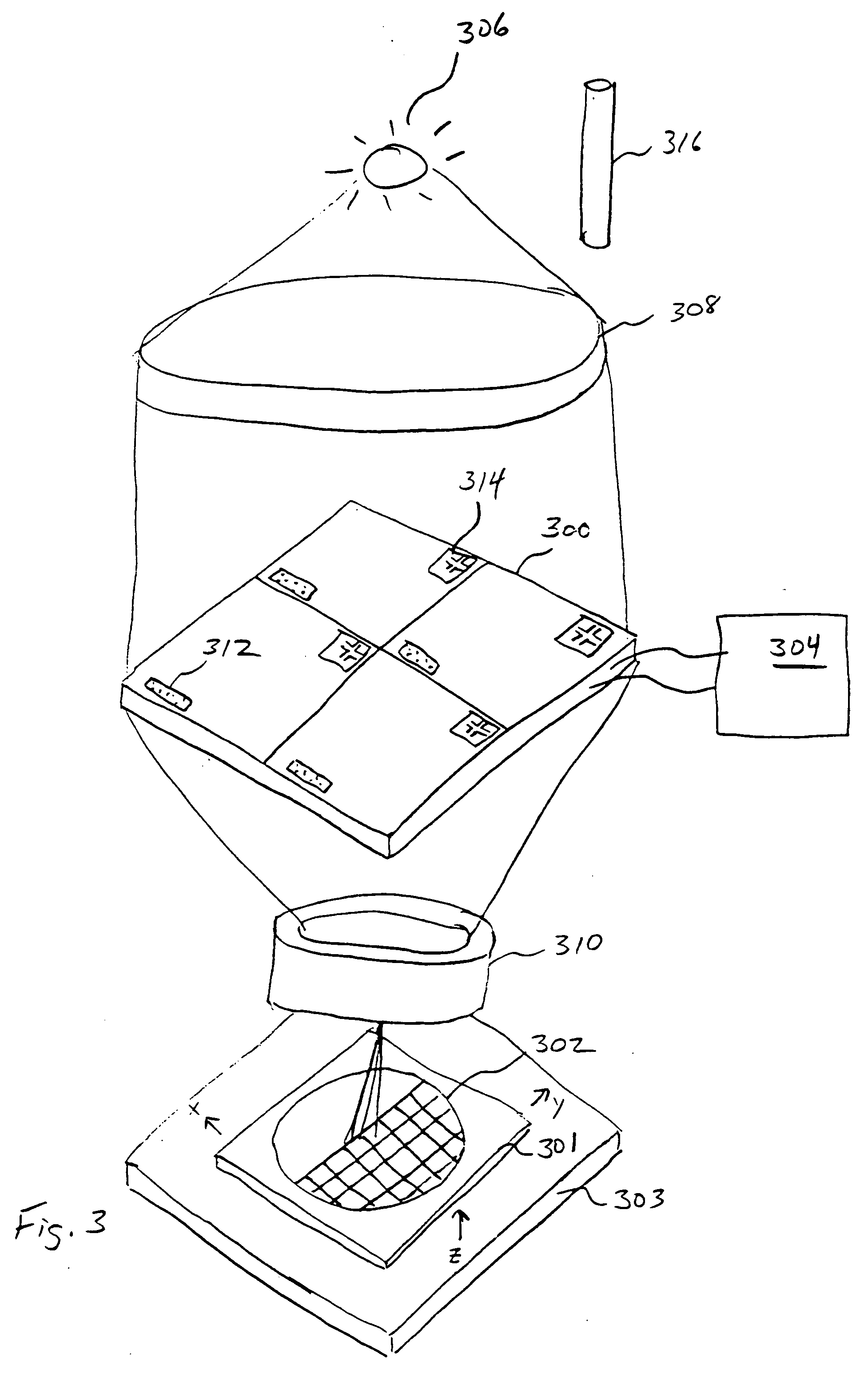

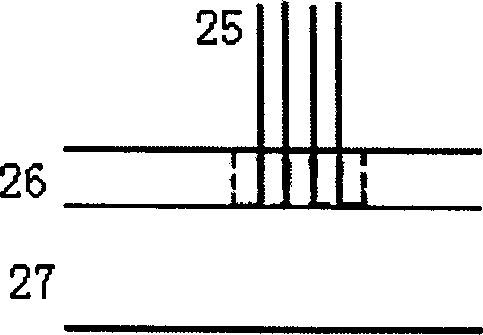

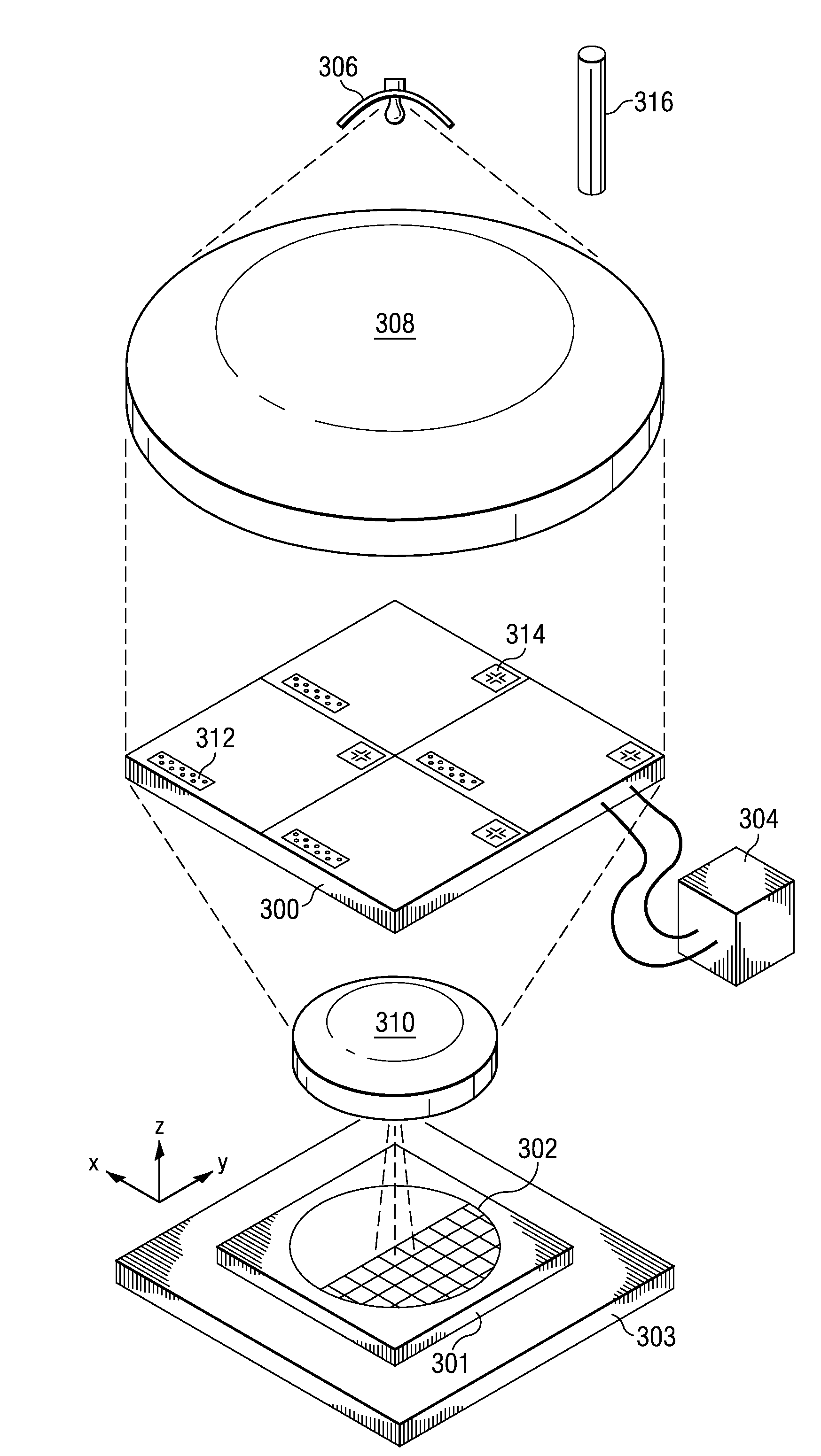

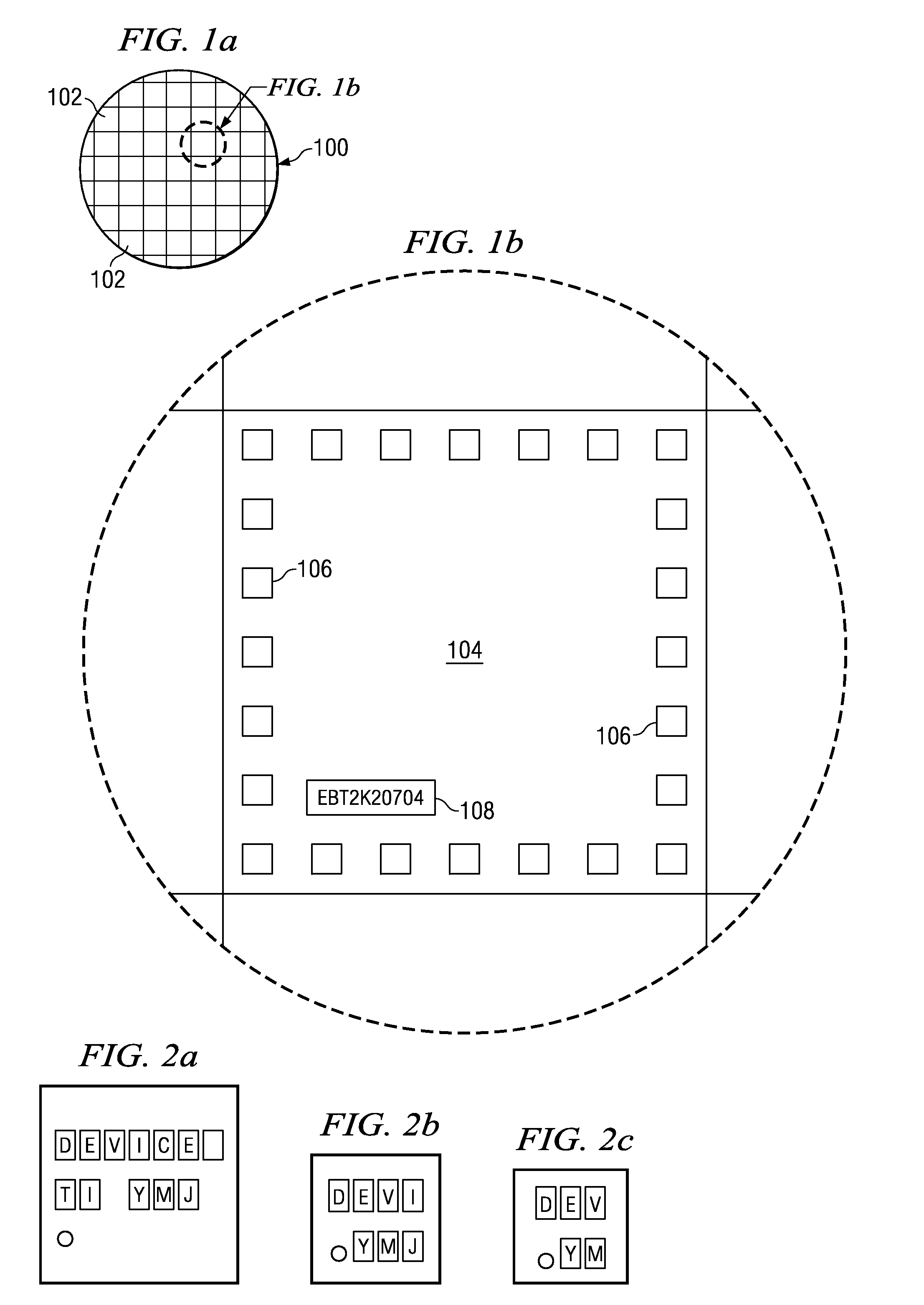

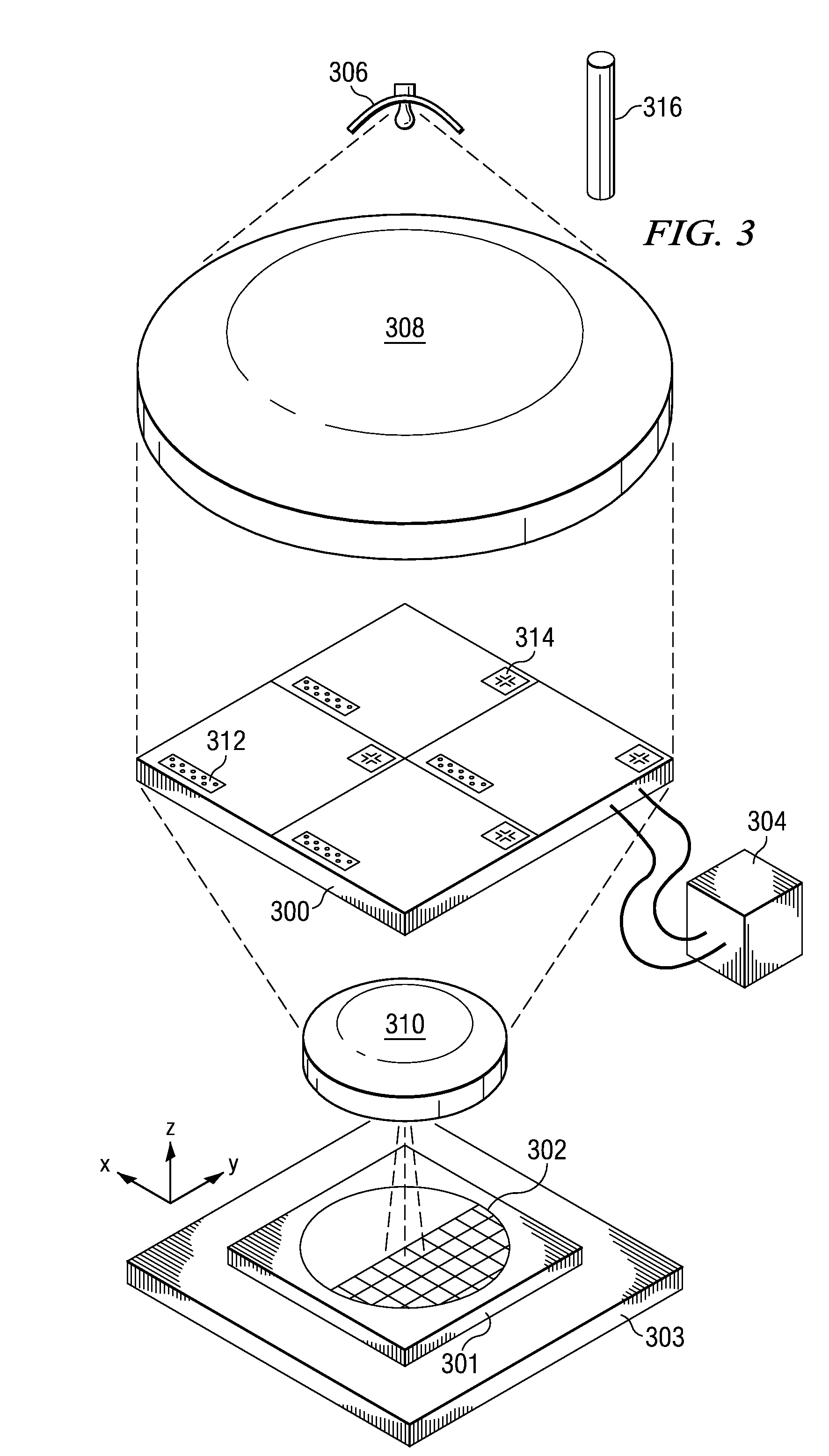

Integrated circuit identification

InactiveUS20050042780A1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsFar ultravioletDirect radiation

A method for marking a semiconductor wafer 302 includes the steps of: providing a reticle 300 including liquid crystal pixels; positioning the semiconductor wafer in proximity to the reticle; directing radiation through a first plurality of the pixels onto a first location on the wafer; changing the relative positions of the semiconductor wafer and the reticle; and directing radiation through a second plurality of the pixels onto a second location on the wafer. The first plurality of pixels can be used to form a first mark and the second plurality of pixels can be used to form a second mark, wherein the second mark is different from the first mark. The marks can be made of a pattern of dots in order to save space. The pixels can be selected to form certain marks by using a computer 304 to turn on or off a transistor that may be associated with each pixel. Also described is a system for marking a semiconductor wafer. The system includes a wafer mount 301; a radiation source 306 in proximity to the wafer mount; a reticle 300 which includes liquid crystal pixels and that is positionable between the radiation source and the wafer mount; and a mechanism 303 for changing the relative positions of the reticle and the wafer mount. The radiation source can be non-coherent far-ultraviolet, near-ultraviolet, or visible sources, or a laser.

