Preparation method of porous polycrystalline cubic boron nitride

A technology of cubic boron nitride and boron nitride micropowder, which is applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as hardness and thermal stability reduction, and difficulty in breaking polycrystalline cubic boron nitride. Improved machining accuracy, good grinding life, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

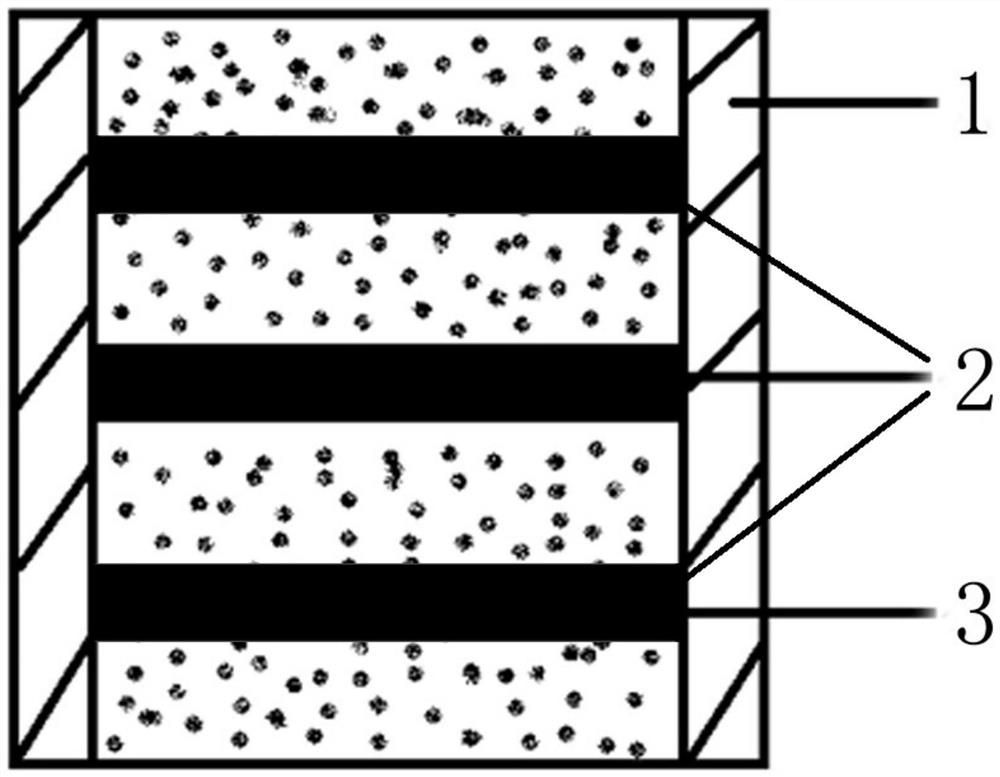

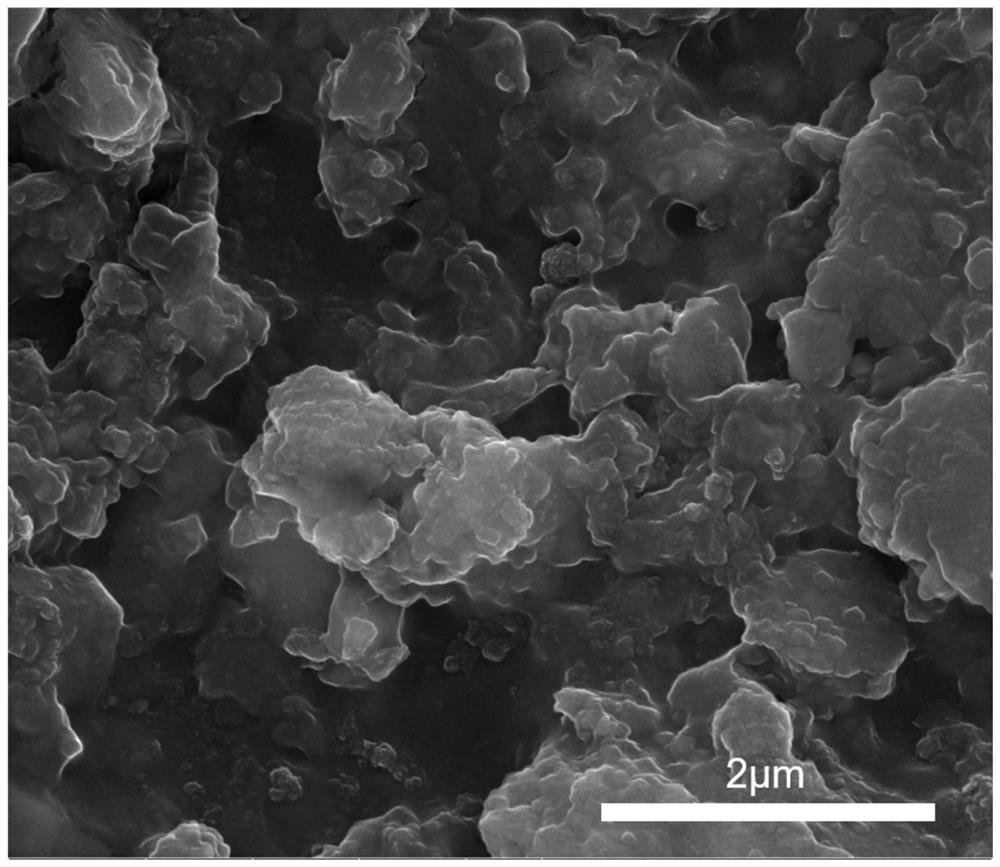

[0034] Please refer to figure 1 and figure 2 ,in, figure 1 It is a schematic diagram of the composite layer structure of cubic boron nitride micropowder block and boron nitride binder in the synthesis cavity; figure 2 Schematic diagram of the structure of porous polycrystalline cubic boron nitride abrasive under the scanning electron microscope. The preparation method of porous polycrystalline cubic boron nitride comprises the following steps:

[0035] S1. Raw materials:

[0036] (1). Prepare raw materials: boron nitride powder, cubic boron nitride powder, dilute hydrochloric acid;

[0037] S2. Preparation of flaky boride nitride binder:

[0038] (1). Press the boride nitride powder prepared in the above S1 into tablets through equipment;

[0039] (2). The boride nitride powder pressed into sheets in the above (1) is placed in a vacuum furnace for sintering, resulting in a flake boride nitride binder;

[0040] S3, preparation mixture:

[0041] (1). The cubic boron ni...

Embodiment 1

[0061] A preparation method of porous polycrystalline cubic boron nitride comprises the following steps:

[0062] (1). Prepare raw materials: boron nitride powder, cubic boron nitride powder, dilute hydrochloric acid, the particle size of the boron nitride powder is ≤10 μm, and the cubic boron nitride powder has a particle size of 10-20 μm. The boride nitride powder is magnesium boride nitride, lithium boride nitride or calcium boride nitride;

