On-line Bending Device for Three-Dimensional Variable Curvature Profiles Actively Pulled by Robot

A technology of bending forming and robotics, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of uneven force on the cross section of the profile and high extrusion load, so as to reduce bending springback and extrusion The effect of loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

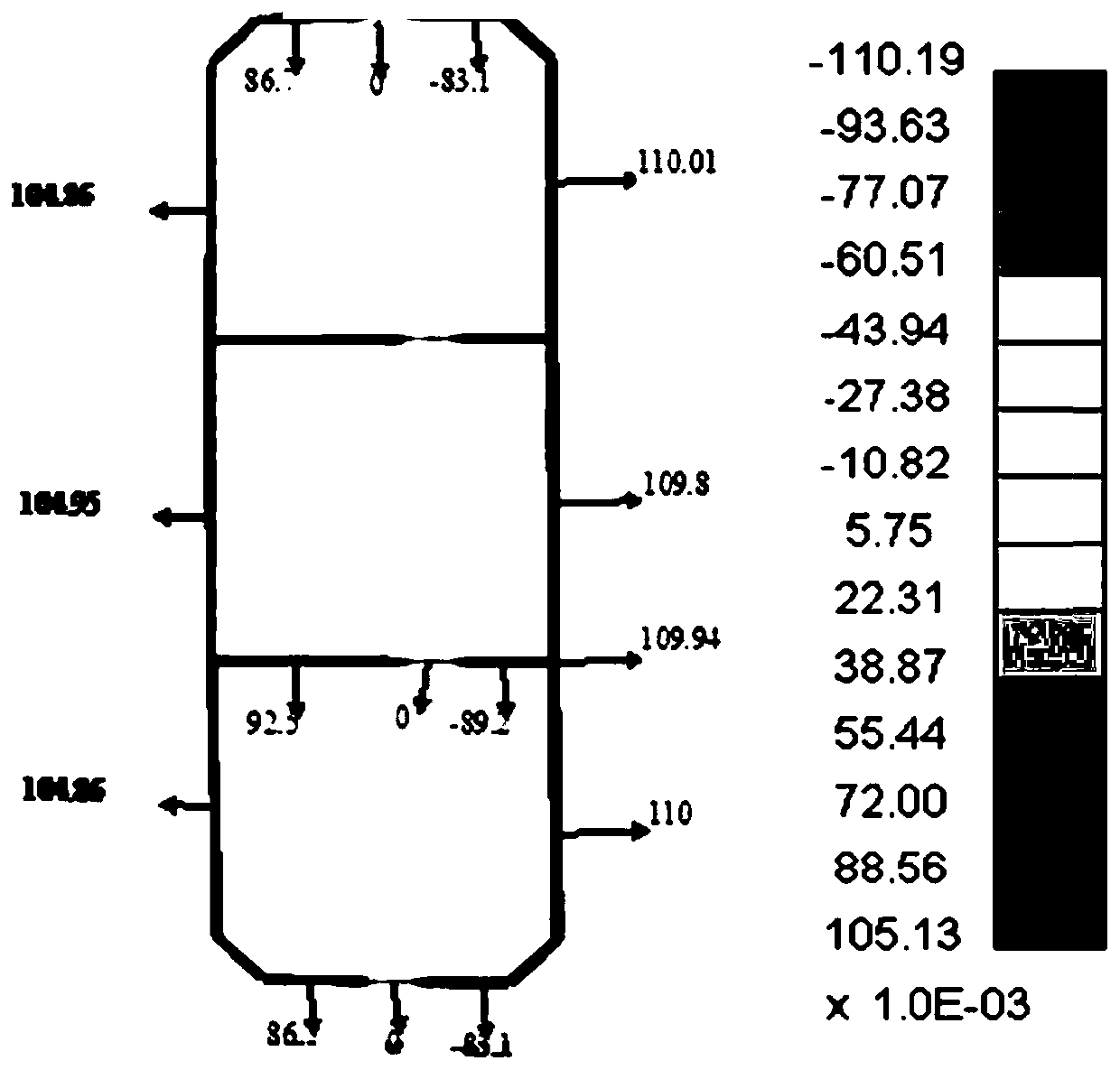

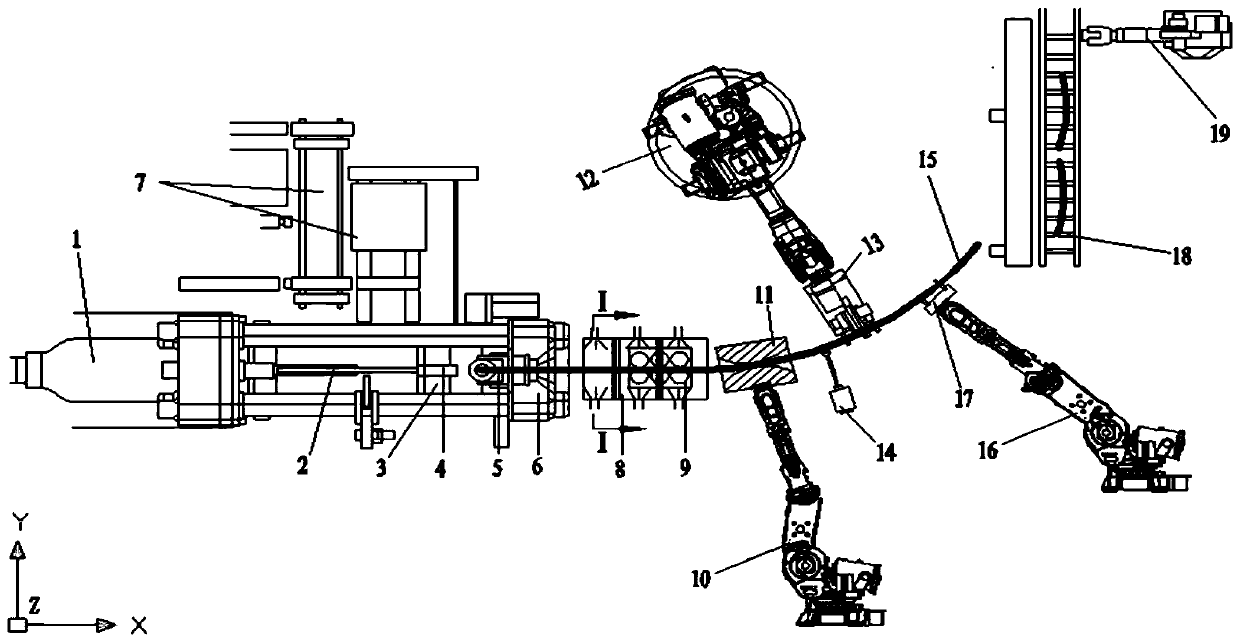

[0057] Embodiment 1: With the method of the present invention, the three-dimensional variable-curvature section bar online bending forming device (see figure 2 ). Figure 7 and 8Shown are the cross-section of the extruded profile and the three-dimensional variable curvature bending radius, the material is 6061 aluminum alloy, the diameter of the extruded ingot is 205mm, and the length is 400mm. The model of the extruder is XJ-1900T, the initial ingot temperature is 480°C, the temperature of the extrusion cylinder is 450°C, the temperature of the extrusion pad and the extrusion die is 450°C, the speed of the extrusion rod is 4mm / s, and the extrusion Ratio 35.4, the quenching method is water jet. The finite element analysis determines that the optimal bending deformation temperature is 310°C, and the radii of the trajectory paths of the traction device of the active traction robot considering springback compensation are 1413 and 1228mm, respectively. The operating speed of th...