Owner:TEXAS INSTR INC

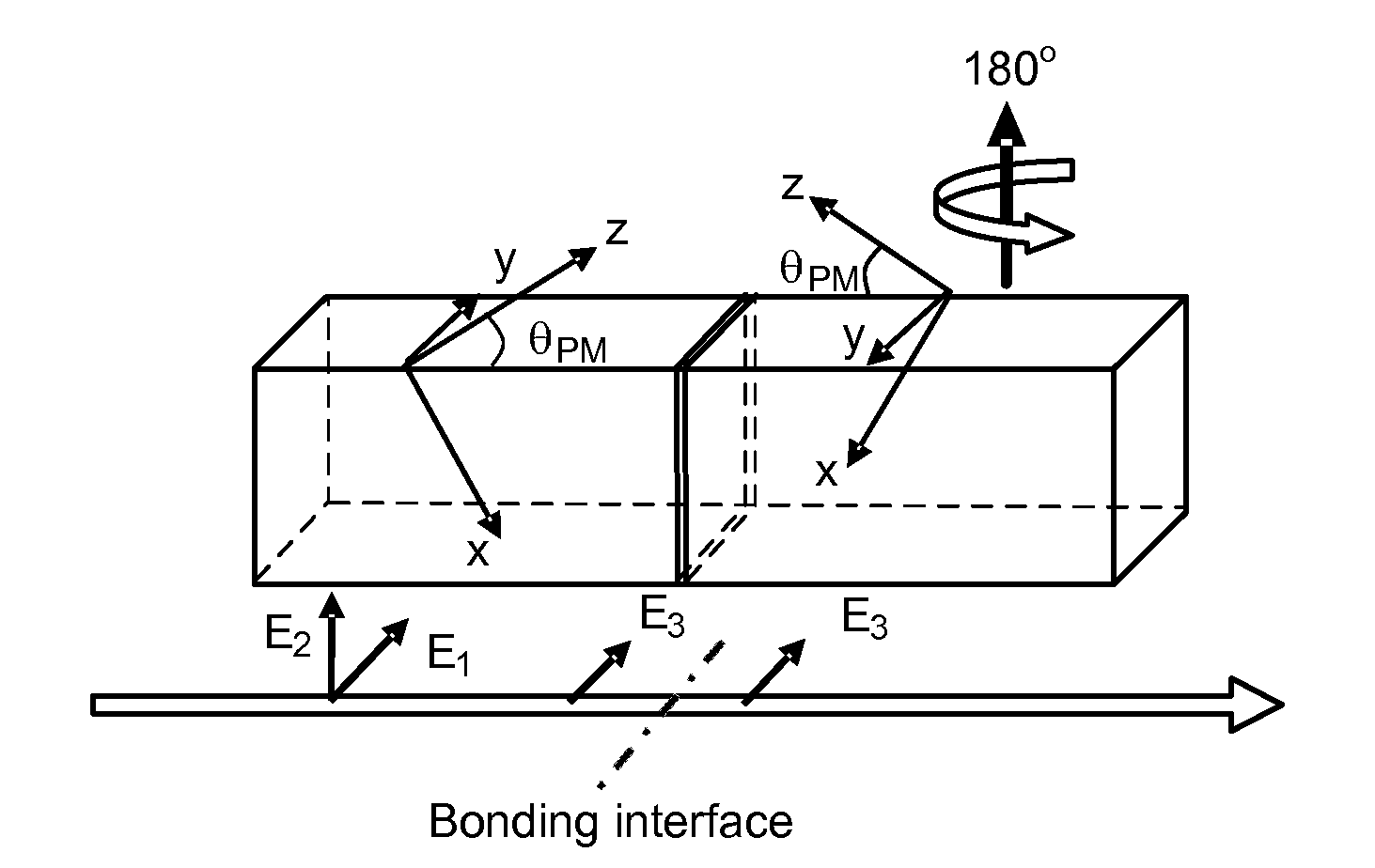

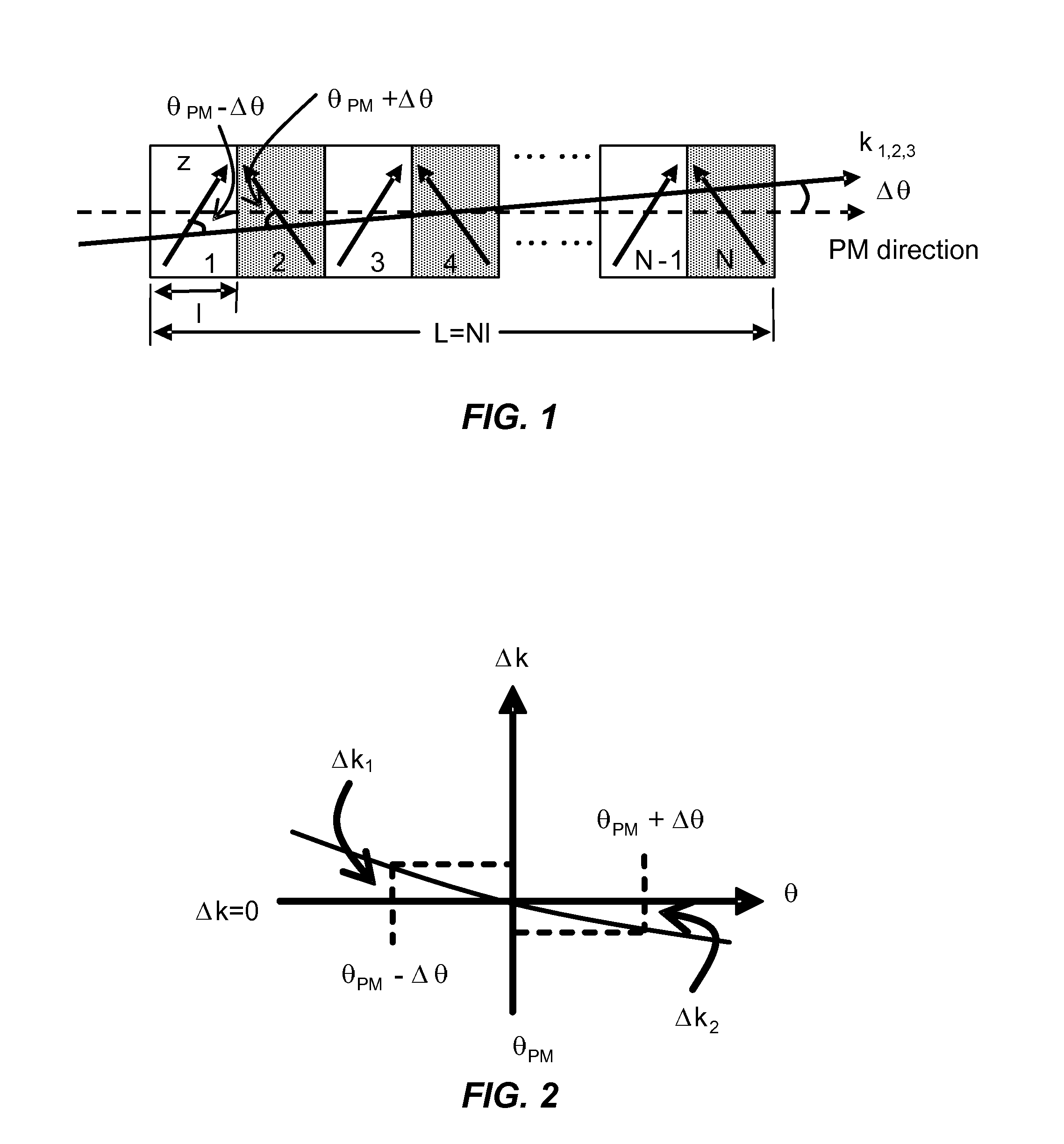

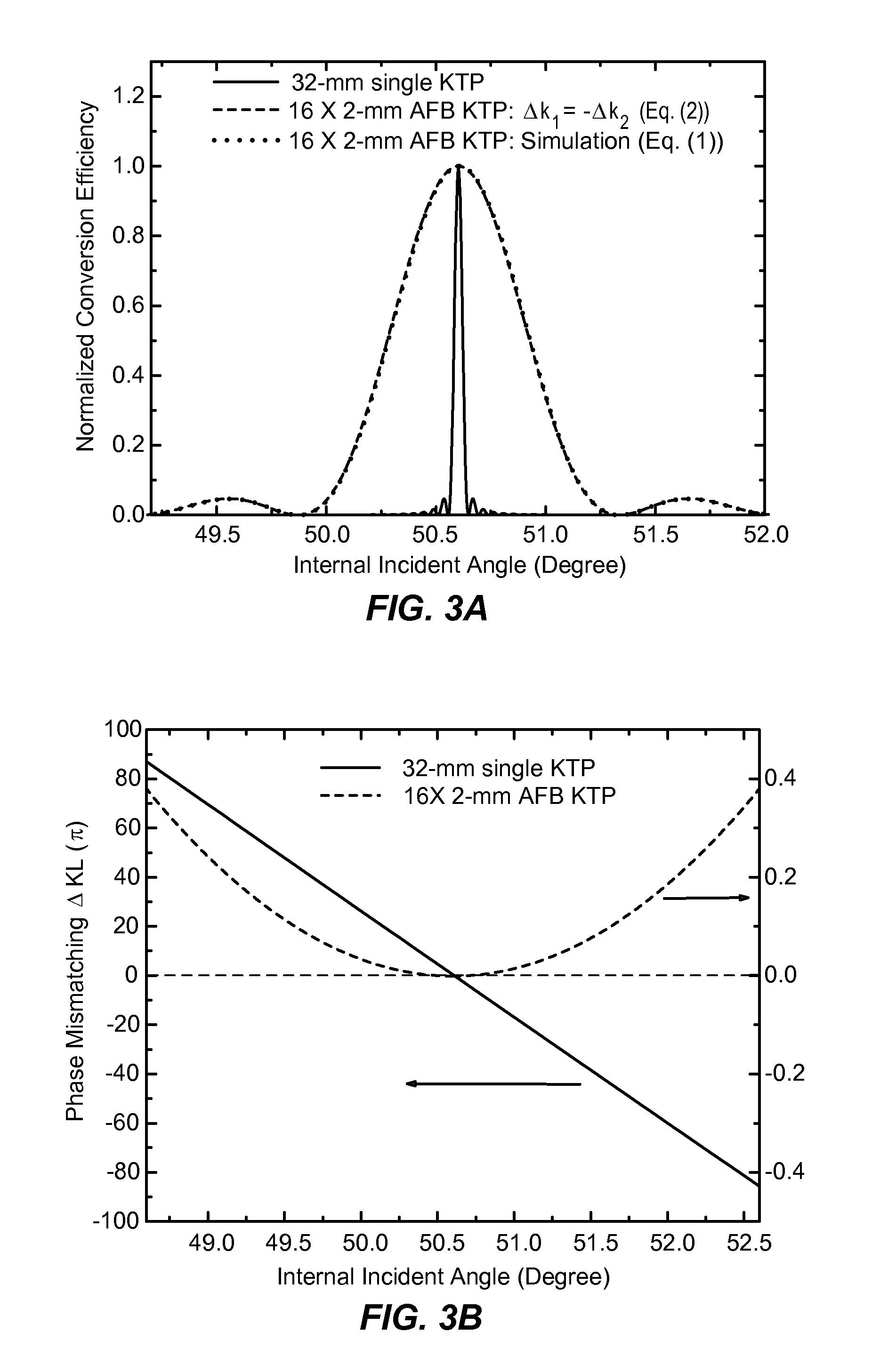

Quasi non-critical phase matched and contra-phase matched structures

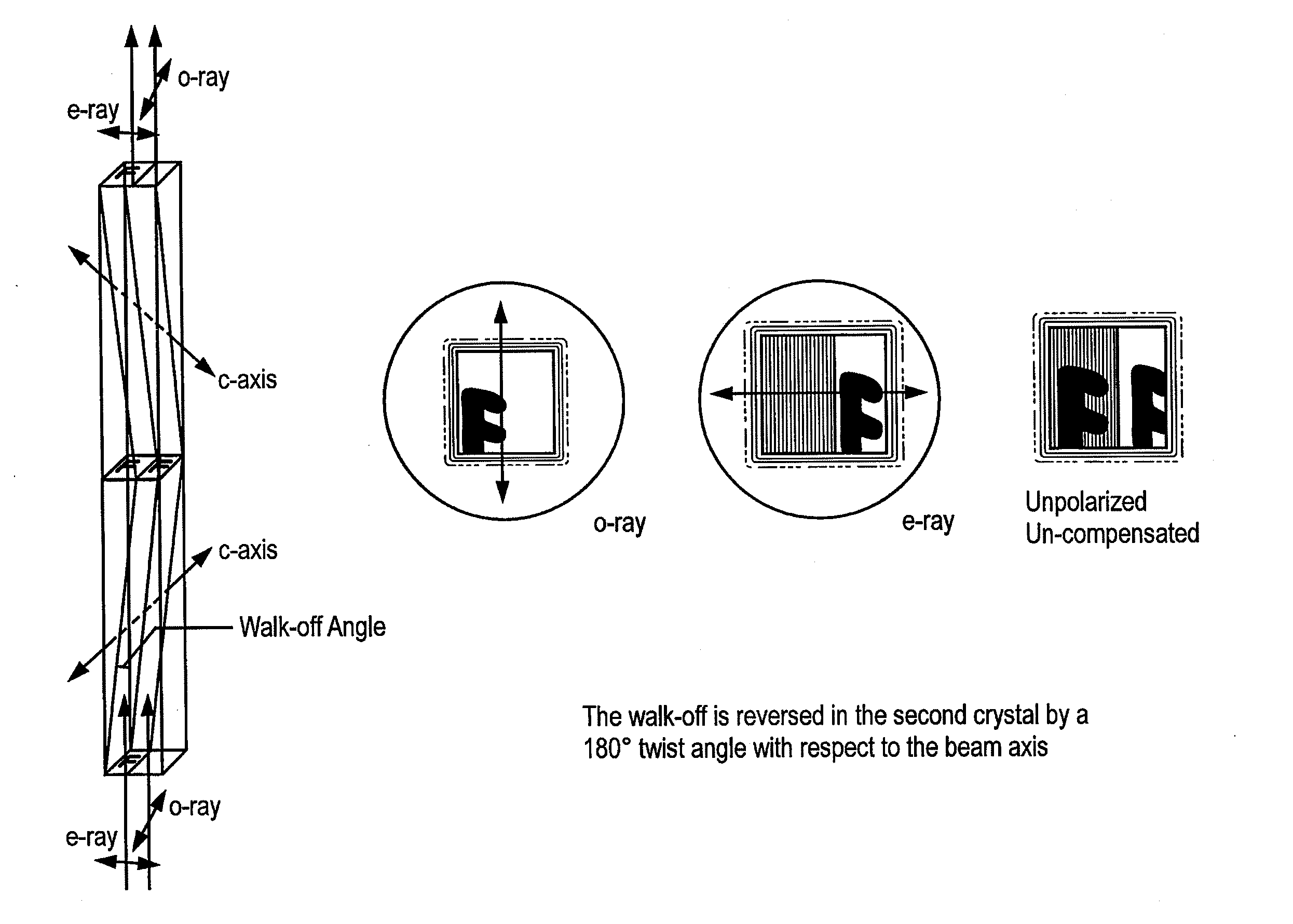

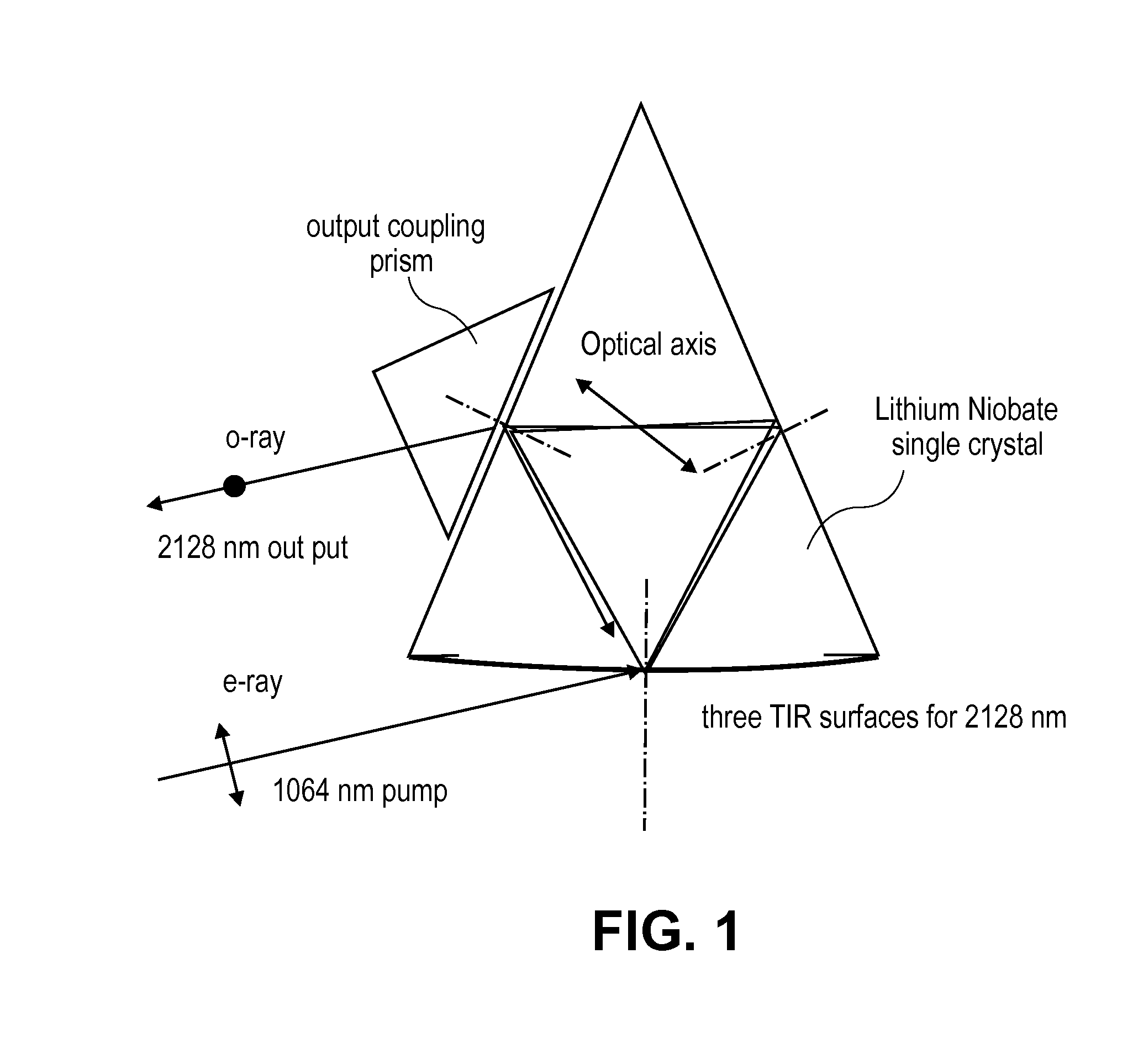

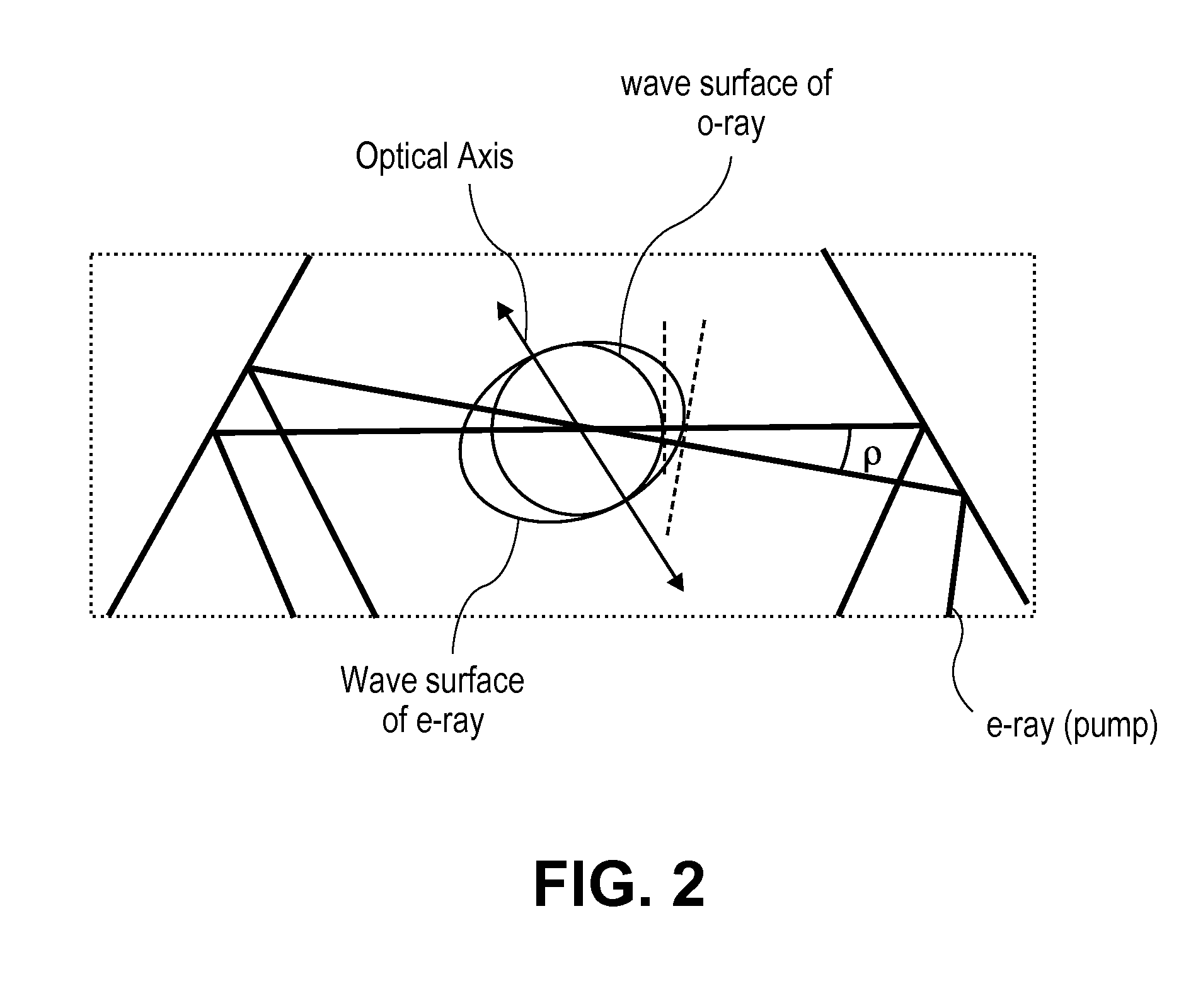

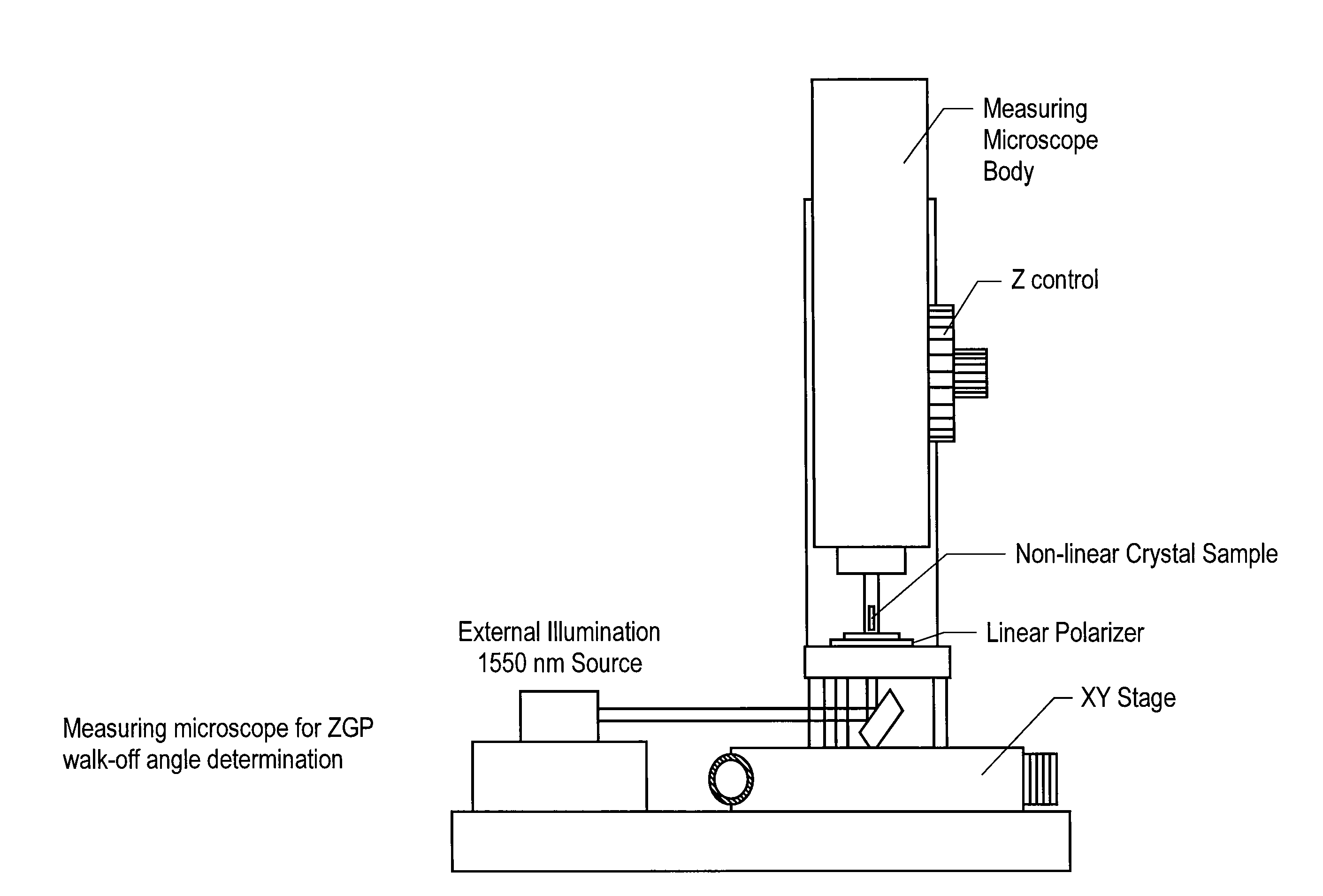

ActiveUS20110013264A1High beam qualityImprove conversion efficiencyLamination ancillary operationsLaminationFar ultravioletFrequency conversion

Adhesive-free bond non-linear optical (NLO) components, devices and systems including one or more engineered quasi non-critical phase matched or contra-phase matched NLO crystal doublets. Such systems and devices advantageously increase the efficiency of NLO frequency conversion and improve beam quality. Devices are applicable to any uniaxial and biaxial NLO crystals in a wide range of wavelengths, e.g., from far ultraviolet to visible to far infrared. Devices employing engineered AFB NLO components according to certain embodiments include any conventional frequency converting architectures. Systems and methods are also provided to unambiguously determine and correct walk-off for any arbitrary uniaxial and biaxial crystal orientation.