[0063] (2). The boride nitride powder prepared in the above (1) is pressed into a tablet by equipment, and then the boride nitride powder pressed into a tablet is placed in a vacuum furnace for sintering, resulting in a sheet-like boride nitride bonded agent, the vacuum degree of the vacuum furnace is below 1×10-5Pa, the temperature of the vacuum furnace is 1500°C, and the sintering time is 2h;

[0064] (3). The cubic boron nitride micropowder prepared in the above (1) is extruded into blocks by equipment, and then the flake boron nit...

Embodiment 2

[0069] A preparation method of porous polycrystalline cubic boron nitride comprises the following steps:

[0070] (1). Prepare raw materials: boron nitride powder, cubic boron nitride powder, dilute hydrochloric acid, the particle size of the boron nitride powder is ≤10 μm, and the cubic boron nitride powder has a particle size of 5-10 μm. The boride nitride powder is magnesium boride nitride, lithium boride nitride or calcium boride nitride;

[0071] (2). The boride nitride powder prepared in the above (1) is pressed into a tablet by equipment, and then the boride nitride powder pressed into a tablet is placed in a vacuum furnace for sintering, resulting in a sheet-like boride nitride bonded agent, the vacuum degree of the vacuum furnace is 1×10 -5 Below Pa, the temperature of the vacuum furnace is 1600°C, and the sintering time is 3h;

[0072] (3). The cubic boron nitride micropowder prepared in the above (1) is extruded into blocks by equipment, and then the flake boron n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com