Method and apparatus for measuring far-ultraviolet laser scratch of interface jointing strength

A technology of interface bonding strength and measuring devices, which is applied in the directions of measuring devices, color/spectral characteristic measurement, mechanical devices, etc., can solve the problems that soft films cannot be measured, the thickness of test pieces is limited, and the scratch mechanism is complicated, etc., to achieve Facilitate measurement automation, accurate and convenient measurement, convenient and fast guidance and energy transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

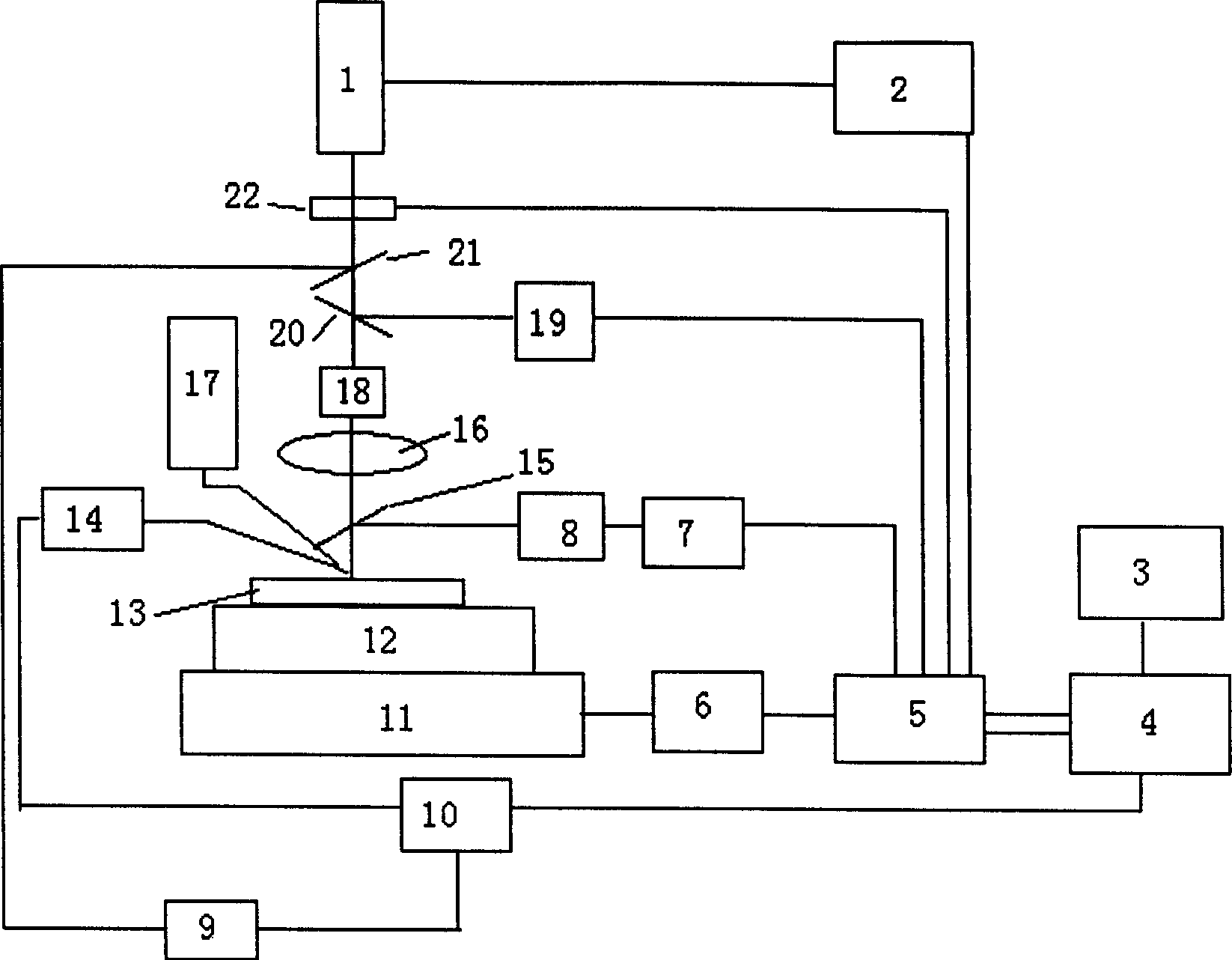

[0042] like figure 1 As shown, the system involved in this method consists of a scratch system, a specimen fixture system, a detection system, a control system and a frame.

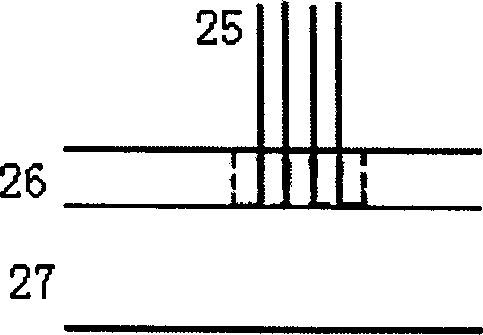

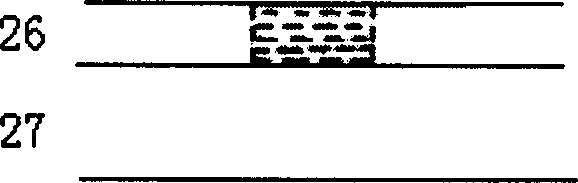

[0043] The method is as follows: the far-ultraviolet laser 24 in the resonant cavity 23 of the scratch laser 1 passes through the incident laser beam optical path system composed of an adjustable diaphragm 22, beam splitters 21, 20, a light guide system 18 with an attenuator, and a focusing mirror 16. It is directly loaded on the surface of the film of the sample 13 installed on the fixture 12. The test piece 13 is composed of the substrate 27 and the film 26 on it. The laser energy is continuously increased through the laser power supply and the control system 2, and the work of the feeding system is simultaneously carried out. The table 11 drives the fixture 12 and the test piece 13 to make a feed movement. The far-ultraviolet laser acts on the surface of the thin film sample, and realizes the ablation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com