Owner:ONYX OPTICS

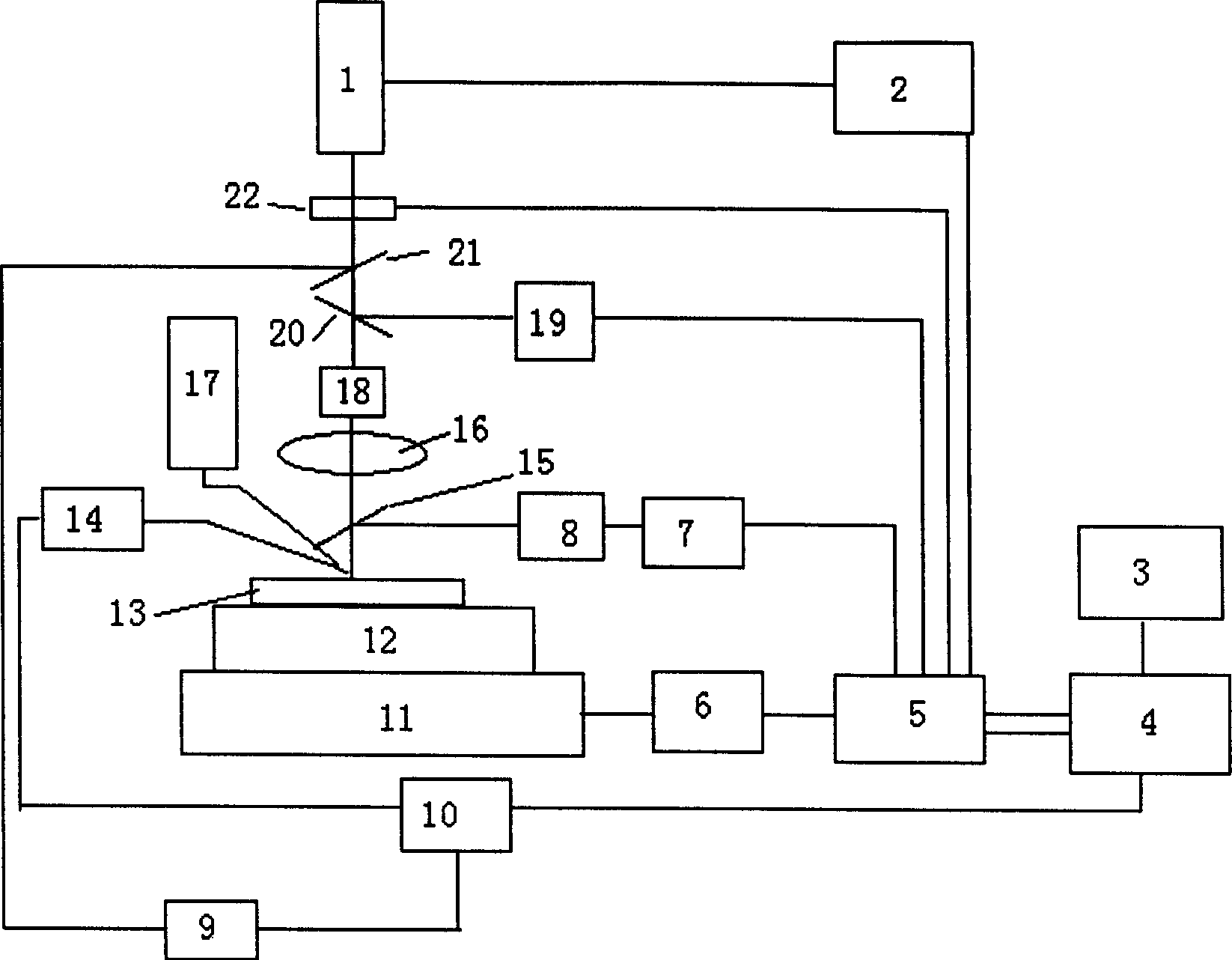

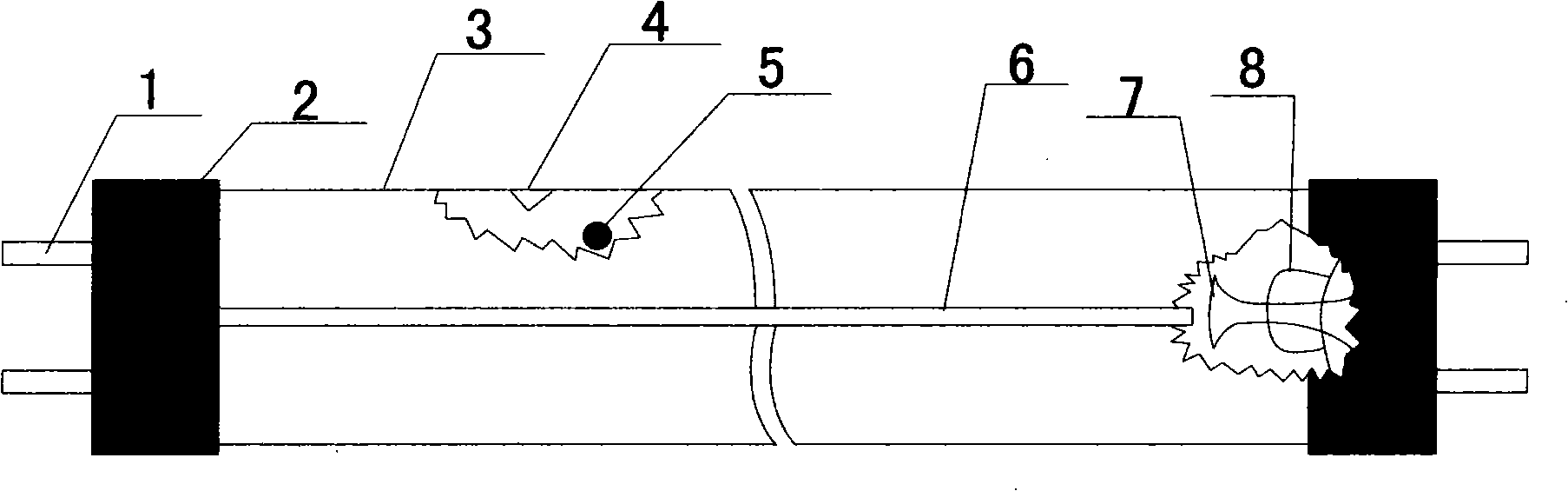

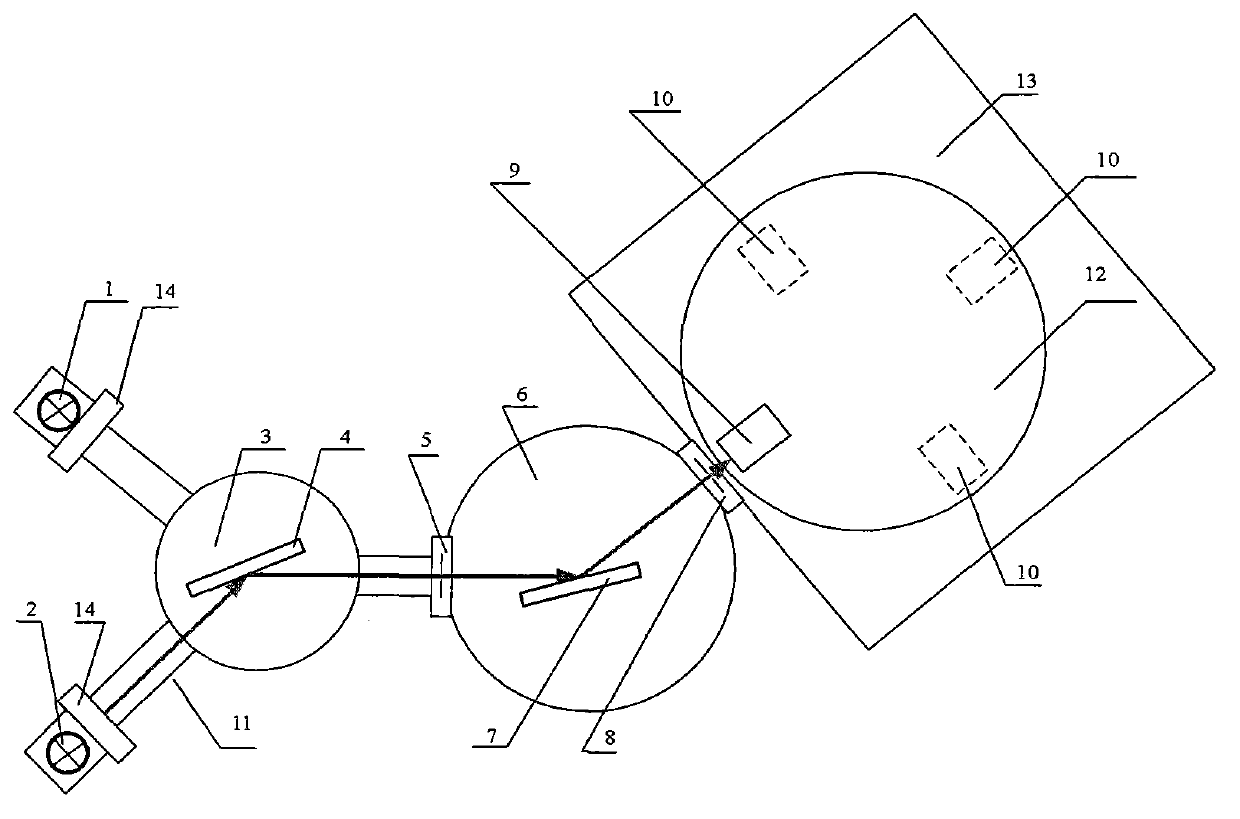

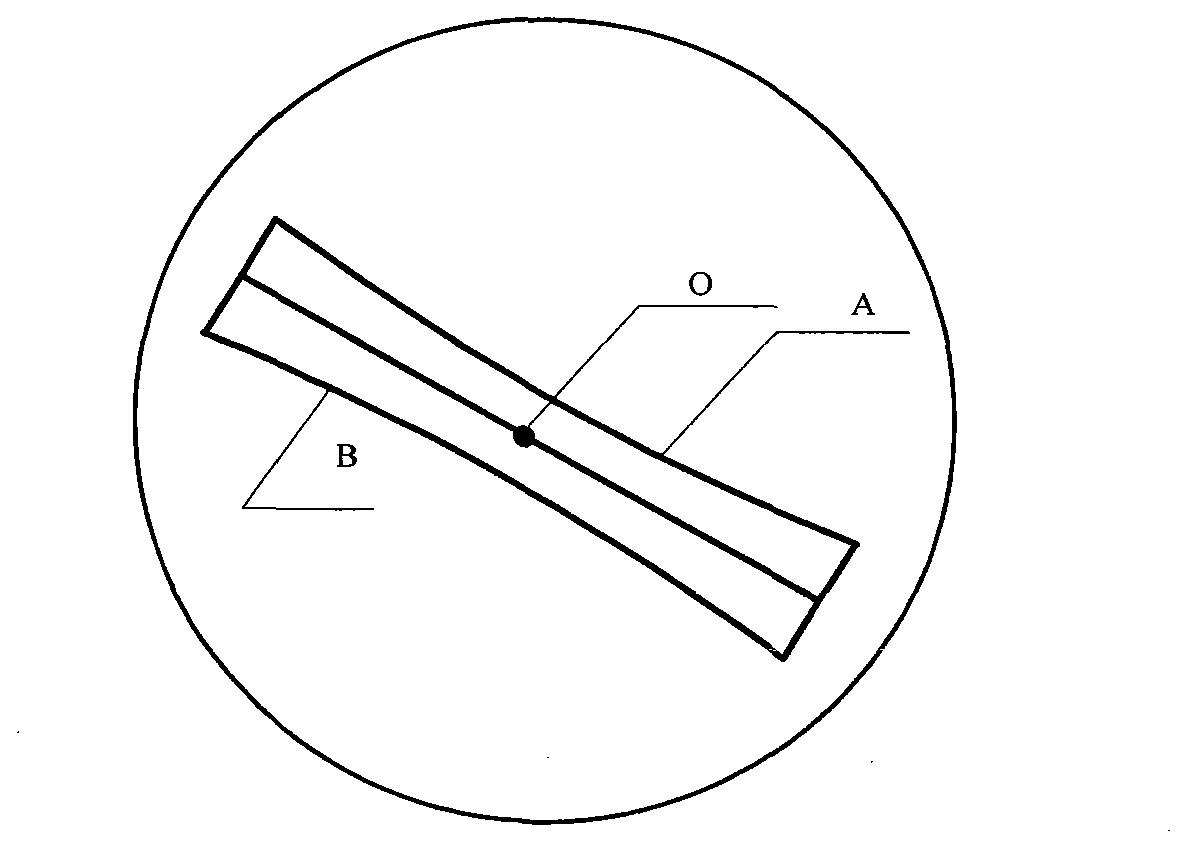

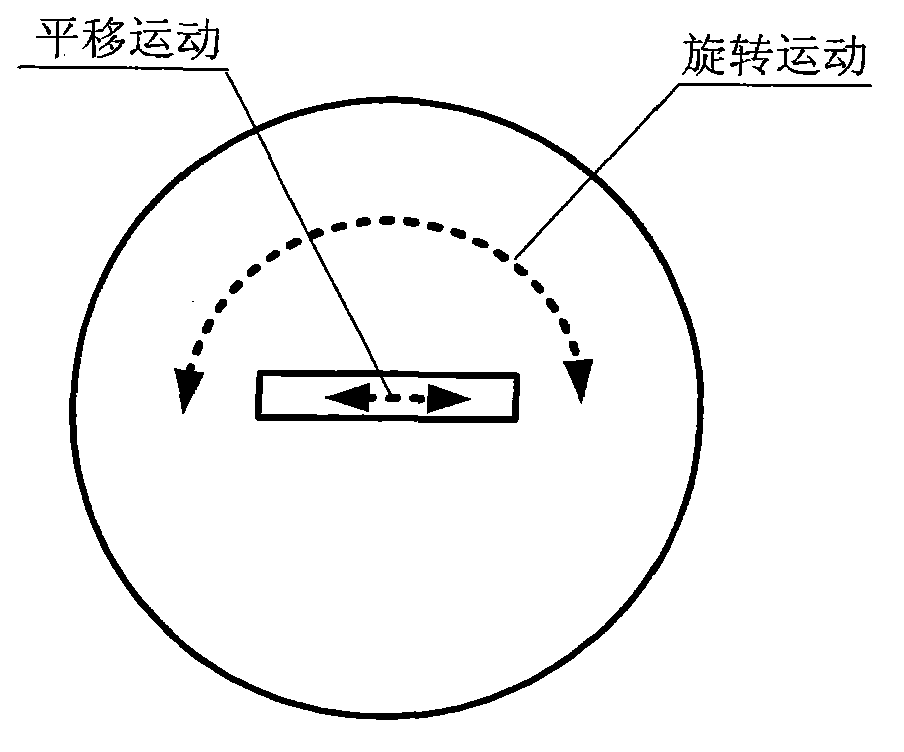

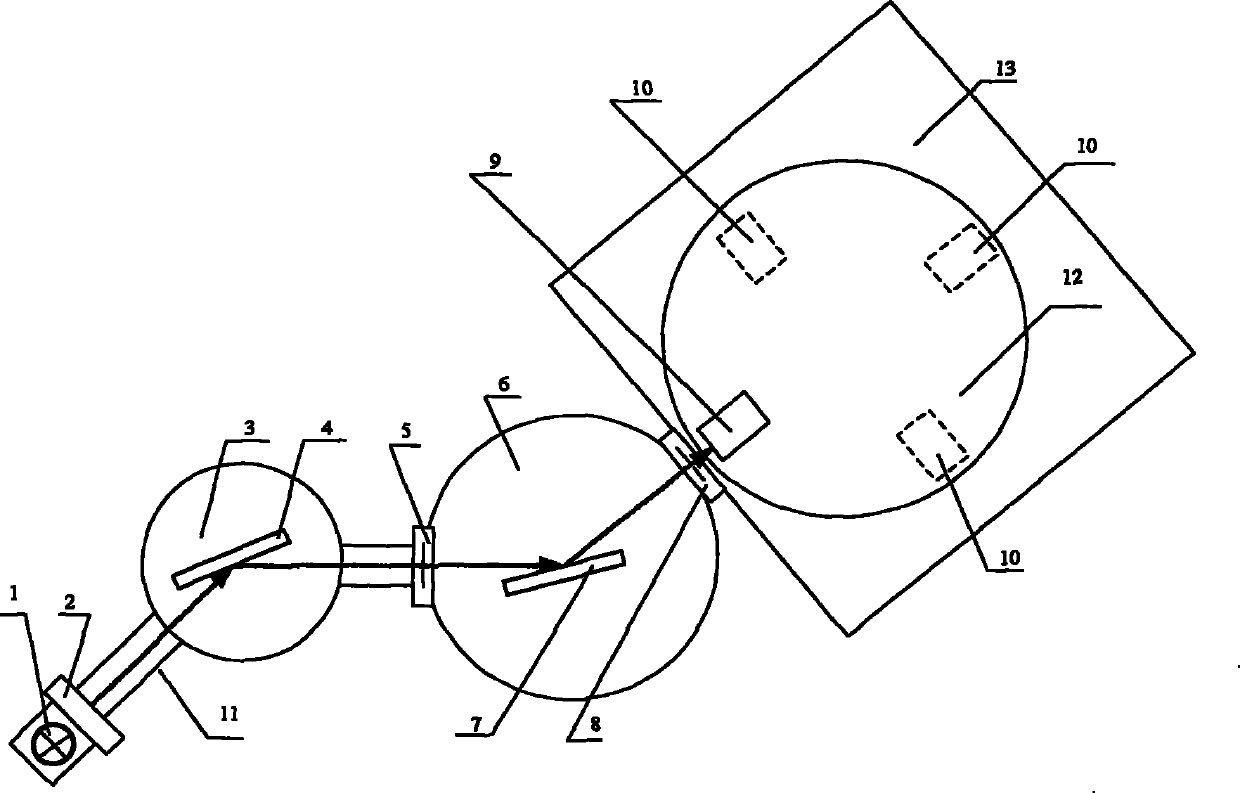

Method and apparatus for measuring far-ultraviolet laser scratch of interface jointing strength

InactiveCN1405554ARealization of ablation processingThe mechanism of laser action is obviousUsing mechanical meansColor/spectral properties measurementsLattice defectsMathematical model

This invention relates to laser test and material performance test in which a continuously loading pulse avaser beam loads to the film surface of a subject directly via an incident laser beam optical path system to form lattice defect and plasma after optical decomposing, and valence photochange to realize erosion process to the subject or even break ibnding keys among moleculars or crystals to some materials by photons directly to break-off the film materials. At the same time, feeding system makes the subject to do feed movement, laser beam forms steadily deepened mars on the film surface until breaks down the film-matrix interface then the said laser beam energy energy is processed by a certain mathematical modeles to express the binding strength of the film-matrix interface.

Owner:JIANGSU UNIV

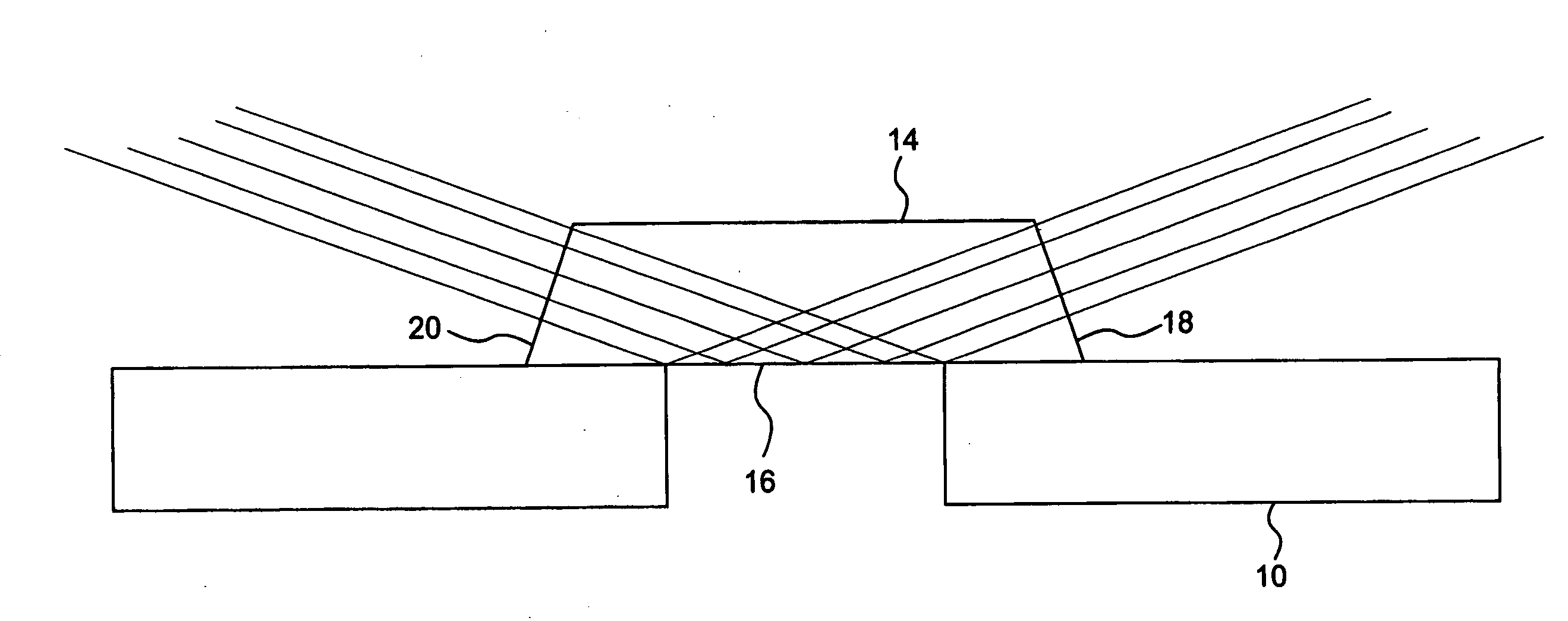

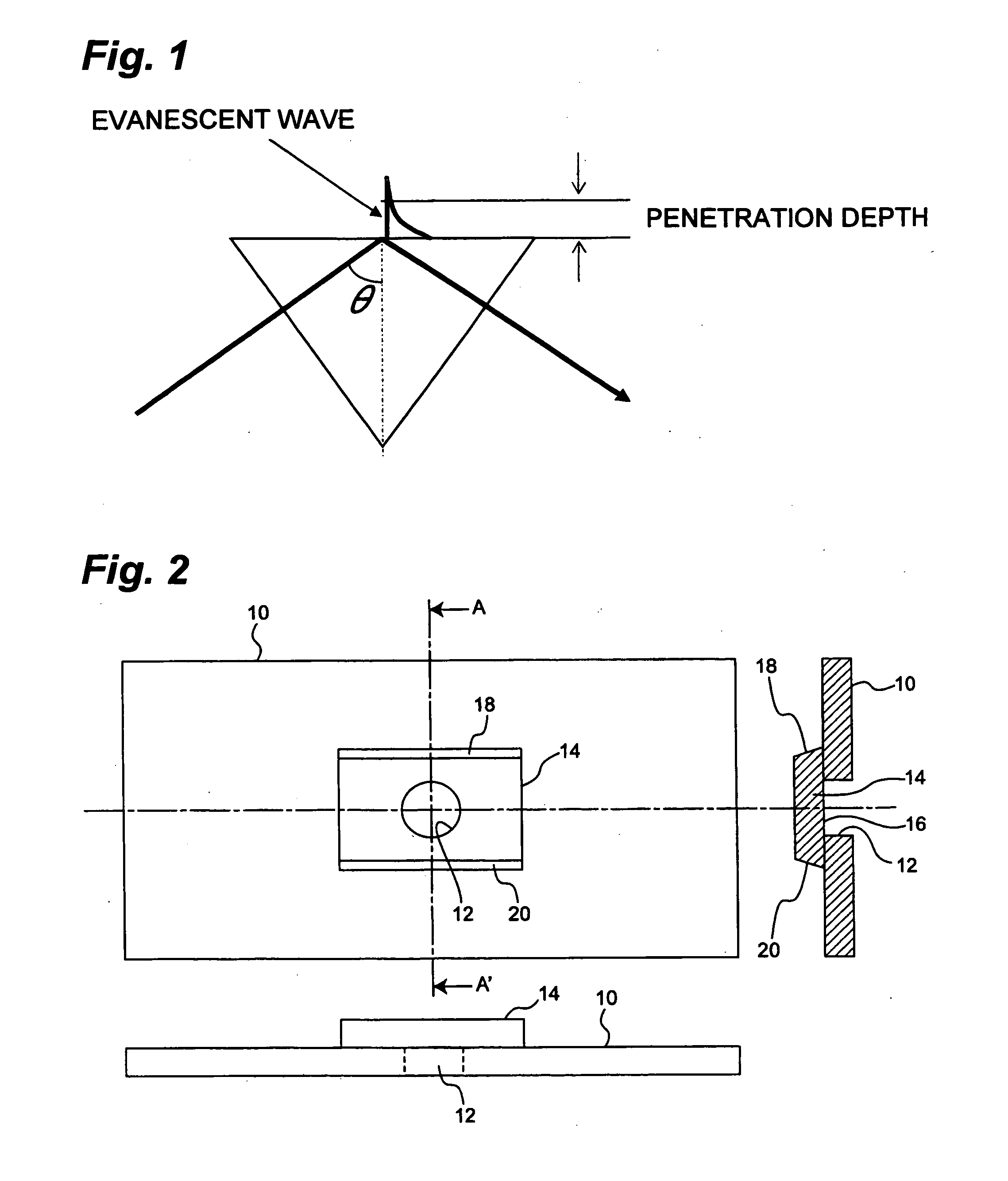

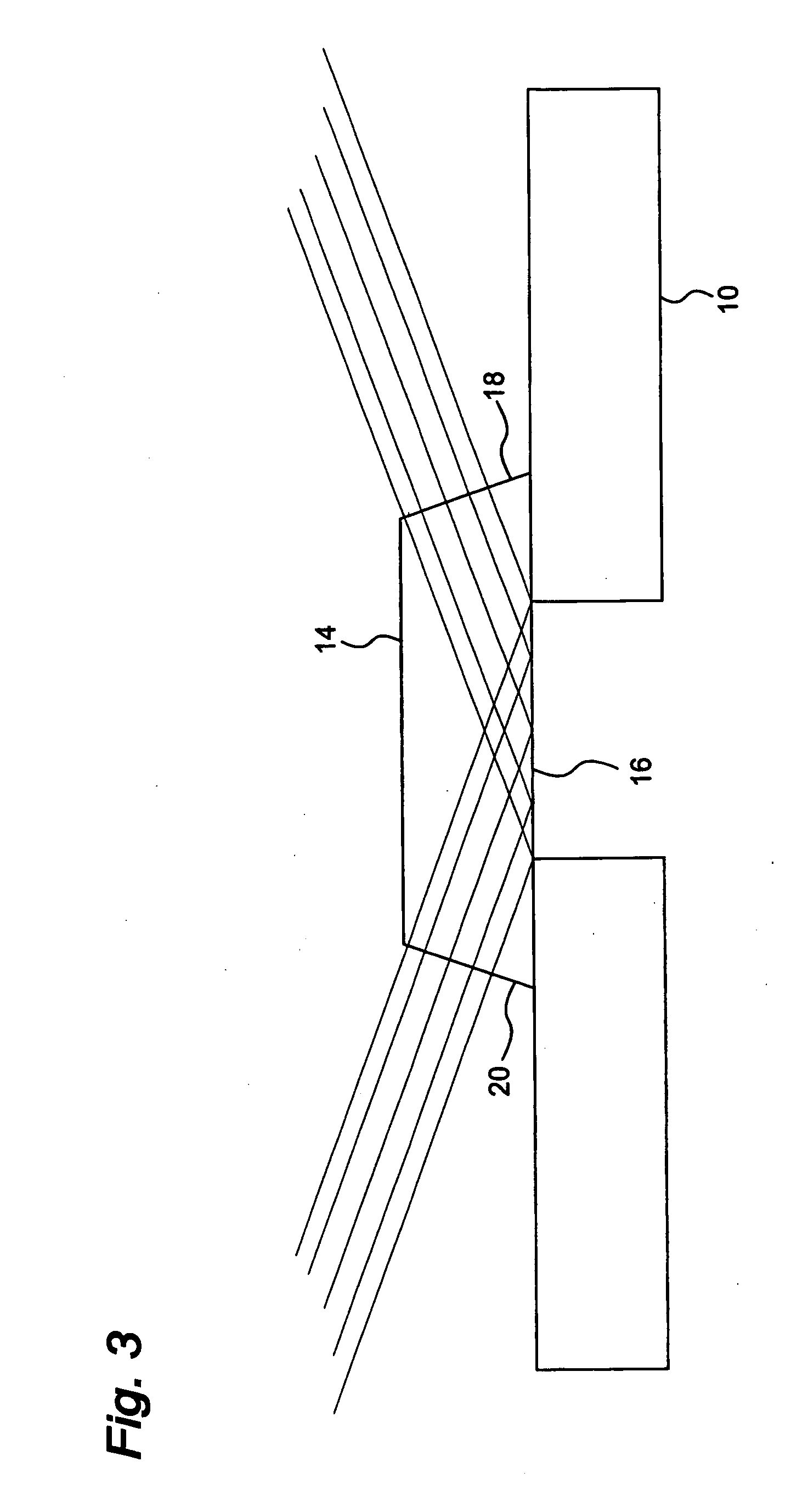

Attenuated total reflection probe and spectrometer therewith

An attenuated total reflection probe has a prism and a supporter. The prism is made of an optical material which transmits light in far ultraviolet region, and has a contact plane to be in contact with a sample, and an incoming plane and an outgoing plane both not to be in contact with the sample. The supporter has an opening and is connected hermetically with the prism around the opening and eventually exposes the contact plane facing the opening. The contact plane, the incoming plane and the outgoing plane of the prism are formed such that light transmitting the incoming plane enters the contact plane at an incident angle larger than critical angle and that the light totally reflected by the contact plane goes out through the outgoing plane.