Embodiment 2

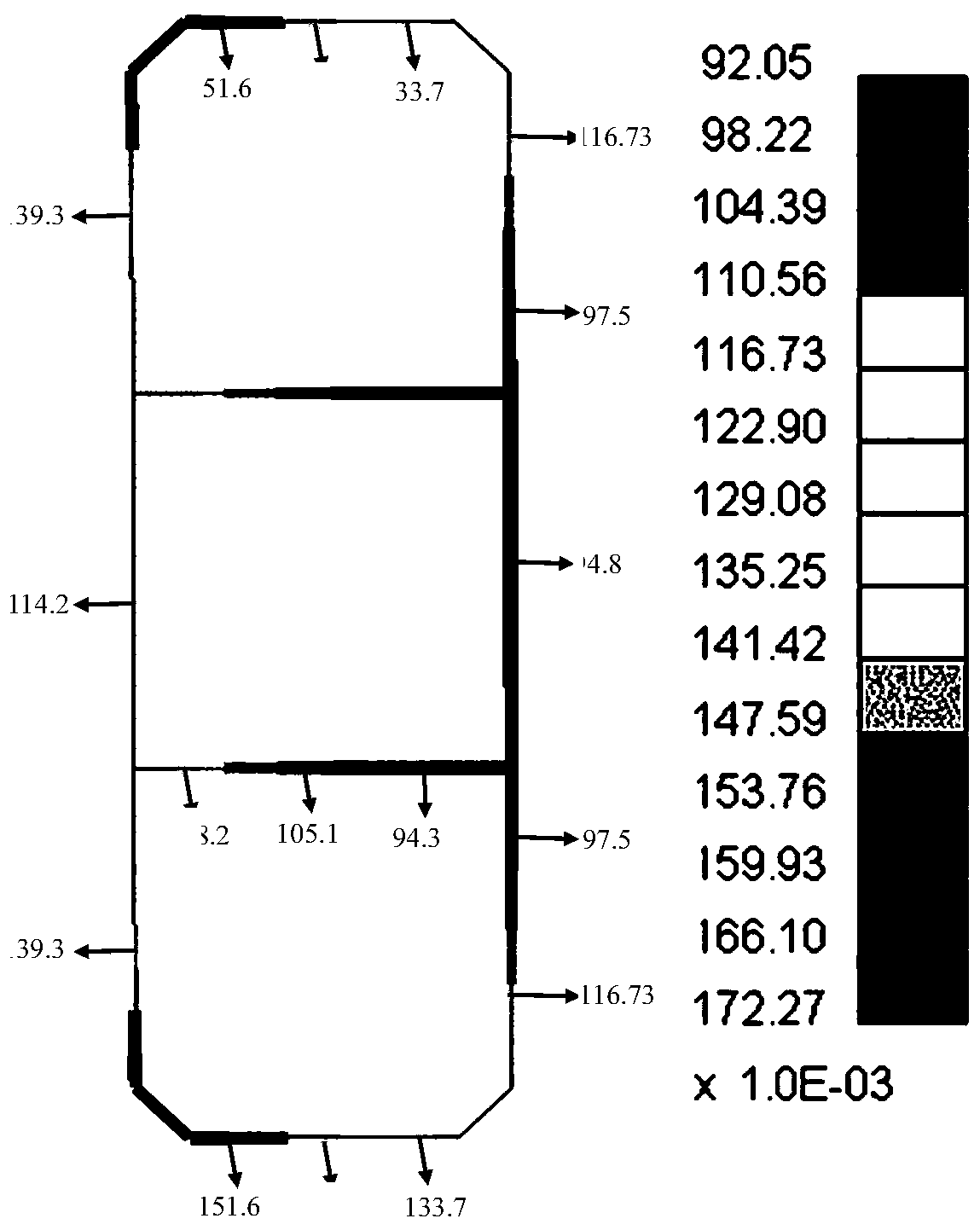

[0058] Embodiment 2: With the method of the present invention, at the outlet of the 800T extruder, arrange the active traction three-dimensional variable curvature profile on-line bending forming device (see figure 2 ). Figure 9 and 10 The section and three-dimensional variable curvature bending radius of the extruded profile are shown, the material is 6063 aluminum alloy, the extruder model is XJ-800T, the diameter of the extruded ingot is 86mm, and the length is 250mm. The initial ingot temperature was 480°C, the temperature of the extrusion cylinder was 430°C, the temperature of the extrusion pad and the extrusion die was 430°C, the speed of the extrusion rod was 5 mm / s, the extrusion ratio was 23.7, and the quenching method was air cooling. The optimal bending deformation temperature determined by finite element analysis is 255°C, and the radii of the traction device running track path of the active traction machine considering the springback compensation are 1358 and 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com