Single crystal of highly purified hexagonal boron nitride capable of far ultraviolet high-luminance light emission, process for producing the same, far ultraviolet high-luminance light emitting device including the single crystal, and utilizing the device, solid laser and solid light emitting unit

a technology of hexagonal boron nitride and single crystal, which is applied in the direction of crystal growth process, crystal growth process, polycrystalline material growth, etc., can solve the problems of not being considered established as the manufacturing method of single crystal, difficult to obtain hbn having the far ultraviolet light emission characteristics corresponding to its specific band gap, and difficult to obtain highly pure single crystals by these reactions. achieve high densification, strong sterilization, and high power outpu

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0090] Hexagonal boron nitride crystal sintered body (about 0.5 μm grain size) on which deoxidation processing by heat treatment in vacuum at 1,500° C. and in nitrogen gas stream at 2,000° C. had been applied, was loaded into a molybdenum capsule in a high-pressure cell together with a barium boronitride solvent. The preparation of the solvent and loading the sample into the capsule were all performed under dry nitrogen atmosphere. The high-pressure reaction cell was treated at the pressure and temperature conditions of 25,000 atmospheric pressure and 1,700° C. for 20 hours by a belt type high-pressure apparatus. The increasing rate of temperature was around 50° C. / min. After cooling with the rate of about 500° C. / min, the cell was decompressed and the sample was recovered together with the molybdenum capsule in the high-pressure cell.

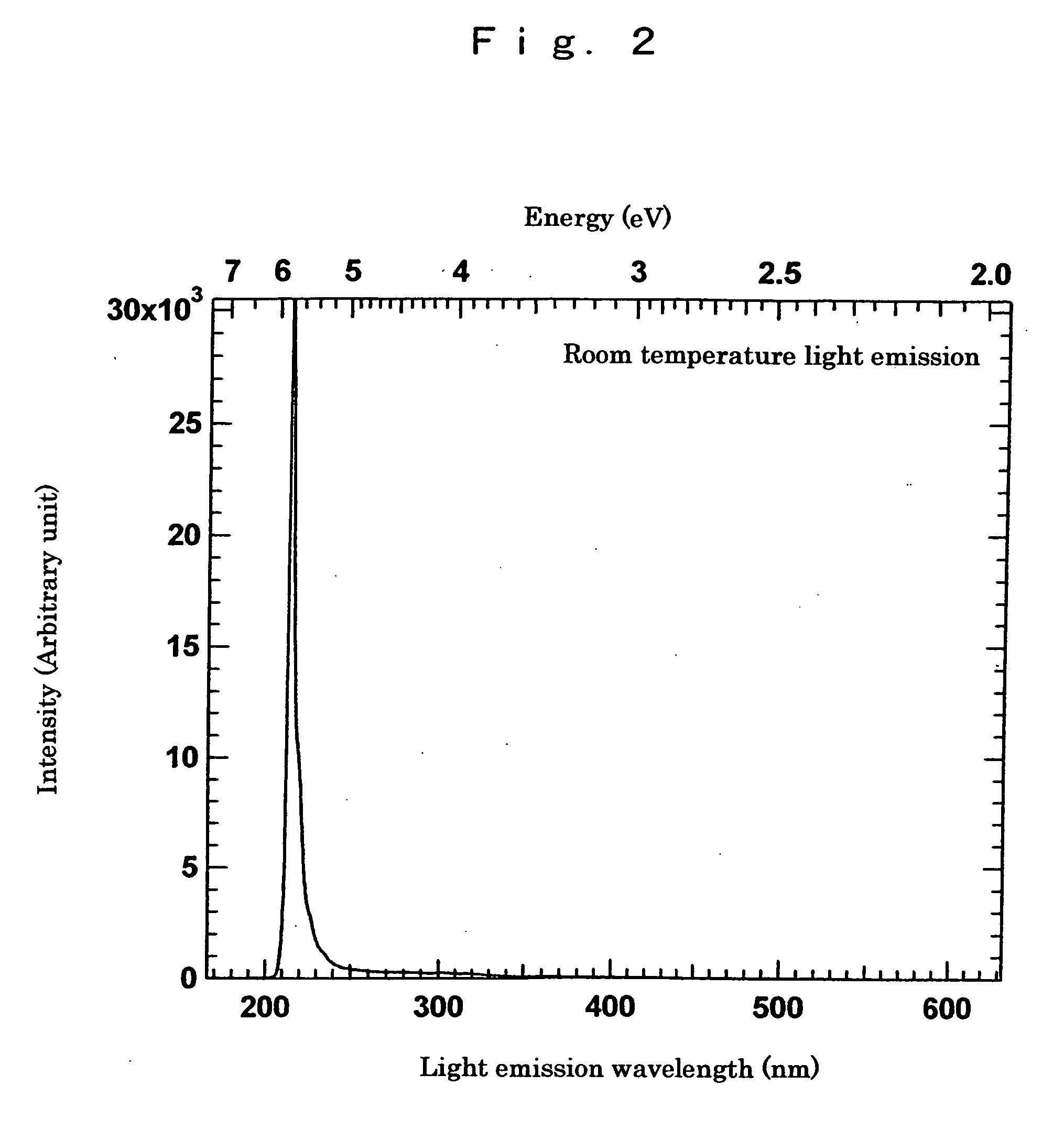

[0091] The molybdenum capsule was removed by mechanical or chemical treatment (mixed solution of hydrochloric acid and nitric acid), and the sample w...

example 2

[0094] A hexagonal boron nitride crystal sintered body (about 0.5 μm grain size), on which deoxidation processing had been applied by heat treatments in vacua at 1,500° C. and in nitrogen gas stream at 2,000° C., was loaded into the molybdenum capsule together with the solvent of mixed barium boronitride and lithium boronitride 1:1 by weight ratio. High-pressure treatment was applied in the same manner as in Example 1 and the sample was recovered.

[0095] The recovered sample had a same morphology as in Example 1, and ascertained to be hBN crystal. By cathode luminescence measurement, a broad light emission was observed near 300 nm, together with a high-luminance light emission at a wavelength of 215 nm.

example 3

[0096] A hexagonal boron nitride crystal sintered body (about 0.5 μm grain size) on which deoxidation processing by heat treatment in vacuum at 1,500° C. and in nitrogen gas stream at 2,000° C. had been applied, was loaded into a molybdenum capsule together with the solvent of mixed barium boronitride and lithium boronitride 1:1 by weight ratio. The preparation of this solvent and loading of the sample into capsule were all performed under dry nitrogen atmosphere. The molybdenum reaction cell was processed in nitrogen gas stream at the pressure and temperature conditions of 1 atmospheric pressure and 1,500° C. for two hours. The rate of temperature increase was about 10° C. / min. The molybdenum capsule was recovered after cooling with the rate of about 20° C. / min.

[0097] Then, the molybdenum capsule was removed by mechanical or chemical treatment (mixed solution of hydrochloric acid and nitric acid), and the sample inside was recovered. The solvent portion partly showed an aspect of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| at a wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com