Owner:KURASHIKI BOSEKI KK

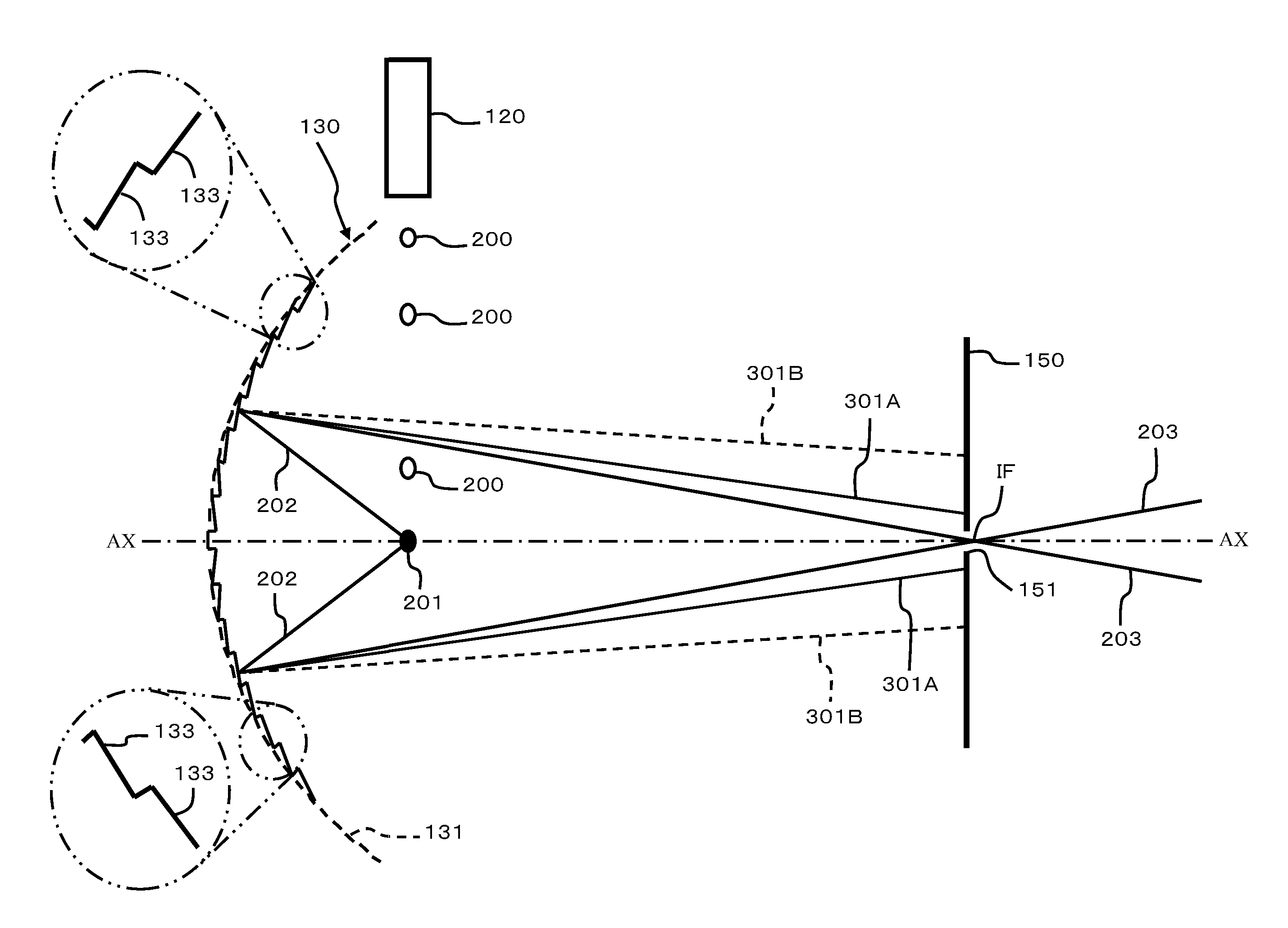

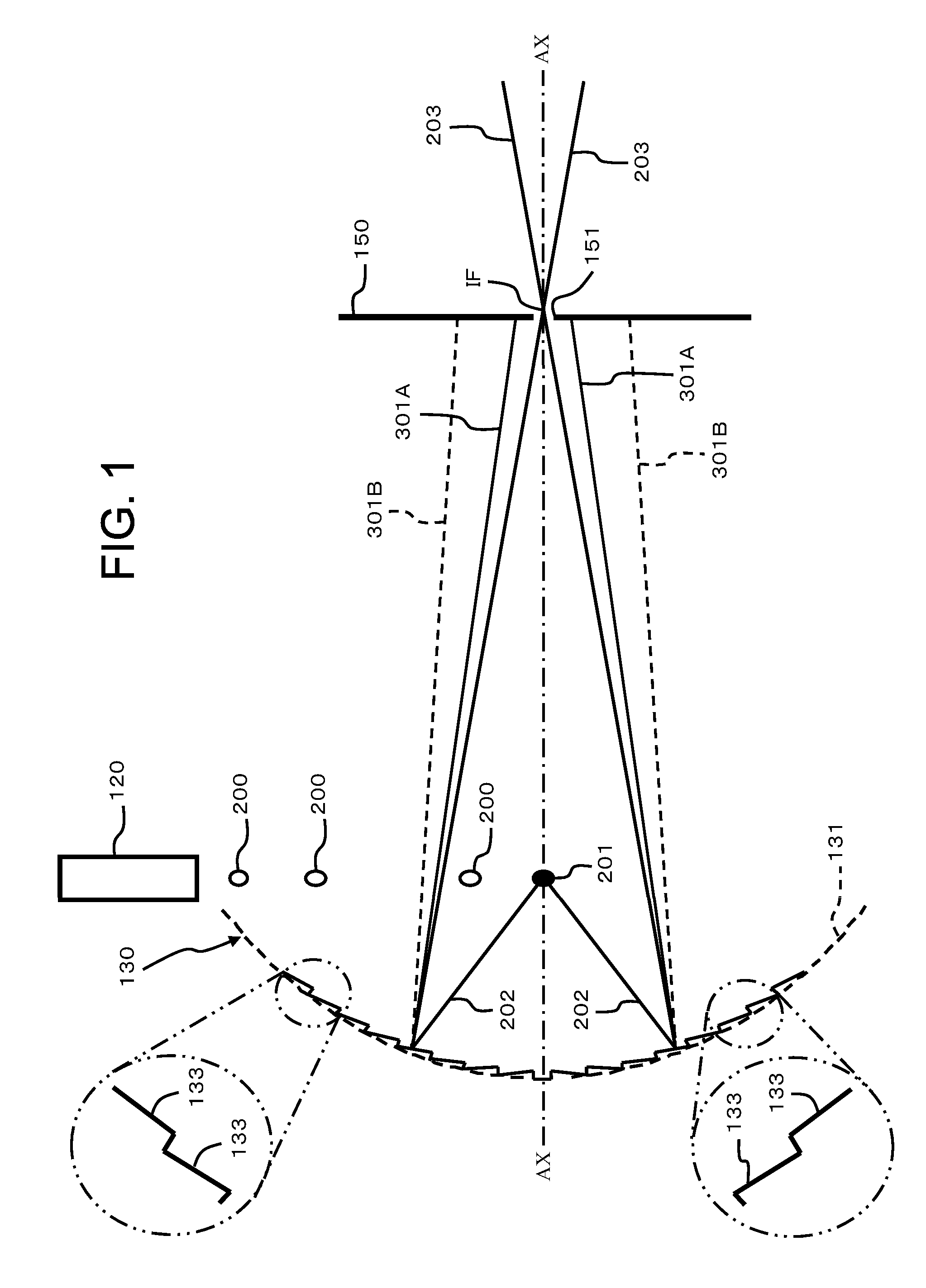

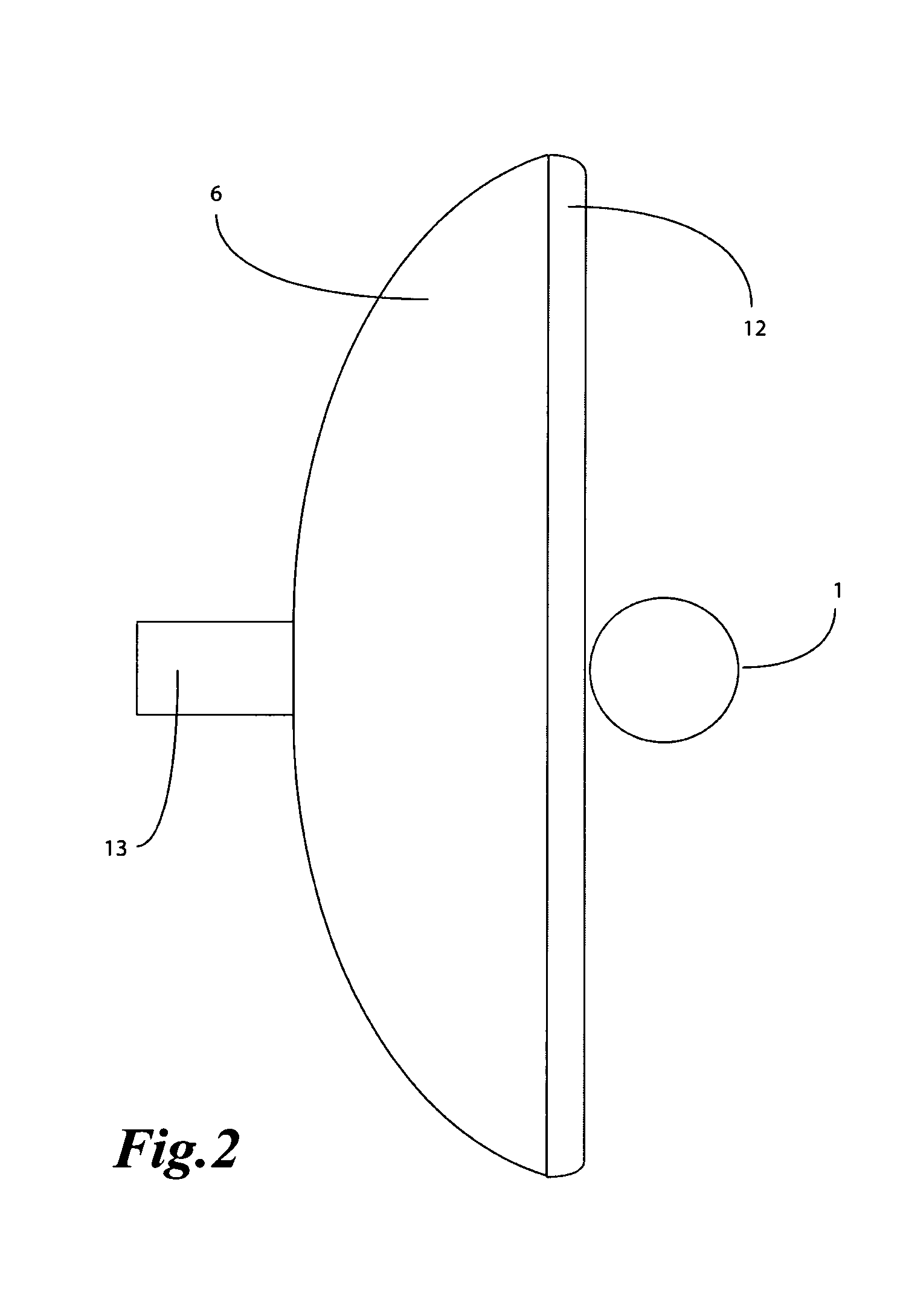

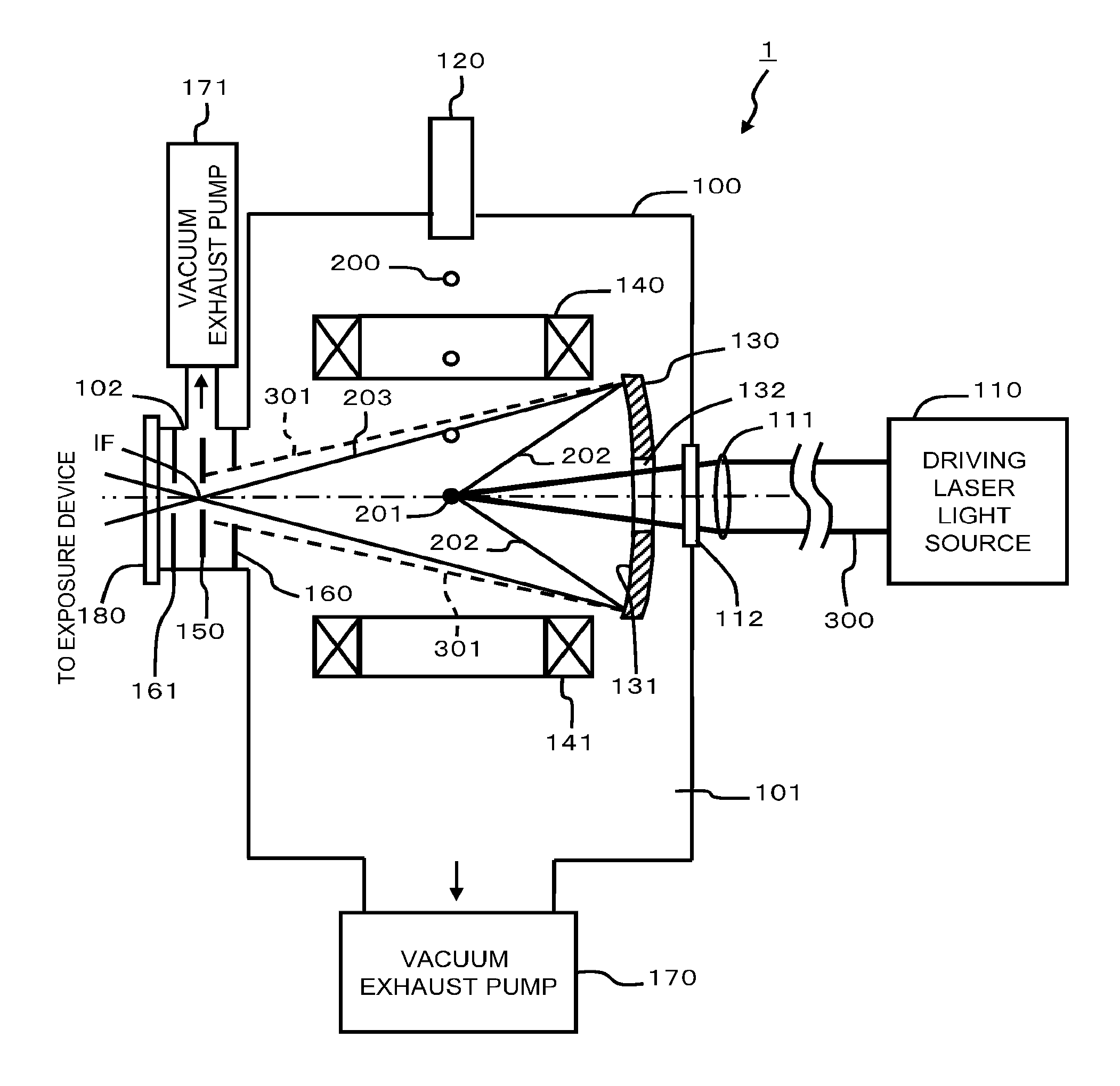

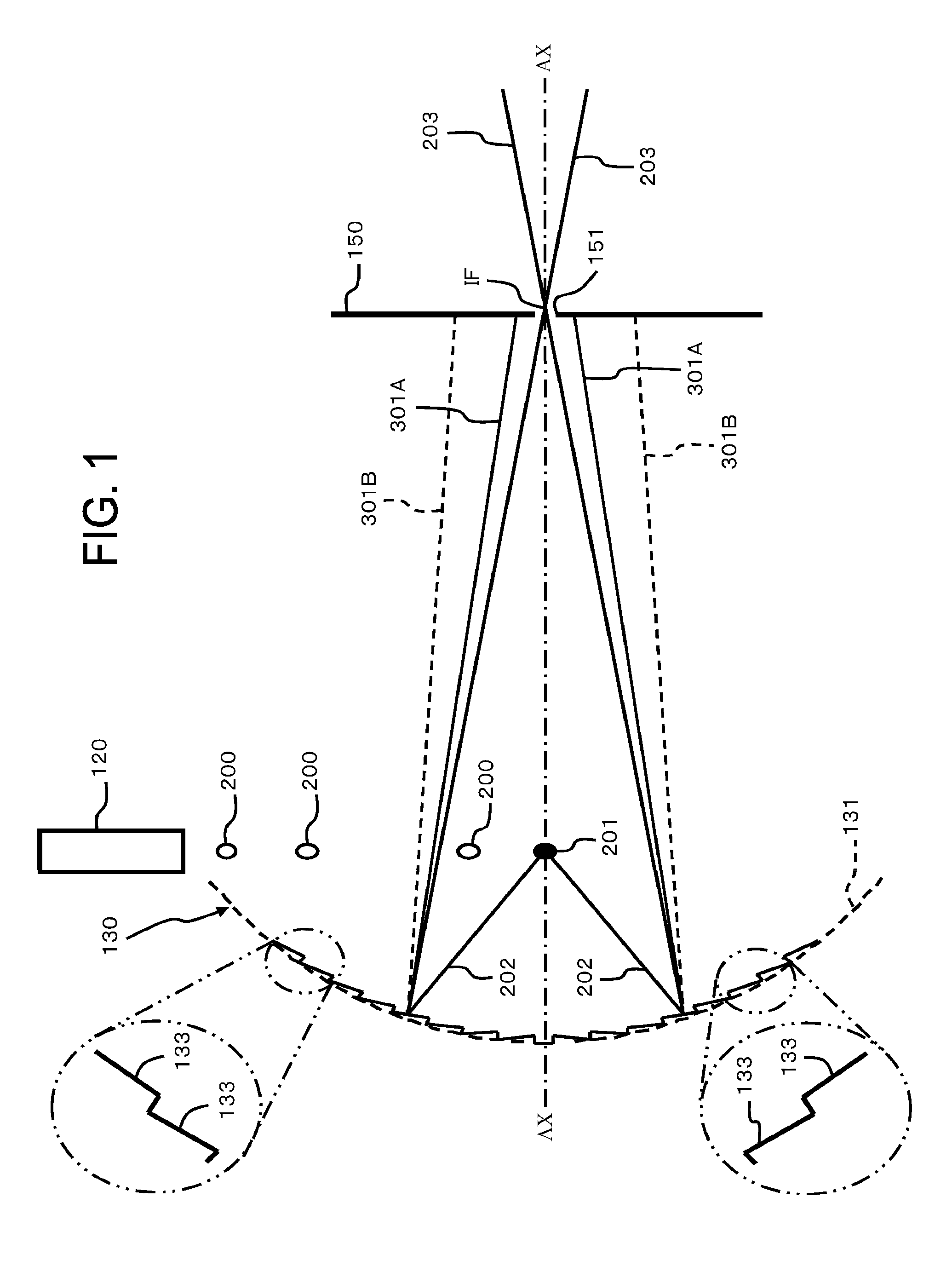

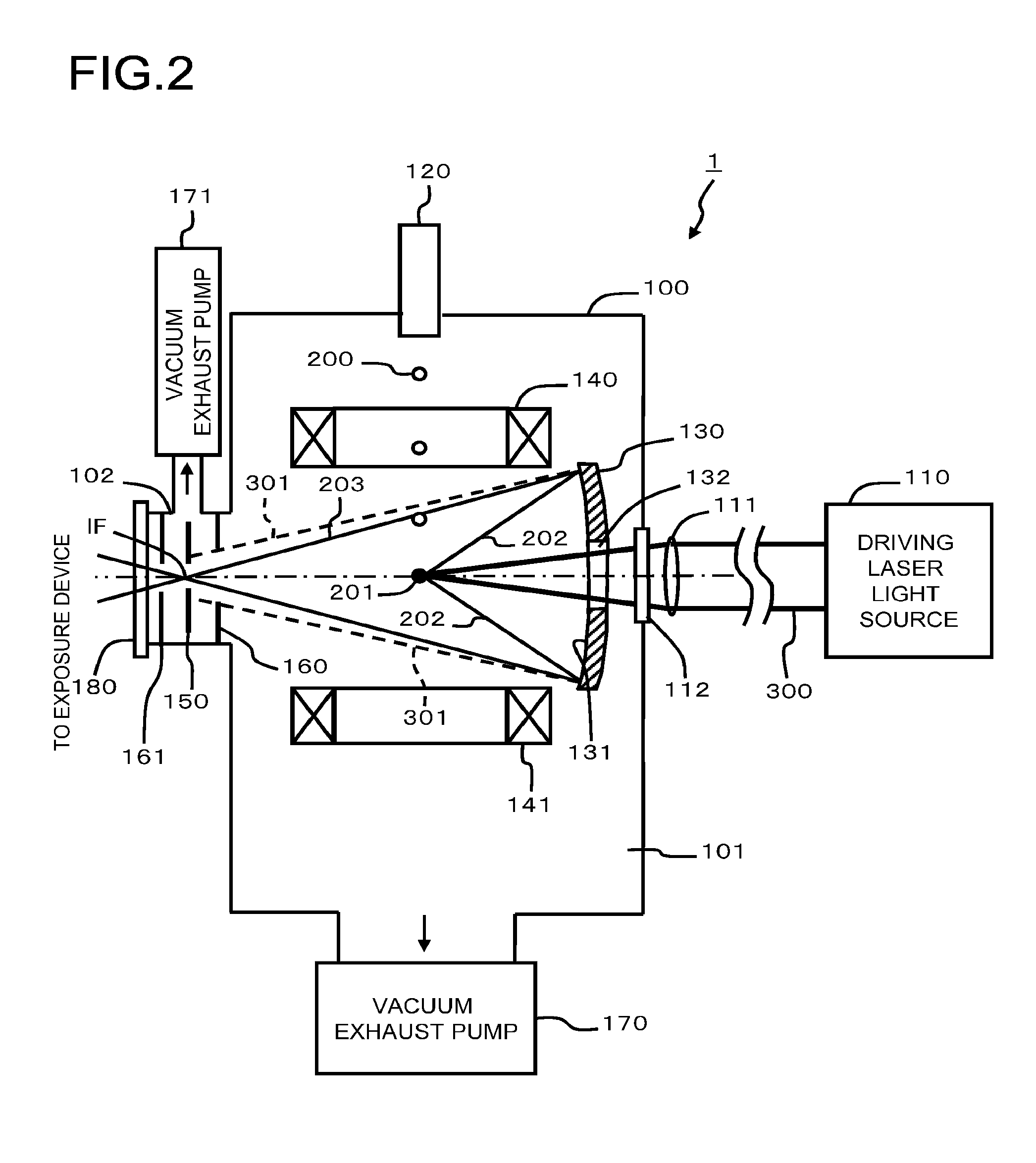

Mirror for extreme ultra violet, manufacturing method for mirror for extreme ultra violet, and far ultraviolet light source device

The EUV light source device eliminates radiation other than EUV radiation from the light which it emits, and supplies only the EUV radiation to an exposure device. A composite layer consisting of a plurality of Mo / Si pair layers is provided upon the front surface of an EUV collector mirror, and blazed grooves are formed in this composite layer. Radiation emitted from a plasma is incident upon this EUV collector mirror, and is reflected or diffracted. The reflected EUV radiation (including diffracted EUV) proceeds towards an intermediate focal point IF. The radiation of other wavelengths proceeds towards some position other than this focal point IF, because its reflection angle or diffraction angle is different. A SPF shield having an aperture portion is provided at the focal point IF. Accordingly, only the EUV radiation passes through the aperture portion and is supplied to the exposure device, while the other radiation is intercepted by the shield.

Owner:GIGAPHOTON

Method of manufacturing hydrophilic carbon nanotubes

InactiveUS7553471B2Easy to introduceLarge hydrophilicityMaterial nanotechnologyMulti-walled nanotubesFar ultravioletHydrogen

There is provided a method of manufacturing hydrophilic carbon nanotubes, which is capable of imparting hydrophilicity without damaging the surface of the carbon nanotubes. By irradiating carbon nanotubes 4 with ultraviolet ray 3, hydrophilic functional group(s) are introduced into the surface of carbon nanotubes 4. Hydrophilicity is imparted to the carbon nanotubes to such an extent that a contact angle of water is in the range of less than 130°. Ultraviolet ray 3 is a far ultraviolet ray having a wavelength ranging from 1 to 190 nm. The irradiation with ultraviolet ray 3 is conducted in the presence of oxygen and hydrogen or in the presence of ozone and hydrogen. The end part(s) of carbon nanotubes 4 is opened by the irradiation with ultraviolet ray 3.

Owner:HONDA MOTOR CO LTD +1

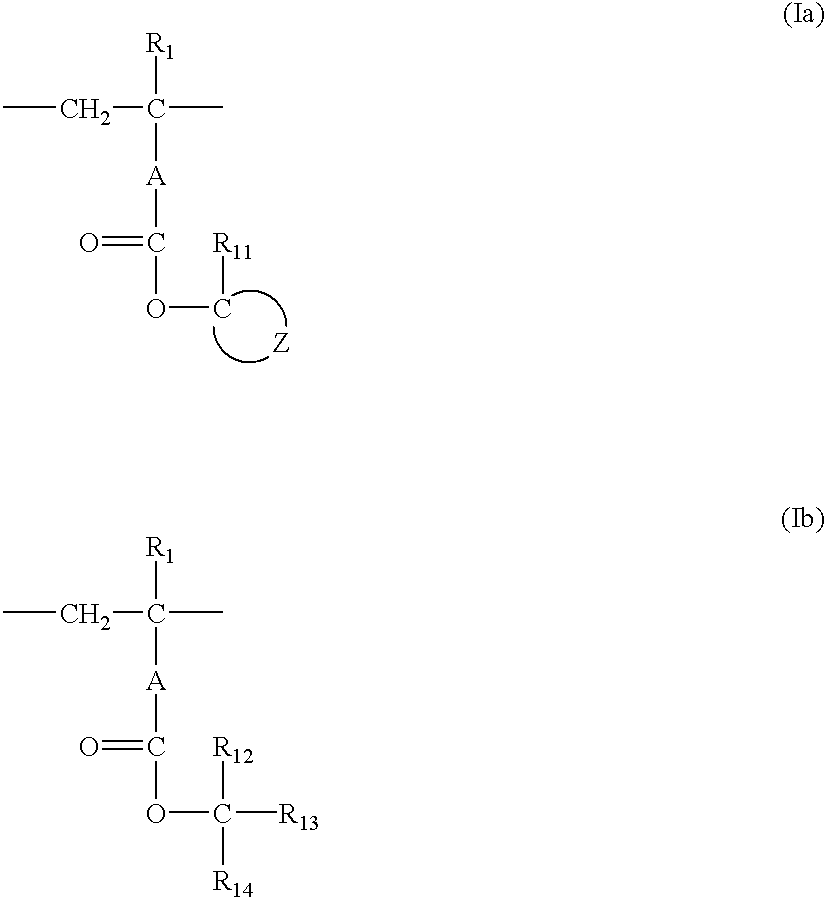

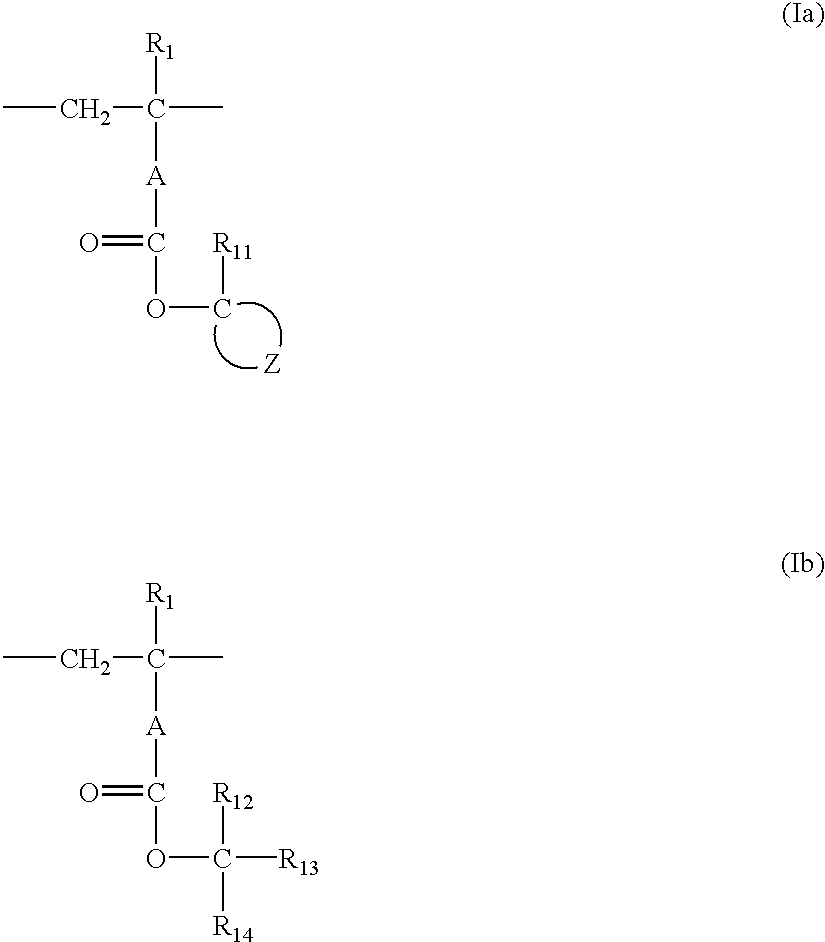

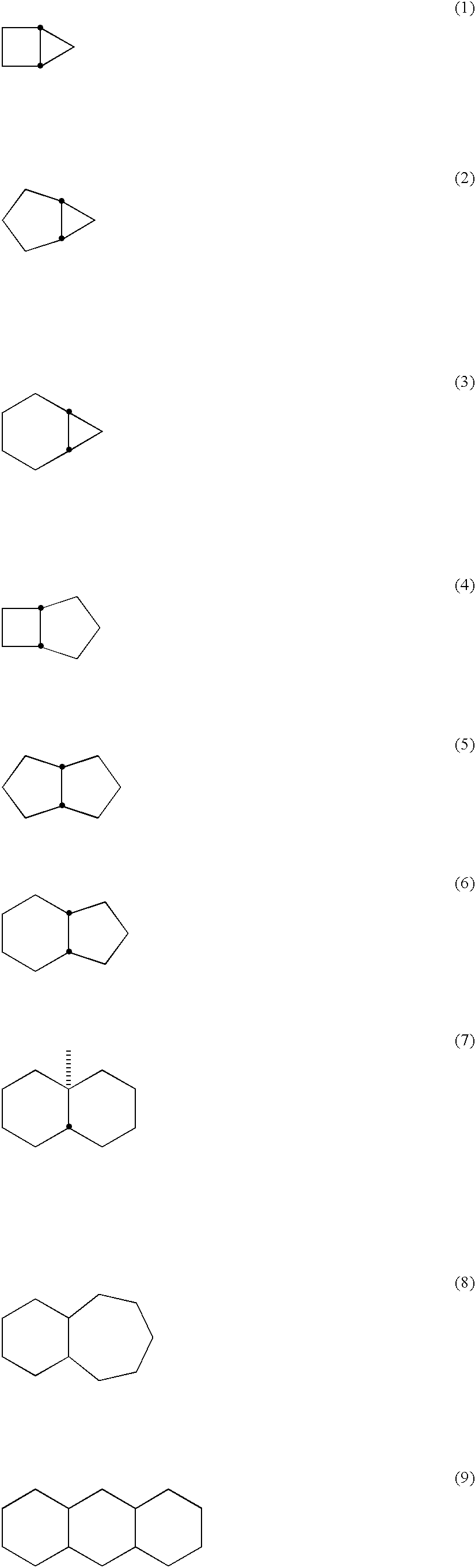

Positive resist composition

InactiveUS7179578B2High sensitivitySmall defocus latitude depended on line pitchPhotosensitive materialsRadiation applicationsEtchingSide chain

To provide a positive resist composition having high sensitivity, small defocus latitude depended on line pitch and less surface roughening at the etching, which can be suitably used for micro-photofabrication using far ultraviolet ray, particularly, ArF excimer laser ray.A positive resist composition comprising (A) a resin containing specific two kinds of repeating units, which has an aliphatic cyclic hydrocarbon group on the side chain and increases the dissolution rate in an alkali developer under the action of an acid, and (B) a specific compound capable of generating an acid upon irradiation with actinic rays or radiation, or a positive resist composition comprising (A) two kinds of resins as the resin having an aliphatic cyclic hydrocarbon group on the side chain and capable of increasing the dissolution rate in an alkali developer under the action of an acid, and (B) a compound capable of generating an acid upon irradiation with actinic rays or radiation.

Owner:FUJIFILM HLDG CORP +1

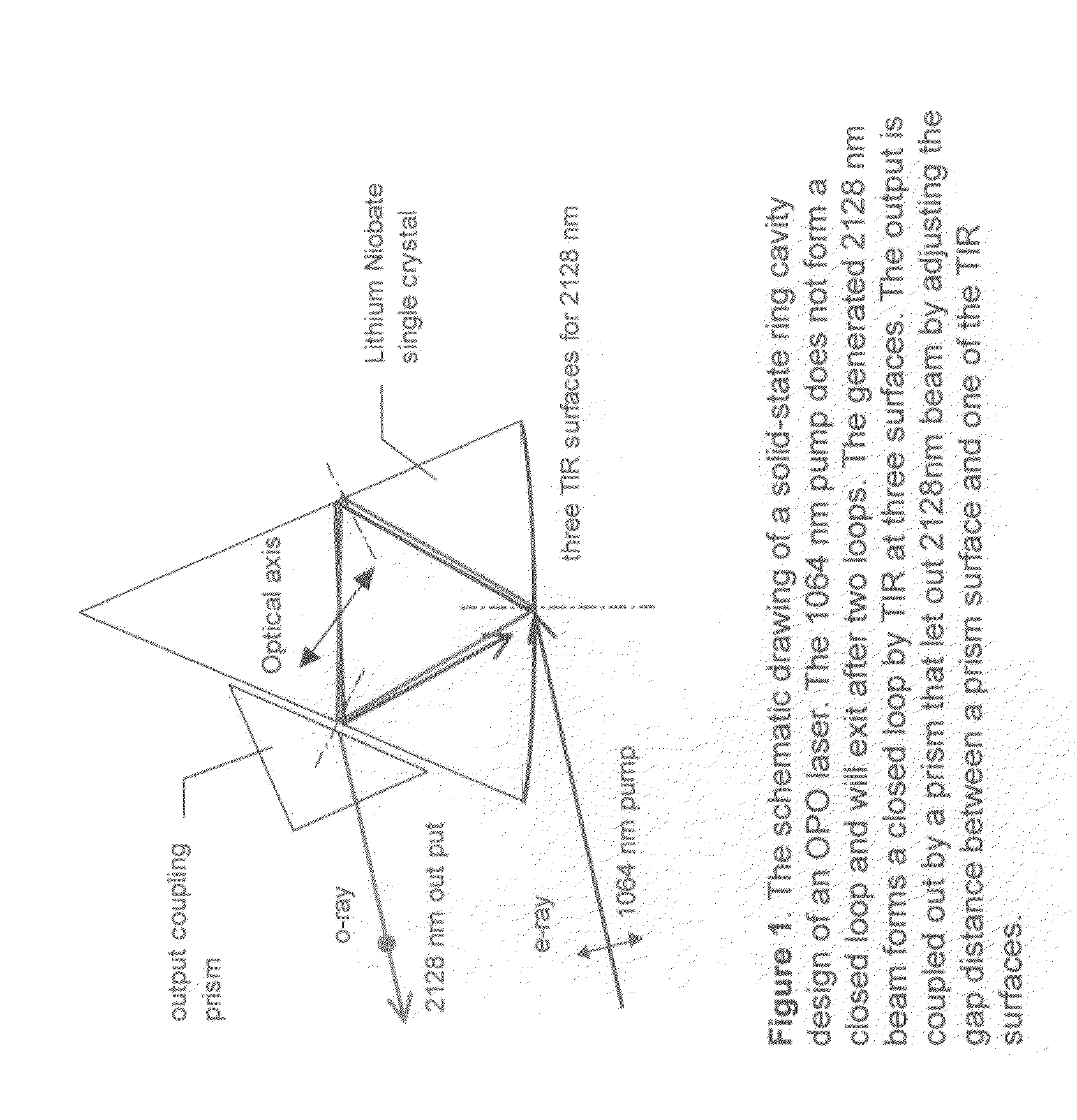

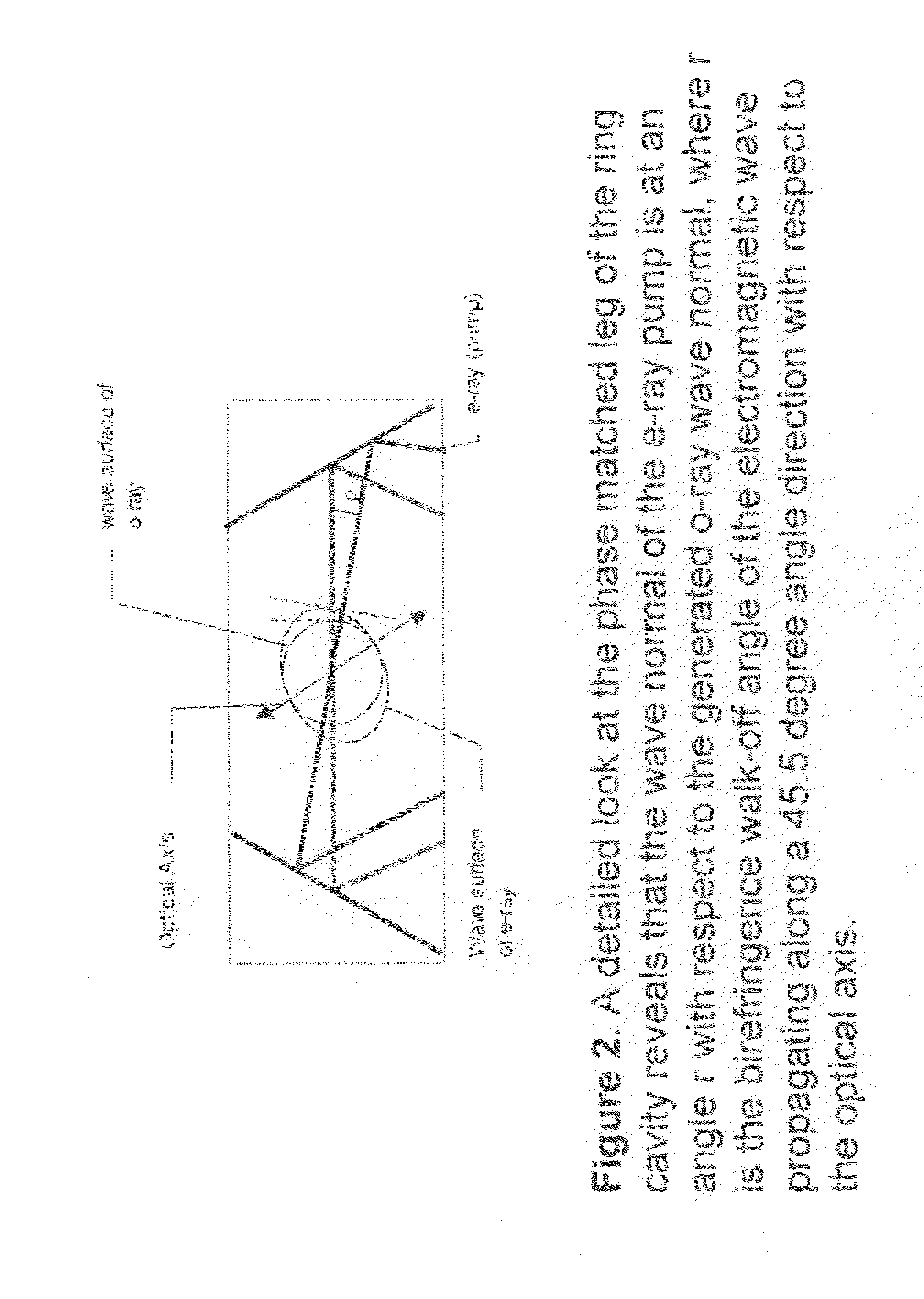

Engineered nonlinear optical crystal composites for frequency conversion

InactiveUS20090237777A1Increase powerImprove efficiencyLight demodulationNon-linear opticsNonlinear optical crystalFar ultraviolet

Walk-off corrected (WOC) non-linear optical (NLO) components, devices and systems including one or more engineered WOC NLO crystal doublets. Such systems and devices advantageously increase the efficiency of an OPO operation. Devices are applicable to any uniaxial and biaxial NLO crystals in a wide range of wavelengths, e.g., from far ultraviolet to visible to far infrared. Devices employing engineered WOC NLO components according to embodiments of the present invention include any conventional frequency converting architectures. Systems and methods are also provided to unambiguously determine and correct walk-off for any arbitrary uniaxial and biaxial crystal orientation. The correct crystal orientation is also experimentally confirmed. This allows the use of WOC crystal doublet assemblies for a wide range of wavelengths and NLO crystals that until now have not been used because of low efficiency due to walk-off and inability of readily correcting walk-off.

