Method and device for vacuum ultraviolet laser cleaning first mirror of tokamak

A vacuum ultraviolet and laser cleaning technology, which is applied to cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as unsatisfactory cleaning efficiency, affecting device operation, and difficult optical analysis, so as to facilitate the operation of automated equipment, easy collection, Mechanism obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

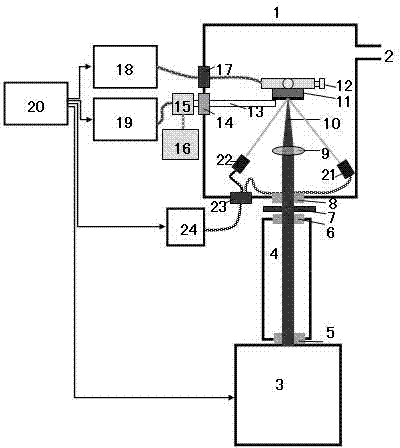

[0048] Specific examples: such as figure 1 As shown, the system involved in this method consists of a cleaning laser system, a first mirror feeding system, an air blowing system, a detection system, a control system and a frame.

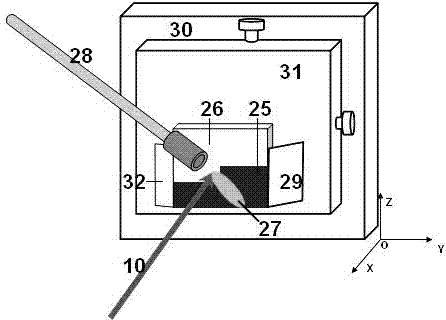

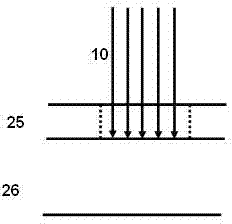

[0049] The method is as follows: the laser light output by the argon fluoride excimer laser 3 enters the sealed optical cavity 4 filled with nitrogen through the quartz window 5 to propagate, so as to avoid the energy dissipation of the excimer laser beam, and then transmits it from the quartz window 6 on the other side of the sealed optical cavity. Emitted, through the adjustable diaphragm 7, the quartz window 8 of the vacuum chamber enters the vacuum chamber 1, and finally is focused by the focusing lens 9 and directly loaded on the surface of the dust layer of the first mirror 11 installed on the workbench 12. A dust impurity layer with a thickness of about 1 micron has been deposited on the surface of the first mirror 11 during the operation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com