Method and apparatus for measuring sub-static laser scratch of interface jointing strength

A technology of interfacial bond strength and measuring device, which is applied in the direction of measuring device, color/spectral characteristic measurement, mechanical device, etc., can solve the problems of limited thickness of test piece, complex scratch mechanism, and inability to measure soft films, etc., to achieve The measurement is accurate and convenient, the guidance and energy transmission are convenient and fast, and it is convenient to measure the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

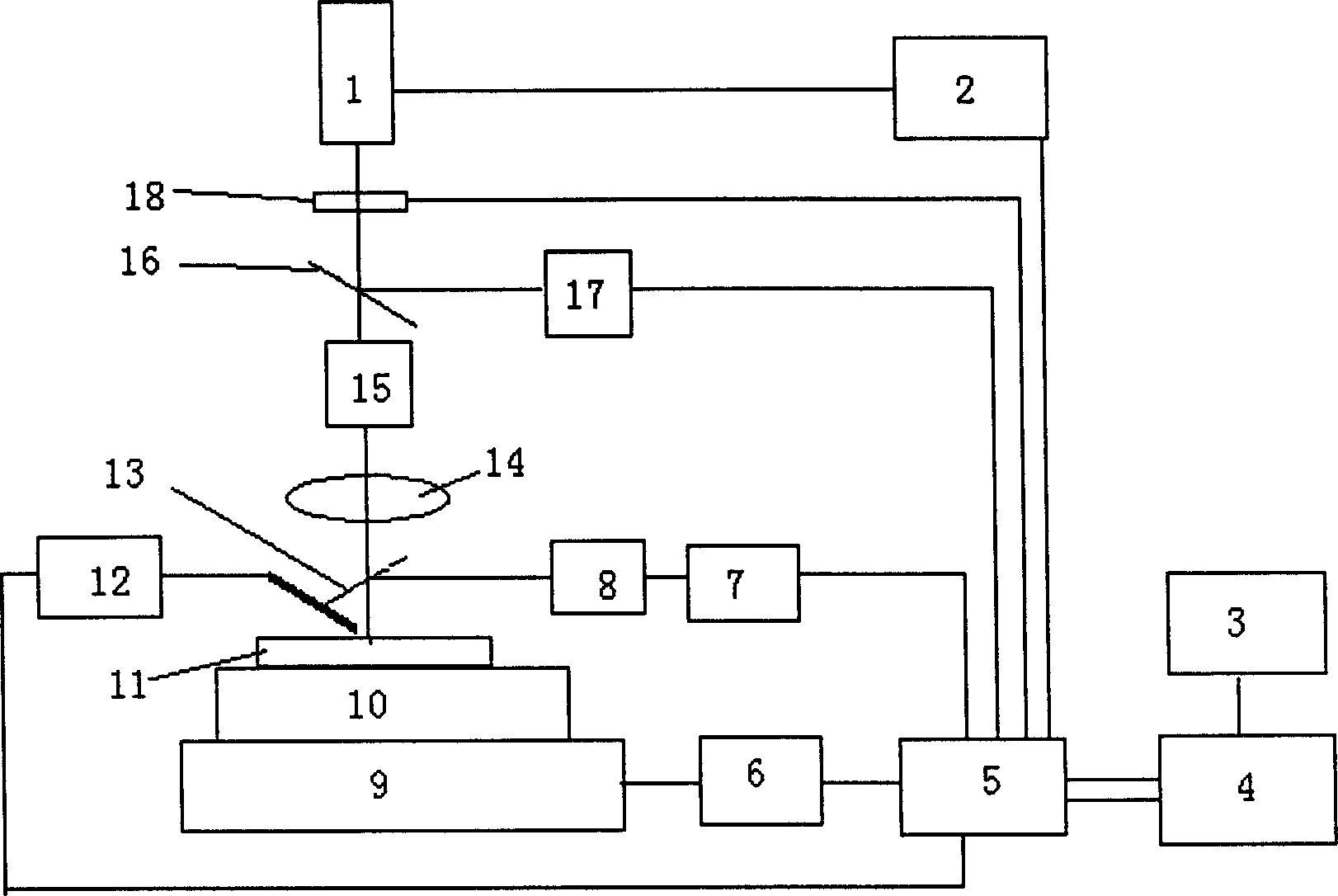

[0037] The invention proposes a method for measuring the bonding strength of the film base interface. Such as figure 1 As shown, the system involved in this method consists of a scratch system, a specimen fixture system, a detection system, a control system, and a frame.