Owner:ONYX OPTICS

Engineered nonlinear optical crystal composites for frequency conversion

InactiveUS20090041067A1Easy to operateIncrease powerLaser detailsUsing optical meansNonlinear optical crystalFar ultraviolet

Walk-off corrected (WOC) non-linear optical (NLO) components, devices and systems including one or more engineered WOC NLO crystal doublets. Such systems and devices advantageously increase the efficiency of an OPO operation. Devices are applicable to any uniaxial and biaxial NLO crystals in a wide range of wavelengths, e.g., from far ultraviolet to visible to far infrared. Devices employing engineered WOC NLO components according to embodiments of the present invention include any conventional frequency converting architectures. Systems and methods are also provided to unambiguously determine and correct walk-off for any arbitrary uniaxial and biaxial crystal orientation. The correct crystal orientation is also experimentally confirmed. This allows the use of WOC crystal doublet assemblies for a wide range of wavelengths and NLO crystals that until now have not been used because of low efficiency due to walk-off and inability of readily correcting walk-off.

Owner:ONYX OPTICS

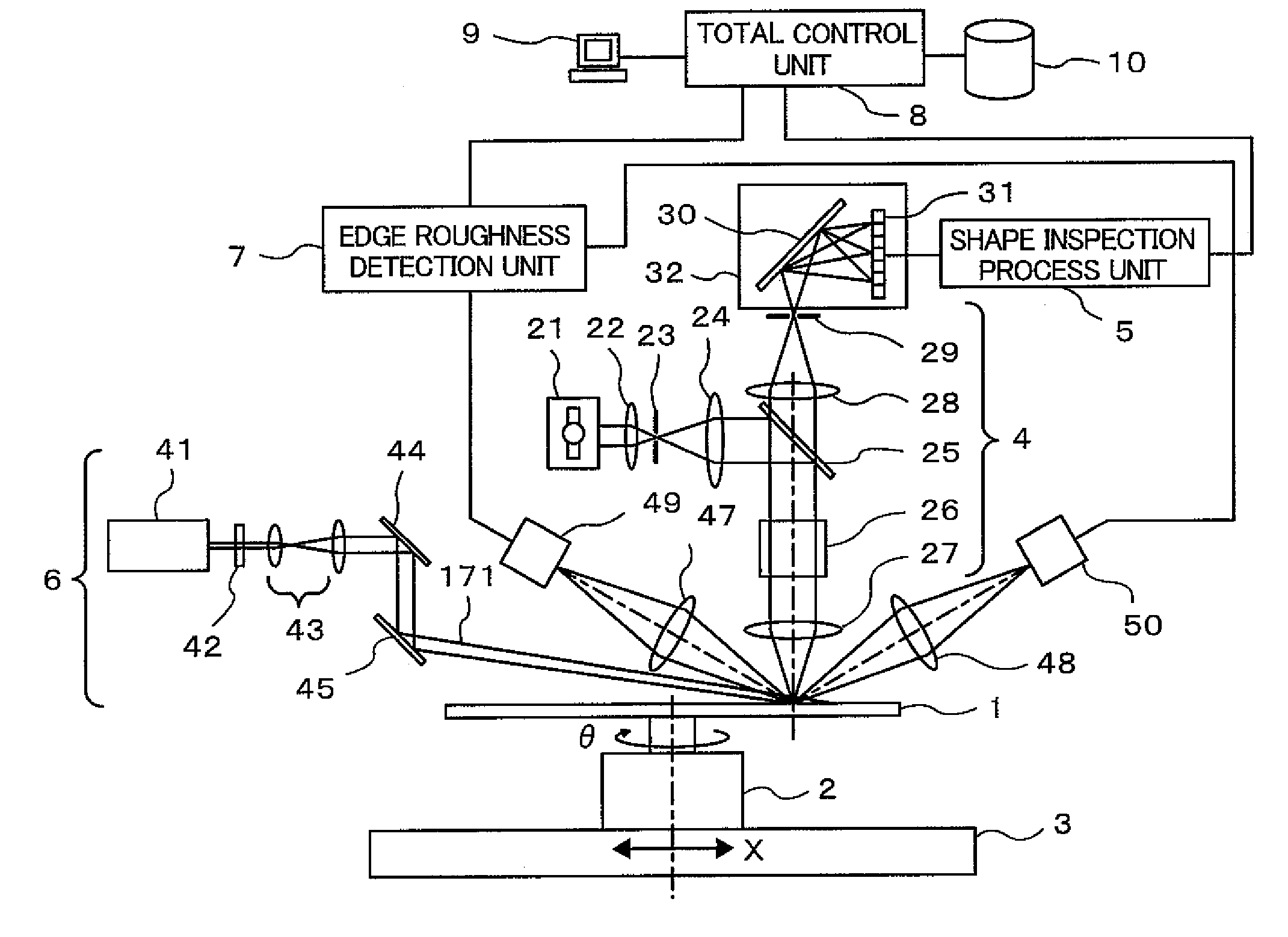

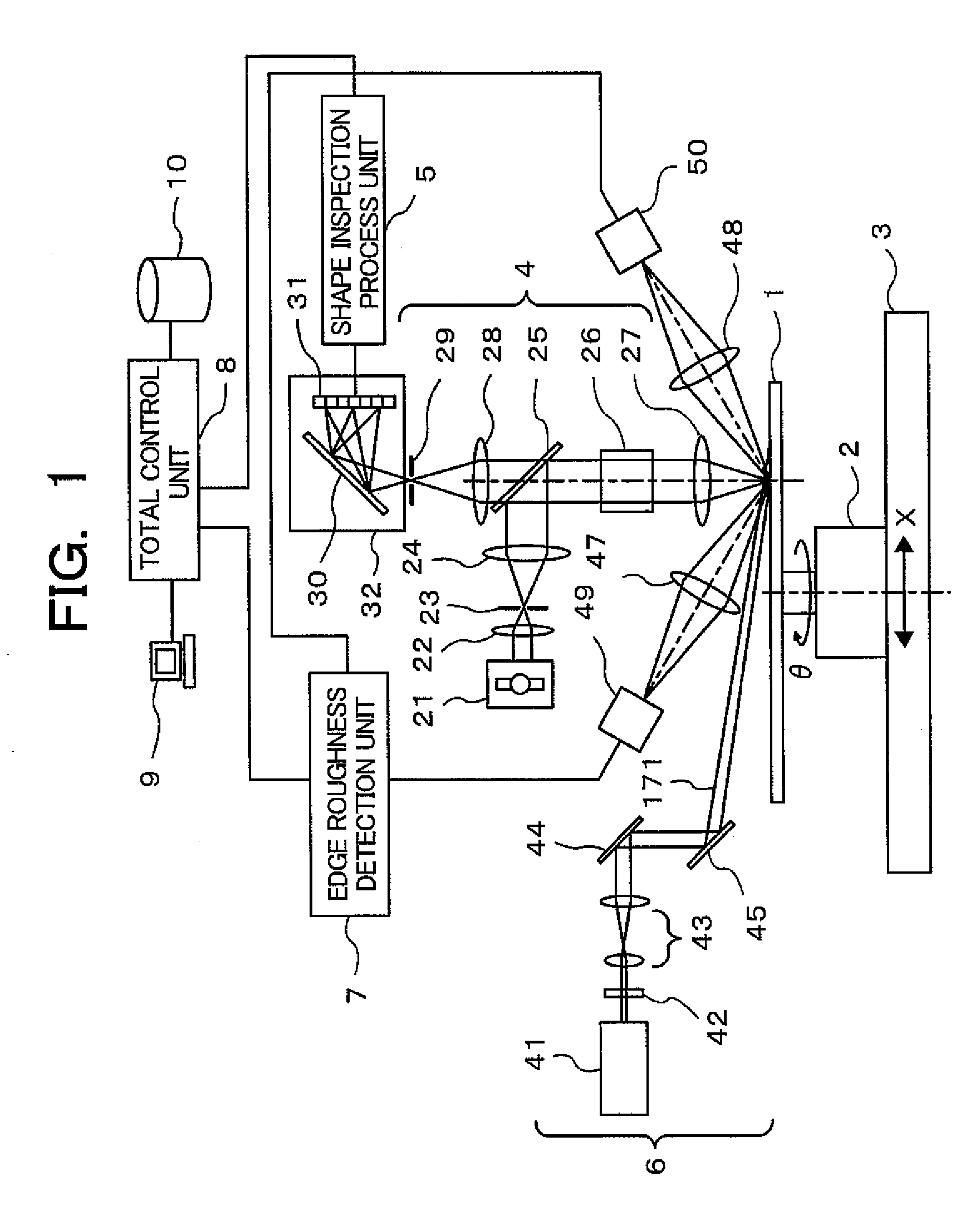

Pattern shape inspection method and apparatus thereof

This invention relates to a pattern shape inspection method and an apparatus thereof for conducting a first step of irradiating wideband illuminating light which contains far ultraviolet light to a sample from a perpendicular direction, inspecting a shape of the pattern based on a spectral waveform of reflecting light detected from the sample, and detecting an edge roughness of the pattern based on the spectral waveform of the reflecting light detected from the sample, and a second step of irradiating a laser beam to the sample from an oblique direction, and detecting the edge roughness of the pattern based on scattered light detected from the sample.

Owner:HITACHI HIGH-TECH CORP

Extreme ultraviolet light source with a debris-mitigated and cooled collector optics

InactiveUS8723147B2Increase speedAvoid absorptionRadiation pyrometryFouling preventionFar ultravioletShielding gas

The extreme ultraviolet light source comprises a production site capable of producing extreme ultraviolet radiation in a laser-produced plasma (3), and a collector optics (6) for collimating the extreme ultraviolet radiation. A pressurized influx of gas forms a gas curtain between the production site and the collector optics (6) in order to protect the collector optics (6) from debris (4) generated at the production site. The gas influx is directed in a way that it follows the surface of the collector optics (6). By thus shielding the collector optics (6) from the debris (4) its lifetime is enhanced. The shielding gas can further be used for cooling the collector optics (6).

Owner:ETH ZZURICH

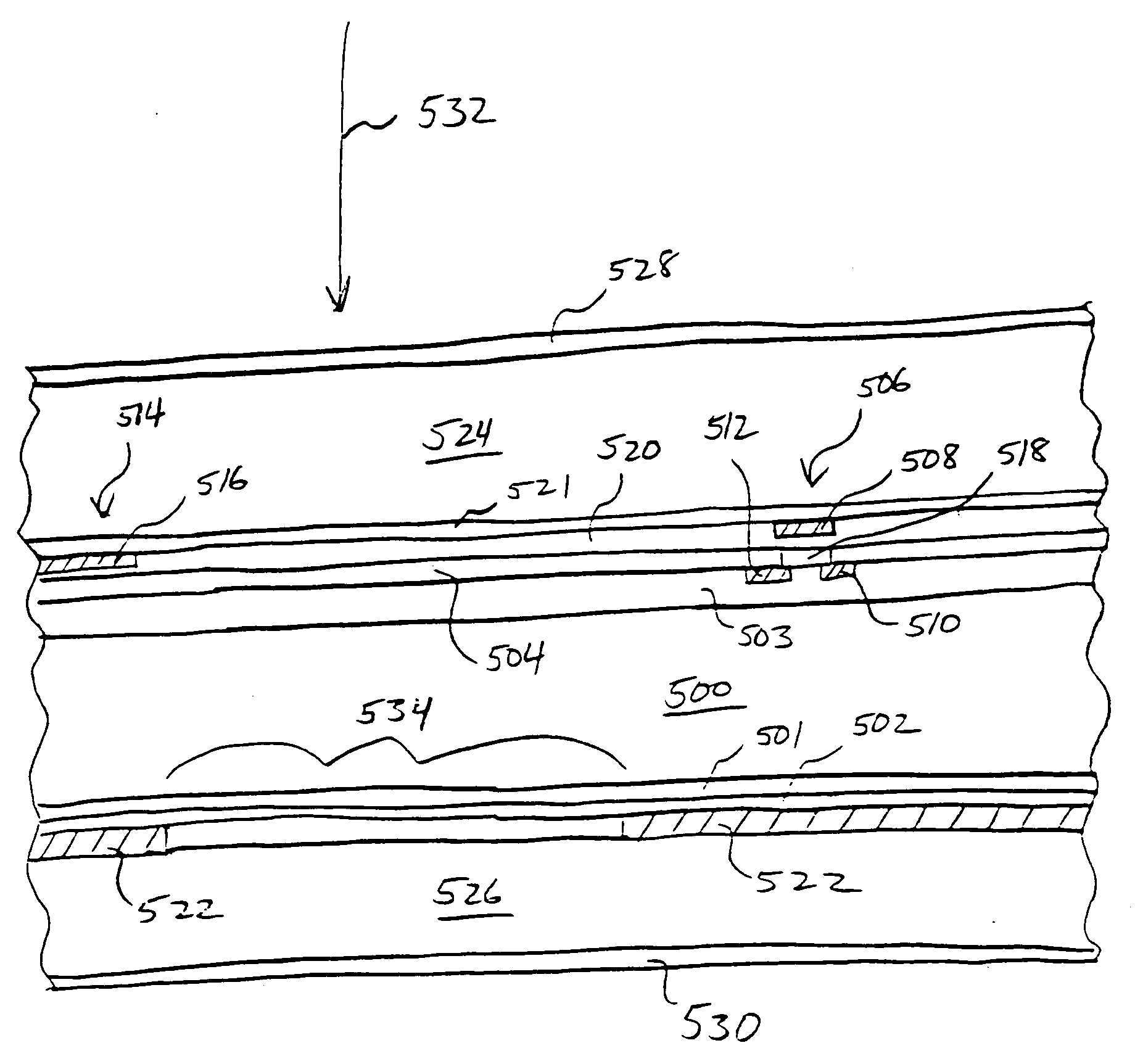

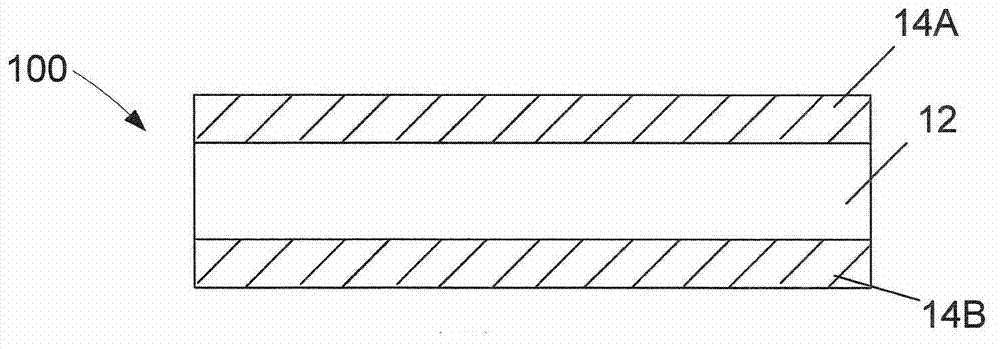

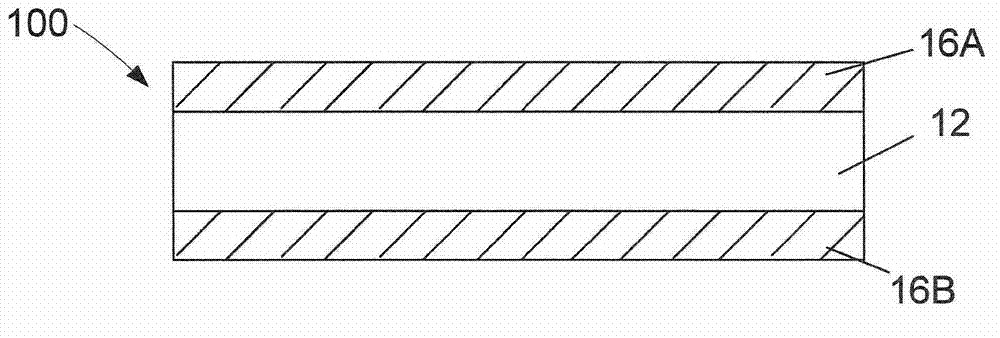

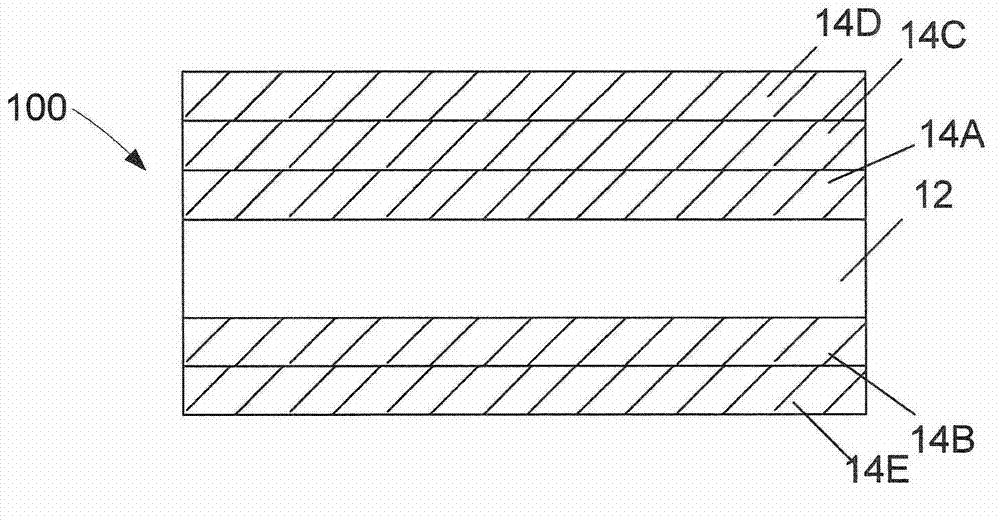

Pellicles for use during euv photolithography processes

InactiveCN103324034APhotomechanical exposure apparatusMicrolithography exposure apparatusFar ultravioletUltraviolet

Disclosed herein are various pellicles for use during extreme ultraviolet (EUV) photolithography processes. An EUV radiation device disclosed herein includes a reticle, a substrate support stage, a pellicle positioned between the reticle and the substrate support stage, wherein the pellicle is comprised of multiple layers of at least one single atomic-plane material, and a radiation source that is adapted to generate radiation at a wavelength of about 20 nm or less that is to be directed through the pellicle toward the reticle.

Owner:GLOBALFOUNDRIES INC

Light source special for livestock and poultry building

InactiveCN101966347ASolve the purification problemSolve sterilizationLight therapyRadiationUltraviolet lightsOxygen

The invention relates to a light source special for a livestock and poultry building. A main body of the light source special for the livestock and poultry building is a luminous tube. The light source is characterized in that: an outer shell of a tube shell is made of far ultraviolet quartz glass; the tube shell is vacuumized and then is filled with inert gases and mercury drops; the inner wall of the tube shell is coated with composite fluorescent powder; a 2mm wide slot in a length direction of the tube shell is not coated with the fluorescent powder to form a transparent open slot; and ultraviolet light with the wavelengths of 185nm and 253.7nm are generated in the collision process of low-pressure mercury vapor and high-speed electrons, wherein the ultraviolet light with the wavelength of 185nm changes oxygen (O2) in air into ozone (O3) by passing through the open slot; part of the ultraviolet light with the wavelength of 253.7nm directly plays a role in sterilizing by passing through the open slot; and most of the ultraviolet light with the wavelength of 253.7nm is used for exciting the fluorescent powder to generate health-care ultraviolet light with the wavelengths of 280 to 320nm. The light source special for the livestock and poultry building has the advantages of not only solving the problem of purification and disinfection of a culture environment but also solving the problem of lack of health-care rays radiation during livestock and poultry breeding, such as ultraviolet B (UVB with the wavelengths of 280 to 320nm) in sunlight, returning a nature-like environment to animals in the livestock and poultry building, and contributing to the healthy growth of the animals in the livestock and poultry building.

Owner:南通格林福得禽业科技有限公司

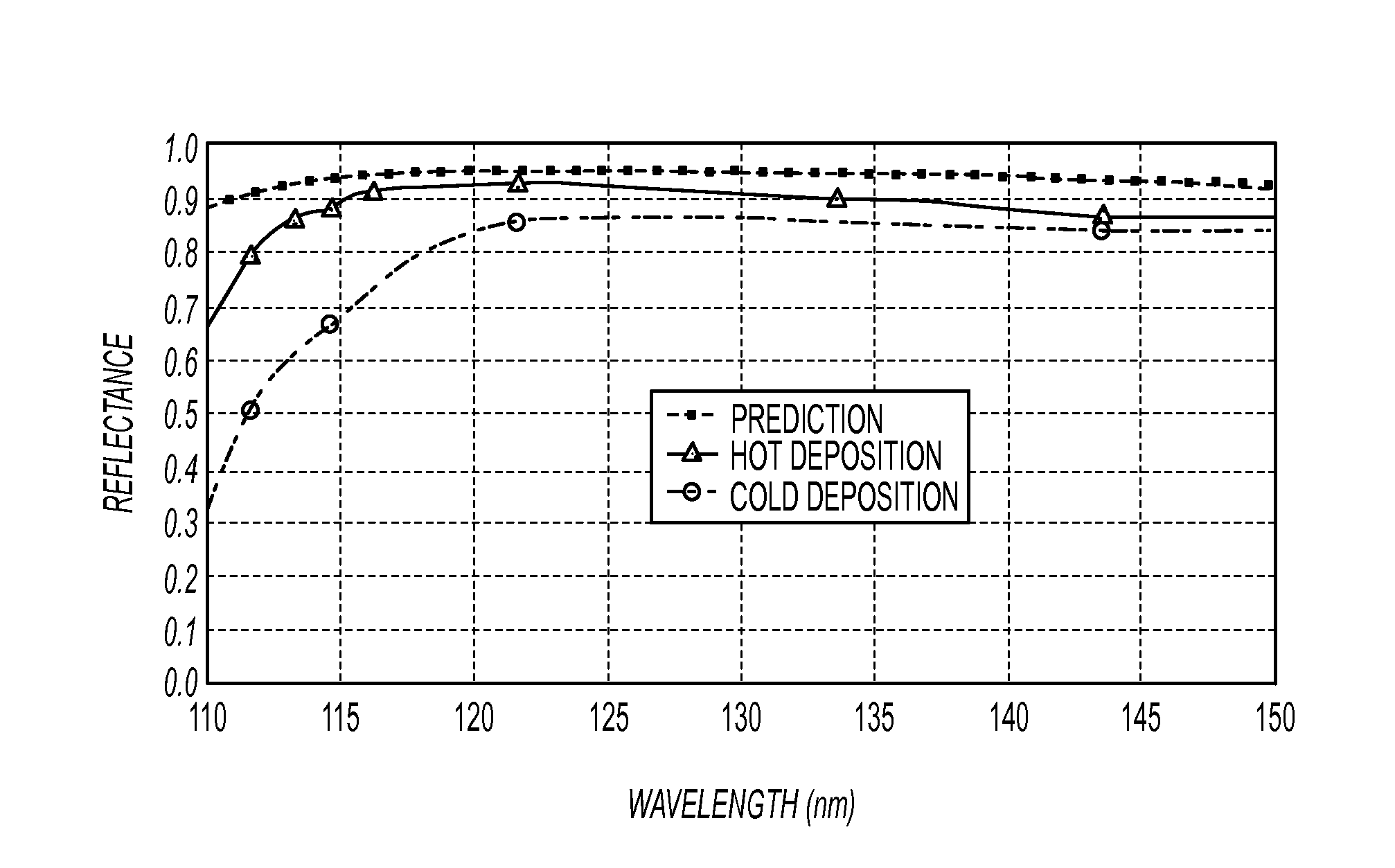

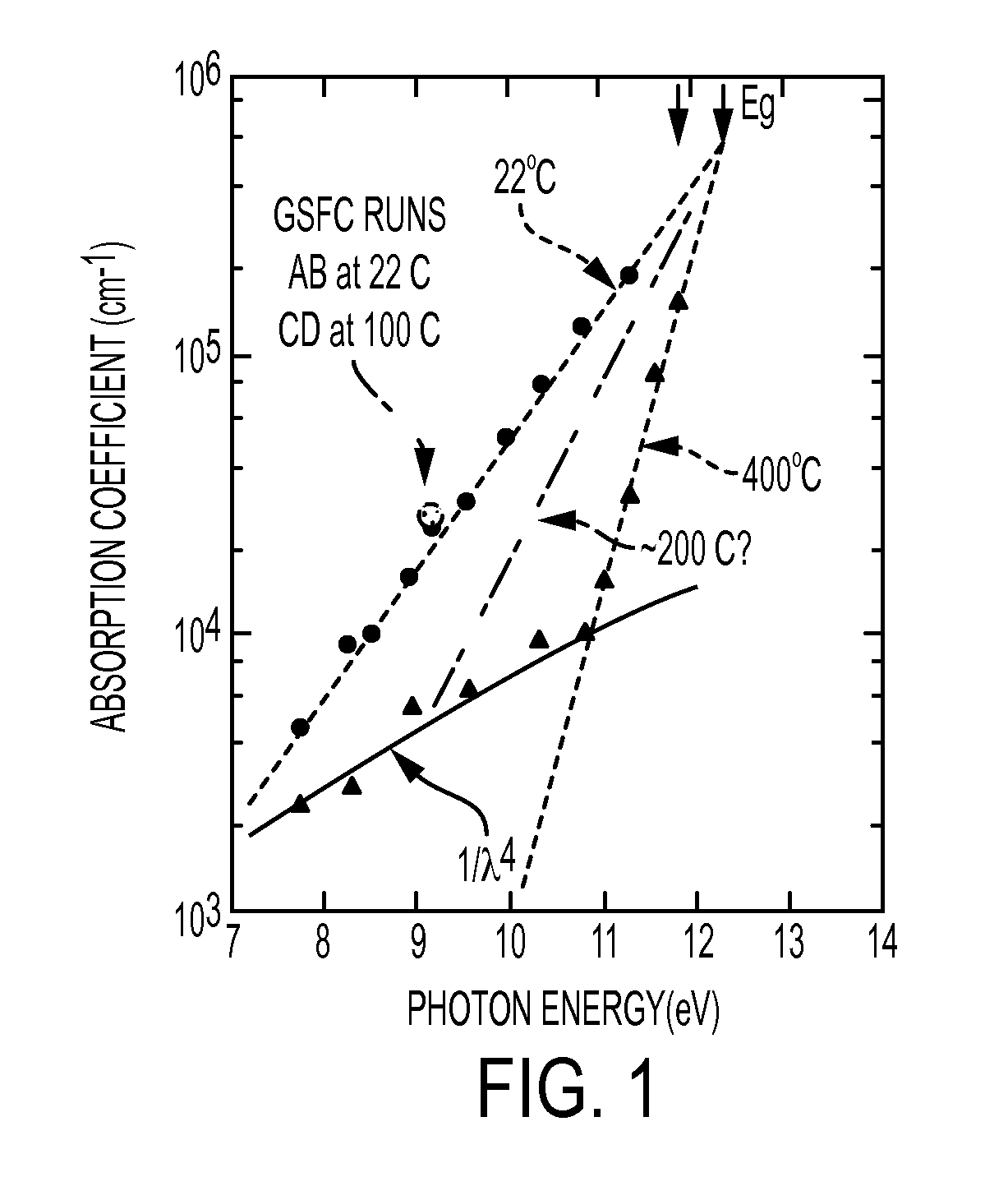

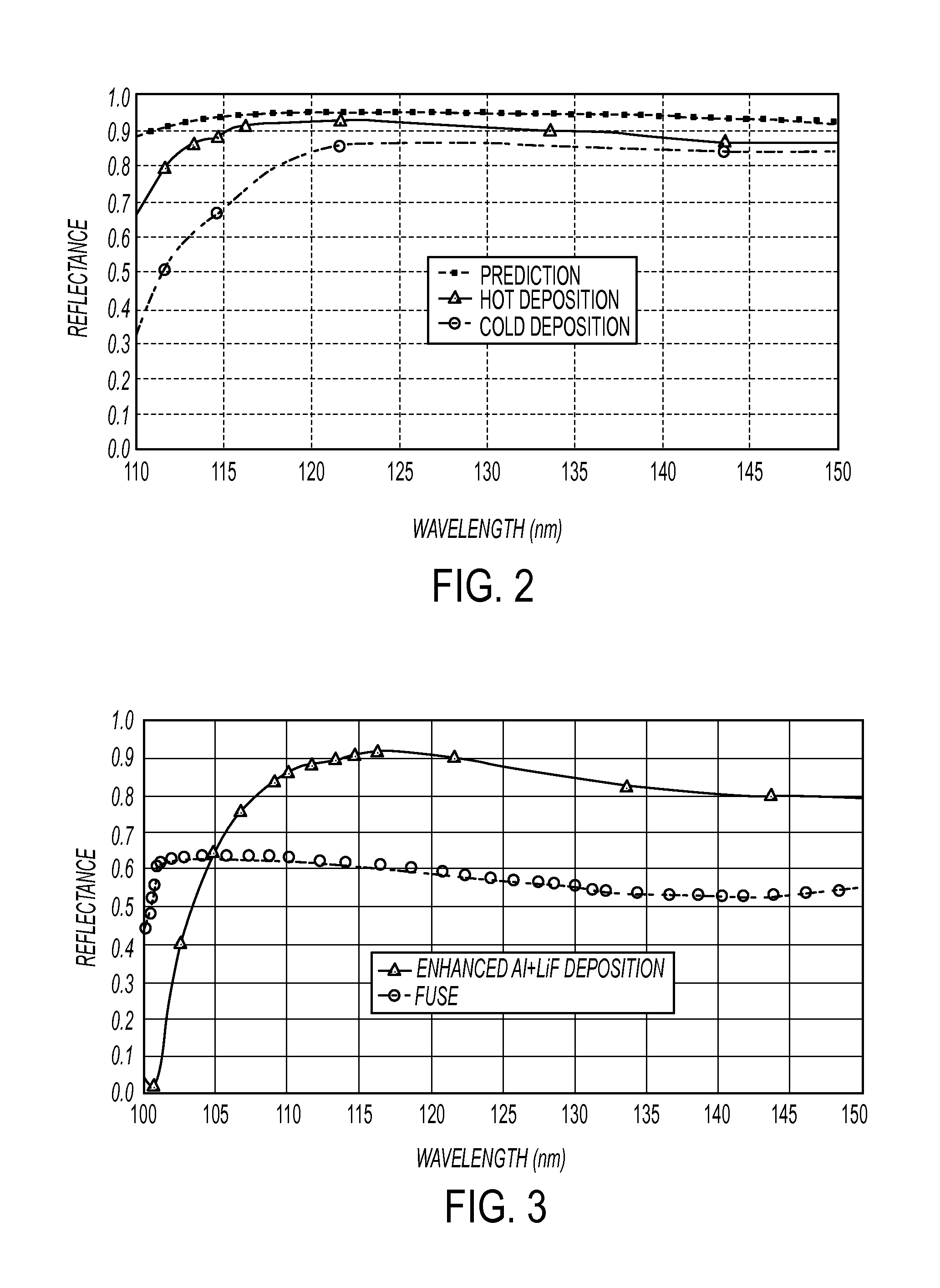

MgF2 AND LIF AND RARE-EARTH FLUORIDE FILMS FOR ALUMINUM MIRRORS FOR FAR-ULTRAVIOLET SPECTRAL REGION AND METHOD OF MAKING SAME

InactiveUS20170031067A1Enhanced magnesium fluorideImprove performanceMirrorsTelescopesFar ultravioletLutetium

The present invention relates to enhanced magnesium fluoride (MgF2) and lithium fluoride (LiF) over-coated aluminum (Al) mirrors, for far-ultraviolet (FUV) spectral region, and a method of making same. In addition, the present invention relates to rare-earth fluorides such as gadolinium fluoride (GdF2) and lutetium fluoride (LuF3) films, which are used as high-index layers, that when paired with the lower index MgF2, will provide multilayer coatings operable in the FUV spectral region.

Owner:NASA

Mirror for extreme ultra violet, manufacturing method for mirror for extreme ultra violet, and far ultraviolet light source device

An EUV light source is configured for generating an EUV light for an exposure device. The EUV light source includes a chamber, a target supply device configured for supplying a target into the chamber, an optical system for introducing laser light from a driver laser into the chamber and irradiating the target with the laser light to turn the target into plasma from which EUV light is emitted, and an EUV collector mirror in the chamber. The EUV collector mirror may include a multilayered reflecting surface with grooves and collect the EUV light from the plasma to a focal spot. The grooves can be arranged in a concentric fashion, and be configured for diffracting at least light at a wavelength which is the same as that of the laser light from the driver laser.

Owner:GIGAPHOTON

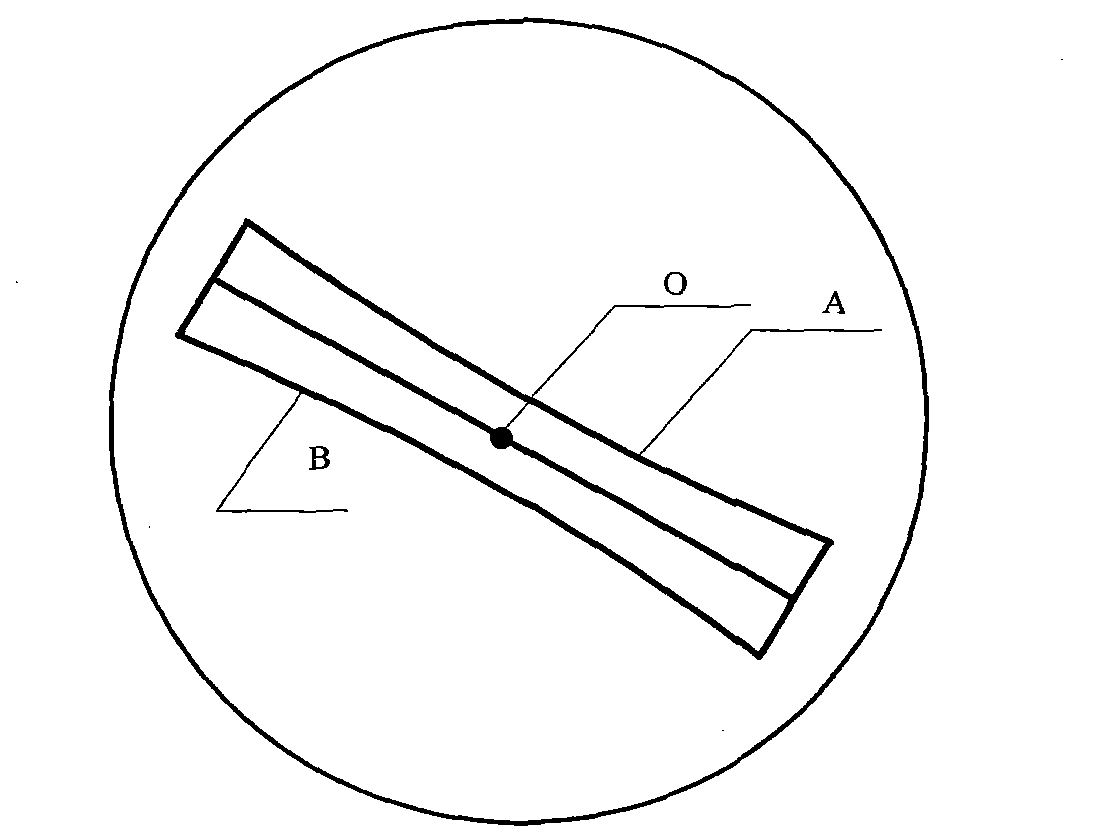

Calibration device of ultra-far ultraviolet source

ActiveCN102998088AAvoid interferenceQuick switchRadiation pyrometryOptical apparatus testingFar ultravioletRadiance

The invention provides a calibration device of an ultra-far ultraviolet source. The calibration device comprises a light source, a converging swing mirror unit, an ultraviolet monochrometer unit, a detector unit and a pressure difference unit, wherein the converging swing mirror unit comprises a converging swing mirror which comprises swing mirrors and a rotation displacement platform, the swing mirrors are two concave reflectors bonded by non-reflecting surfaces, central axes of the reflectors of the swing mirrors are coincide, a 30nm-200nm reflecting film is coated on a reflecting surface A of one reflector, and a 60nm-200nm reflecting film is coated on a reflecting surface B of the other reflector. The calibration device can correct spectral radiance parameters of the light source in 30nm-200nm. The calibration device can correct spectral radiance parameters of the light source in 30nm-200nm. The calibration device is small in size, has sufficient ports, has unique design on ultra ultraviolet and far ultraviolet radiation calibration and removal of high-level spectra, and improves accuracy of the ultra ultraviolet and far ultraviolet radiation calibration.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

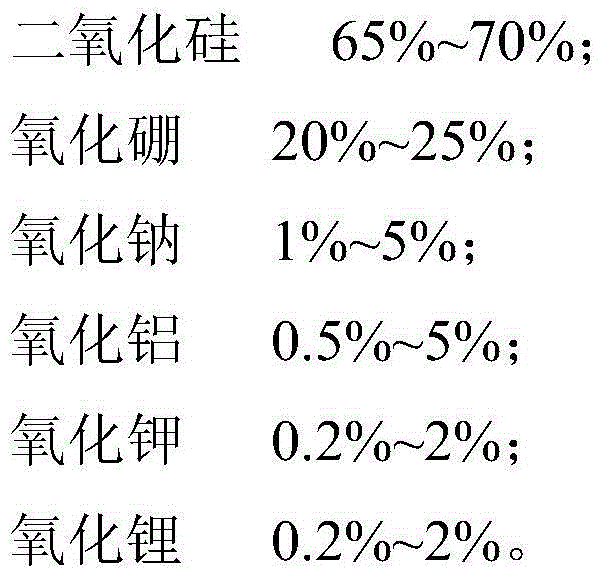

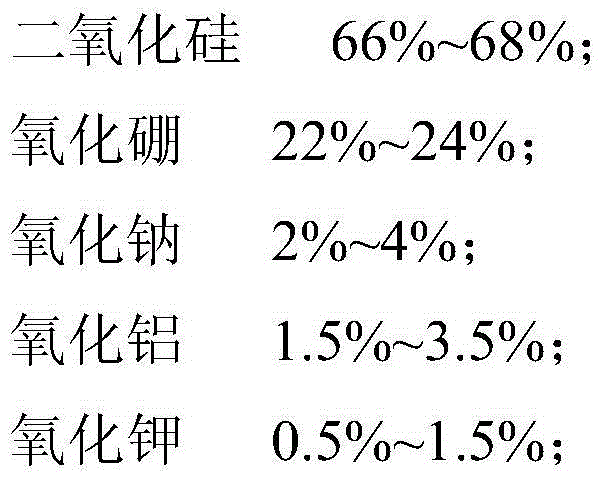

Borosilicate glass with high transmittance at far ultraviolet band and preparation method thereof

InactiveCN104591539AImprove transmittanceExcellent chemical stability against waterLithium oxideThermal expansion

The invention relates to the field of glass manufacturing and particularly relates to borosilicate glass with high transmittance at a far ultraviolet band and a preparation method thereof. The borosilicate glass is composed of the following components in percentage by mass: 65-70% of silica, 20-25% of boron oxide, 1-5% of sodium oxide, 0.5-5% of alumina, 0.2-2% of potassium oxide and 0.2-2% of lithium oxide. The preparation method comprises the following steps: weighing materials: weighing the raw material components according to a set proportion and mixing to form a mixture; calcining: calcining the mixture; smelting: smelting the calcined mixture into molten glass under a high temperature condition; molding: carrying out casting molding on the molten glass to obtain a glass block, and annealing the glass block. The borosilicate glass has good chemical stability, small thermal expansion coefficient band, good matching property with a kovar alloy and high transmittance at the far ultraviolet band, the preparation method is simple, and the production cost is low.

Owner:CHINA BUILDING MATERIALS ACAD

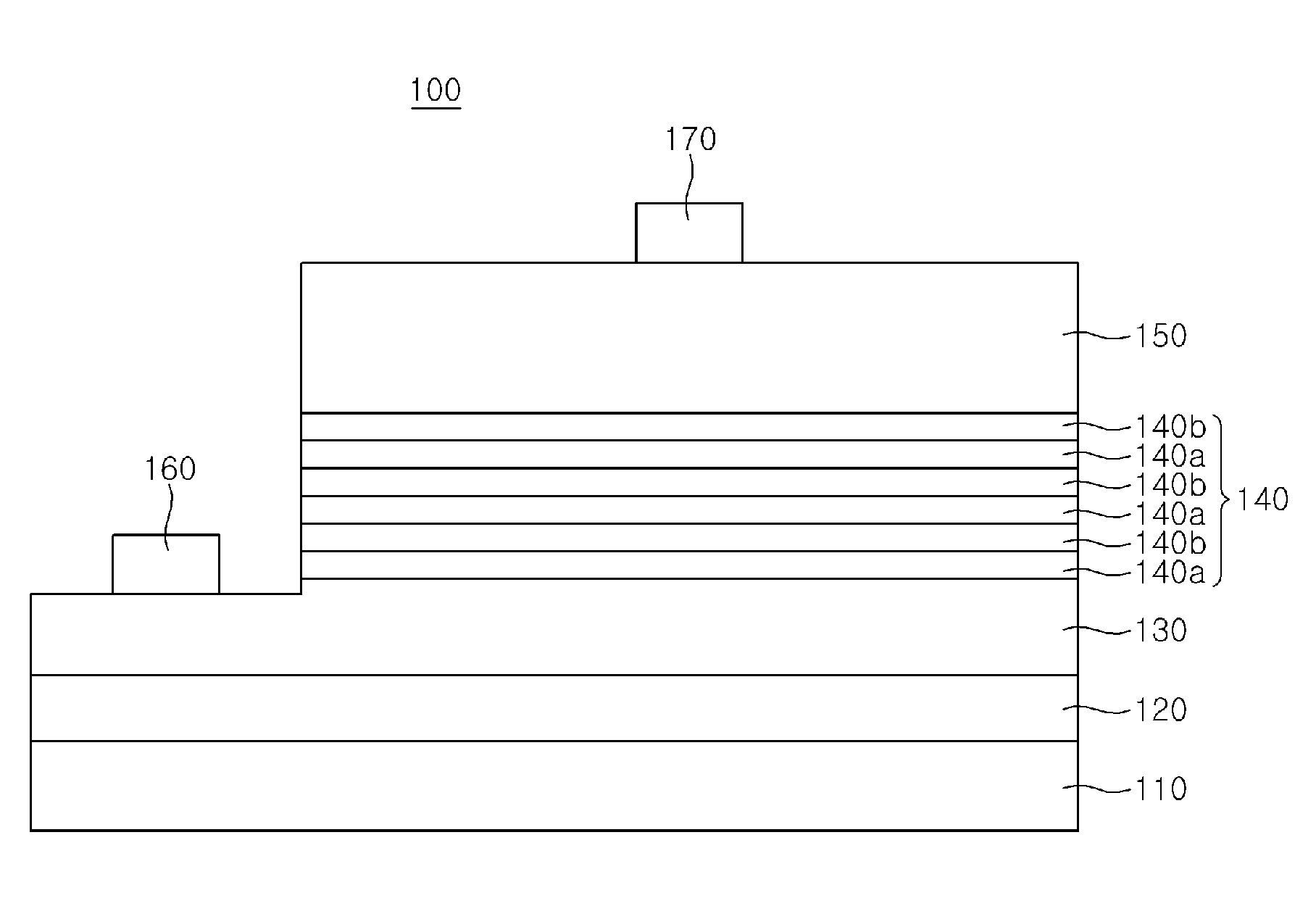

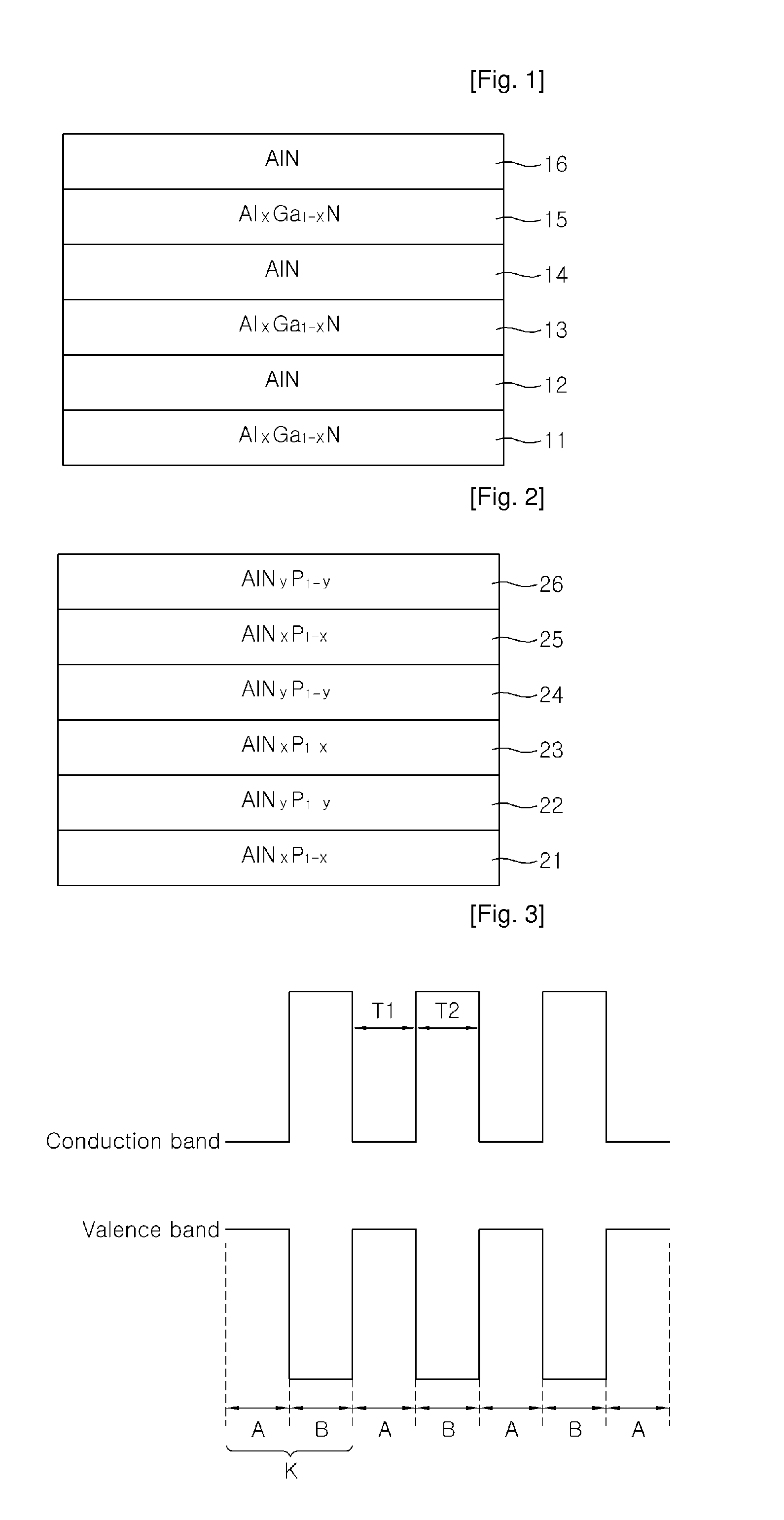

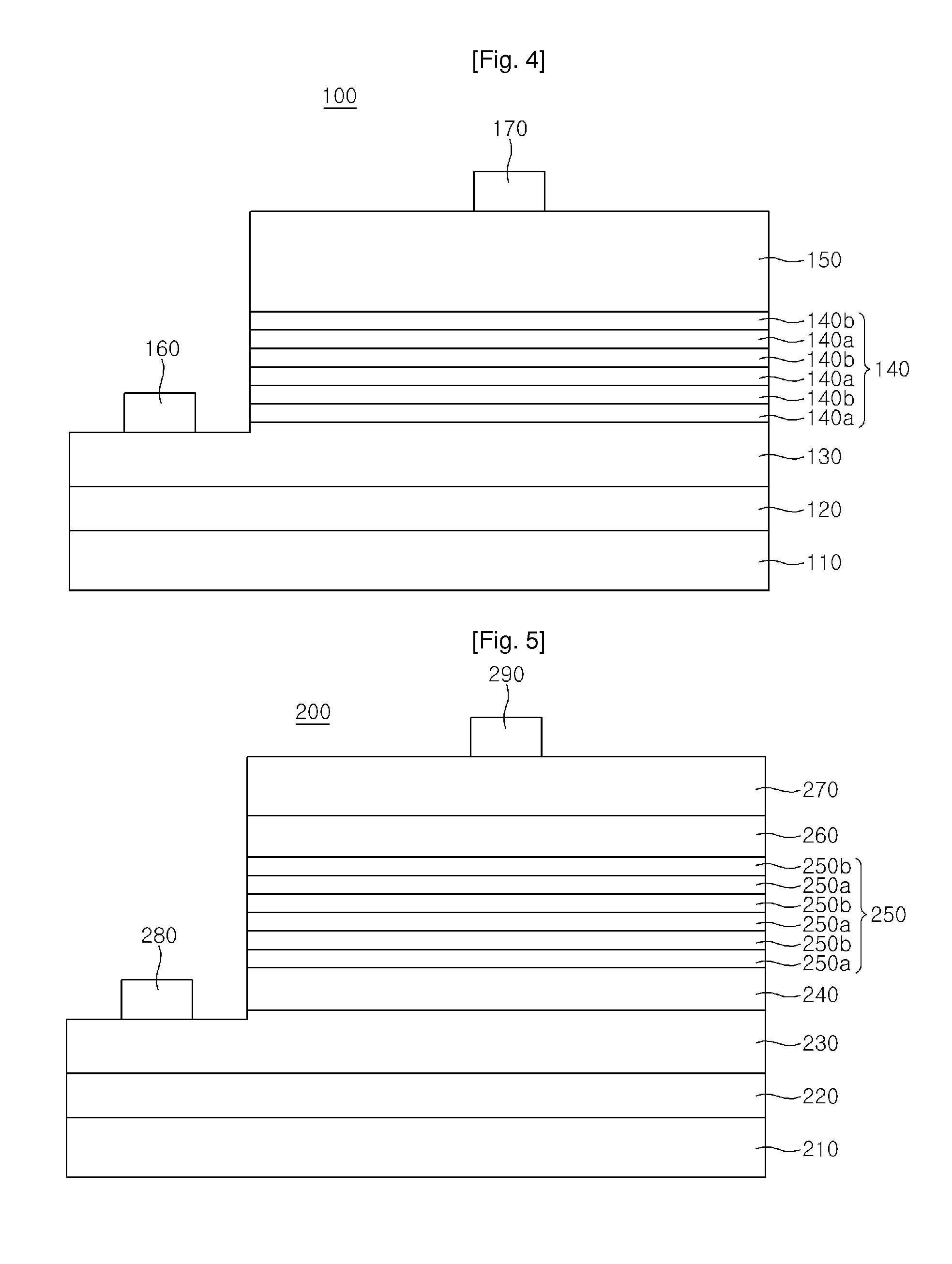

Light Emitting Diode

InactiveUS20080258131A1Improve distributionEnhance layeringNanoopticsSemiconductor devicesFar ultravioletQuantum well

The present invention relates to a light emitting diode. More specifically, the present invention relates to a light emitting diode comprising an N-type semiconductor layer formed on a substrate, an active layer formed on the N-type semiconductor layer and a P-type semiconductor layer formed on the active layer, wherein the active layer is formed to have either a quantum well structure in which an AlxGa1-xN (0≦x<1) well layer and an AlN barrier layer are alternately laminated or a quantum well structure in which a well layer and a barrier layer are formed of a compound semiconductor layer containing phosphorous (P) and are alternately laminated. Accordingly, far-ultraviolet light can be easily emitted and the optical power of the light emitting diode can also be improved.