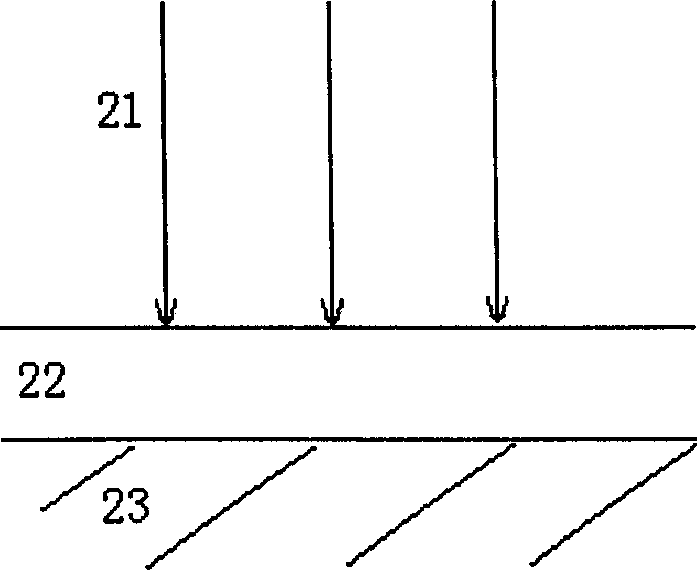

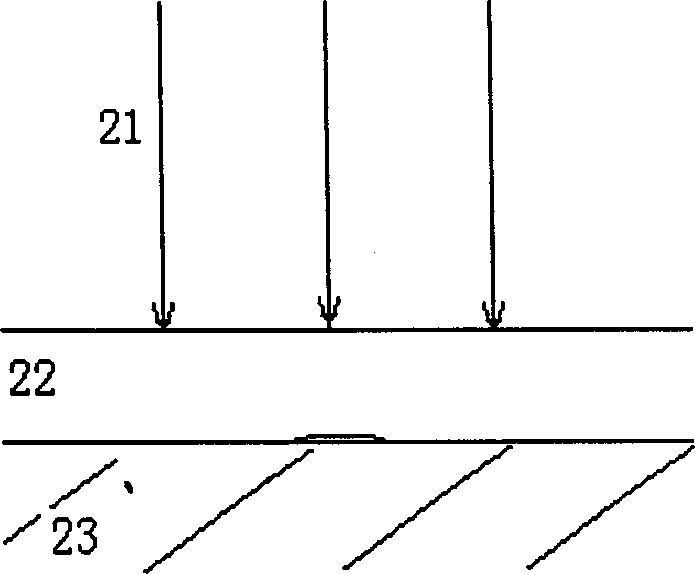

[0038] The long-pulse infrared laser 20 in the resonant cavity 19 of the scratch laser 1 directly radiates through the incident laser beam optical path system composed of an adjustable diaphragm 18, a beam splitter 16, a light guide system 15 with an attenuator, and a focusing mirror 14. The surface of the thin film sample 11 on the fixture 10, the test piece 11 is composed of a substrate 23 and a thin film 22 on it, and the laser beam 21 is used to quasi-statically heat the surface of the thin film 22 with a thickness of tens of nanometers, and the subsequent heat conduction, A temperature field is formed in the test piece. Due to the difference in thermal expansion coefficient and temperature of the film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com