Owner:SEOUL OPTO DEVICE CO LTD

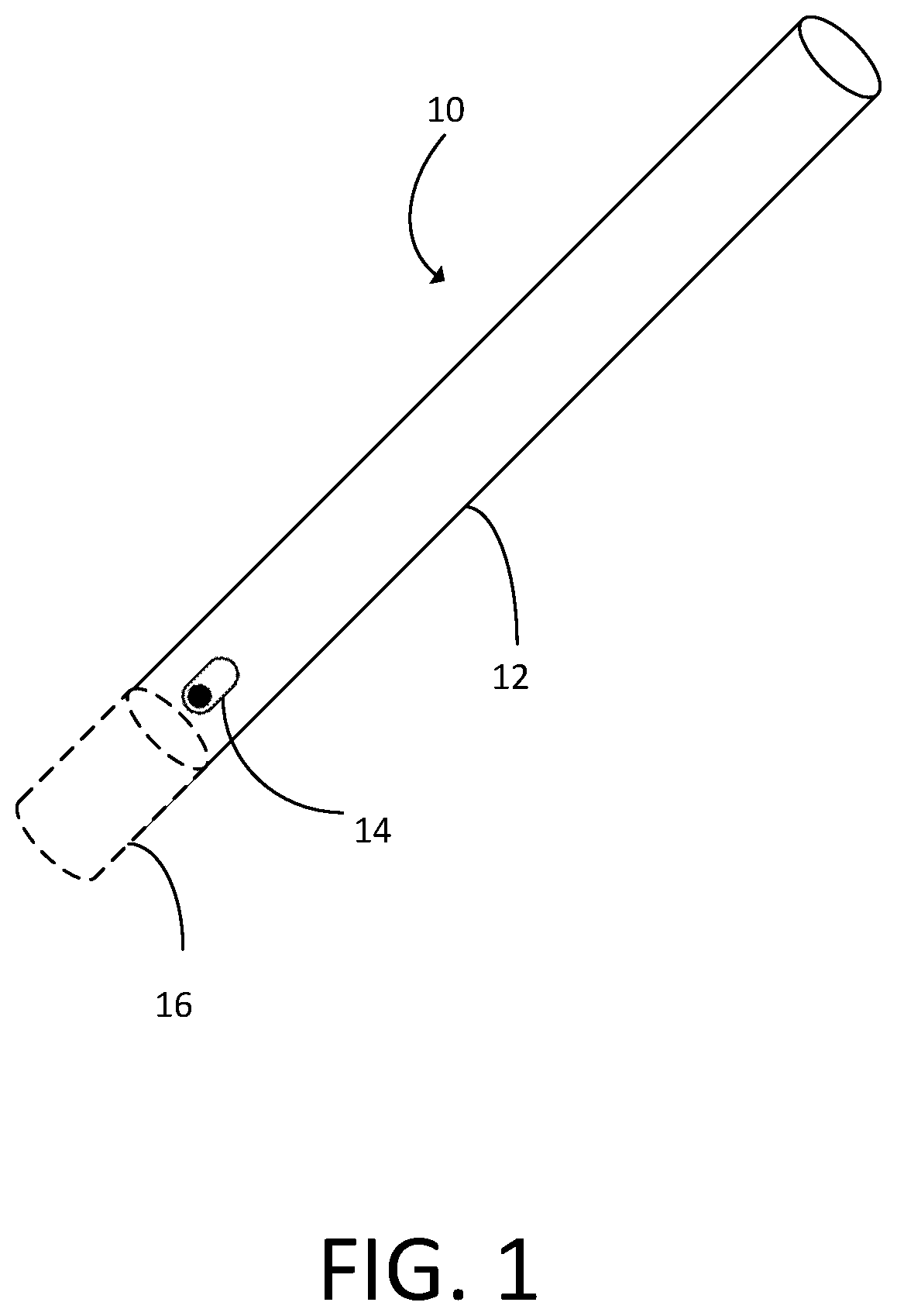

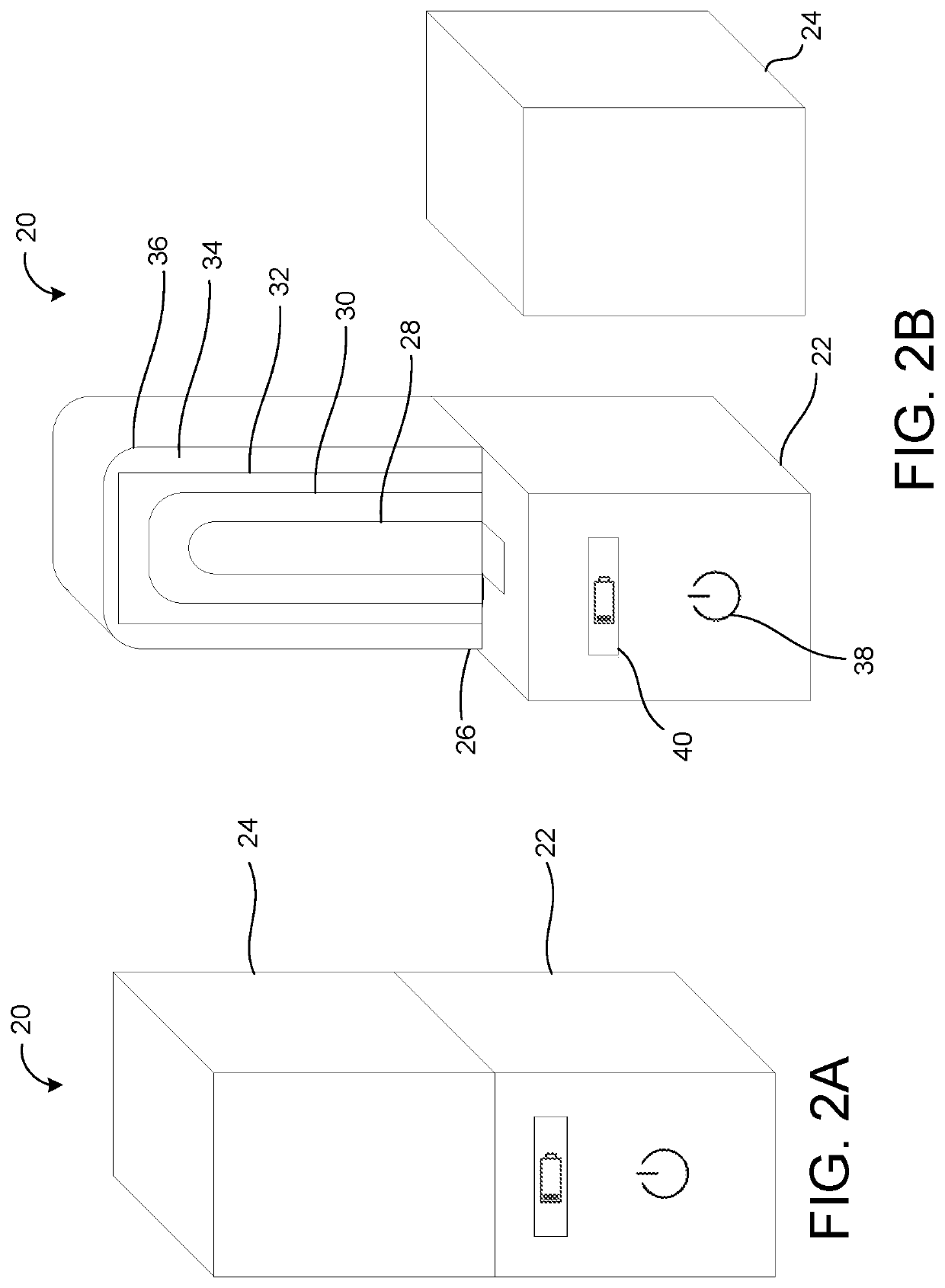

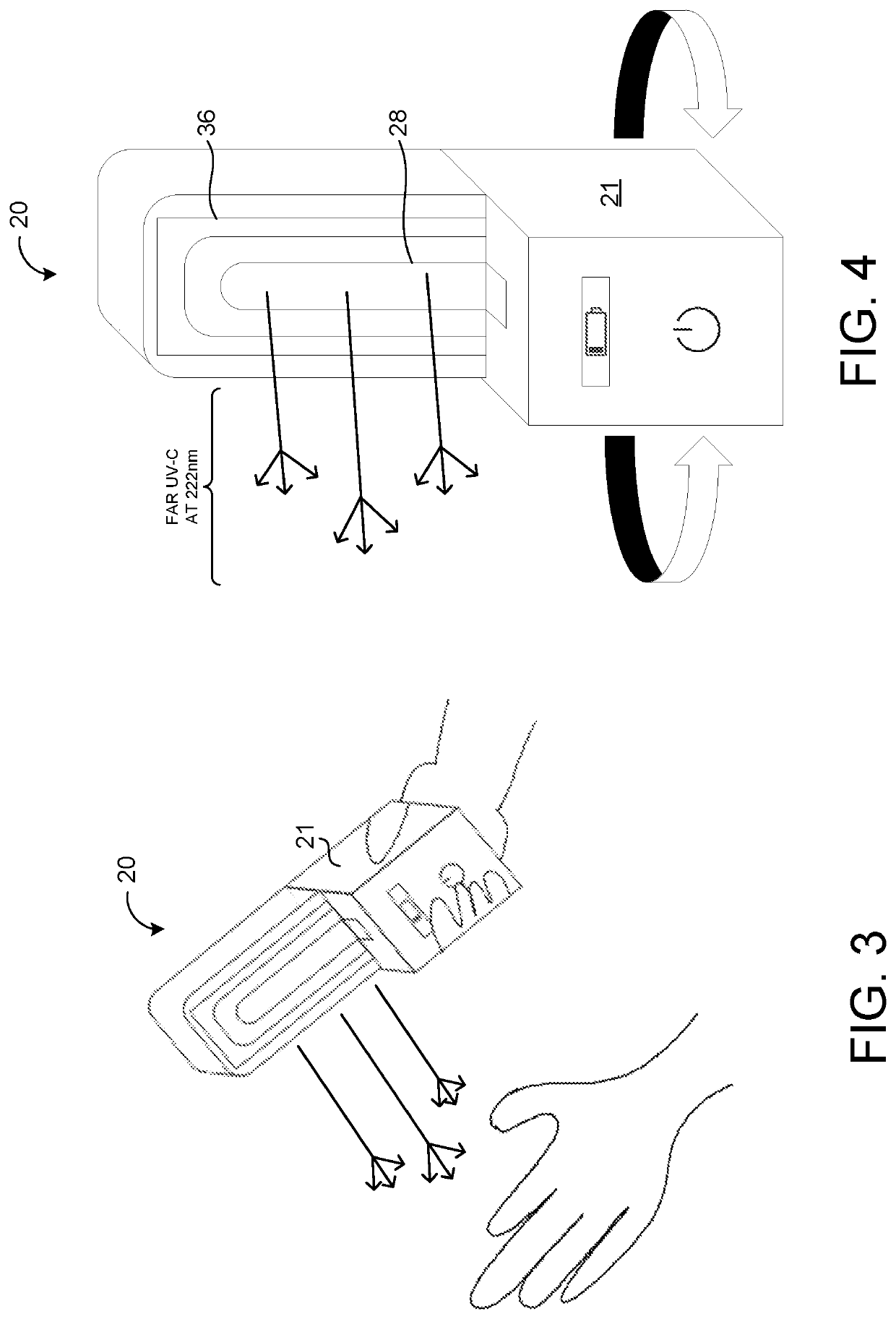

Portable and disposable far-uvc device

A method of destroying pathogens disposed upon an epidermis includes providing a hand held device including a grip and a lamp, transmitting far-UVC light via the lamp, and filtering the transmitted far-UVC light to attenuate portions of transmitted UVC light that have a wavelength known to cause damage to an epidermis of a human. The epidermis is scanned by tracing the hand held device over a localized area of the epidermis thereby illuminating the localized area with the filtered far-UVC light. The filtered far-UVC light destroys pathogens disposed upon the epidermis while not causing adverse biological damage to the epidermis.

Owner:FREESTYLE PARTNERS LLC

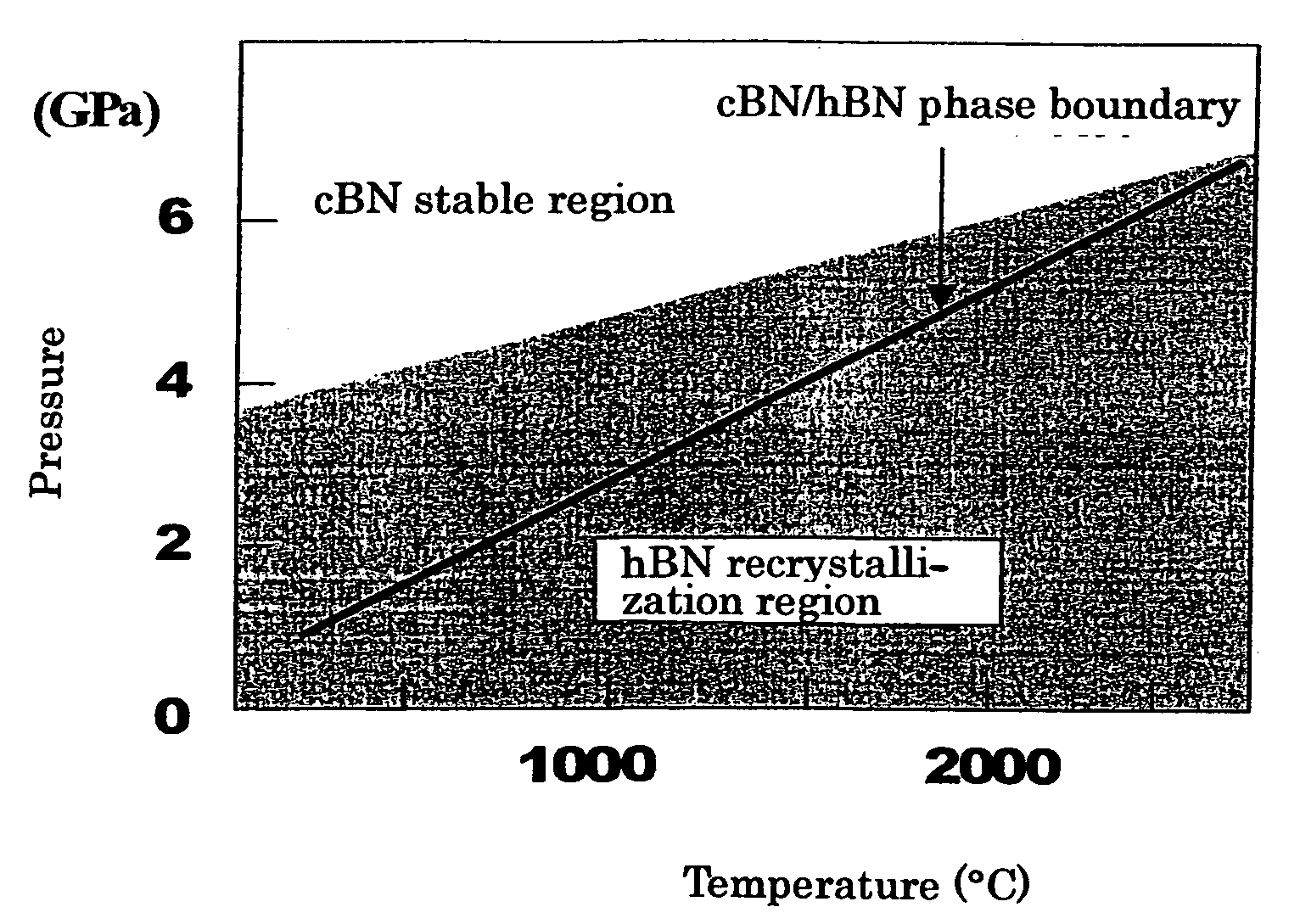

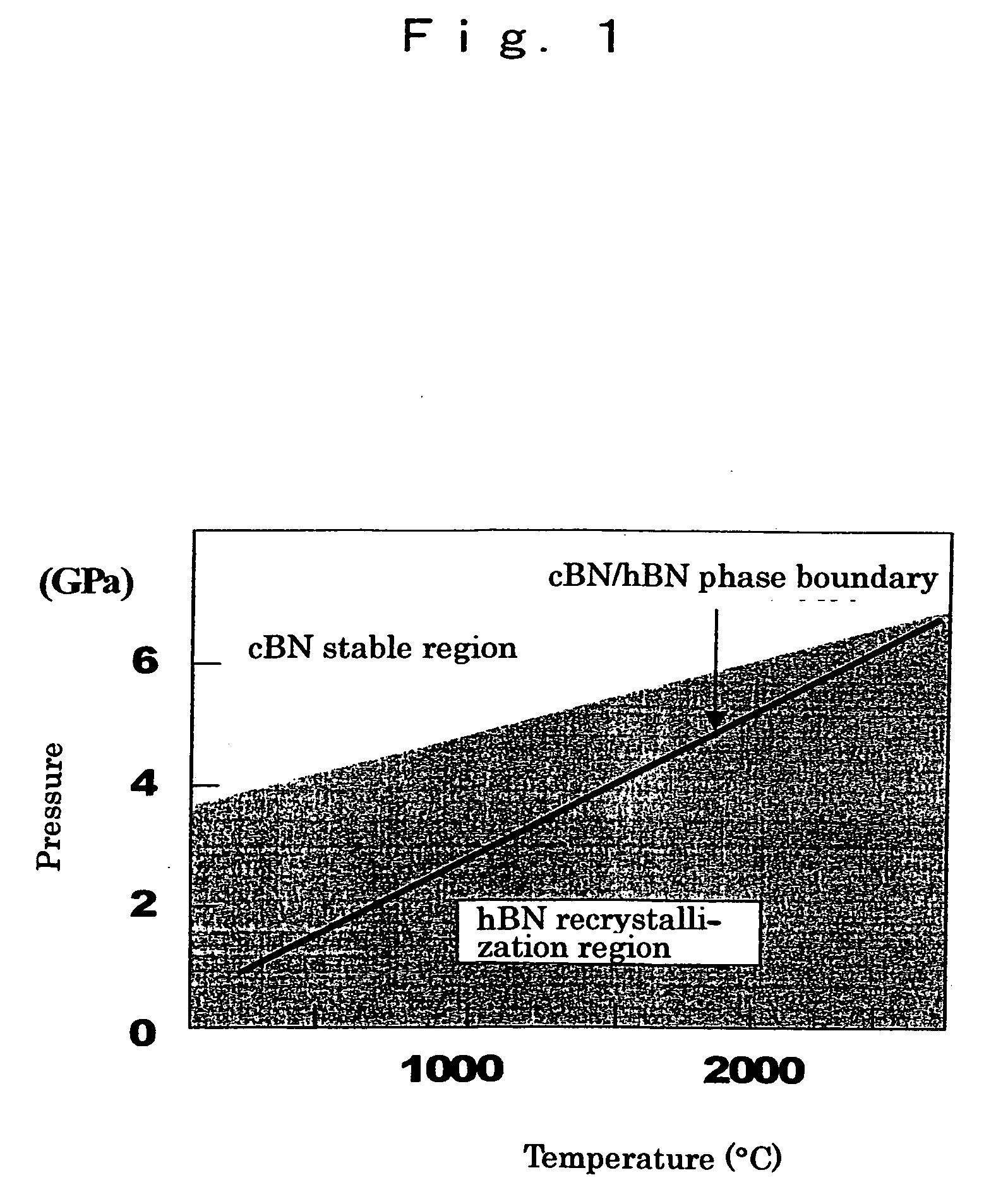

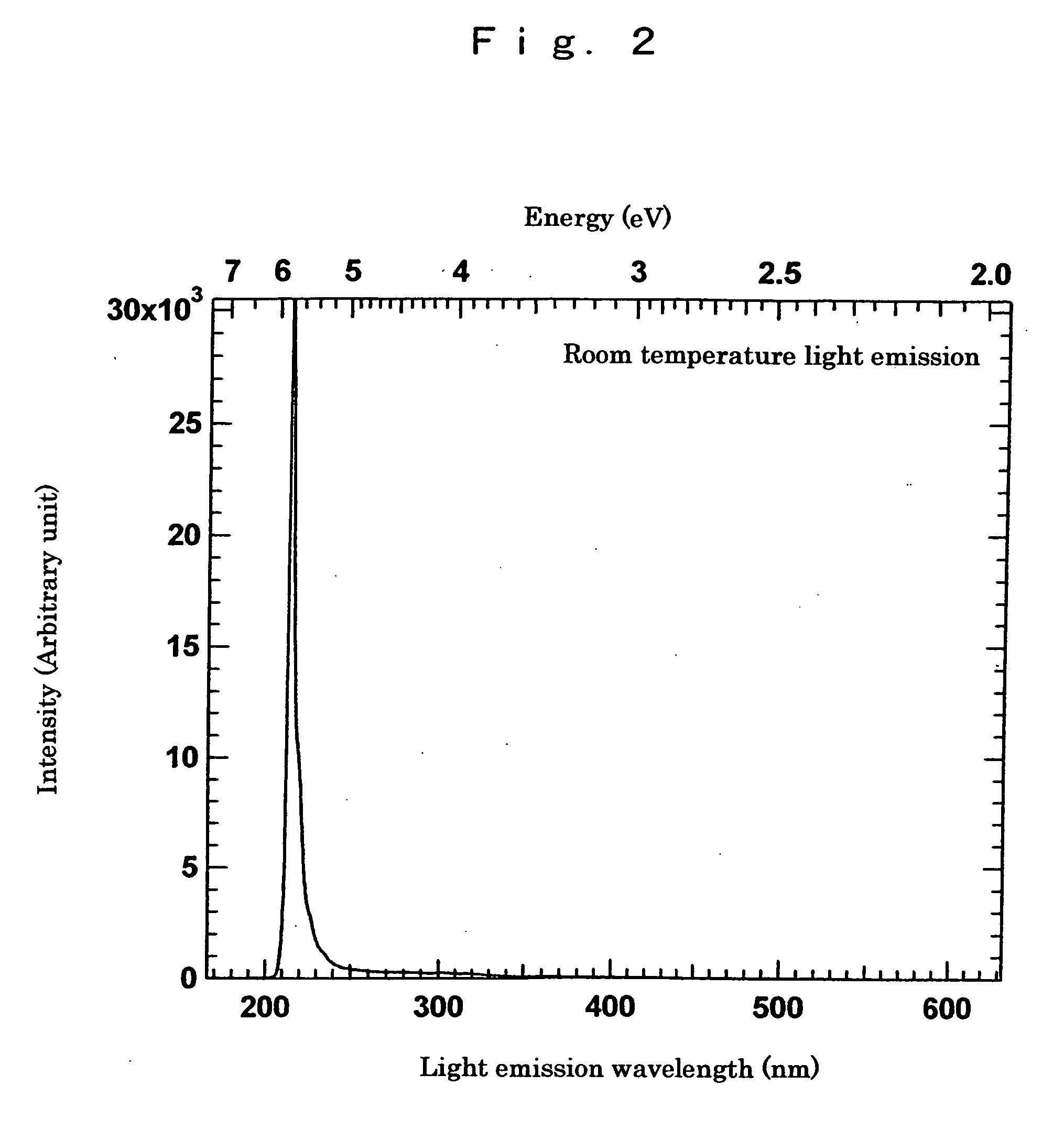

Single crystal of highly purified hexagonal boron nitride capable of far ultraviolet high-luminance light emission, process for producing the same, far ultraviolet high-luminance light emitting device including the single crystal, and utilizing the device, solid laser and solid light emitting unit

InactiveUS20060185577A1Improve compactnessStrong sterilizationPolycrystalline material growthLaser detailsHexagonal boron nitrideUltraviolet lights

A highly pure hexagonal boron nitride single crystal not influenced by impurities and capable of high-luminance short wave ultraviolet light emission reflecting inherent characteristics is provided; a high-luminance ultraviolet light emitting element is provided by using the above single crystal; and utilizing the above element, a simple compact low-cost long-lived far ultraviolet solid-state laser and far ultraviolet solid-state light emitting apparatus are provided. A highly pure hexagonal boron nitride single crystal having a single light emission peak in the far ultraviolet region of up to a wavelength of 235 nm is produced by melting said boron nitride crystal as raw material in the presence of a highly pure solvent under high-temperature and high-pressure, followed by crystallization. A light emitting element or a light emitting layer comprised of the obtained crystal is excited with electron beams, and the thus generated far ultraviolet light resonated or without resonation is taken out.

Owner:NAT INST FOR MATERIALS SCI

Light-absorbing polymers and application thereof to antireflection film

InactiveCN1258302AIncrease coverageEasy to filmSemiconductor/solid-state device manufacturingRadiation-absorbing paintsUltravioletKetone

A high-performance antireflection film which highly absorbs a given light, e.g., far ultraviolet, tenaciously adheres to substrates upon film formation, is satisfactory in covering, and eliminates the influence of standing waves in the production of integrated circuits; novel light-absorbing polymers for forming the antireflection film; and a process for producing the polymers. One of the polymers is produced by esterifying a copolymer comprising carboxylic anhydride groups and / or dicarboxylic acid groups such as maleic acid as basic repeating units with a hydroxylated aromatic chromophore. The unreacted carboxylic acid groups or acid anhydride groups remaining in the esterified light-absorbing polymer may be amidated and / or imidized with an aminated aromatic compound. These polymers each is dissolved in an organic solvent comprising an alcohol, aromatic hydrocarbon, ketone, ester, or combination of these, and the solution is applied to a substrate and then baked to form an antireflection film.

Owner:MERCK PATENT GMBH

Integrated circuit identification

InactiveUS7220606B2Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsFar ultravioletLiquid-crystal display

A method for marking a semiconductor wafer 302 includes the steps of: providing a reticle 300 including liquid crystal pixels; positioning the semiconductor wafer in proximity to the reticle; directing radiation through a first plurality of the pixels onto a first location on the wafer; changing the relative positions of the semiconductor wafer and the reticle; and directing radiation through a second plurality of the pixels onto a second location on the wafer. The first plurality of pixels can be used to form a first mark and the second plurality of pixels can be used to form a second mark, wherein the second mark is different from the first mark. The marks can be made of a pattern of dots in order to save space. The pixels can be selected to form certain marks by using a computer 304 to turn on or off a transistor that may be associated with each pixel. Also described is a system for marking a semiconductor wafer. The system includes a wafer mount 301; a radiation source 306 in proximity to the wafer mount; a reticle 300 which includes liquid crystal pixels and that is positionable between the radiation source and the wafer mount; and a mechanism 303 for changing the relative positions of the reticle and the wafer mount. The radiation source can be non-coherent far-ultraviolet, near-ultraviolet, or visible sources, or a laser.

Owner:TEXAS INSTR INC

Calibration device of ultra-far ultraviolet detector

ActiveCN102998089AAvoid interferenceHigh precisionRadiation pyrometryOptical apparatus testingFar ultravioletRadiance

The invention provides a calibration device of an ultra-far ultraviolet detector. The calibration device comprises a light source, a converging swing mirror unit, an ultraviolet monochrometer unit, a detector unit and a pressure difference unit, wherein the converging swing mirror unit comprises a converging swing mirror which comprises swing mirrors and a rotation displacement platform, the swing mirrors are two concave reflectors bonded by non-reflecting surfaces, central axes of the reflectors of the swing mirrors are coincide, a 30nm-200nm reflecting film is coated on a reflecting surface A of one reflector, and a 60nm-200nm reflecting film is coated on a reflecting surface B of the other reflector. The detector comprises a standard detector and a detector to be detected. The calibration device can correct spectral radiance parameters of the detector in 30nm-200nm. The calibration device is small in size, has sufficient ports, has unique design on ultra ultraviolet and far ultraviolet radiation calibration and removal of high-level spectra, and improves accuracy of the ultra ultraviolet and far ultraviolet radiation calibration.

Owner:BEIJING ZHENXING METROLOGY & TEST INST

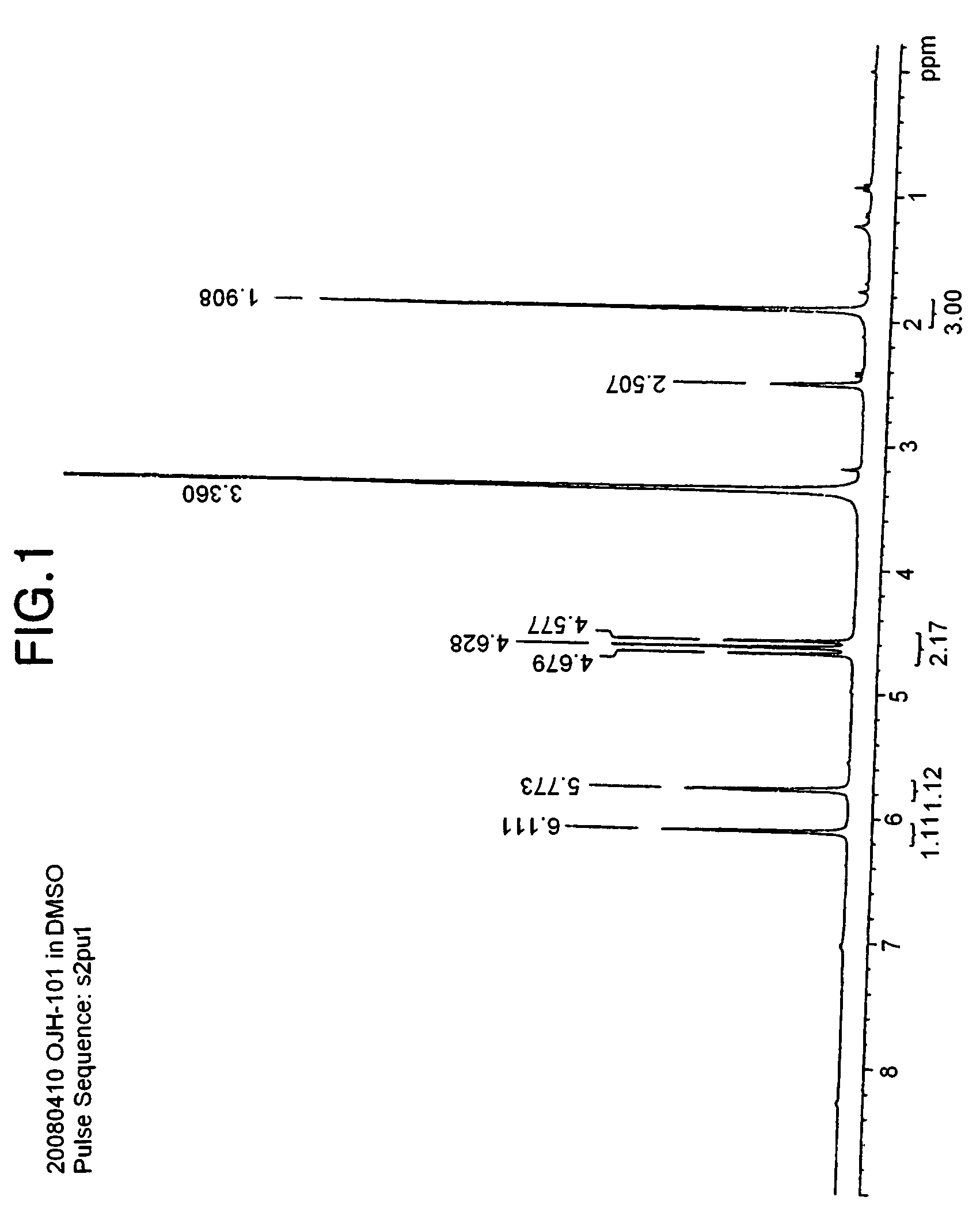

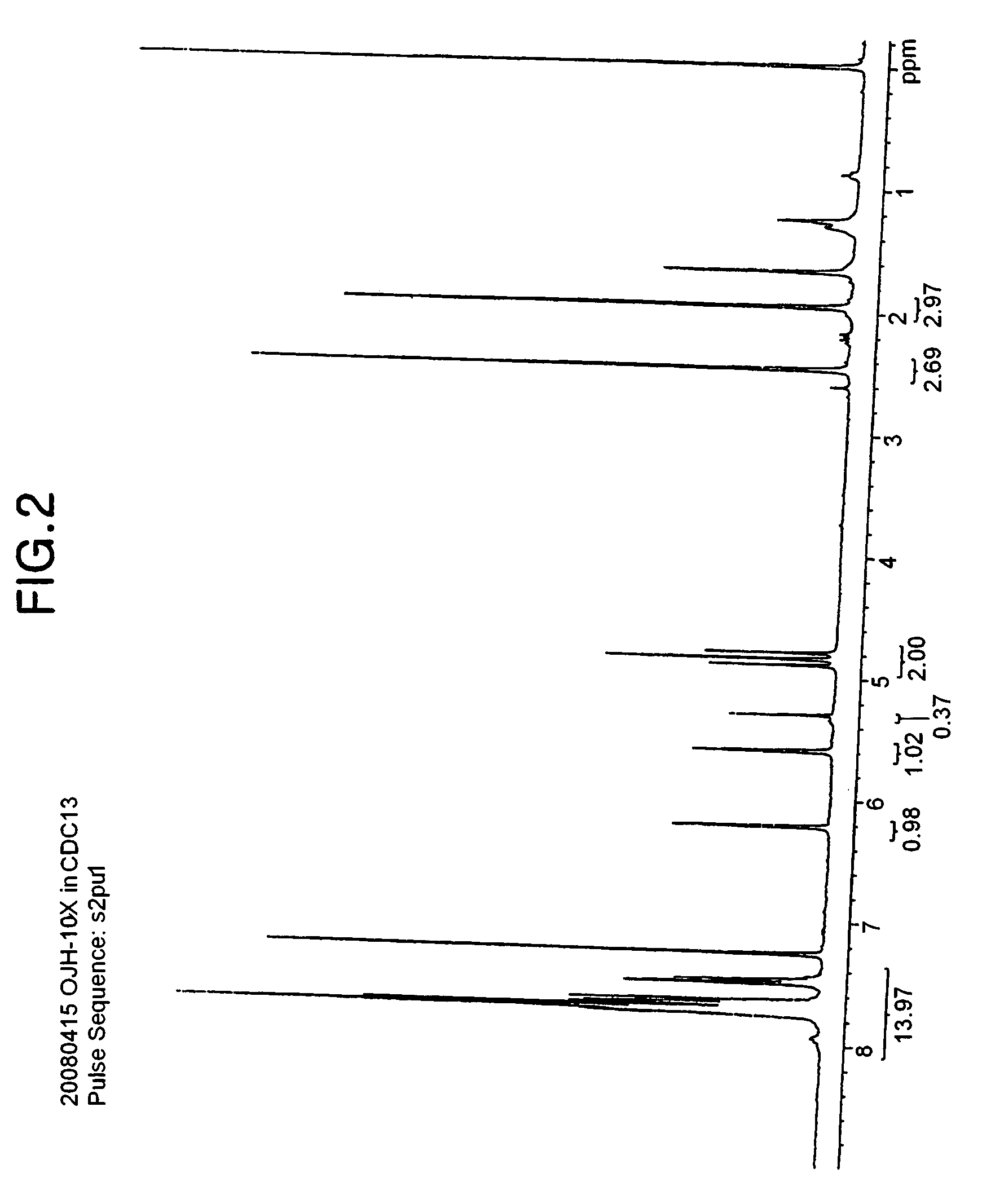

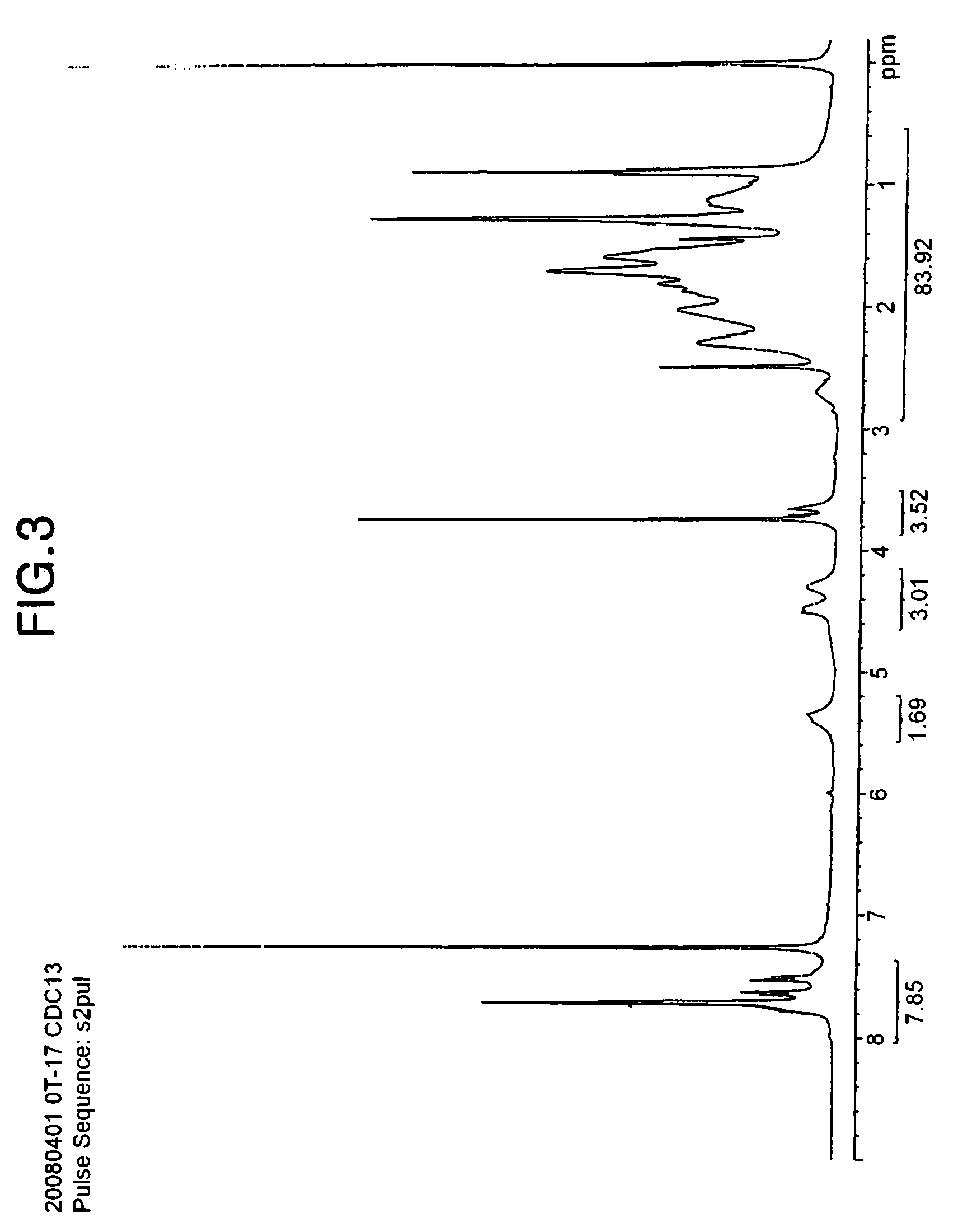

Onium salt compound, polymer compound comprising the salt compound, chemically amplified resist composition comprising the polymer compound, and method for patterning using the composition

ActiveUS8158327B2Reduce amountReduce roughnessOrganic chemistryPhotosensitive materialsResistFar ultraviolet

A compound represented by the following formula (1) is provided:wherein R1 represents a hydrogen atom, a trifluoromethyl group, an alkyl group, or an alkoxy group; and A represents a group represented by the following formula (2) or formula (3):wherein R2, R3, R4, R5 and R6 each independently represent a substituted or unsubstituted alkyl group, a substituted or unsubstituted allyl group, a substituted or unsubstituted perfluoroalkyl group, a substituted or unsubstituted benzyl group, or a substituted or unsubstituted aryl group; and two or more of R2, R3 and R4 may be linked to each other to form a saturated or unsaturated carbon ring or a saturated or unsaturated heterocyclic ring.The chemically amplified resist composition comprising a polymer compound which is produced from the compound of formula 1 according to the present invention provides a chemically amplified resist sensitive to far-ultraviolet radiation, which is represented by KrF excimer laser or ArF excimer laser.

Owner:SK MATERIALS PERFORMANCE CO LTD

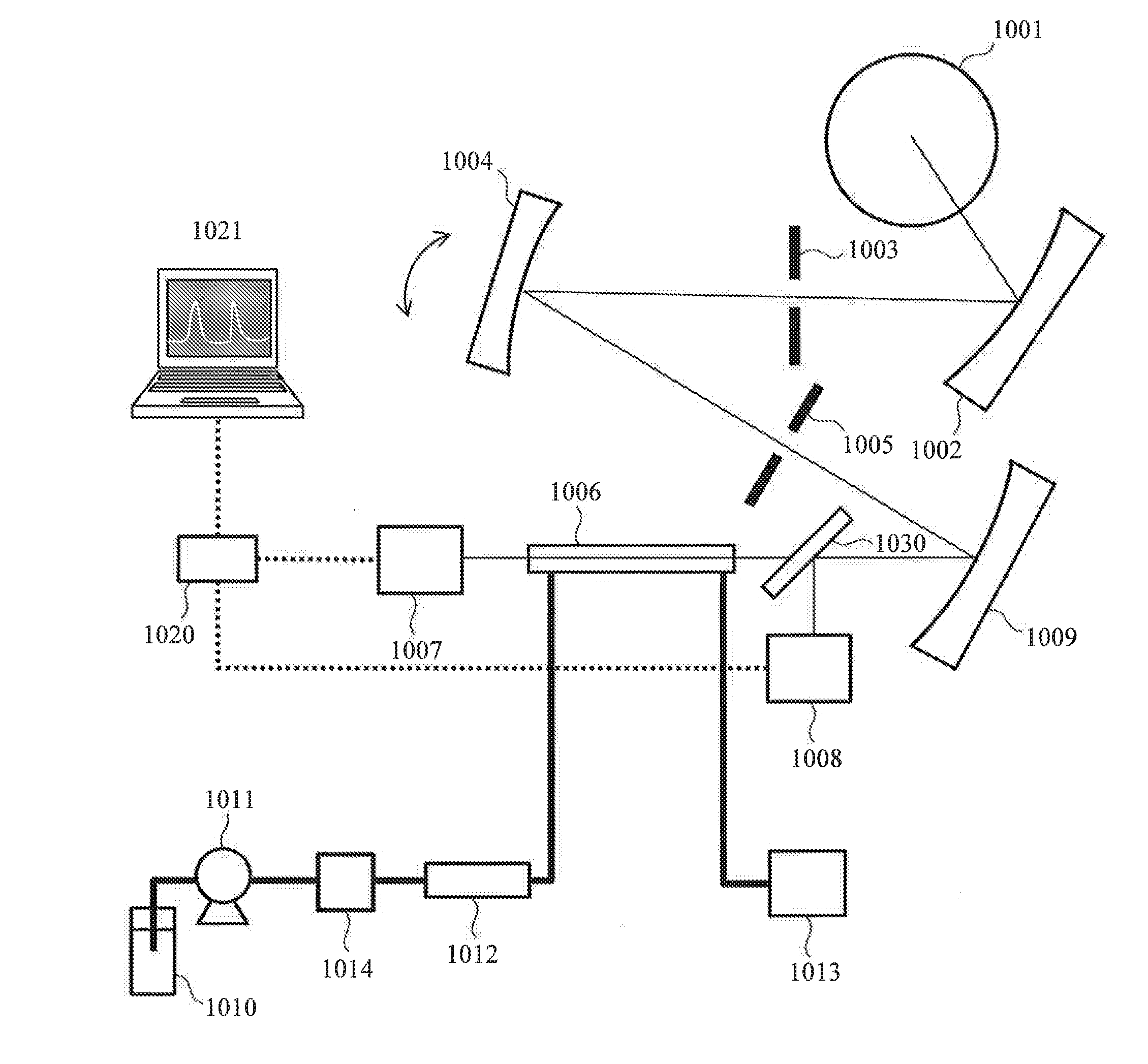

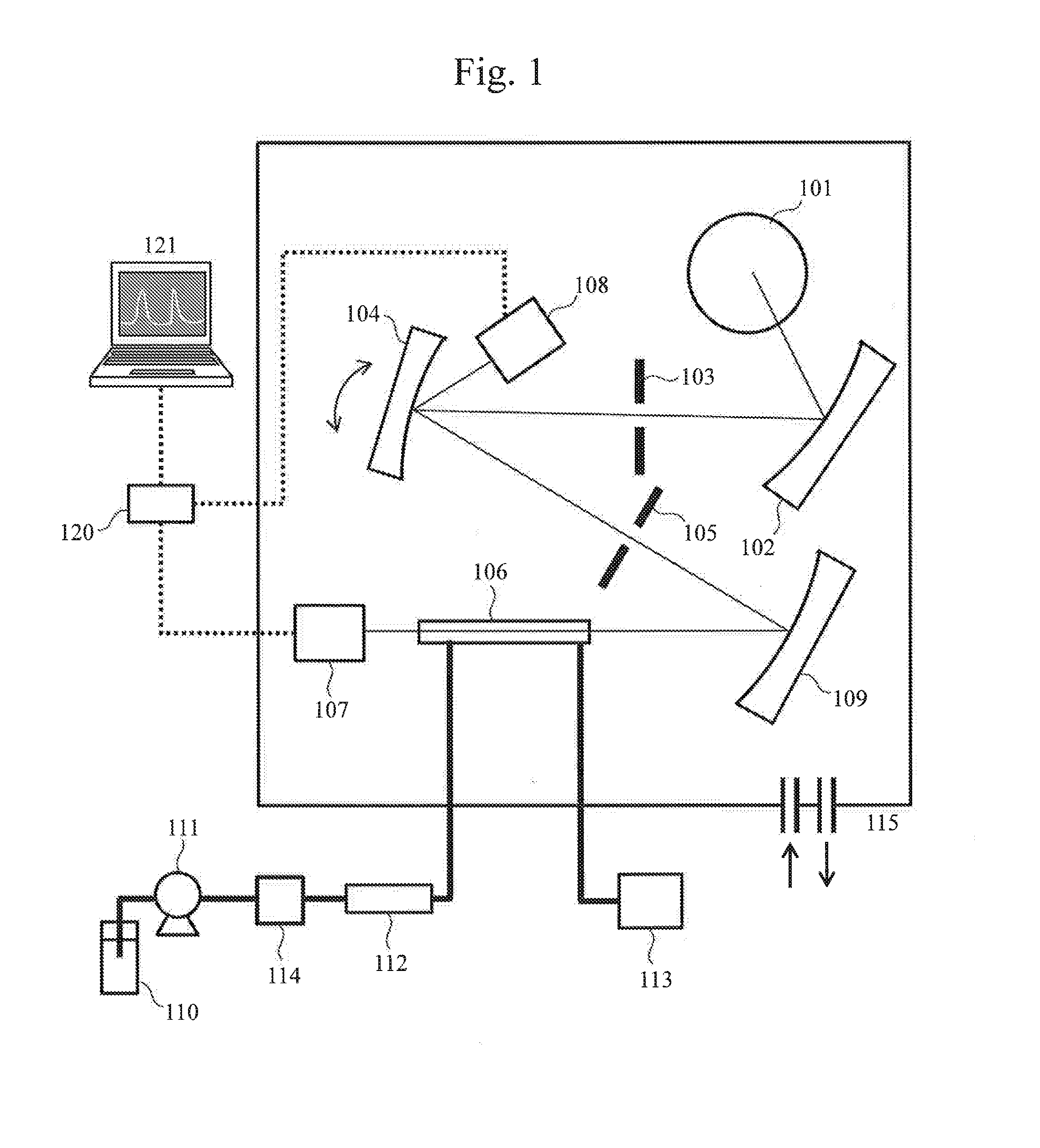

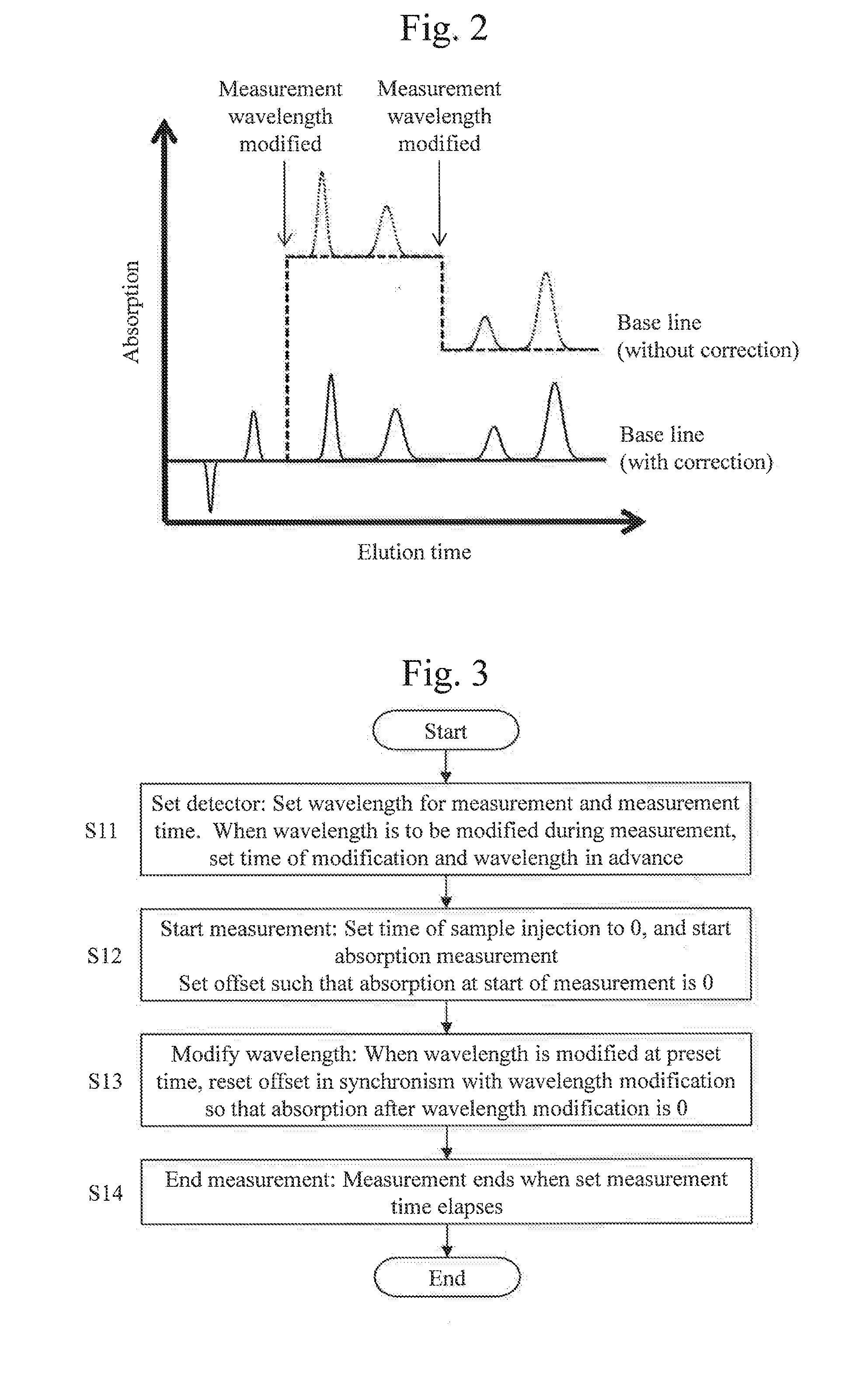

Far-Ultraviolet Absorbance Detection Device for Liquid Chromatography

ActiveUS20160258913A1Decrease in amountReduce component countComponent separationColor/spectral properties measurementsFlow cellPhotodetector

In order to achieve high sensitivity without an increase in device complexity or cost, a far-ultraviolet absorbance detection device for liquid chromatography is provided with: an optical system including a light source that emits light including far-ultraviolet light, a diffraction grating for dispersing the light emitted from the light source, a flow cell through which a liquid is passed, a slit for selecting a predetermined wavelength of +1 order light diffracted by the diffraction grating and causing the light to enter the flow cell, a first photodetector for detecting the light transmitted by the flow cell, and a second photodetector for detecting light other than the +1 order light diffracted by the diffraction grating; a mechanism for evacuating or substituting the optical system with nitrogen gas; and a computation unit that calculates absorbance from an output signal from the first photodetector and an output signal from the second photodetector. The second photodetector is fixedly disposed.

Owner:HITACHI HIGH-TECH CORP

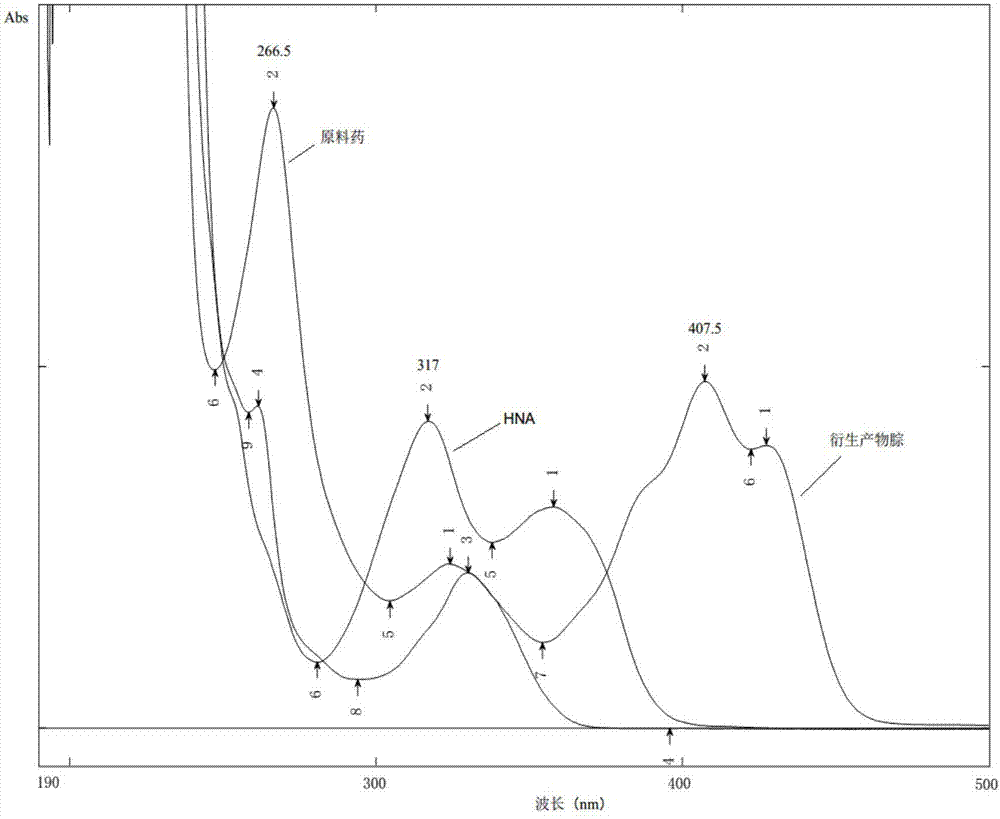

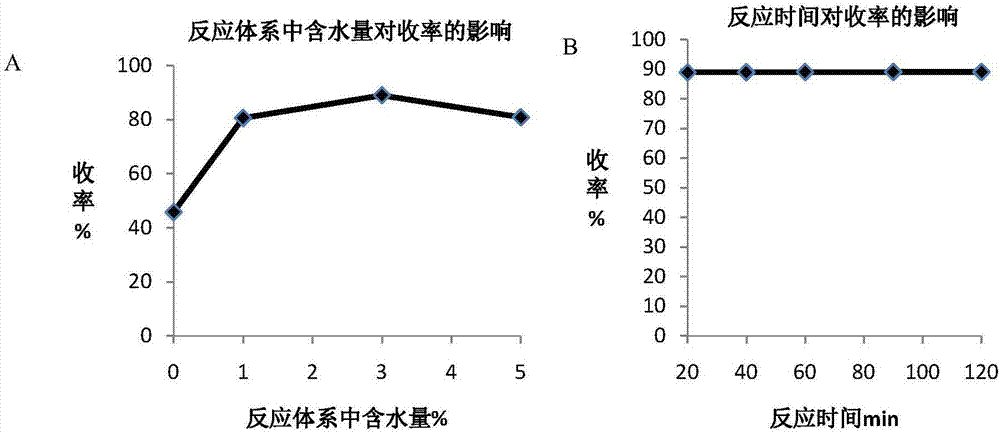

Method for determining hydrazine hydrate through derived HPLC (High Performance Liquid Chromatography)

InactiveCN107064368AWon't interfereImprove stabilityComponent separationWater bathsHydrazine compound

The invention discloses a method for determining hydrazine hydrate through derived HPLC (High Performance Liquid Chromatography). The method comprises the following steps: carrying out derivatization on hydrazine by using an aldehyde ketone derivatization reagent under a water bath condition of 100 DEG C, and generating a product-hydrazone having stronger absorptivity in an ultraviolet visible zone; using a reaction solution after completing a derivatization reaction as a sample injection sample, and determining the derived product-hydrozone of the hydrazine hydrate in the ultraviolet visible zone by utilizing the HPLC and based on reversed partition chromatography, thus realizing quantitative detection on the hydrazine hydrate. Since the absorptivity of most of bulk drugs and impurities thereof in a far ultraviolet visible zone is very weak, the simple method for determining the hydrazine hydrate through pre-column derivatization HPLC is established based on the hydrazine derivatization product of the aldehyde ketone derivatization reagent. A methodology validation result shows that the method is good in specificity.

Owner:常州佳德医药科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com